Patents

Literature

34results about How to "Avoid overflow loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

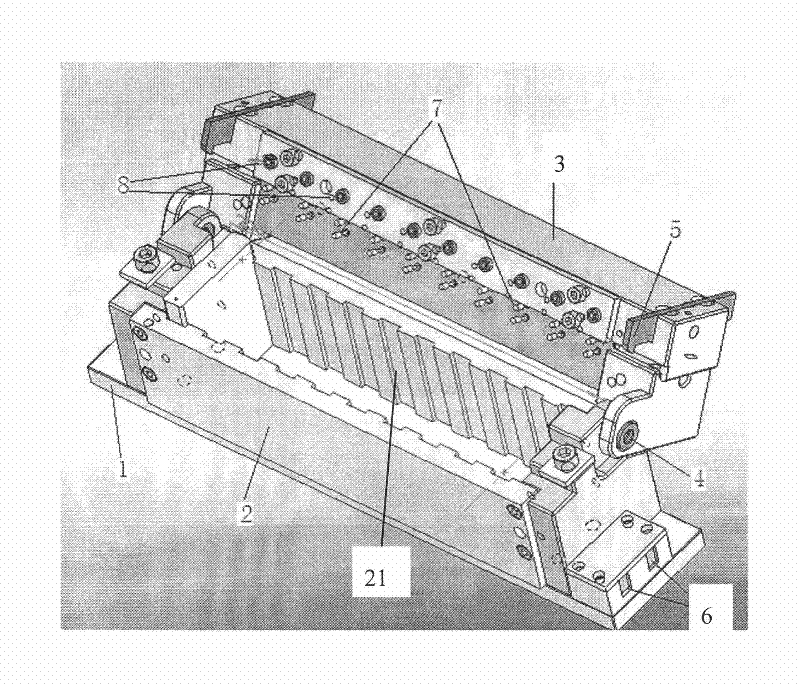

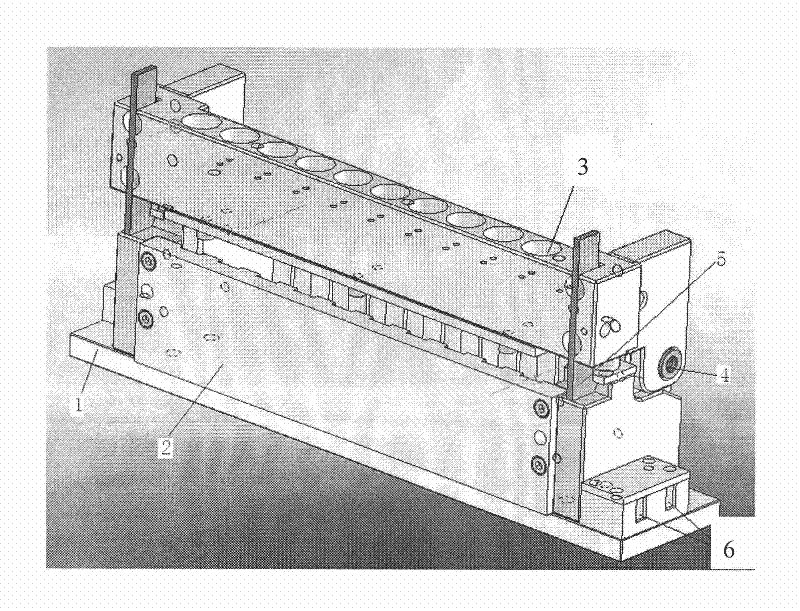

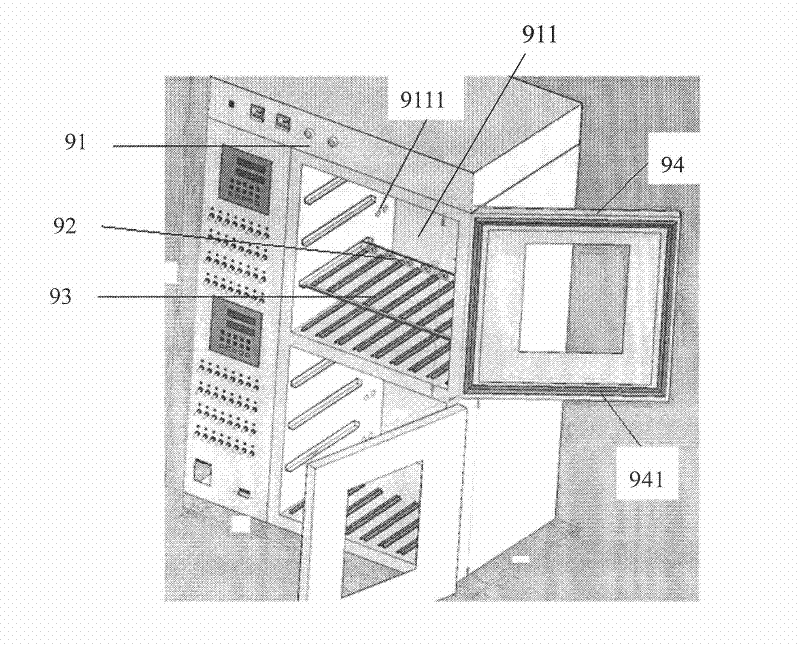

Vacuum formation method of lithium ion battery

ActiveCN101887994AImprove exhaust efficiencyShield negative influenceFinal product manufactureSecondary cells charging/dischargingEngineeringLithium-ion battery

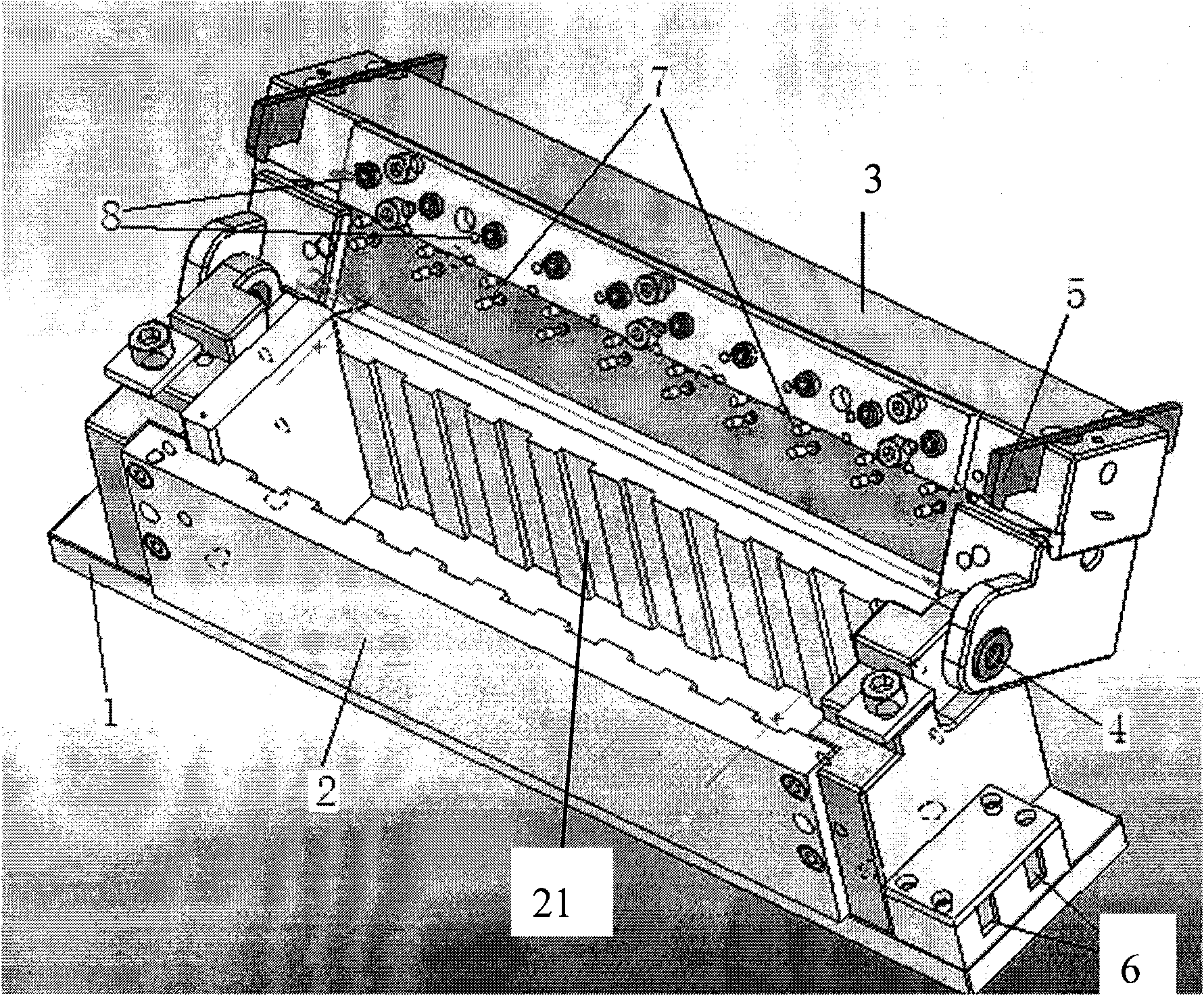

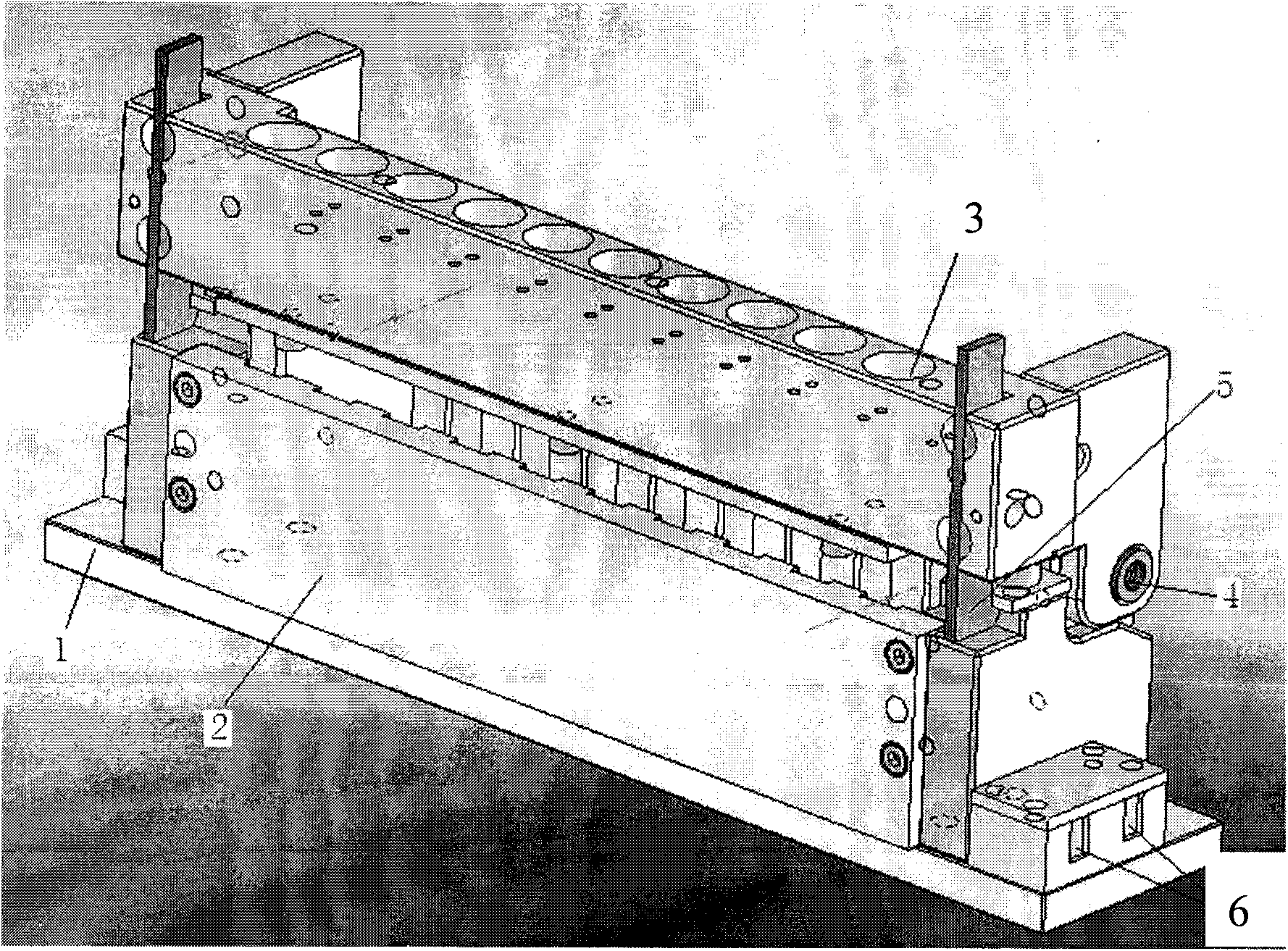

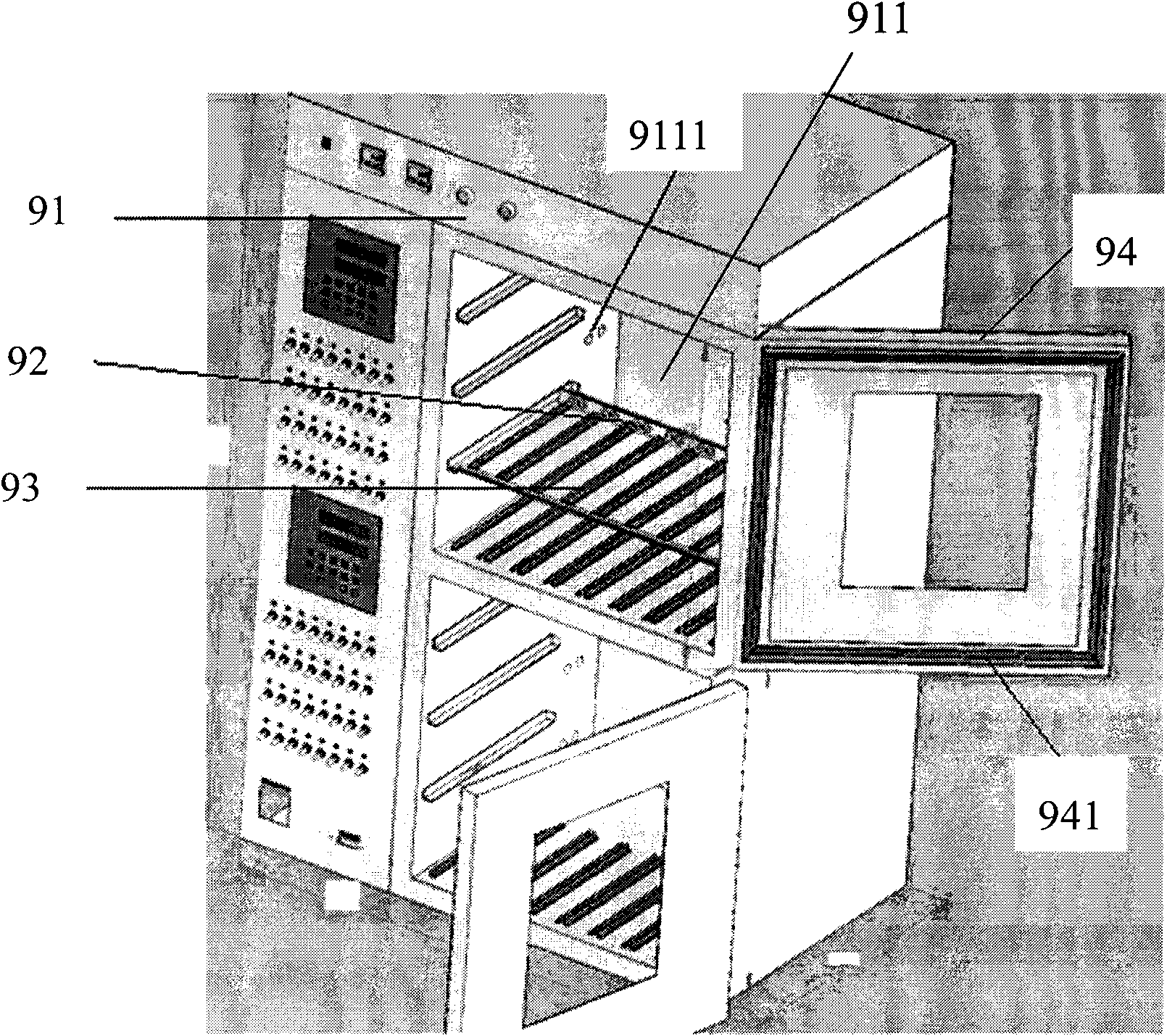

The invention discloses a vacuum formation method of a lithium ion battery. In the method, an electrolyte injection process and a formation process of the battery are completed by adopting an integrated fixture with electrolyte-injecting and charging functions and a vacuum formation device with charging and vacuumizing functions. The vacuum formation device charges the battery arranged in the integrated fixture, and the battery is electrically connected with the vacuum formation device by the integrated fixture. The vacuum formation method of the invention provides an enclosed and controllable microenvironment, thereby reducing electrolyte waste, avoiding overflow loss of electrolyte and corrosion on a battery casing, the fixture or charging equipment, and effectively reducing environmental pollution.

