Speed reducer and shell thereof

A reducer and shell technology, which is applied in the field of reducer shells, can solve the problems of irreconcilable lubrication and efficiency, uncontrollable, high oil churning loss, etc., achieve stable and balanced lubrication effect, improve efficiency, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

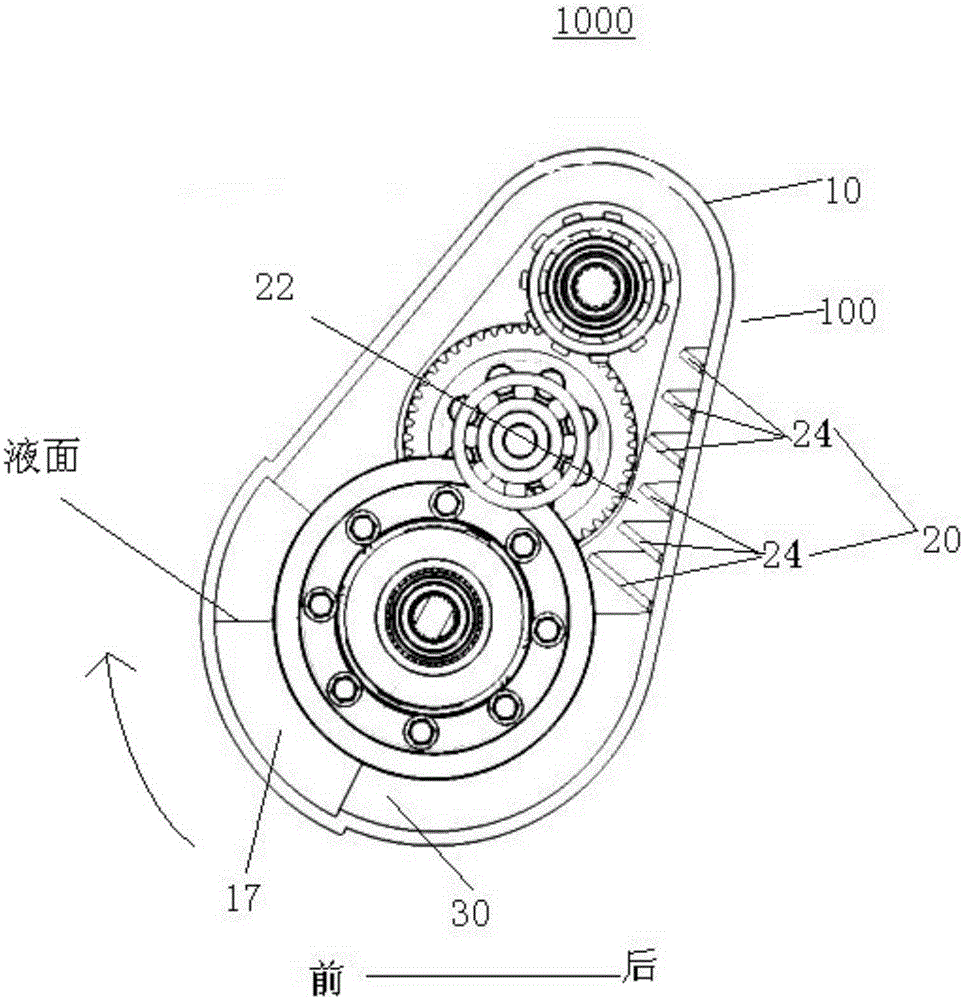

[0031] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

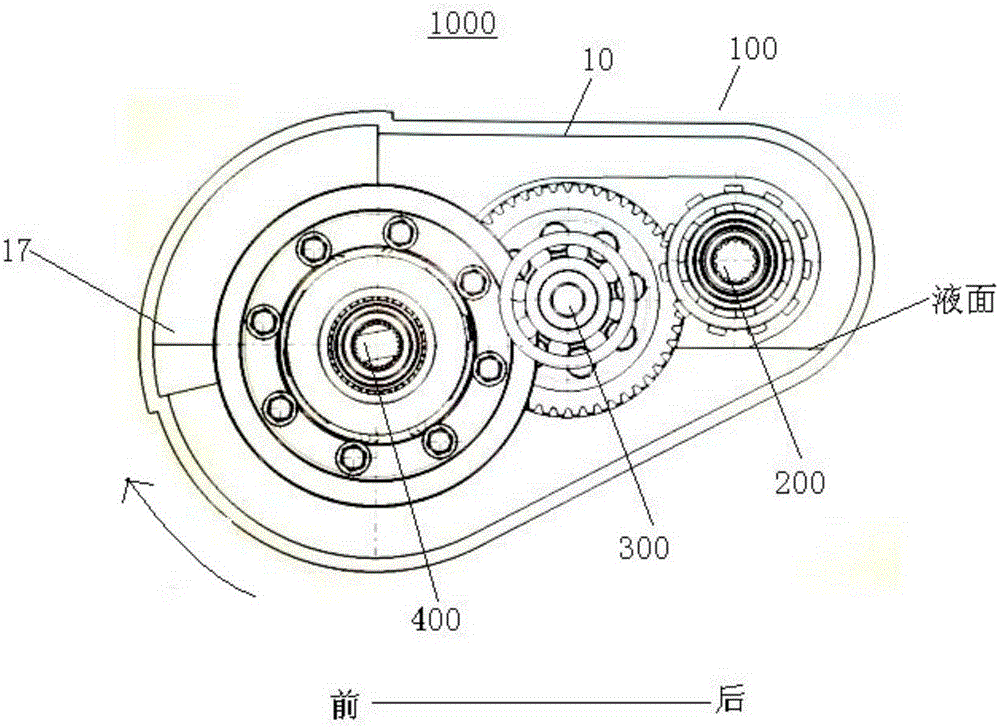

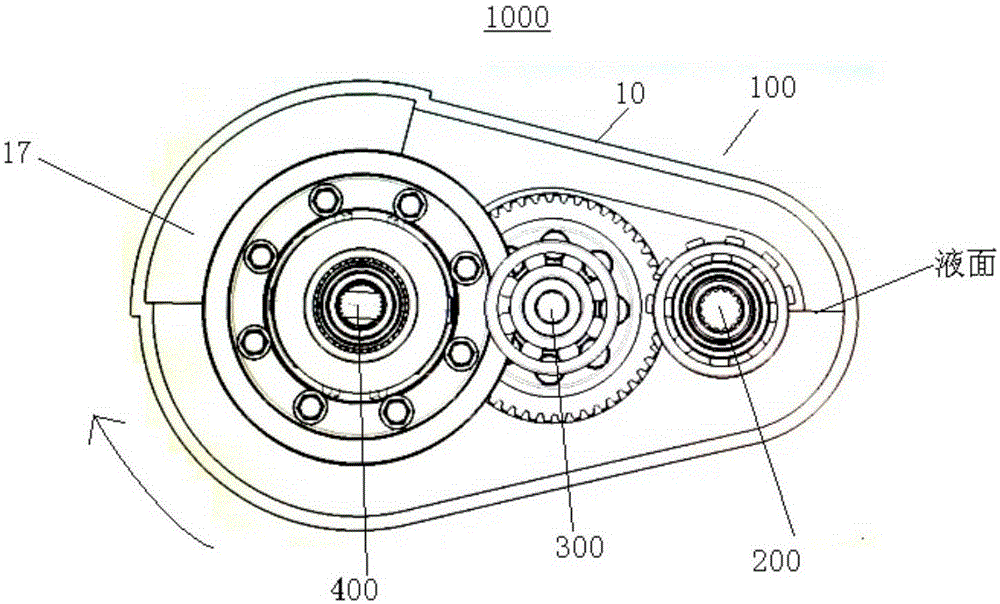

[0032] The housing 100 of the speed reducer 1000 according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] The housing 100 of the speed reducer 1000 according to the embodiment of the present invention may include: a housing body 10 and an isolation device 20 . Such as Figure 4 As shown, there is a cavity in the housing body 10, and the housing body 10 is provided with output shaft holes 11, intermediate shaft holes 12 and Input shaft hole 13.

[0034] According to an embodiment of the present invention, the housing body 10 may include: a first housing 14 and a second housing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com