Speed change gear structure, transmission and vehicle

A technology for shifting gears and transmissions, applied in the field of shifting gears, can solve the problems of reducing abnormal idle noise, disadvantage, increase in transmission weight, volume and cost, and achieve the effect of weight reduction and cost optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

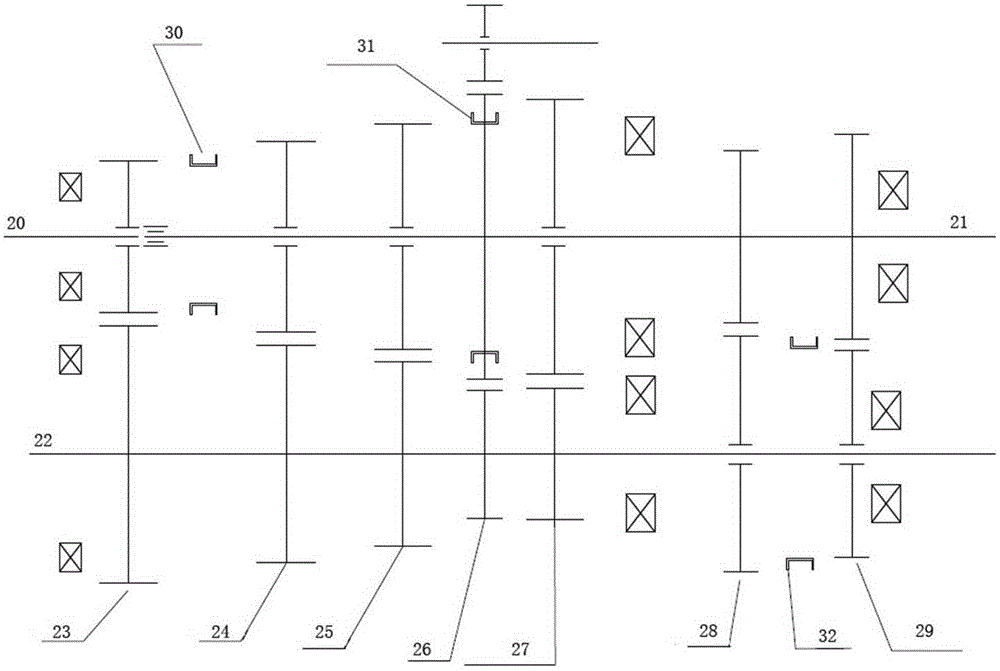

[0027] Such as figure 2 As shown, the transmission gear structure of the first embodiment of the present invention includes an input shaft 9, an output shaft 10, an intermediate shaft 14, three gear transmission pairs and three synchronizers, wherein the input shaft 9 and the output shaft 10 are coaxially spaced apart The intermediate shaft 14 is arranged parallel to the input shaft 9 and the output shaft 10, wherein the input shaft 9 is relatively rotatably mounted with a first gear 1, the output shaft 10 is relatively rotatably mounted with a second gear 2, and the input shaft 9 A rotatable third gear 3 is provided in the space between the output shaft 10 and the output shaft 10, such as figure 2 As shown, in a more preferred structure, the support shaft 17 of the third gear 3 is installed in the transmission housing through the bearings 18 on both sides, and the support shaft 17 is coaxial with the input shaft 9 and the output shaft 10, and the intermediate shaft 14 is pro...

Embodiment 2

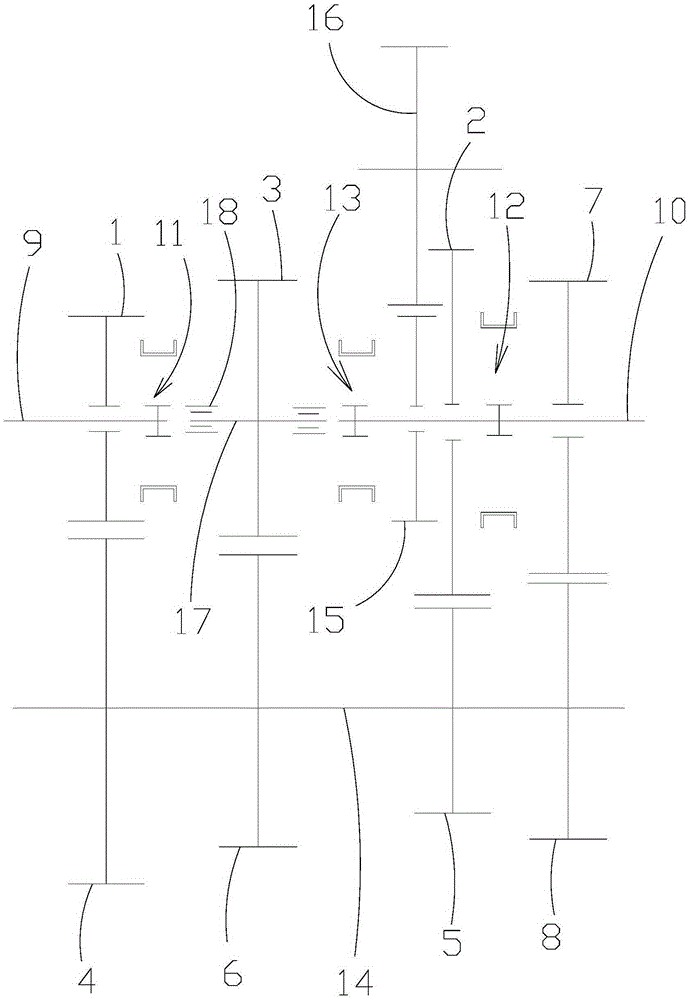

[0041] The transmission gear structure of the second embodiment of the present invention is obtained on the basis of the first embodiment, that is, while keeping the structure of the first embodiment unchanged, only adding a pair of gear transmission pairs can increase two forward gears. , To obtain the transmission gear structure of the second embodiment, specifically,

[0042] Such as figure 2 As shown, in the transmission gear structure of the second embodiment, a seventh gear 7 is relatively rotatably mounted on the output shaft 10, and the seventh gear 7 is assembled in the same manner as the second gear 2, and the second synchronizer 12 can be axially The movement is combined with the second gear 2 or the seventh gear 7 respectively. The eighth gear 8 meshing with the seventh gear 7 is fixedly installed on the intermediate shaft 14 so that two other forward gears can be obtained. figure 2 ,specifically:

[0043] At 5th gear: the first synchronizer 11 is combined with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com