Owner:东莞市鸿德电池有限公司 +1

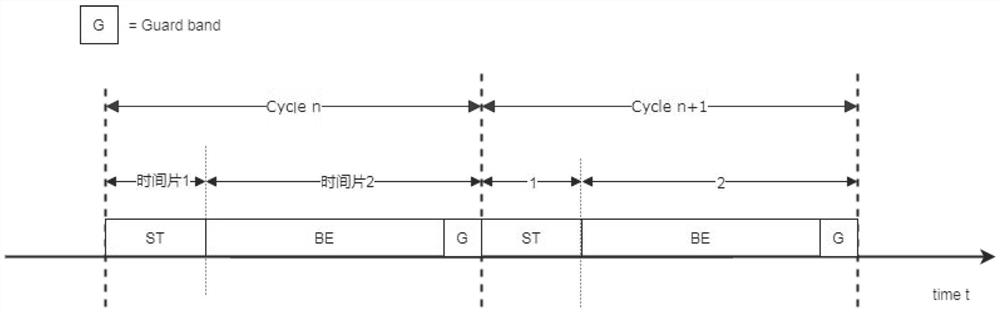

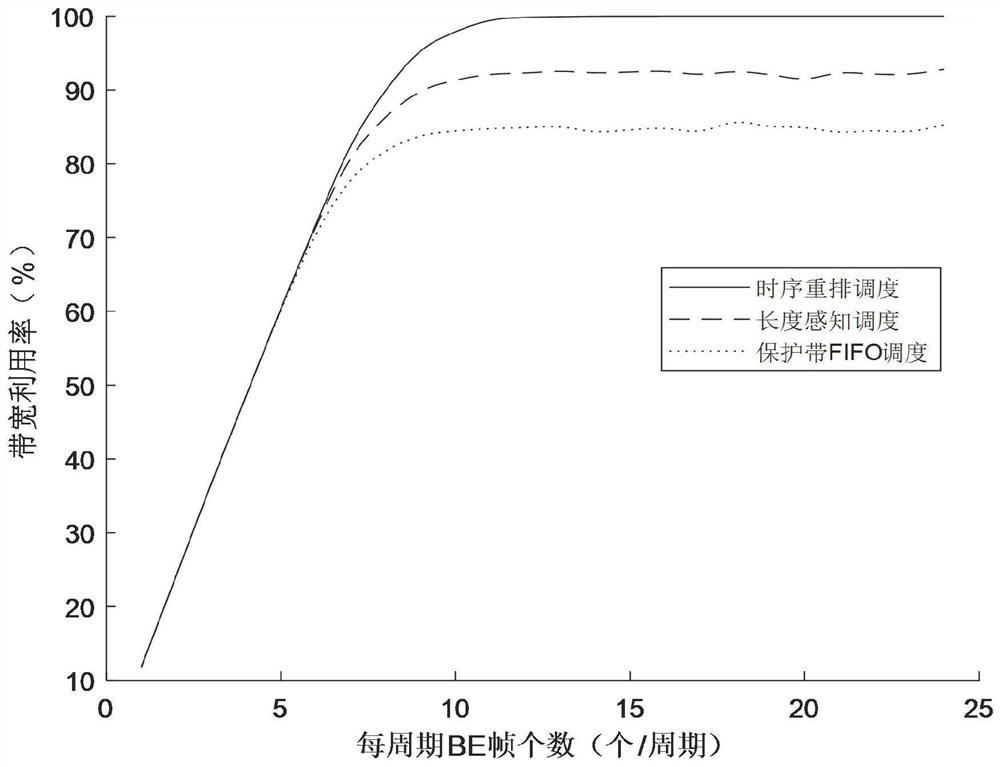

Time-sensitive network best-effort flow scheduling method

ActiveCN112737979AIncrease profitAvoid strandedData switching networksNetwork communicationNetwork data

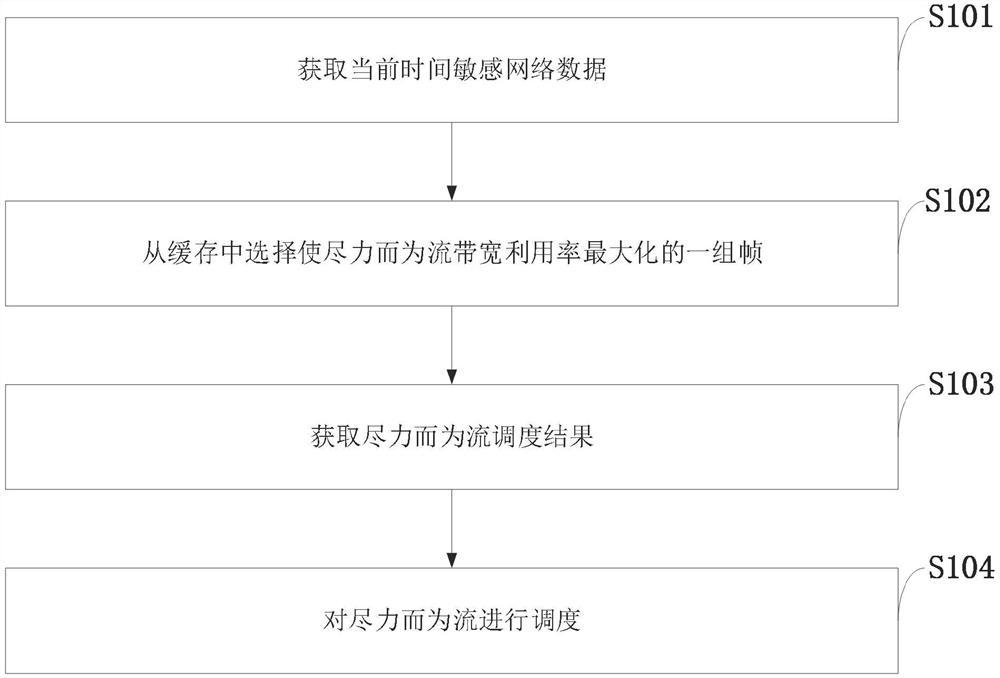

The invention belongs to the technical field of network communication, and discloses a best-effort flow scheduling method for a time sensitive network. The method comprises the following steps: acquiring current time sensitive network data; selecting a set of frames from the cache that maximizes the best-effort flow bandwidth utilization; obtaining a best-effort flow scheduling result; and scheduling the best-effort flow. According to the method, the bandwidth utilization rate of the best-effort flow time slot is maximized in each bandwidth period in the Qbv protocol, and the bandwidth resource utilization rate of the best-effort flow is improved. Along with accumulation of bandwidth periods, the utilization rate of bandwidth resources is increased to a great extent in terms of overall service.

