Gearbox lubricating test device and measuring device for lubricating oil injection quantity

A lubricating test device and lubricating oil technology, which is applied in the field of gearboxes, can solve the problem of inability to quantitatively measure the lubricating oil filling amount of the gearbox, and achieve the effects of reducing oil churning loss, improving lubricating efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

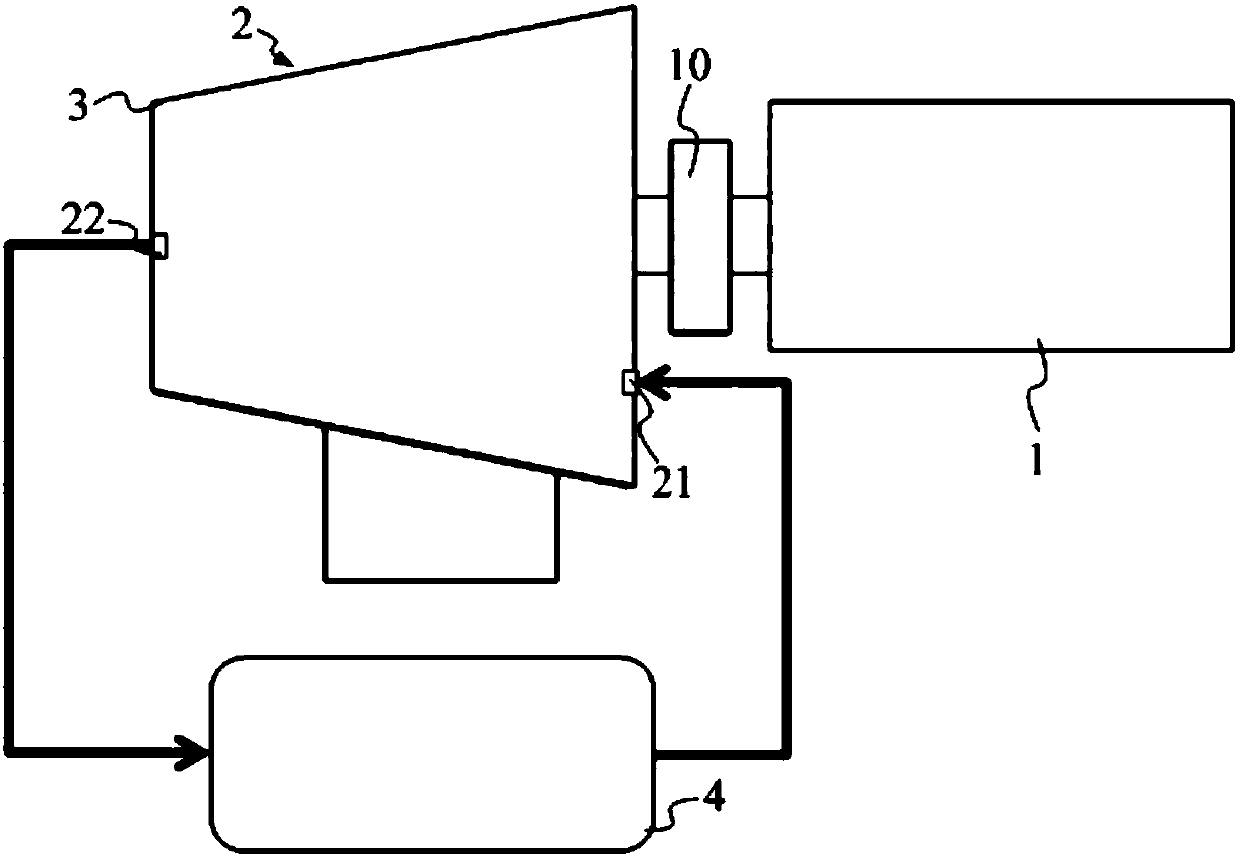

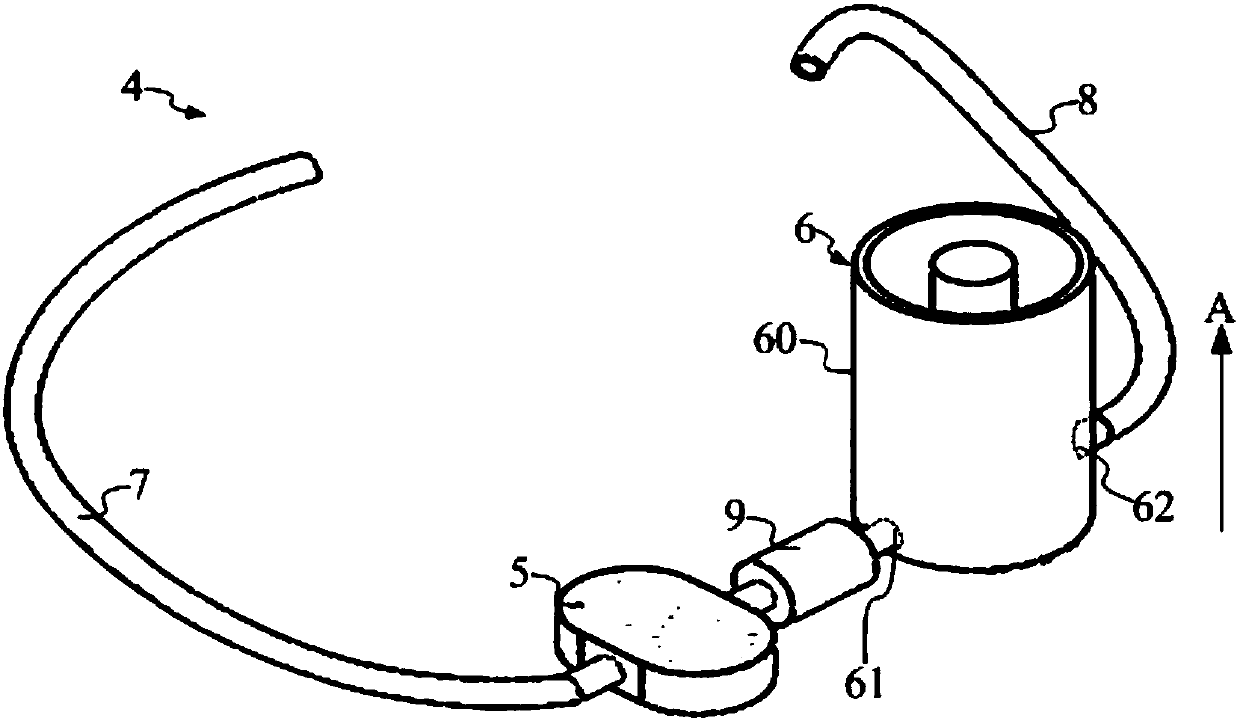

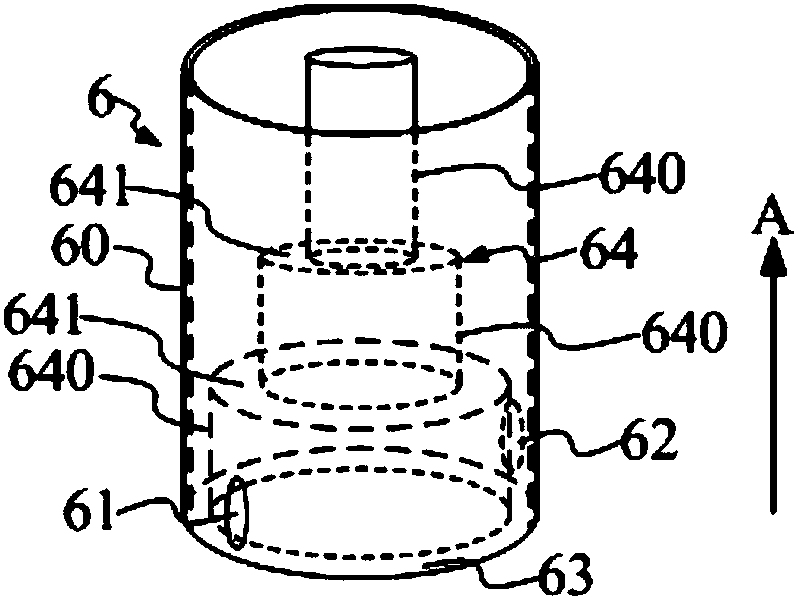

[0028] refer to figure 1 , the gearbox lubrication test device includes: a torque supply unit 1 and a gearbox 2, the torque supply unit 1 is used to provide torque to the gearbox 2, and the gearbox 2 includes a gearbox casing 3 and a to-be-tested device located in the gearbox casing 3 axis (not shown). Wherein, the shaft to be tested may be a rotating shaft in the transmission housing 3 such as an odd-numbered gear input shaft, an even-numbered gear input shaft, a transmission output shaft, and a differential gear bearing.

[0029] The gearbox casing part at one end of the shaft to be measured has an oil filling port 21 , and the gearbox casing part at the other end of the shaft to be measured has an oil collecting port 22 . The gearbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com