Double-side needling machine speed reducing system

A deceleration system and double-sided needle technology, which is applied in the fields of acupuncture machines, mechanical equipment, textiles and papermaking, etc., can solve problems such as affecting the use, unstable phase of the upper and lower reducers, and excessive temperature rise of the reducer, etc., to achieve convenient maintenance, Less oil in gear agitation and good lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

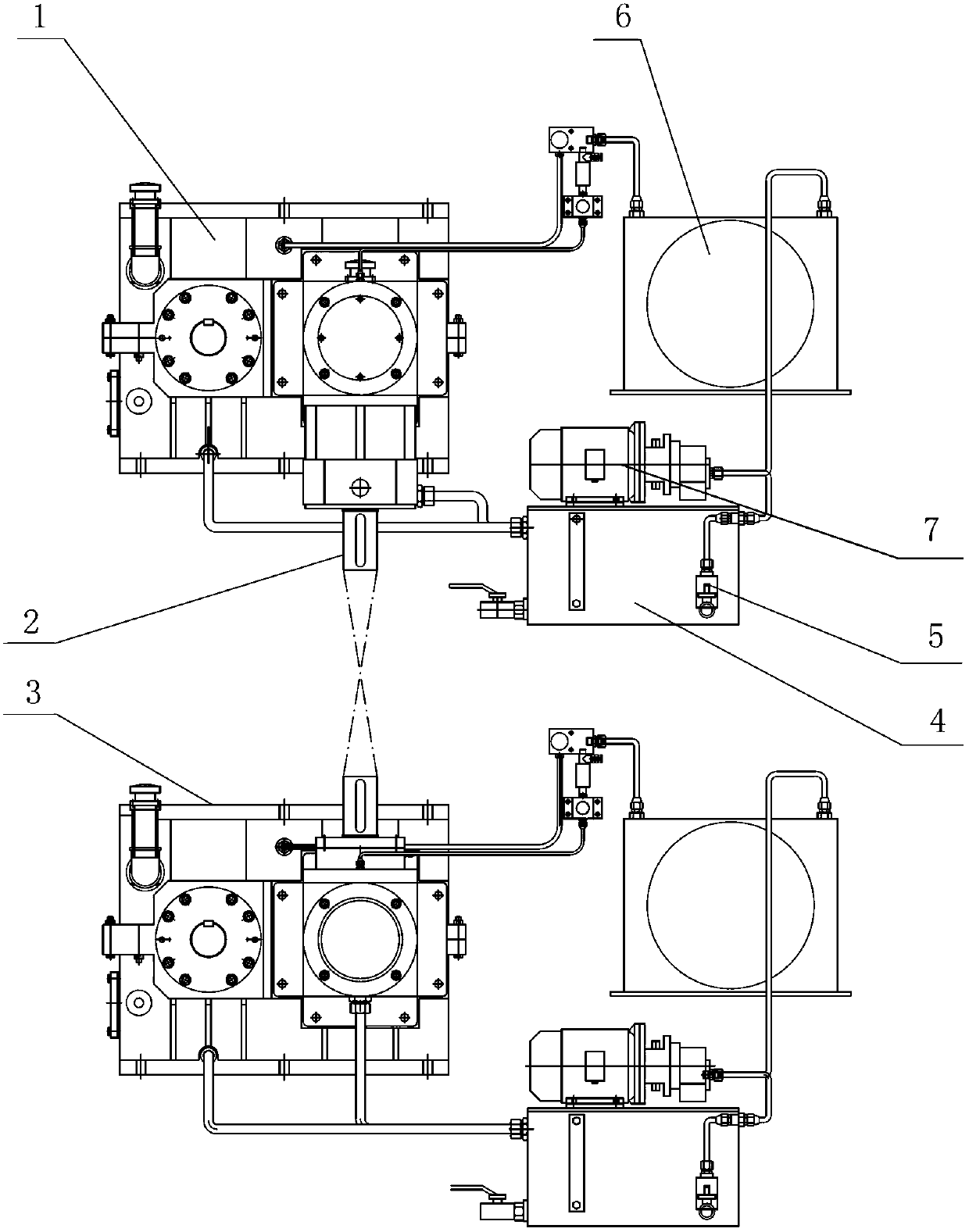

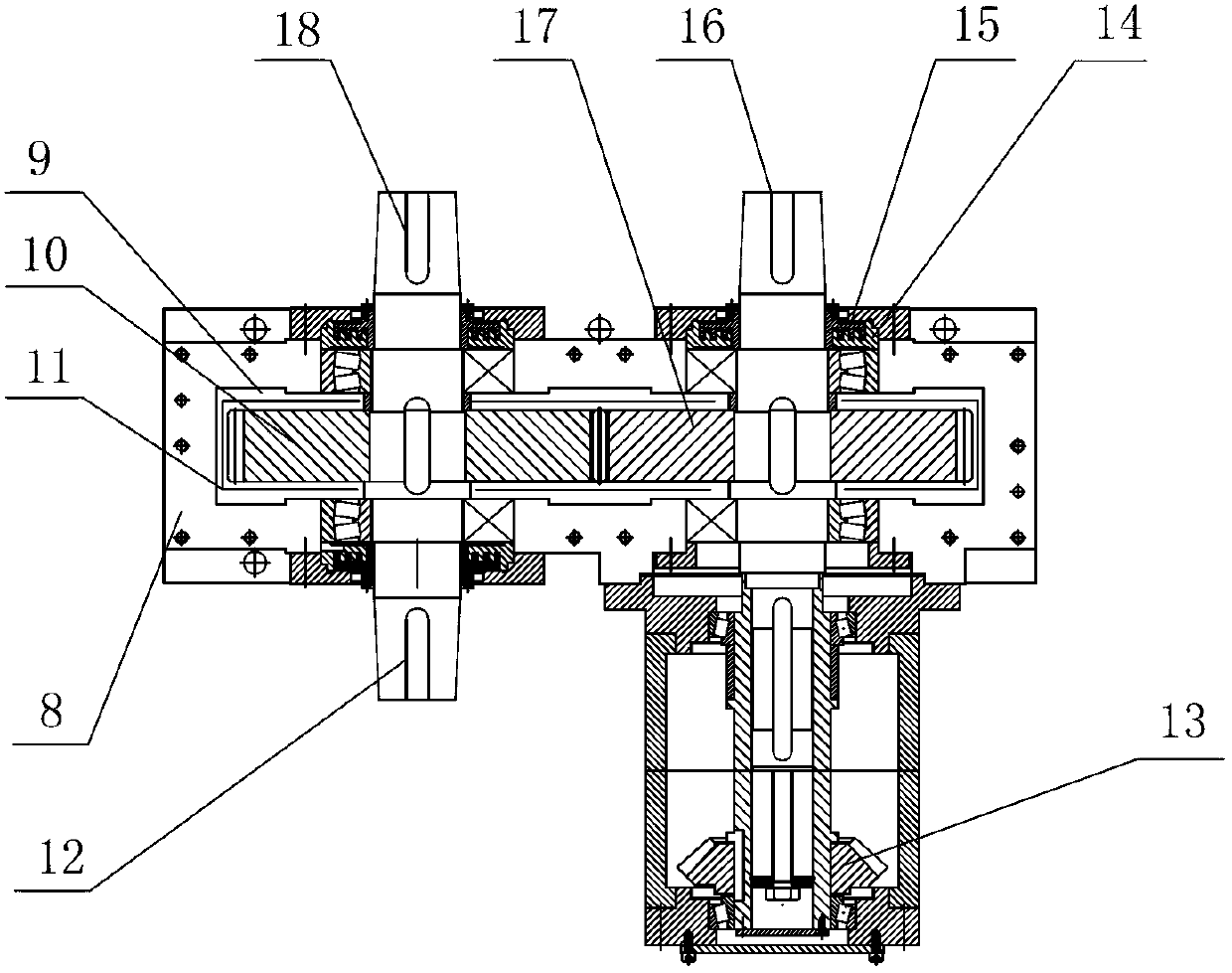

[0019] Such as Figure 1-Figure 2 As shown, the transmission shafts 2 corresponding to the spiral bevel gears 13 of the upper reducer 1 and the lower reducer 3 with the same structure are arranged in the vertical direction, and the drive shafts 2 of the upper reducer 1 and the lower reducer 3 correspond up and down and pass through ten thousand Knuckle connection, the phases of the output shafts of the upper reducer 1 and the lower reducer 3 are the same, and the steering of the two transmission shafts 2 is also the same. The gear boxes 9 of the upper reducer 1 and the lower reducer 3 are respectively provided with anti-stirring oil devices 11.

[0020] The universal joint connects the upper and lower speed reducers together, and keeps the phases of the output shafts 16 and 18 consistent during power transmission. The anti-scrambling oil device 11 divides the lubricating oil in the gear box 9 in the body 8 into two parts. When the gears are running at high speed, only the lubr...

Embodiment 2

[0023] On the basis of Embodiment 1, the upper reducer 1 is equipped with a first external forced lubrication system, the first forced lubrication system includes oil pipes, oil tank 4, filter 5 and gear pump group 7, the outlet of oil tank 4 passes through filter 5 and The gear pump unit 7 is connected to the gear case 9 of the upper reducer 1, and the oil pipe between the gear pump unit 7 and the upper reducer 1 is provided with an air cooler 6, and the temperature rise of the gear case 9 of the upper reducer 1 is lower than 45°C. The forced lubrication of the external oil tank can make the lubricating oil directly spray the gears and bearings, which can further reduce the oil level in the gearbox and further reduce the oil churning loss; the high-temperature lubricating oil of the gear box 9 passes through the outlet at the bottom of the Under the action, it returns to the oil tank, and the gear pump unit 7 sucks the filtered high-temperature lubricating oil out of the oil t...

Embodiment 3

[0025] On the basis of Example 2, the lower reducer is equipped with a second external forced lubrication system. The second external forced lubrication system is the same as the first external forced lubrication system. It can be set separately, or share a set of oil tank, filter and gear pump group, so as to reduce investment, improve efficiency and facilitate maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com