Owner:XIDIAN UNIV

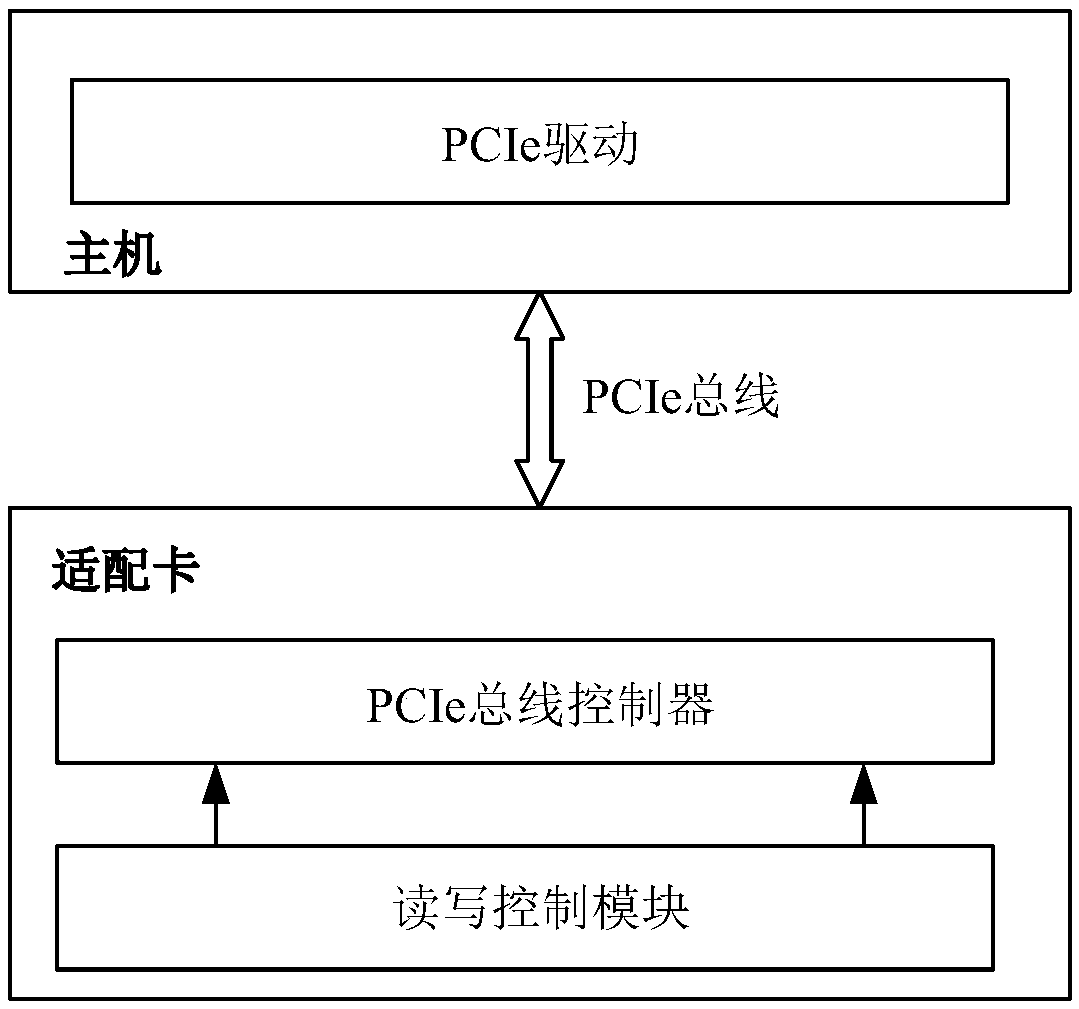

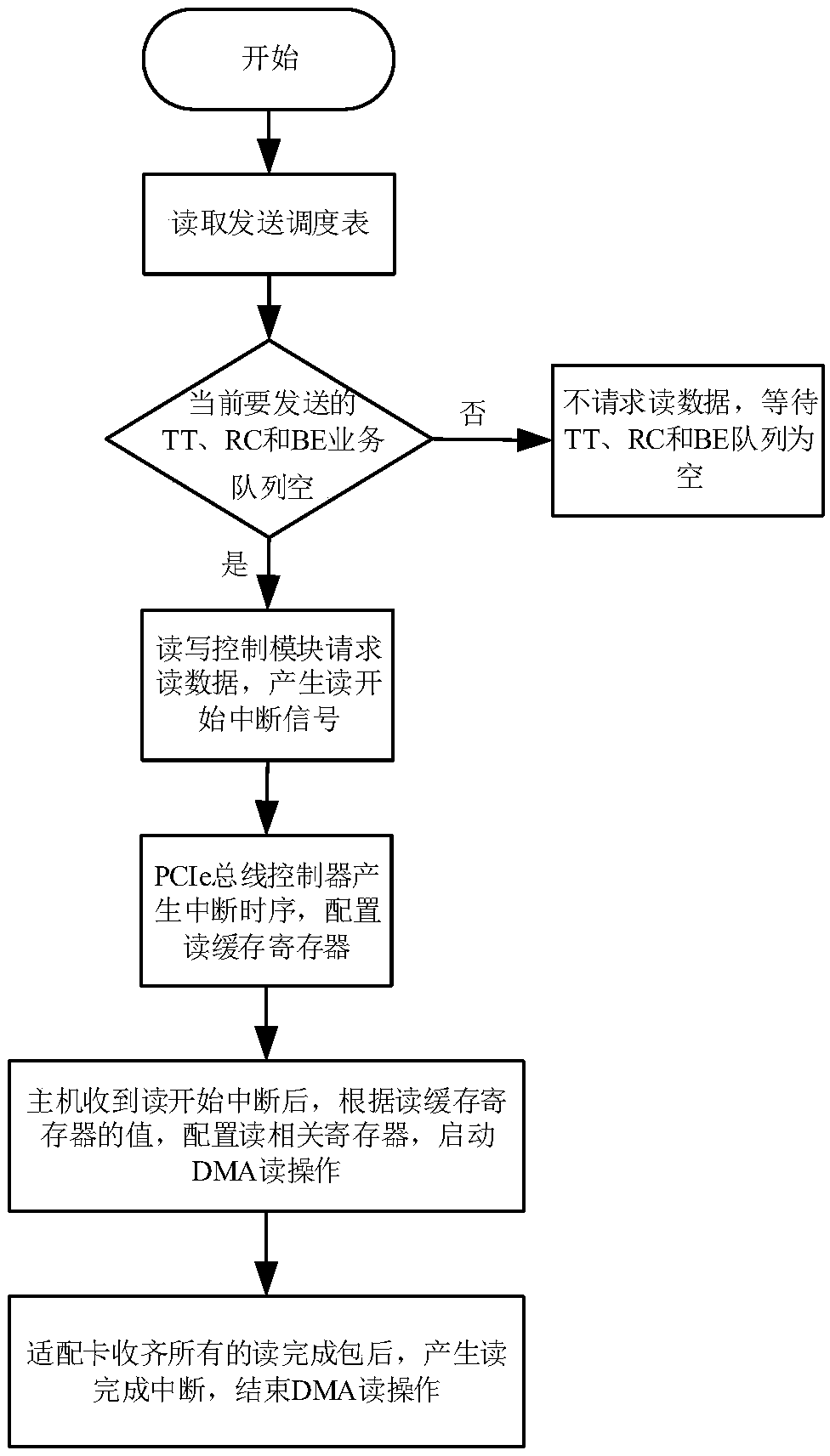

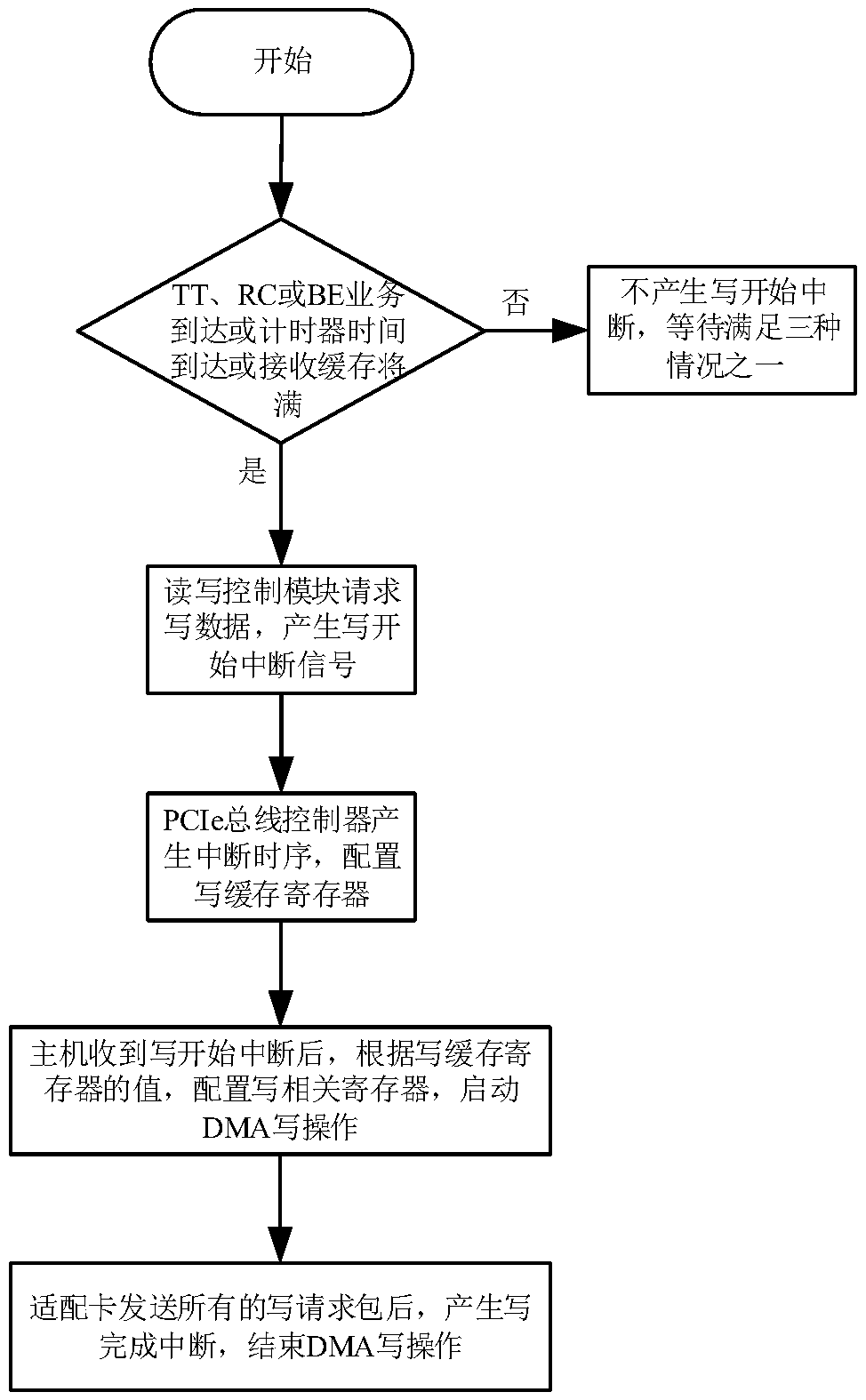

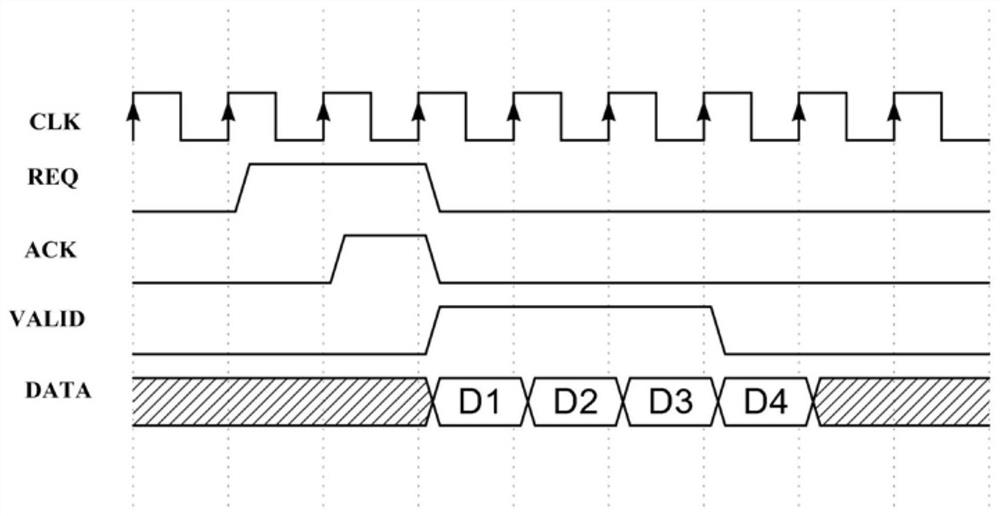

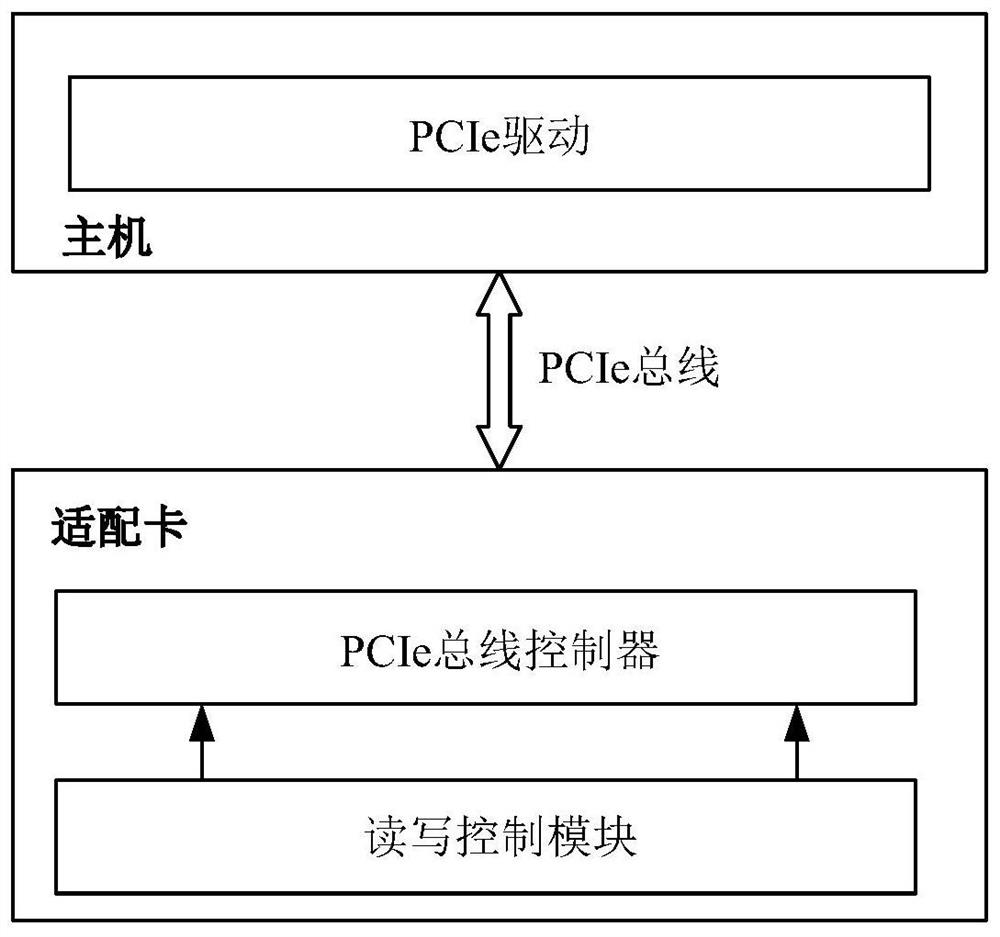

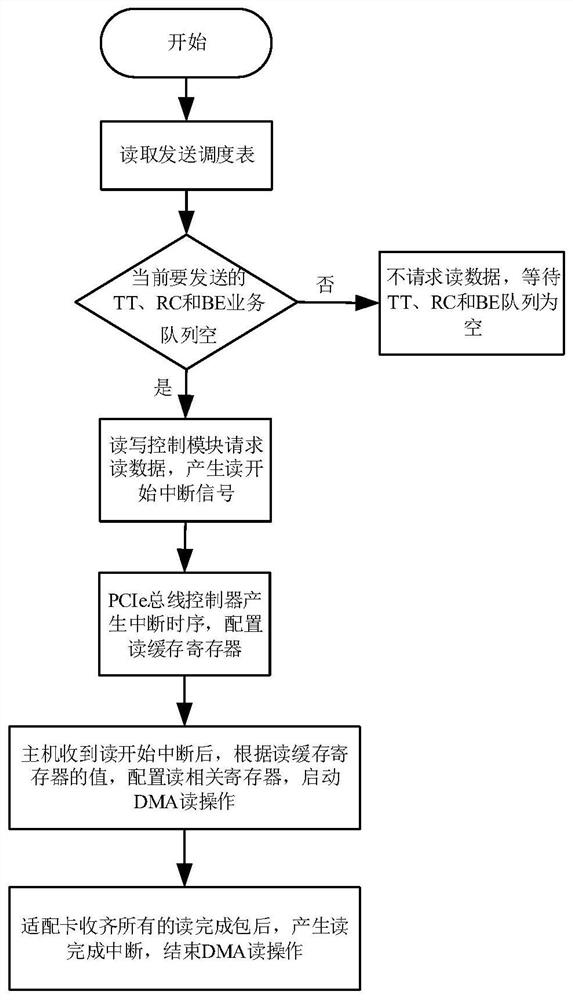

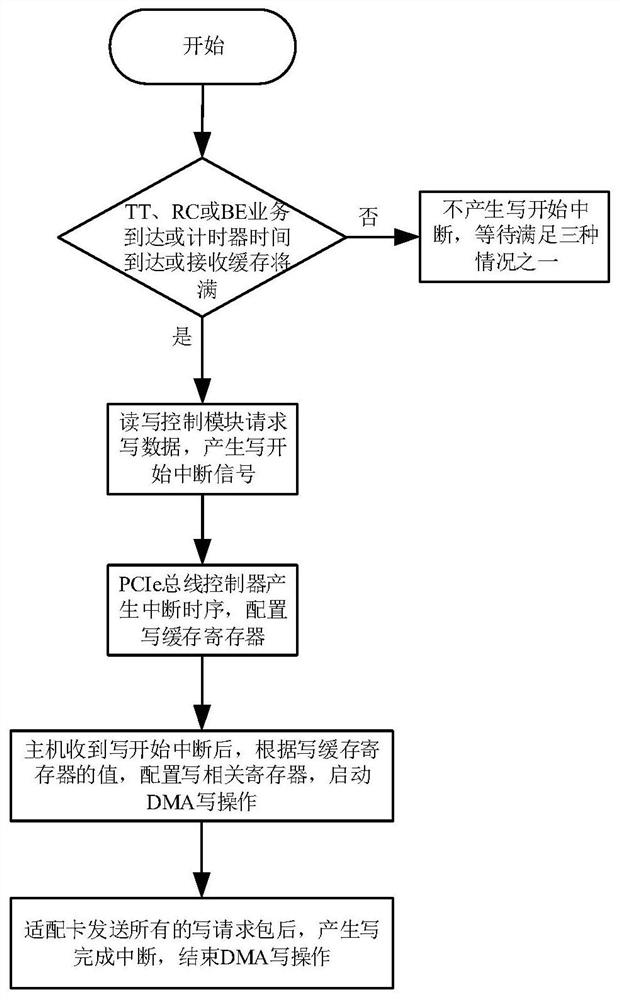

Interrupt operation method for PCIe controller of adapter card of TTE terminal system

ActiveCN108763121AAvoid overflow lossGuaranteed low latency requirementsElectric digital data processingDirect memory accessProcessor register

The invention discloses an interrupt operation method for a PCIe controller of an adapter card of a TTE terminal system, and aims to solve the problem of overflow loss of data due to insufficient cache space of the adapter card caused by the fact that a host initiates a read interrupt in the prior art. According to the technical scheme, the method comprises the steps of 1) requesting for read or write data; 2) periodically requesting for the read or write data to the PCIe bus controller; 3) generating an interrupt time sequence and configuring a read or write cache register by the PCIe bus controller; 4) identifying an interrupt type and determining a data migration amount by a PCIe driver; and 5) configuring read or write related registers and starting a direct memory access operation tocomplete data migration by the PCIe driver, and finishing the direct memory access operation. According to the method, the direct memory access read or write operation is initiated through the adaptercard; the flow control is realized; the adapter card is used for actively sending out the interrupt, so that the time precision of the terminal system is improved; and the method can be used for design of a time-triggered interrupt module in the adapter card of the Ethernet TTE terminal system.

Owner:XIDIAN UNIV

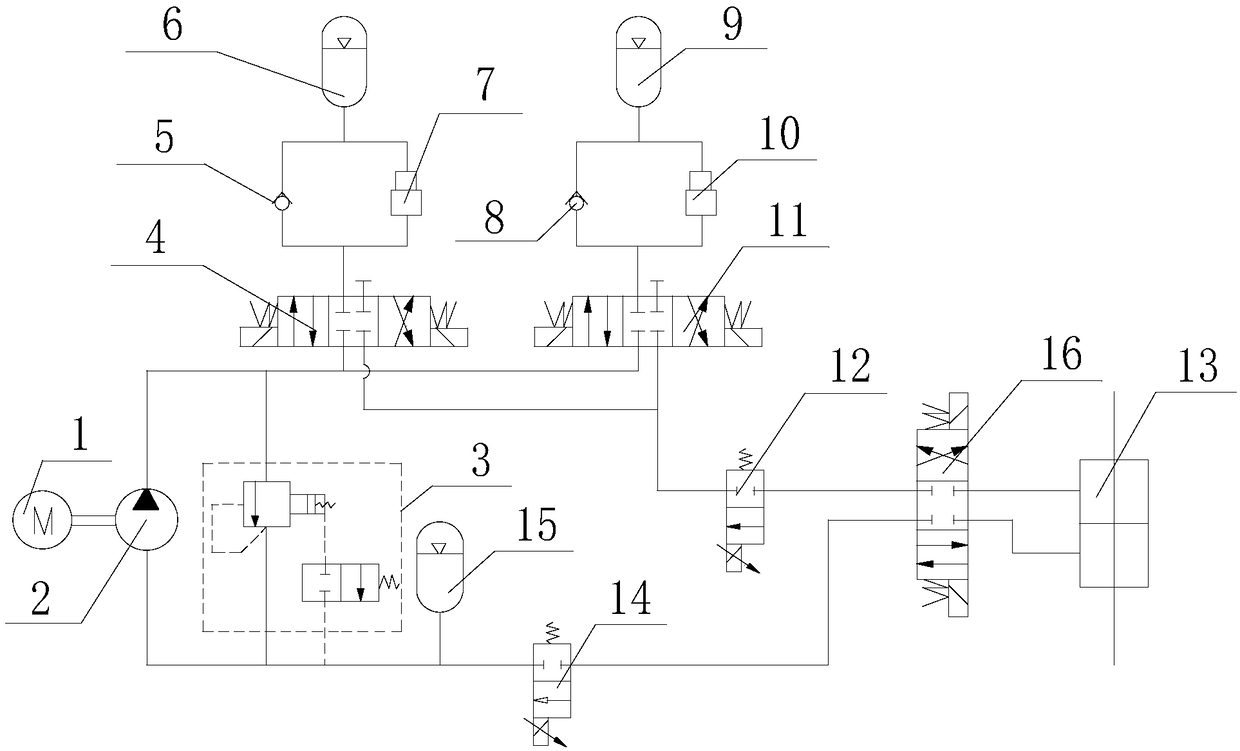

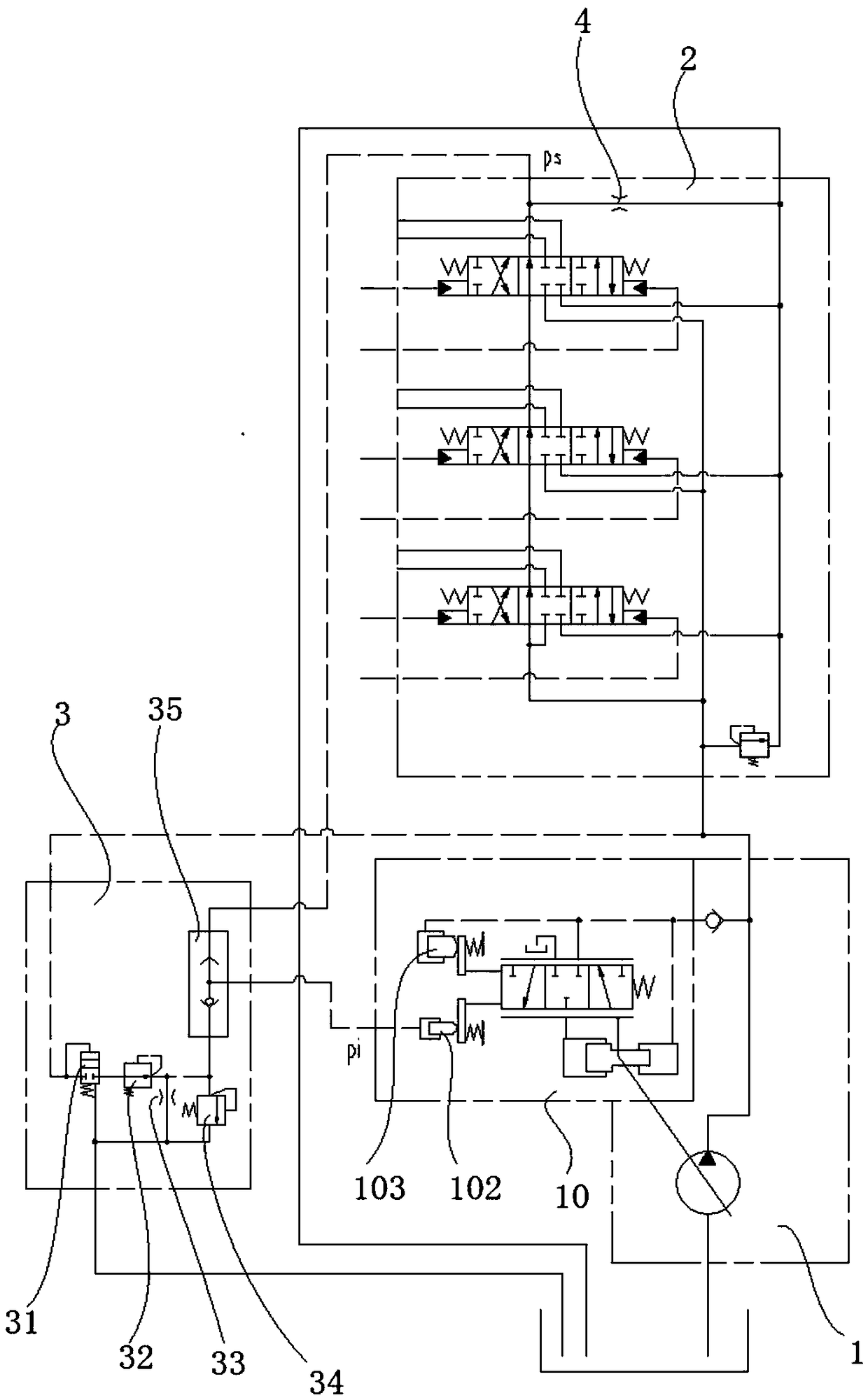

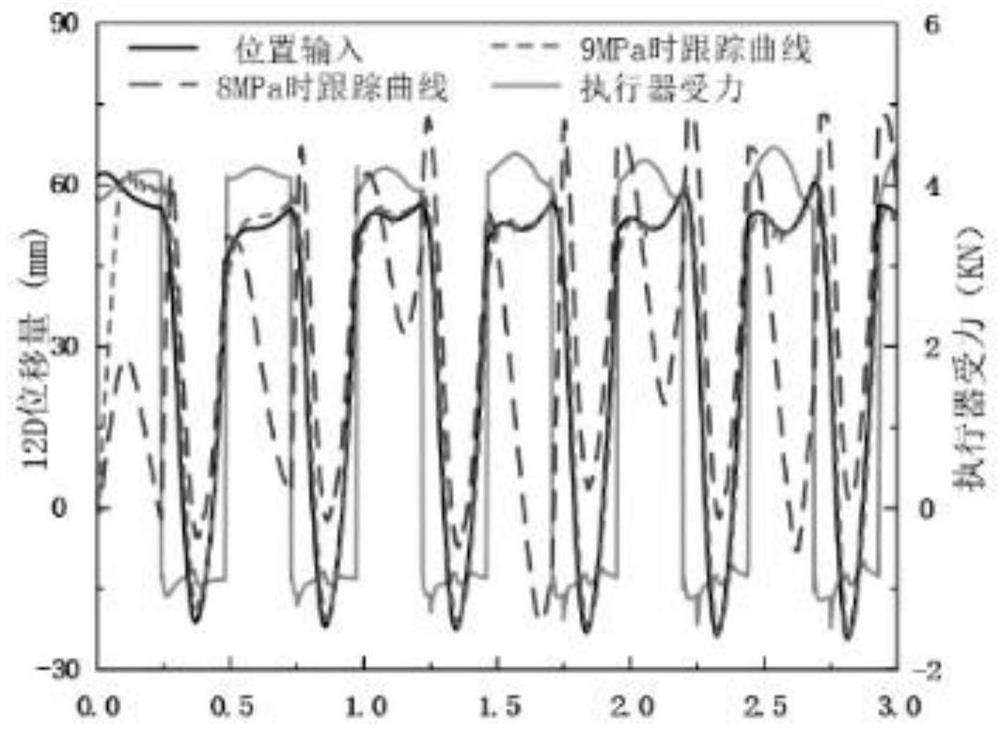

Novel robot hydraulic joint drive system

PendingCN108591137AStable powerAvoid dischargeJointsServomotor componentsHydraulic pumpHigh pressure

The invention discloses a novel robot hydraulic joint drive system. The novel robot hydraulic joint drive system comprises a motor, a hydraulic pump and a double-action piston rod cylinder. The motoris connected with the hydraulic pump. An oil inlet way and an oil return way are formed between the hydraulic pump and the double-action piston rod cylinder in parallel. The part, from the hydraulic pump to the double-action piston rod cylinder, on the oil inlet way is sequentially provided with a first high-pressure energy storage mechanism, a second high-pressure energy storage mechanism and a first proportional valve or a first servo valve. The first high-pressure energy storage mechanism comprises a first one-way valve and a first high-pressure energy accumulator forming a first loop. Thefirst loop communicates with the oil inlet way through a first three-position four-way electromagnetic reversing valve. The second high-pressure energy storage mechanism comprises a second one-way valve and a second high-pressure energy accumulator forming a second loop. The second oil way communicates with the oil inlet way through a second three-position four-way electromagnetic reversing valve.The novel robot hydraulic joint drive system solves the problem that an existing hydraulic drive system is large in energy loss.

Owner:SOUTHWEST JIAOTONG UNIV

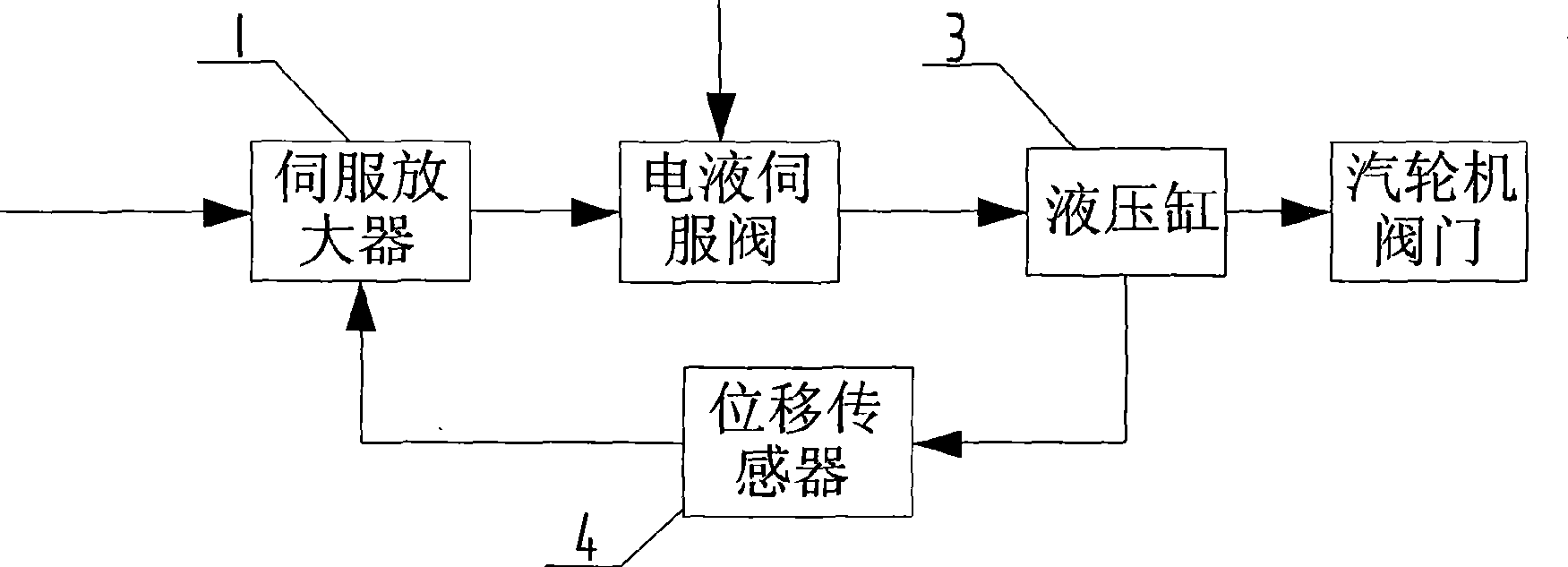

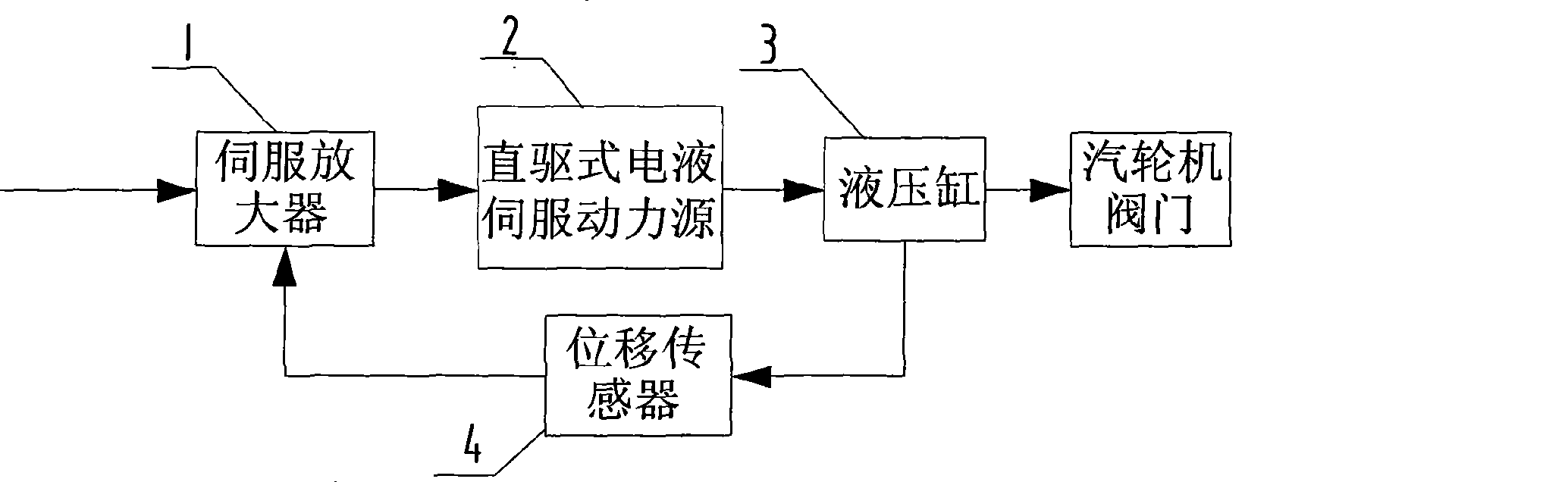

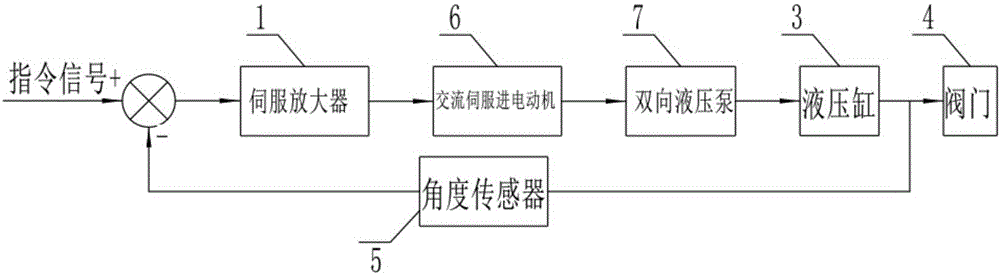

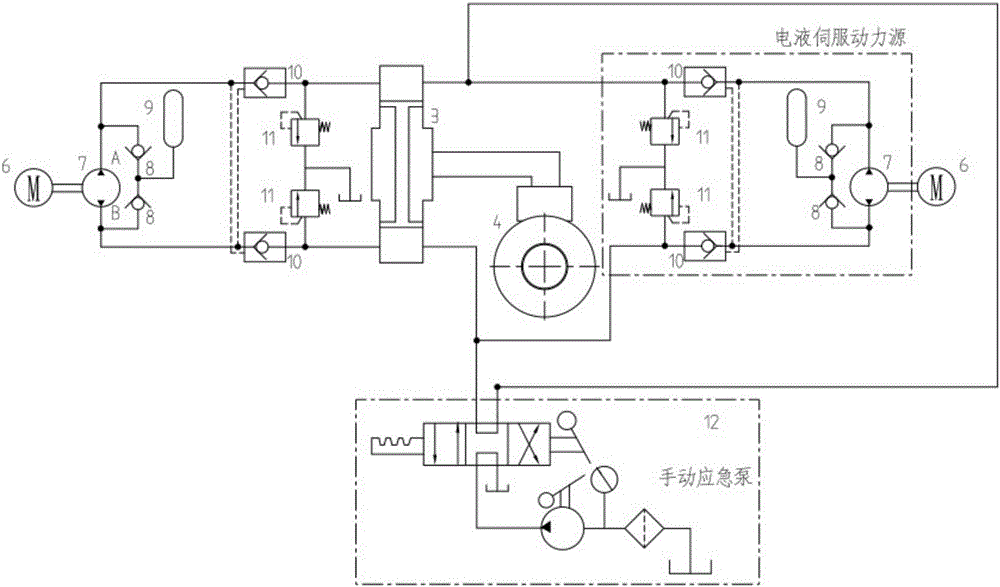

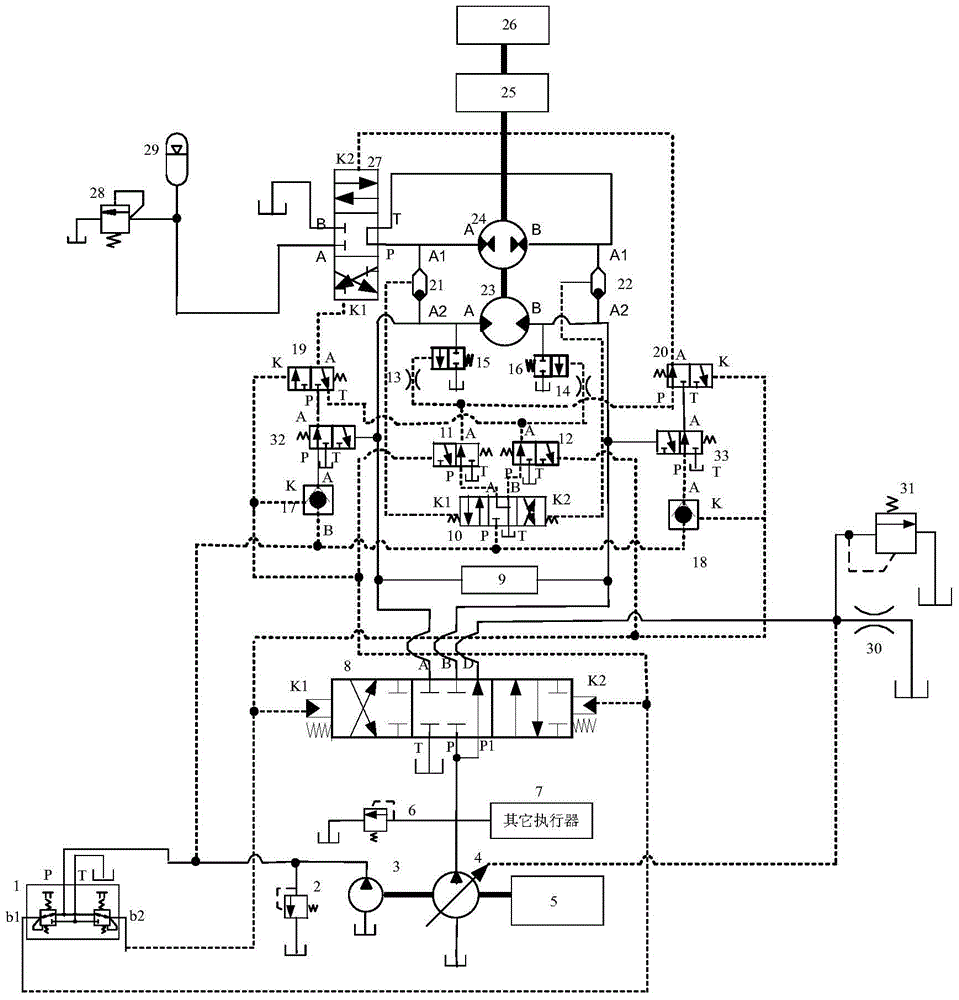

Direct drive type oil servo motor based on direct drive type electrohydraulic servo power source

InactiveCN101413406AImprove reliabilityClose fastMachines/enginesEngine componentsHydraulic cylinderAlternating current

The invention discloses an electrohydraulic servo power source-based direct drive servo motor and relates to a servo motor. The direct drive servo motor overcomes the drawbacks of the prior art of inevitable clamping stagnation, high fault rate and low efficiency due to long-term operation of an electrohydraulic servo valve. The direct drive servo comprises a direct drive electrohydraulic servo power source which comprises a closed oil tank, an alternating current servo motor, a bidirectional fixed displacement pump, an oil supplement valve and a bidirectional hydraulic lock, wherein a power outlet shaft of the alternating servo motor is connected with a power inlet shaft of the bidirectional fixed displacement pump which is connected with a hydraulic cylinder through the bidirectional hydraulic lock, two oil lines between the bidirectional fixed displacement pump and the hydraulic cylinder form a closed circuit, two oil inlet and outlet openings of the oil supplement valve are connected to the two oil lines between the bidirectional fixed displacement pump and the hydraulic cylinder respectively, a third oil inlet and outlet opening is connected with an oil inlet and outlet opening of the closed oil tank. The direct drive servo motor is used on an actuating mechanism of a steam turbine regulating and safety system and has the advantages of high reliability, energy conservation and high efficiency.

Owner:HARBIN INST OF TECH +1

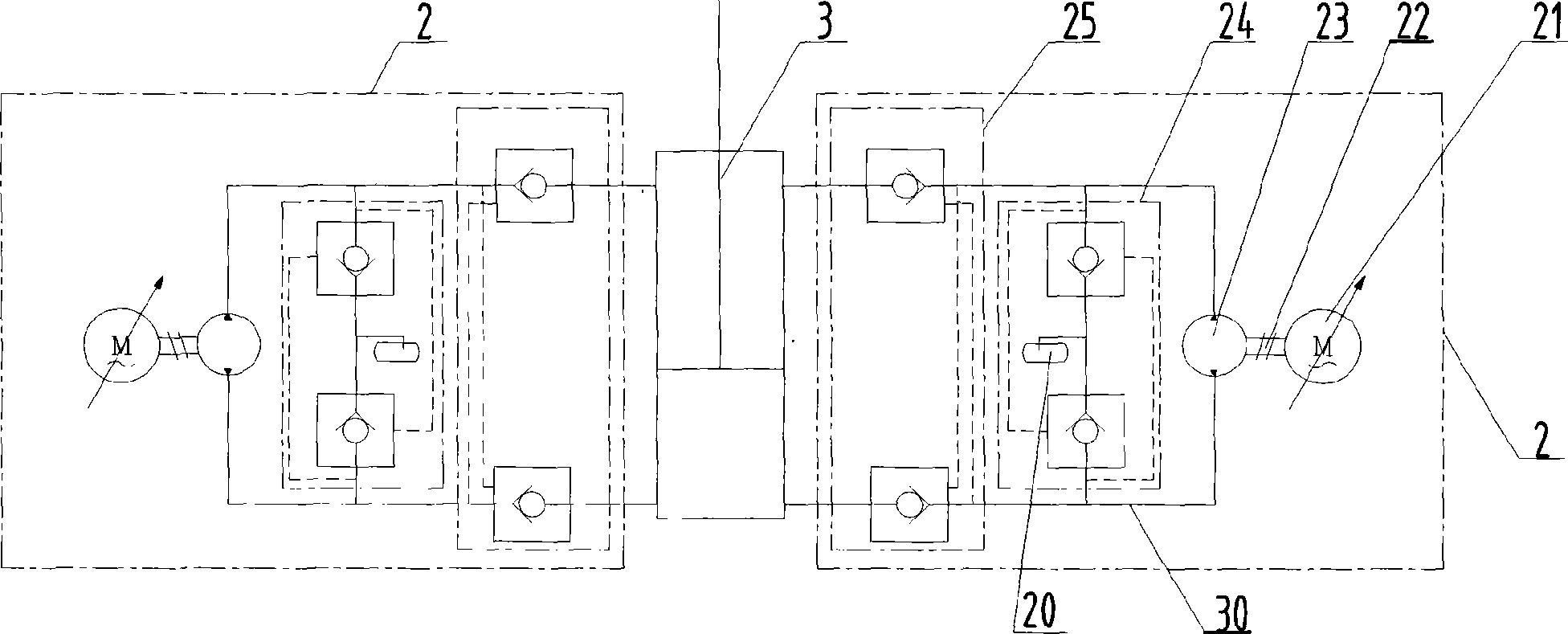

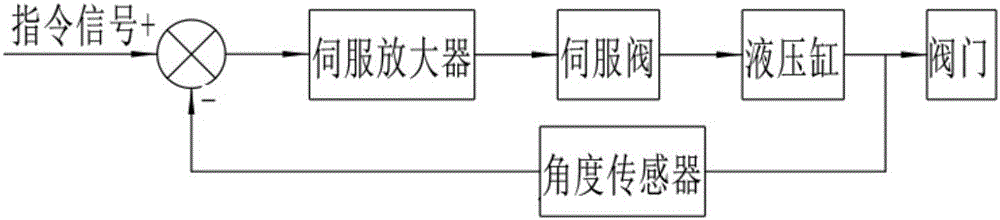

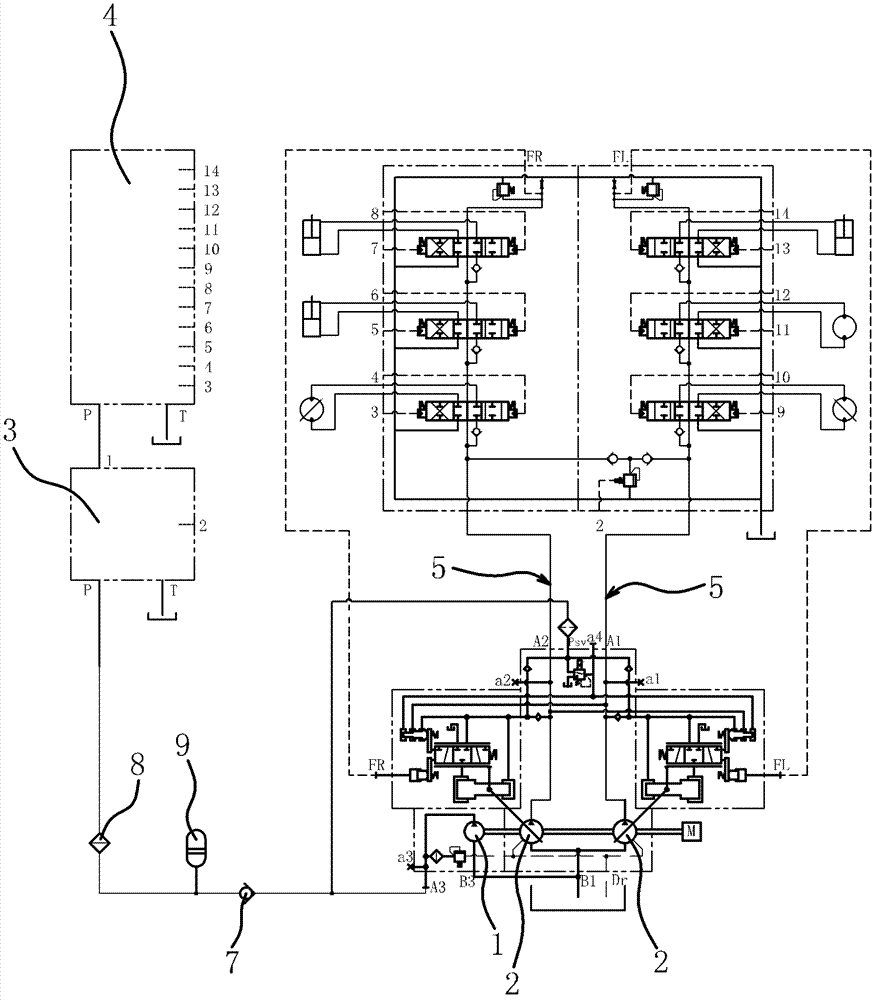

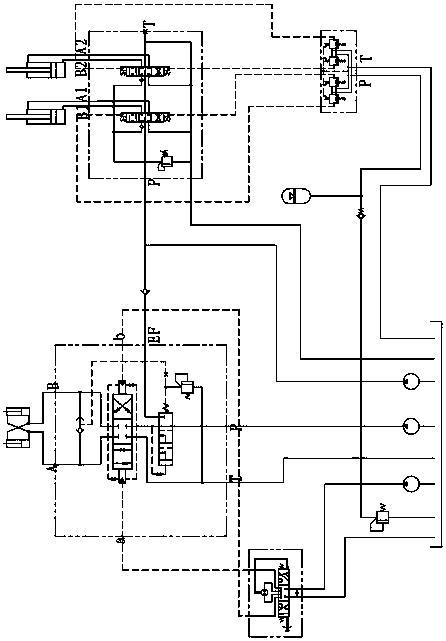

Electro-hydraulic-servo-driven valve controlling device

InactiveCN105135033AIncrease the opening speedSpeed up closingOperating means/releasing devices for valvesServomotorsHydraulic cylinderFuel tank

The invention provides an electro-hydraulic-servo-driven valve controlling device. The valve controlling device comprises a pinion-and-rack hydraulic cylinder, two sets of electro-hydraulic servo power sources and an electronic control part. The electronic control part comprises a controller, a displayer, a control switch and an angle transducer, wherein the displayer, the control switch and the angle transducer are connected with the controller. The angle transducer is fixed to the upper portion of the pinion-and-rack hydraulic cylinder. A rotating shaft of the pinion-and-rack hydraulic cylinder is connected with a rotating shaft of the angle transducer. The rotating shaft of the pinion-and-rack hydraulic cylinder is connected with a rotating shaft of a valve. Each set of electro-hydraulic servo power source comprises a bidirectional gear quantitative hydraulic pump, an alternating-current servo motor, a pressure oil tank and a double-hydraulic control one-way valve which are connected with the controller. Output shafts of the alternating-current servo motors and input shafts of the hydraulic pumps are connected. The pressure oil tanks are communicated with low-pressure oil suction openings of the hydraulic pumps through the one-way valves. Two outlets of the bidirectional gear quantitative hydraulic pumps of the two sets of electro-hydraulic servo power sources are communicated with the hydraulic cylinder through the double-hydraulic control one-way valves. The valve controlling device has the beneficial effects of being good in reliability, capable of saving energy and efficient.

Owner:JIANGSU UNIV

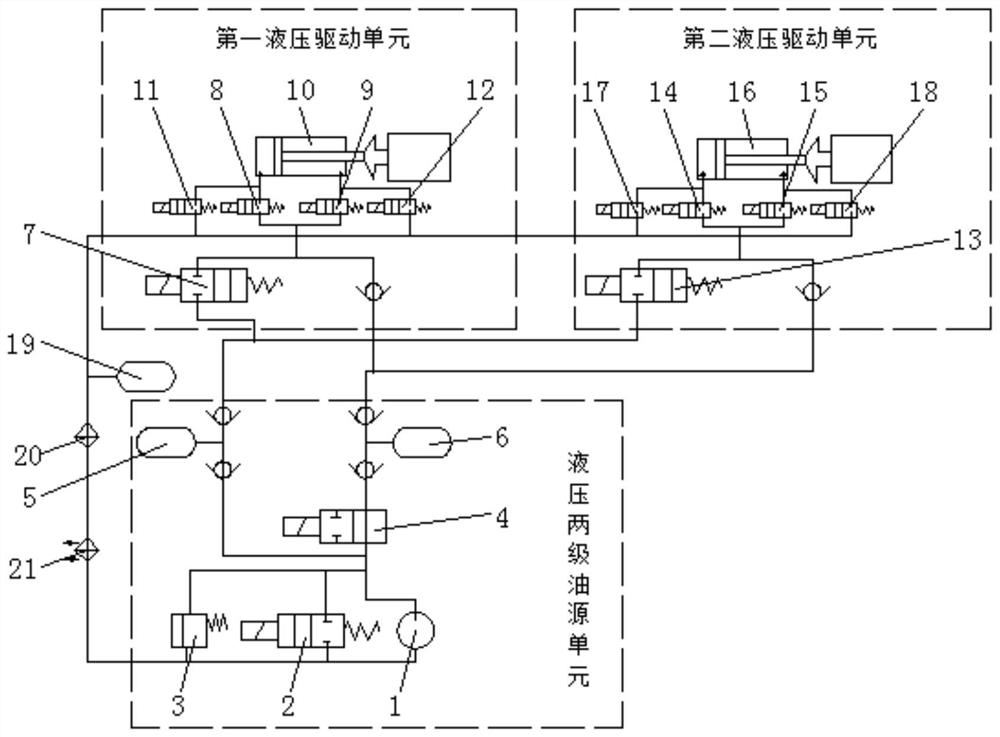

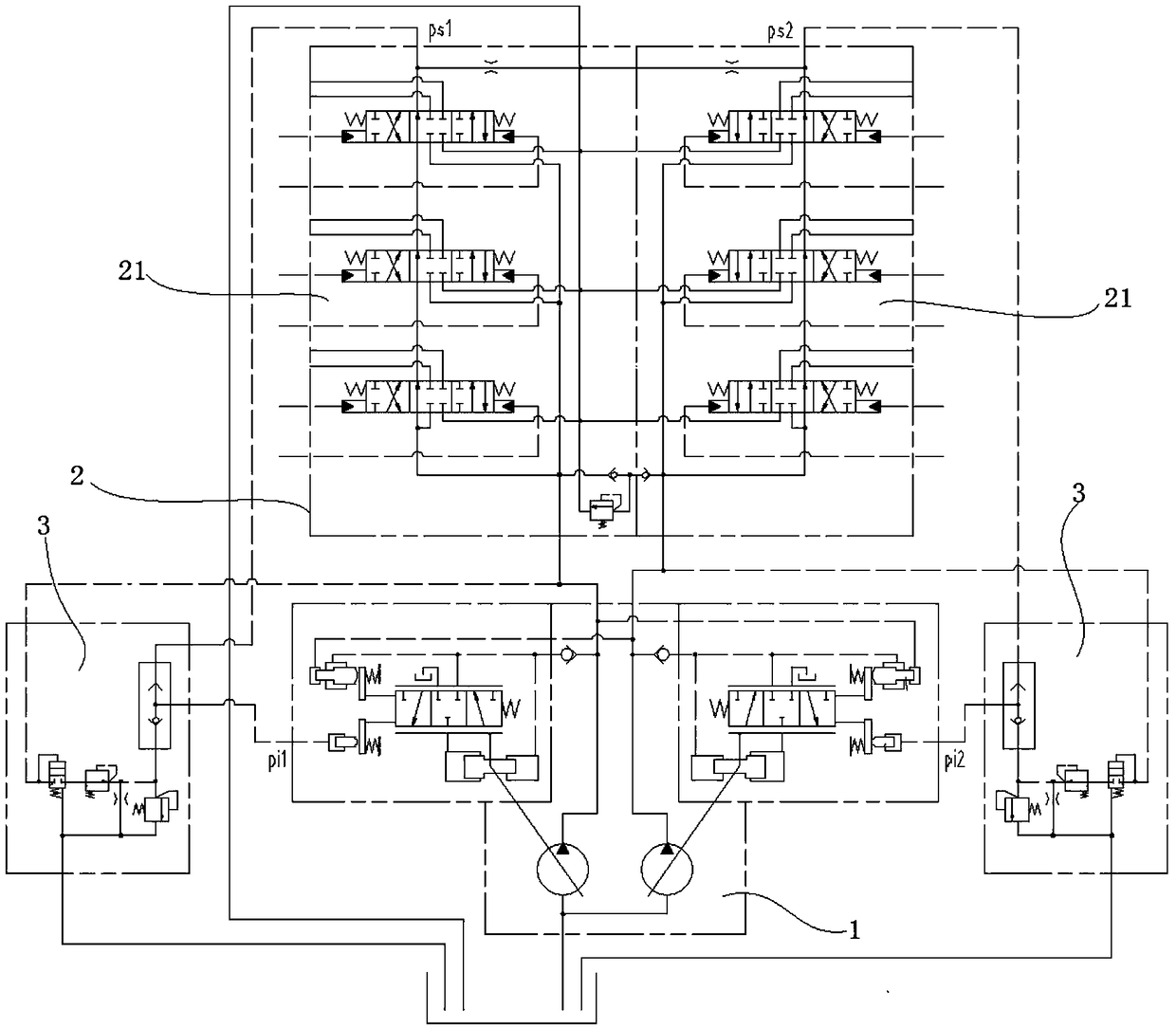

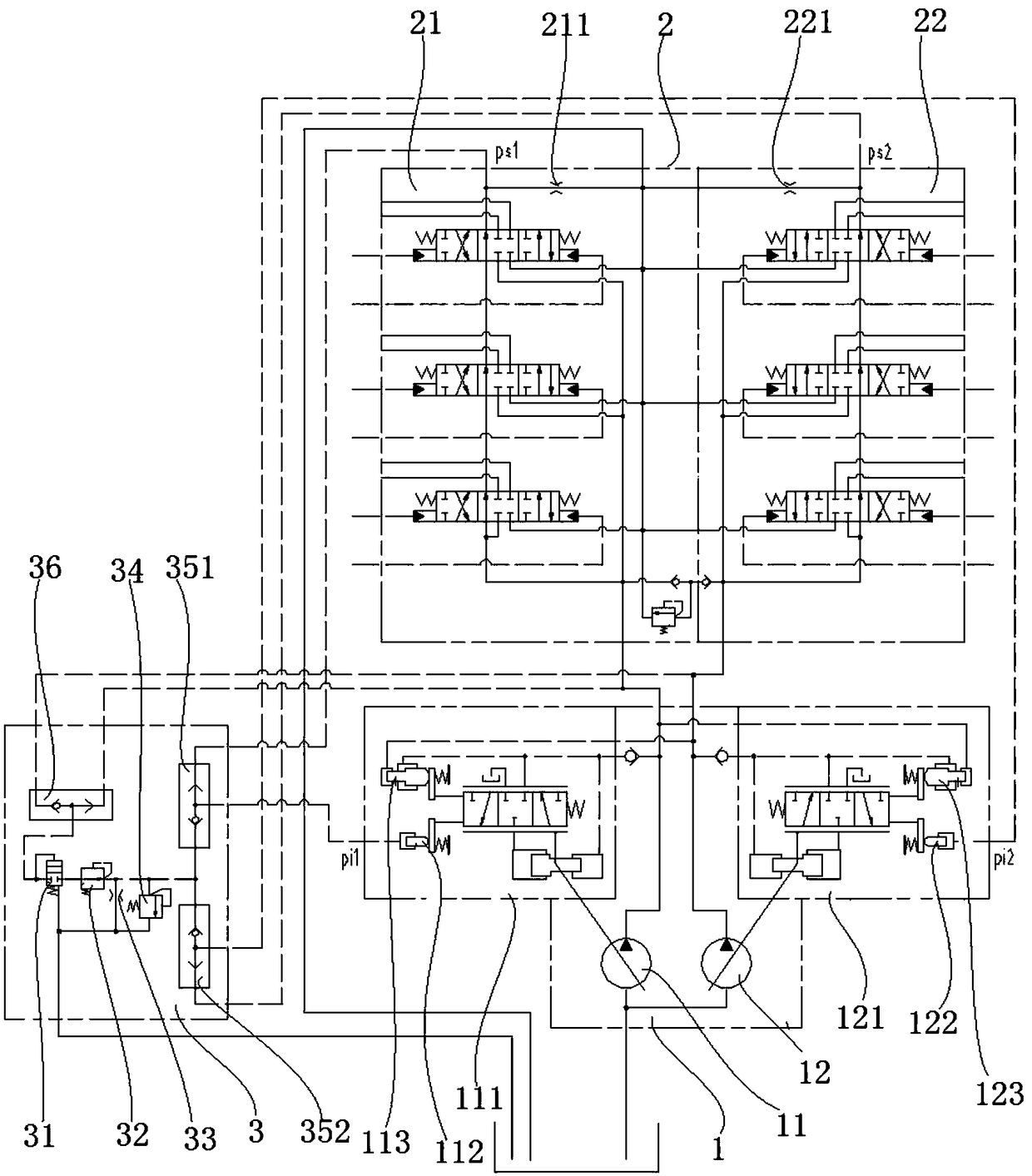

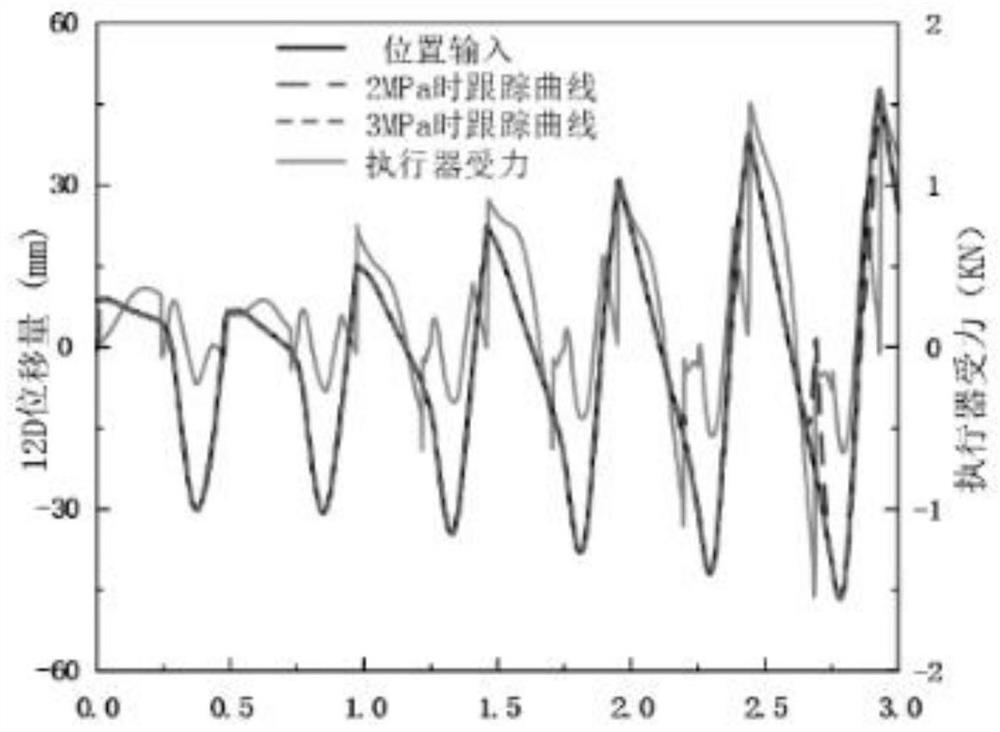

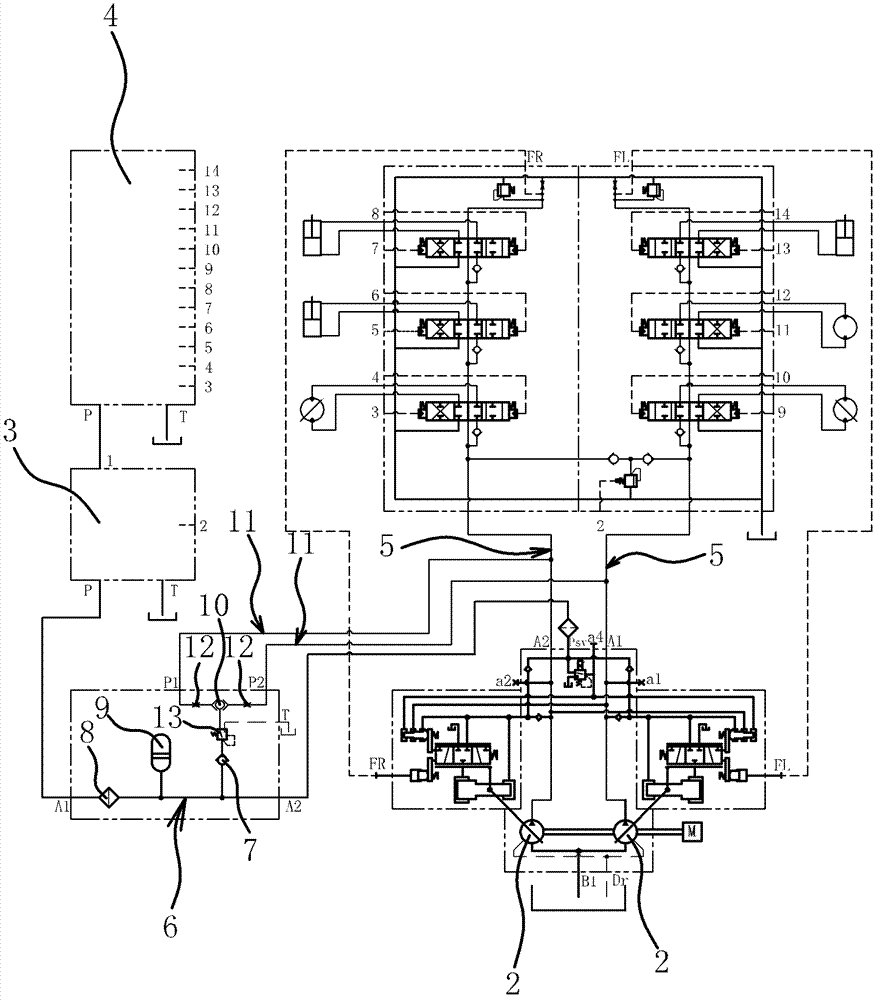

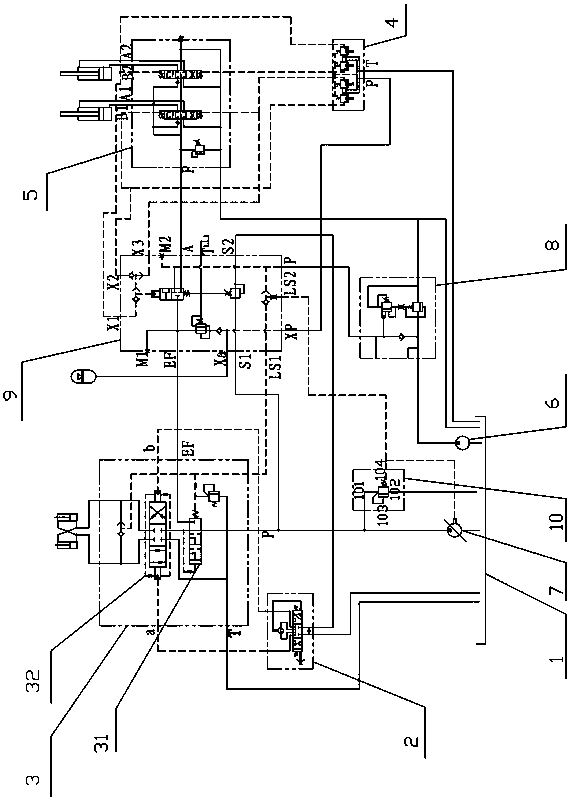

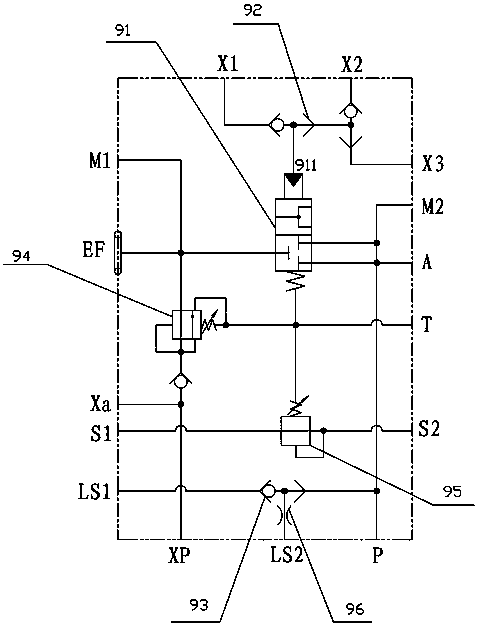

Quadruped robot hydraulic system based on two-stage energy supply and loading opening independent valve control

ActiveCN111828410AImprove efficiencyReduce energy consumptionServomotor componentsAccumulator installationsControl engineeringEnergy supply

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +2

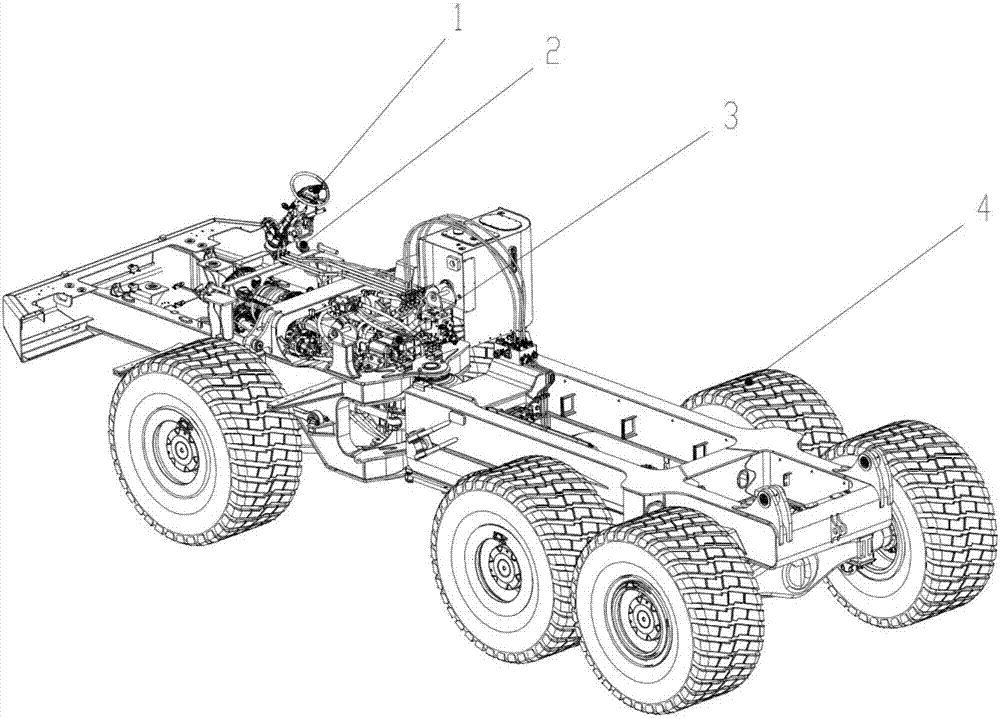

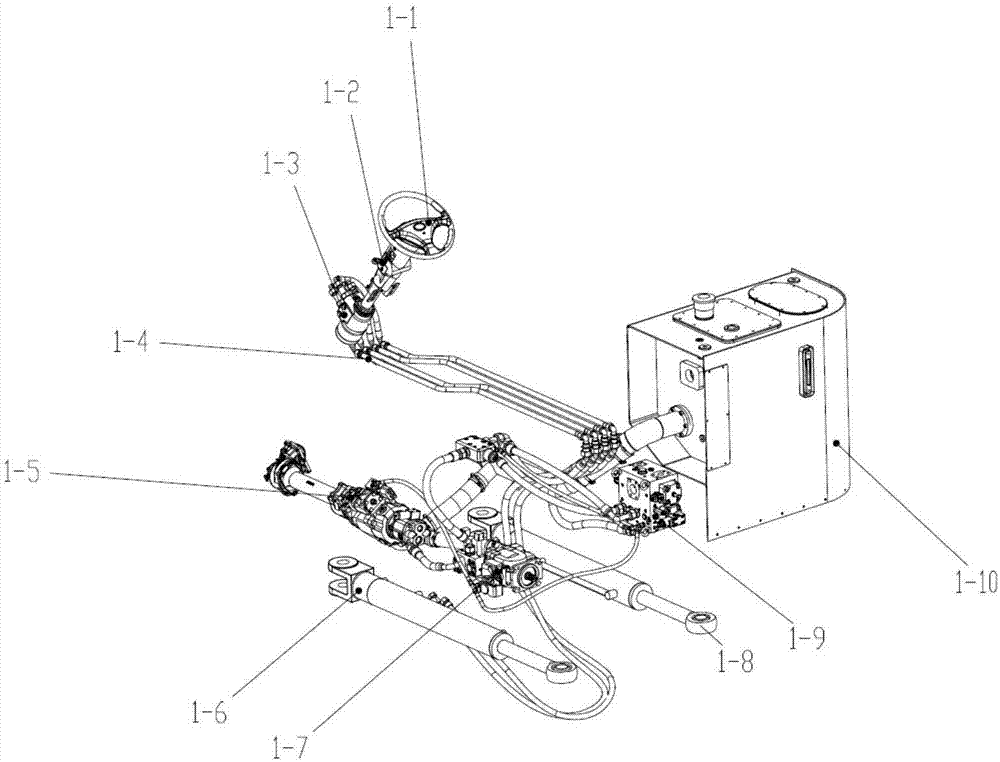

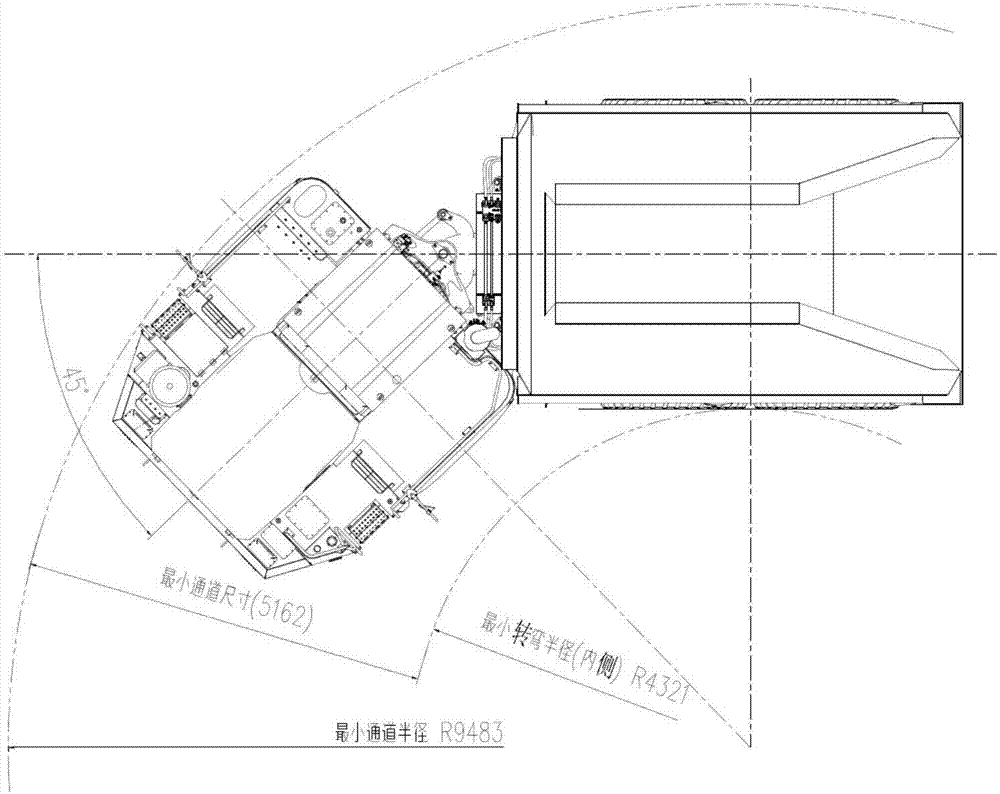

Hinging-type dump truck chassis

PendingCN107963132AReduce weightGuaranteed weightBraking action transmissionUnderstructuresVehicle frameEngineering

The invention discloses a hinging-type dump truck chassis. The hinging-type dump truck chassis comprises a steering system, a braking system, a drive system and a driving system, wherein the driving system comprises a truck frame assembly, the truck frame assembly comprises a front truck frame, a hinging body and a rear truck frame, a front axle is arranged below the front truck frame, a middle axle and a rear axle are arranged below the rear truck frame, one end of a left front hydro-pneumatic suspension unit and one end of a right front hydro-pneumatic suspension unit are connected to the upper surfaces of the left side and the right side of the front axle respectively, the other end of the left front hydro-pneumatic suspension unit and the other end of the right front hydro-pneumatic suspension unit are connected with the front truck frame, a right front cross pull rod, a front V rod and a left front cross pull rod are installed between the front truck frame and the front axle, themiddle axle is connected with the rear axle through a left balancing beam and a right balancing beam, a right middle cross pull rod, a middle V rod and a left middle cross pull rod are installed between the rear truck frame and the middle axle, and a right rear cross pull rod, a rear V rod and a left rear cross pull rod are installed between the rear truck frame and the rear axle. The hinging-typedump truck chassis is simple in structure, safe and reliable, and can effectively improve the trafficability and the comfort of the complete machine.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

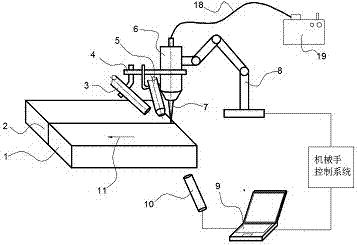

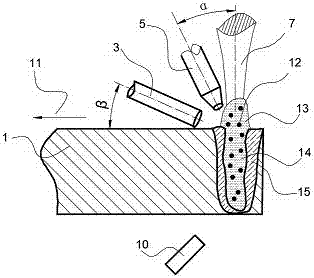

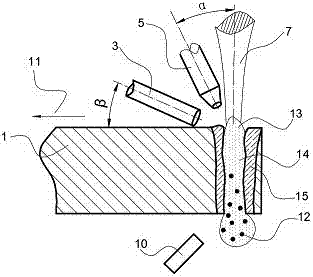

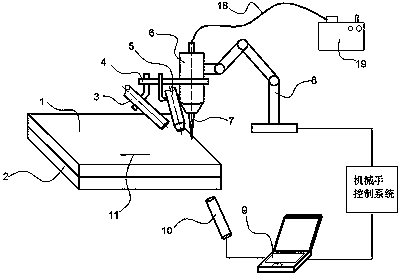

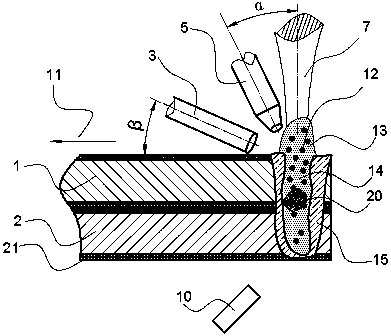

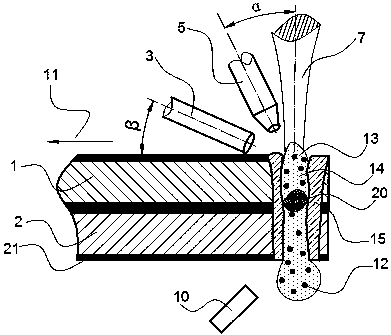

Plate welding method adopting laser penetration

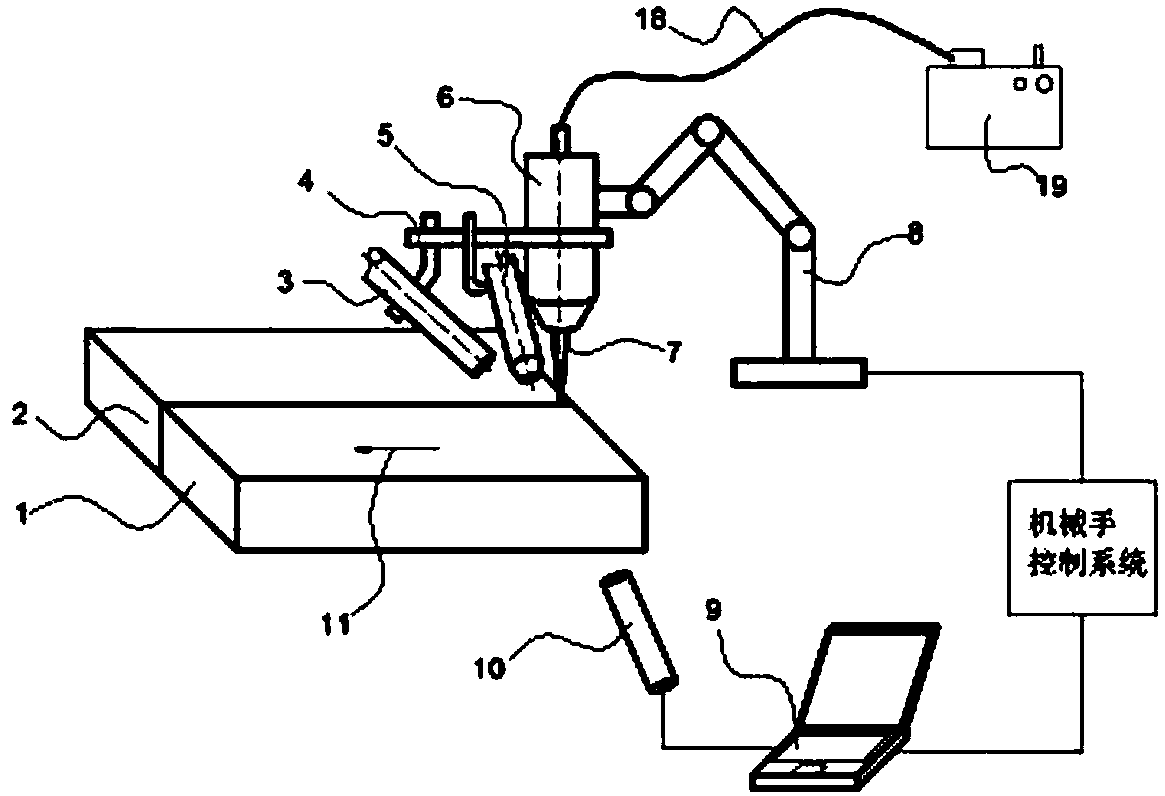

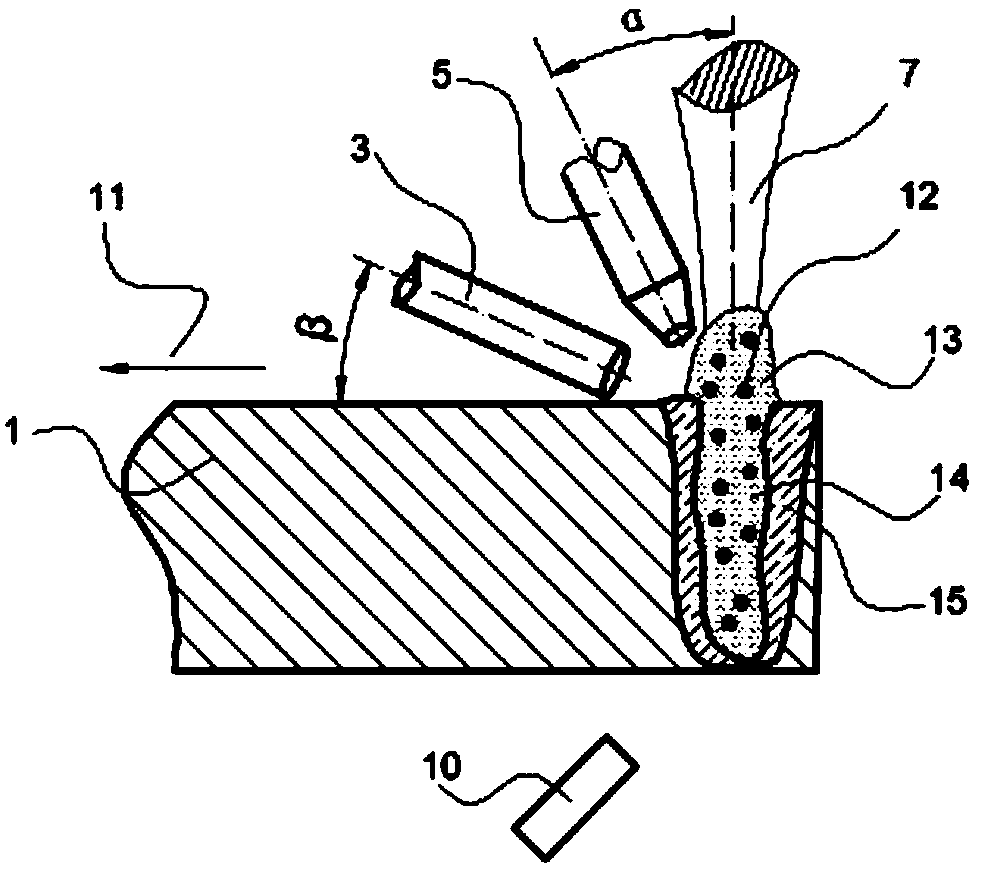

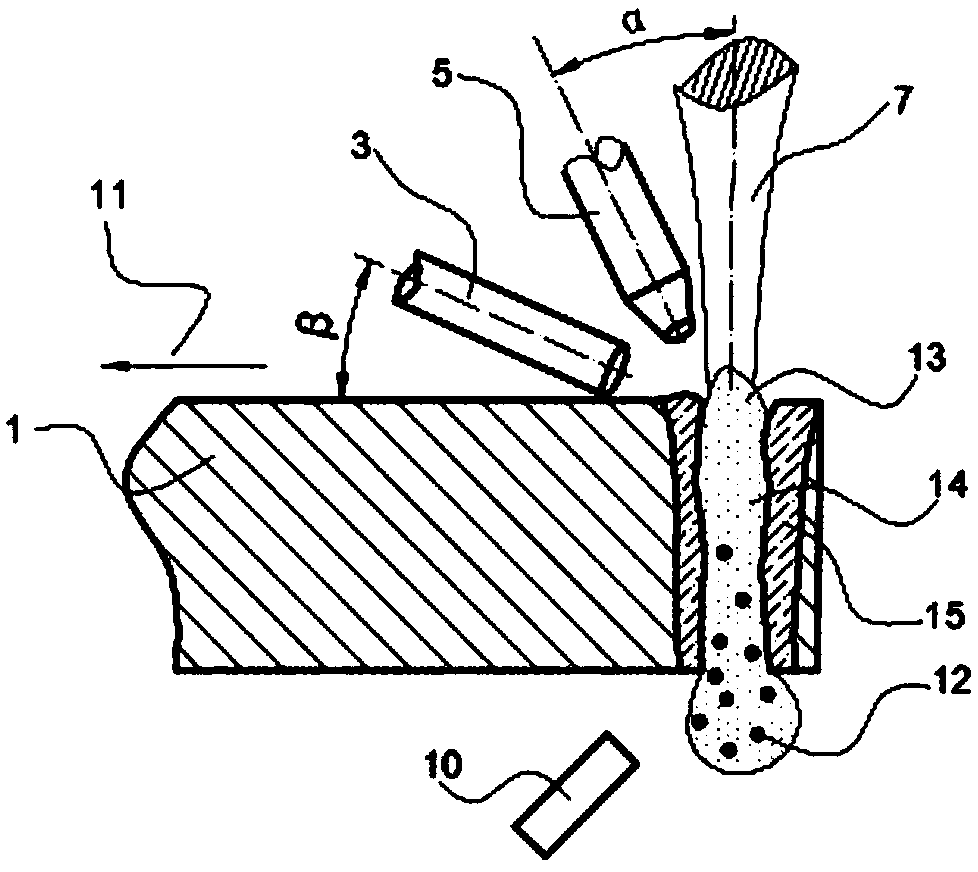

ActiveCN107052582AAvoid Intermittent PenetrationImprove stabilityLaser beam welding apparatusShielding gasEngineering

The invention relates to a plate welding method adopting laser penetration. A laser welding head, a high-pressure gas column nozzle and a protective gas spraying pipe can move relative to base materials, when the temperature of the back surfaces of the base materials reaches or exceeds a gasification temperature value of the base materials, the laser welding head and the high-pressure gas column nozzle are rotated, so that the laser welding head is inclined relative to the upper surfaces of the base materials, and the high-pressure gas column nozzle is in vertical alignment with the upper surfaces of the base materials; and a gas supply valve of the high-pressure gas column nozzle is controlled so that inert gas columns can be sprayed by the high-pressure gas column nozzle to penetrate through welding keyholes. The invention further relates to a laser welding system, and the laser welding head and the high-pressure gas column nozzle can move relative to the base materials so that the laser welding head and the high-pressure gas column nozzle can be switched between a first state and a second state. According to the plate welding method adopting laser penetration, high-pressure superfine gas columns are adopted to assist in maintaining the keyholes, so that discontinuous penetration of the keyholes and the loss of laser energy overflow in the penetration welding process are avoided, and the stability of the keyholes and the energy utilization rate are improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Negative flow hydraulic control oil circuit and hydraulic system and excavator

InactiveCN109210024AReduce displacementAvoid overflow lossServomotor componentsServomotorsHigh pressureReturn channel

Owner:LIUZHOU LIUGONG EXCAVATORS +2

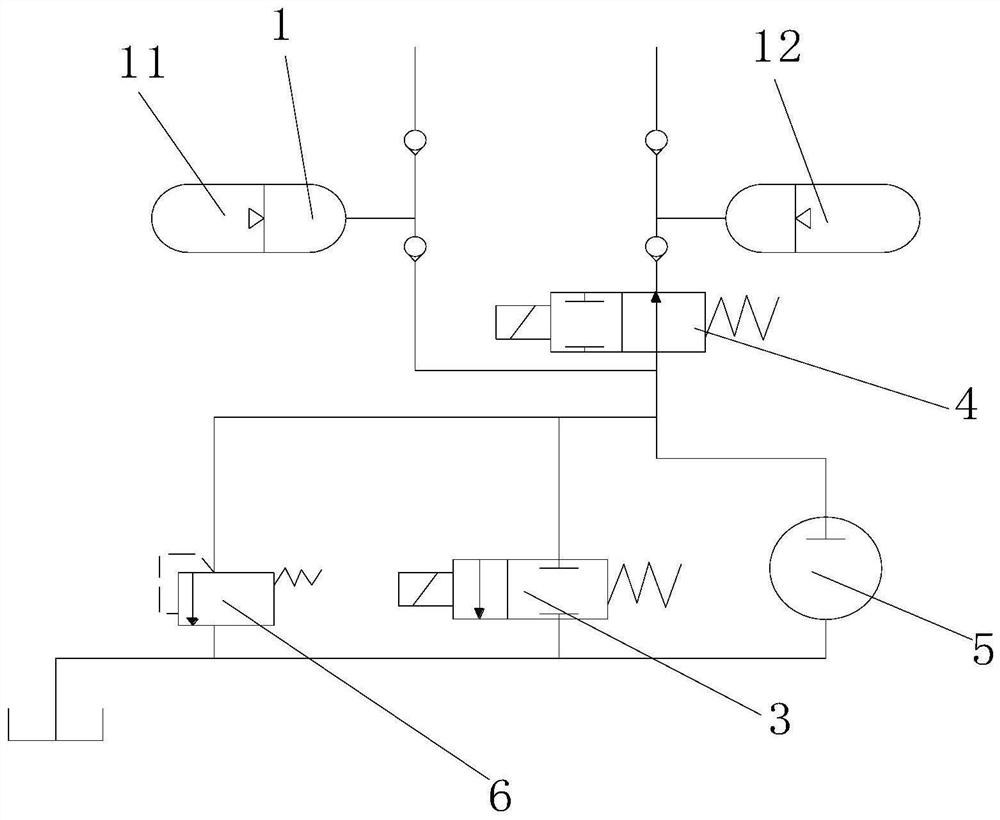

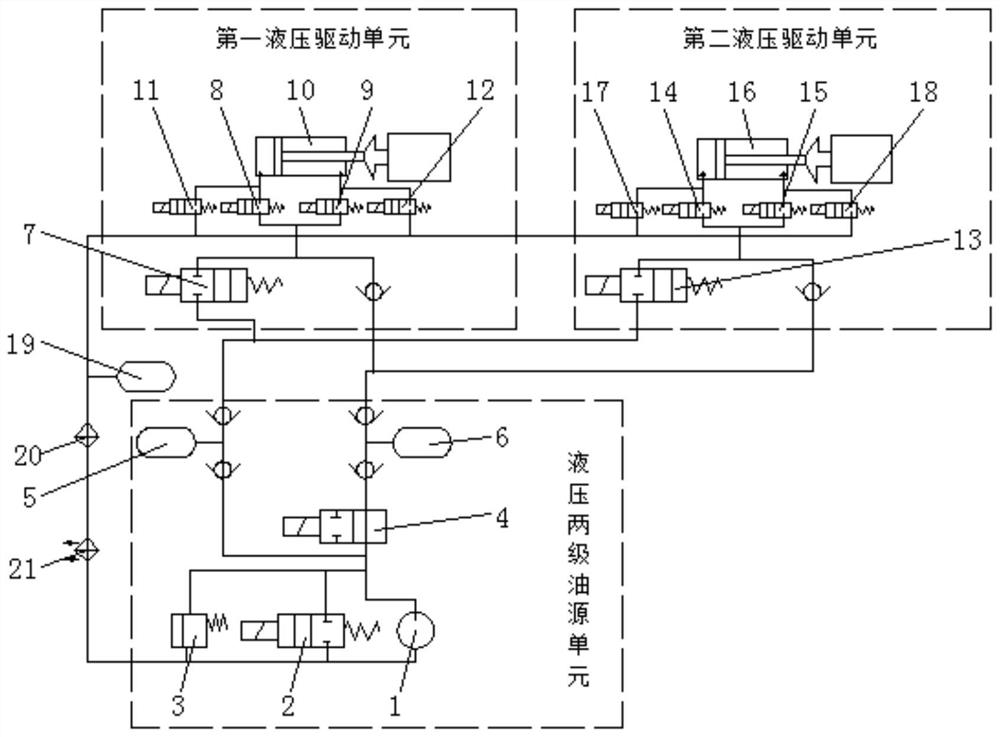

Hydraulic two-stage oil source for supplying energy through two-stage energy accumulator

InactiveCN111810461AAvoid overflow lossReduce churning lossAccumulator installationsServometer circuitsWork cycleEngineering

The invention relates to the technical field of robots, and discloses a hydraulic two-stage oil source for supplying energy through a two-stage energy accumulator. The hydraulic two-stage oil source comprises the energy accumulator, a switching valve A, a switching valve B, a constant displacement pump and an overflow valve. The energy accumulator comprises a high-pressure energy accumulator bodyand a low-pressure energy accumulator body. Through the arrangement of the high-pressure energy accumulator body and the low-pressure energy accumulator body, the degrees that gas is compressed in theoil charge process and the oil drainage process are different, and the oil pressure in the energy accumulator changes constantly; when the working cycle of the energy accumulator is smaller than 3 min, it can be considered that the energy accumulator works under the adiabatic condition; when the energy accumulator serves as an auxiliary power source, the inflation pressure should be lower than 90% of the lowest work pressure and higher than 25% of the highest work pressure, at this moment, the pressure change range in the energy accumulator does not exceed 20% of the work pressure, and the energy supply requirement of a hydraulic drive unit is met; and in the process that the energy accumulator stores and releases energy, less energy is lost, the requirement of a quadruped robot hydraulicsystem for energy consumption is completely met, and reasonable parameter selection is achieved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +2

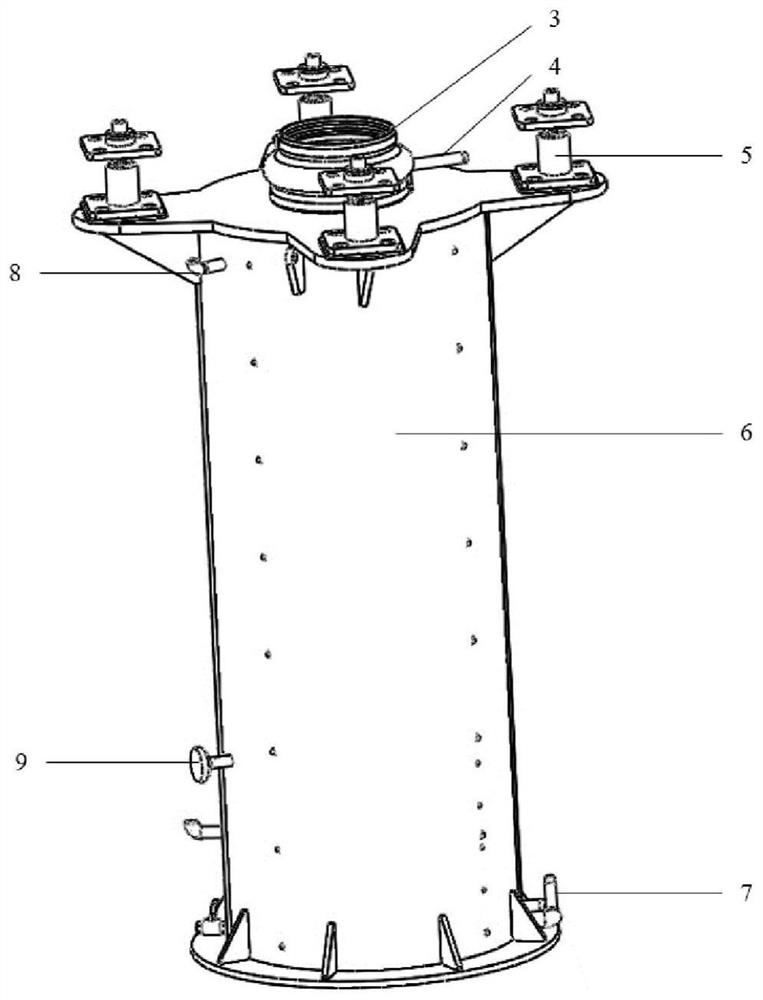

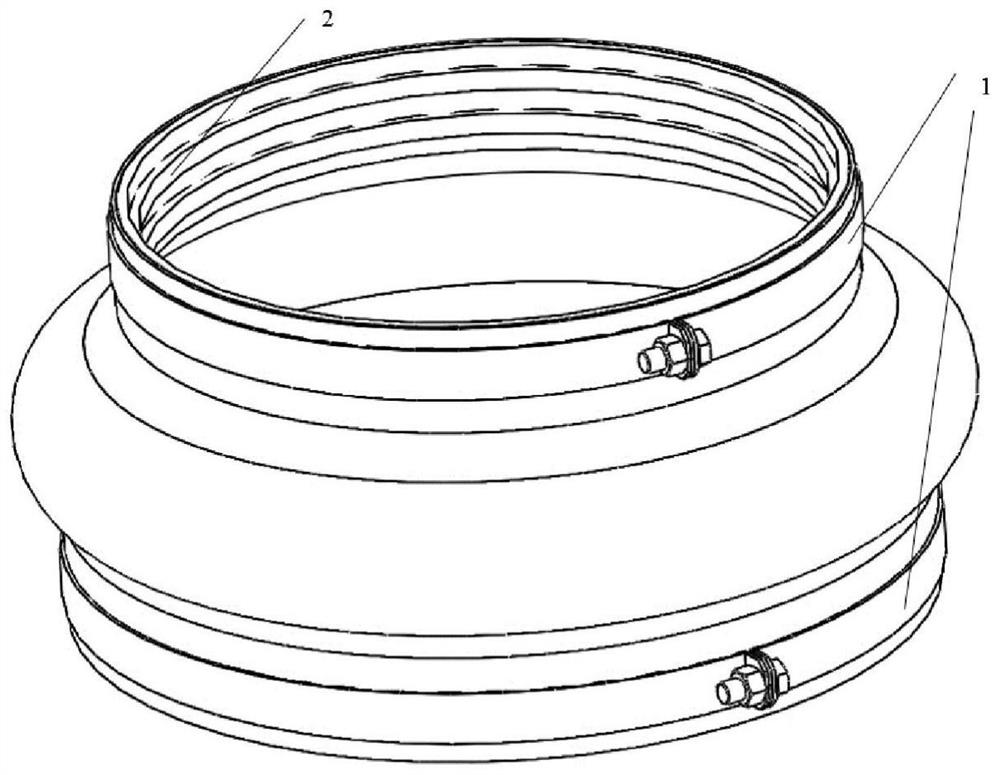

Sealed smoke hood suitable for rotary electrode vacuum electroslag remelting technology

InactiveCN112342401AReduce oxygen contentReduce hydrogen contentIncreasing energy efficiencyWaste heat treatmentMetallurgyEngineering

The invention discloses a sealed smoke hood suitable for a rotary electrode vacuum electroslag remelting technology. A smoke hood body is connected with a lifting platform of a rotary electrode vacuumelectroslag furnace in rotary electrode vacuum electroslag remelting equipment through a smoke hood suspension device arranged at the upper end of the smoke hood body; a rotary shaft of a rotary electrode vacuum electroslag furnace in the rotary electrode vacuum electroslag remelting equipment penetrates through an upper end opening of the smoke hood to enter the smoke hood body, the lower portion of the smoke hood body is in butt joint with a crystallizer of the electroslag furnace, a sealing sleeve is arranged on the upper portion of the smoke hood body, the upper end face where a pump-outpipeline is arranged and the side edge of the sealing sleeve are connected with of a vacumm pump of the rotary electrode vacuum electroslag furnace; and a water inlet pipe and a water outlet pipe arerespectively arranged at the upper part and the lower part of the side wall of the smoke hood body and communicate with a water circulation system in the rotary electrode vacuum electroslag remeltingequipment. By improving the sealing smoke hood, the problems of rotating body sealing and vacuum environment sealing in a rotary electrode vacuum electroslag remelting system are solved, the refiningeffect of an electroslag remelting process is improved, the structure is simple, and the sealing performance is good.

Owner:NORTHEASTERN UNIV

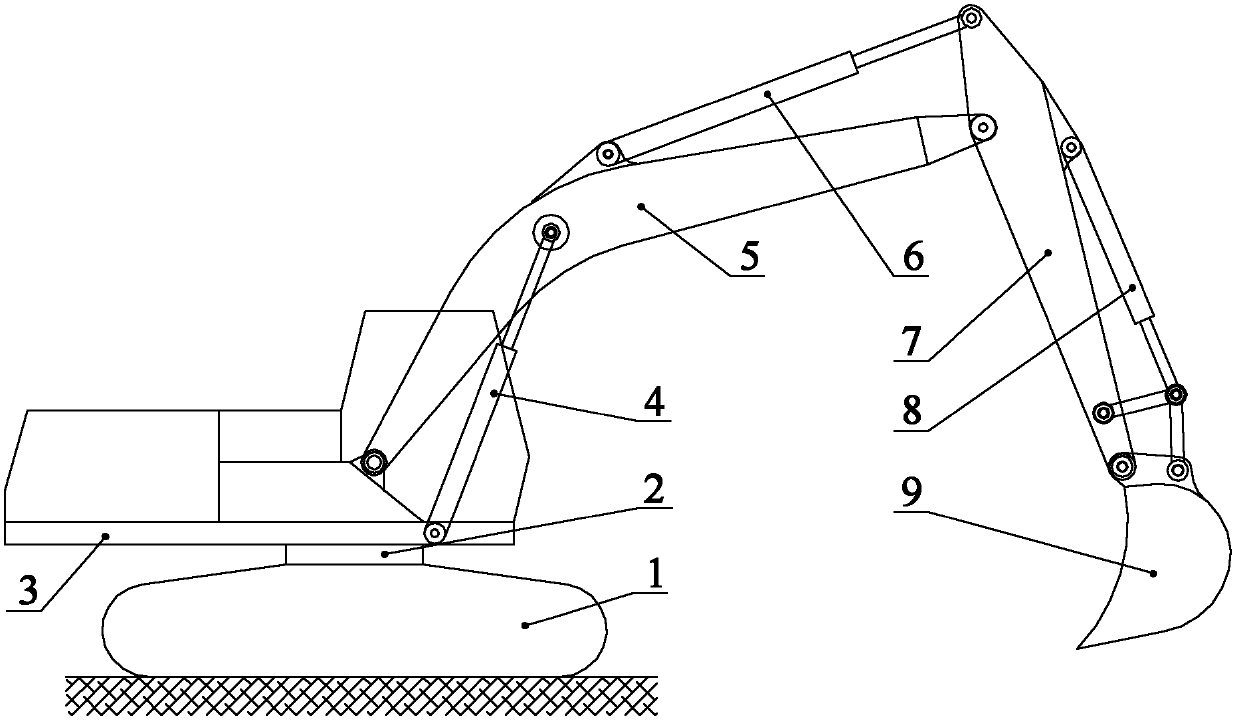

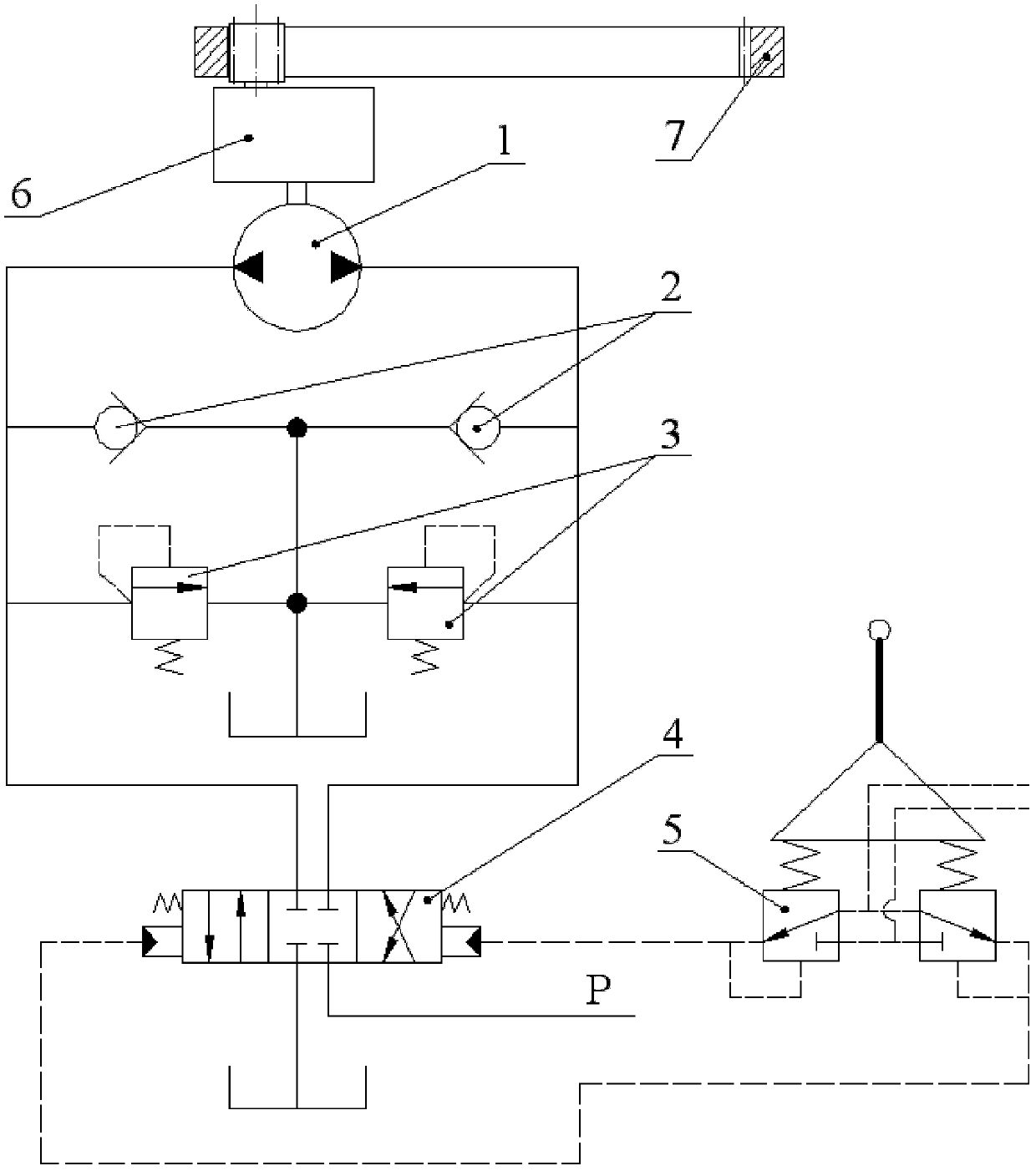

Rotary energy saving system of hydraulic excavator

InactiveCN102704524BSimple technical meansLow costSoil-shifting machines/dredgersHydraulic motorControl engineering

The invention discloses a rotary energy saving system of a hydraulic excavator. The rotary energy saving system comprises a two-position four-way reversing valve, an energy storage unit, a three-position four-way hydraulic control reversing valve, an air storage cylinder and two one-way valves. Outlets of the two one-way valves are connected with a lower chamber of the energy storage unit and a port P of the three-position four-way hydraulic control reversing valve while inlets of the two one-way valves are connected with an inlet oil channel and an outlet oil channel of a hydraulic motor. The energy storage unit is jointed with the two-position four-way reversing valve, a piston butts against a valve stem when being close to the end of the lower chamber so as to be capable of driving the valve stem of the reversing valve to switch, and an upper chamber is connected with an air storage cylinder. A port P and a port O of the two-position four-way reversing valve are connected with a port A and a port B of a main-control reversing valve, and the port A and the port B of the main-control reversing valve are connected with the inlet oil channel and the outlet oil channel of the hydraulic motor. Hydraulic control ports on two sides of the three-position four-way hydraulic control reversing valve are respectively in parallel connection with an oil channel from the main control reversing valve and a pilot operating valve. The roary energy saving system is easy to implement and low-cost, and has the advantages that performance of conventional rotary hydraulic systems can be kept, rotary braking energy can be restored sufficiently, efficiency is high, and overload and impact of the hydraulic motor can be improved by the energy storage unit.

Owner:SOUTH CHINA UNIV OF TECH

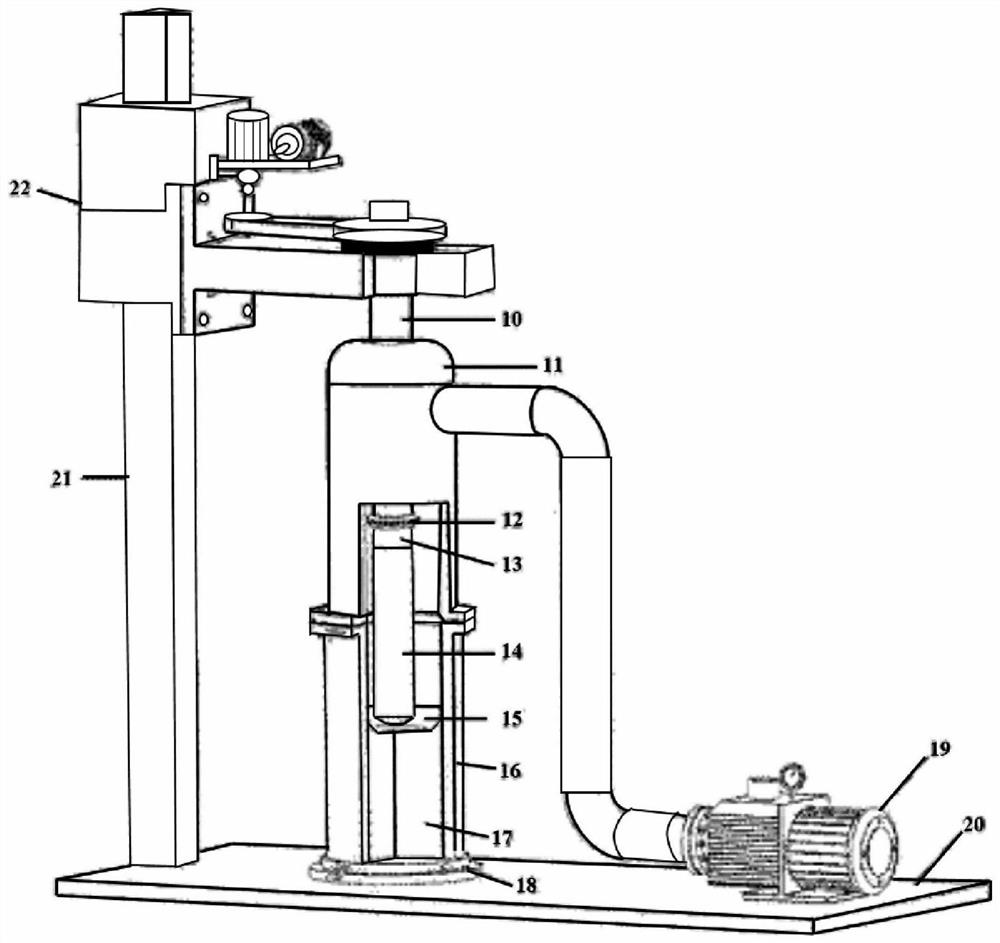

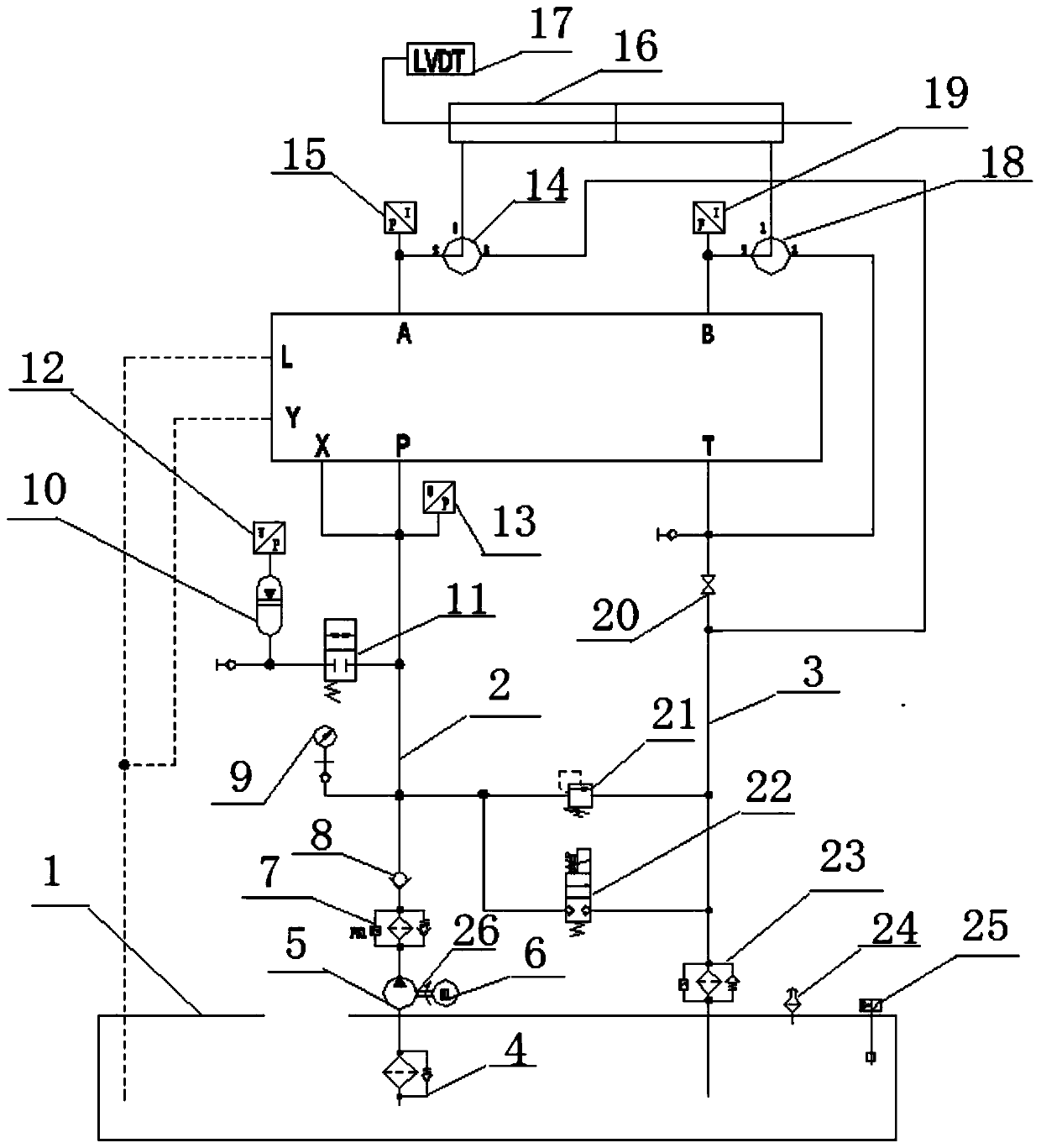

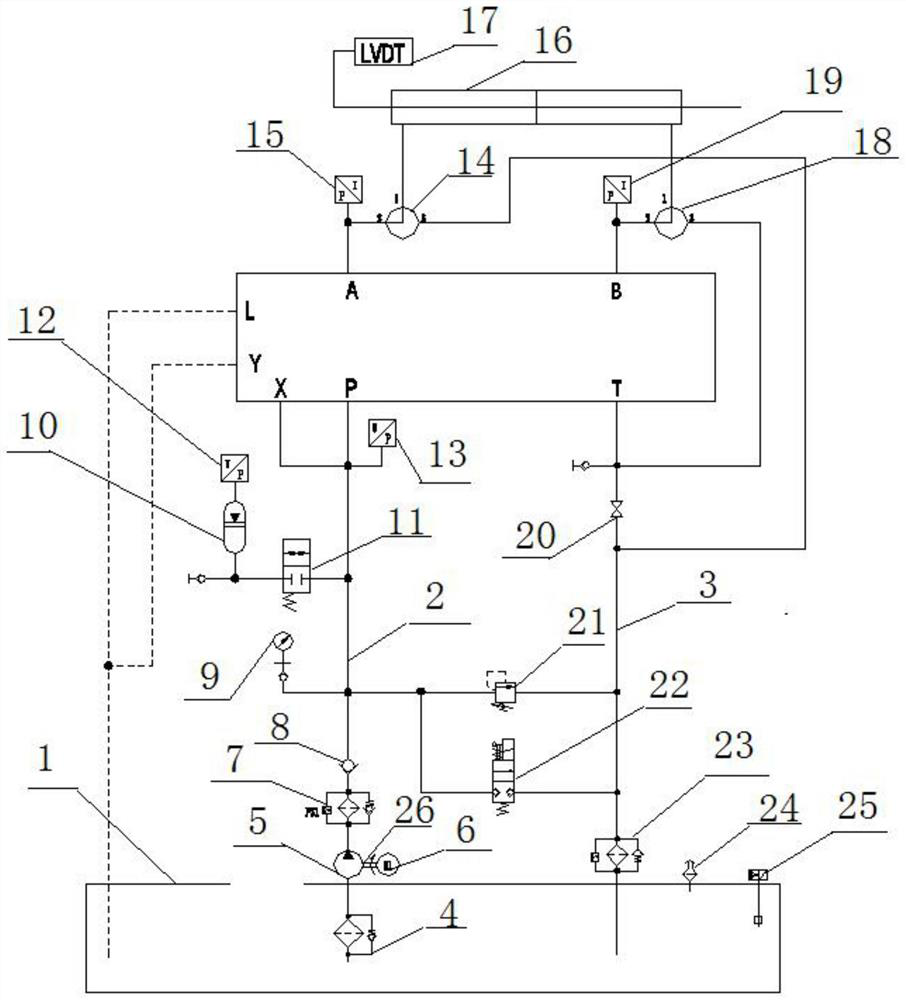

Proportional valve and servo valve testing table

ActiveCN109667812ALow powerSolve the noise problemFluid-pressure actuator testingFuel tankProportional valve

The invention relates to a proportional valve and servo valve testing table. The table comprises an oil tank and a test valve group, wherein the oil tank is provided with an oil outlet pipe. The oil outlet pipe from the oil tank to the test valve group is sequentially provided with an oil pump, an oil filter, a pressure gage and an energy accumulator; the test valve group comprises a flow measuring device, a first three-way ball valve, a second three-way valve and a two-way ball valve; the three ports of the first three-way ball valve are separately connected with an oil outlet of the oil outlet pipe, one of the end of the flow measuring device, and an oil inlet of an oil return pipe; the three ports of the second three-way ball valve are separately connected with an oil outlet of the oiloutlet pipe, the other end of the flow measuring device and the oil inlet of the oil return pipe; the joint of the first three-way ball valve and the oil return pipe is arranged above the two-way ballvalve; and the oil outlet of the oil return pipe is connected with the oil tank. According to the table, most of the hydraulic oil in the testing process is supplied by the energy accumulator, so that the motor capacity is greatly reduced, and the problem of equipment noise is also completely solved.

Owner:北京凯德福液压技术有限公司

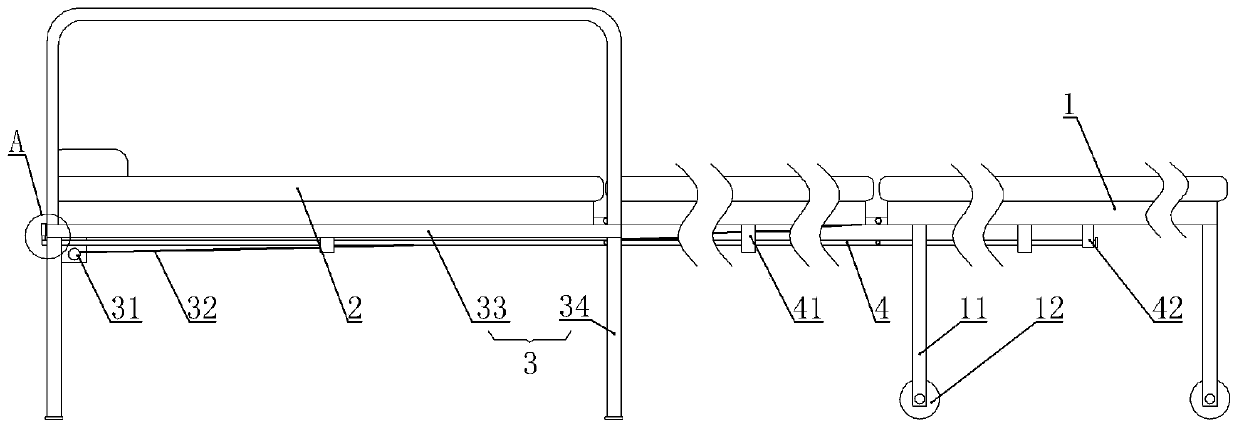

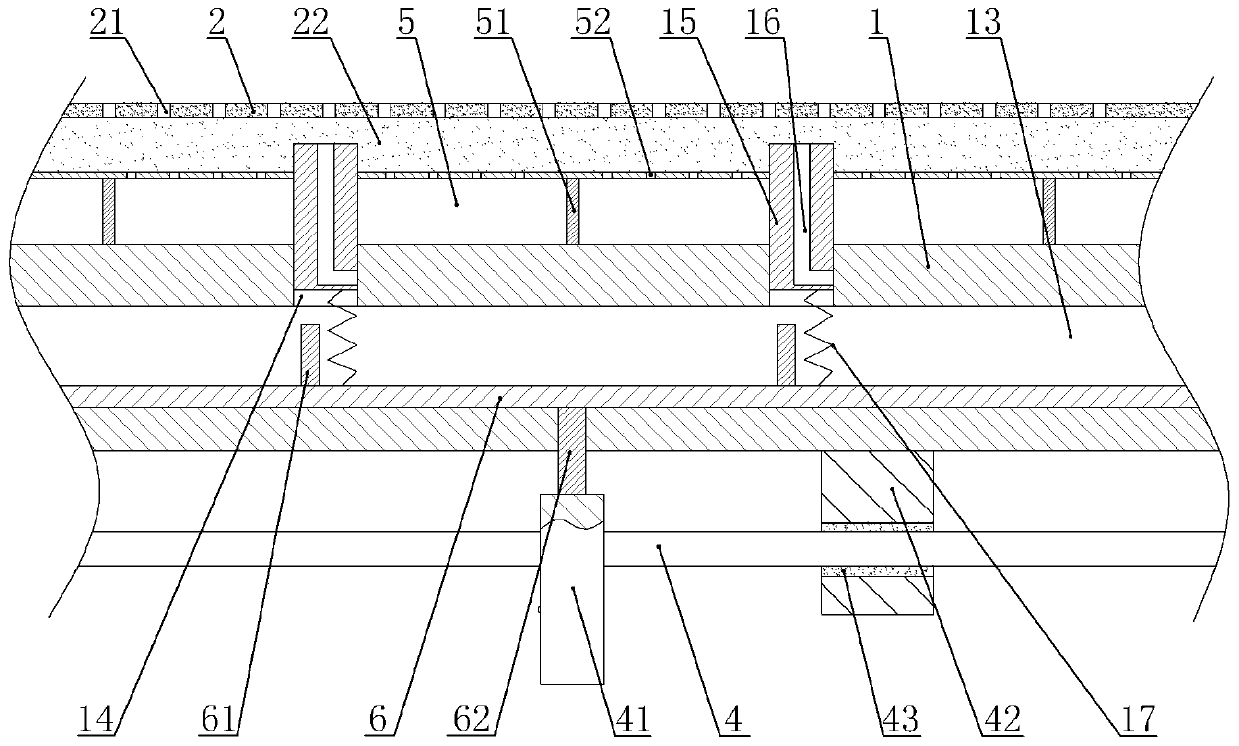

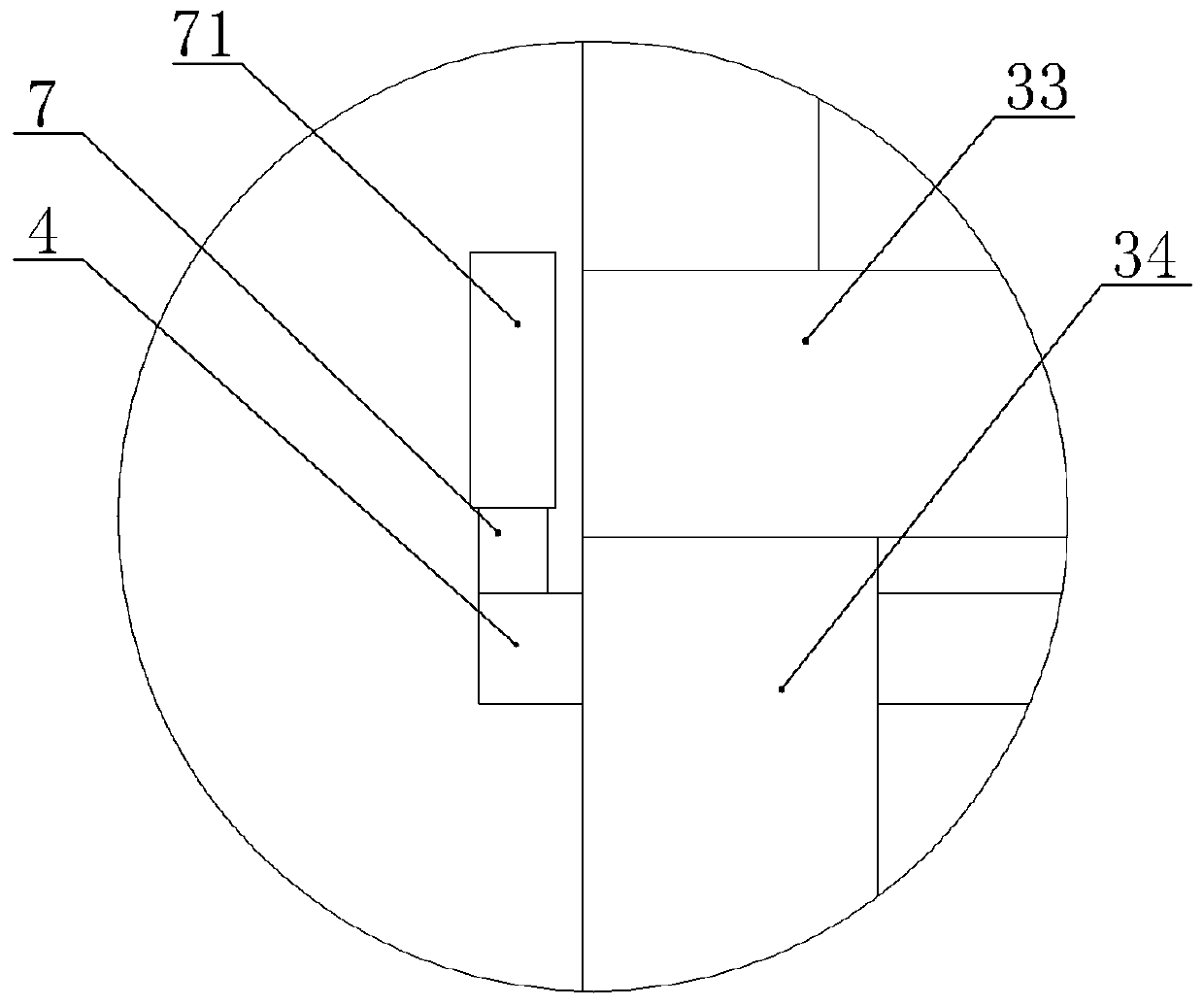

Automatic accompanying bed

PendingCN110638248AGood thermal effectAvoid overflow lossBenchesConvertible chairsPhysicsElectric machinery

The invention relates to the field of furniture and particularly discloses an automatic accompanying bed. The automatic accompanying bed comprises at least three bottom plates, wherein the adjacent bottom plates are hinged, a buffer layer is fixed to the top of each bottom plate, supporting legs are fixed to the bottom of the bottom plate at one side, and a supporting frame is hinged to the bottomof the bottom plate at the other side; a pull rope is fixed to the bottom plate where the supporting legs are fixed, and a stepping motor capable of rolling the pull rope is fixed to the supporting frame; a heating cavity is formed in each bottom plate, a plurality of hot air channels are formed in the top wall of each heating cavity, a piston is connected into each hot air channel in a verticalsliding mode, each piston is higher than the top of the corresponding bottom plate, a spring is fixed between each piston and the inner wall of the corresponding heating cavity, and each piston is provided with an exhaust channel which communicates with the corresponding heating cavity in the slide-down process; and each buffer layer is provided with a plurality of through holes, and each heatingcavity communicates with an air-in piece and a heating piece. According to the scheme, the accompanying bed can be unfolded slowly and automatically without being unfolded by manpower completely, andthe situation that a large sound is generated in the unfolding process is avoided.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

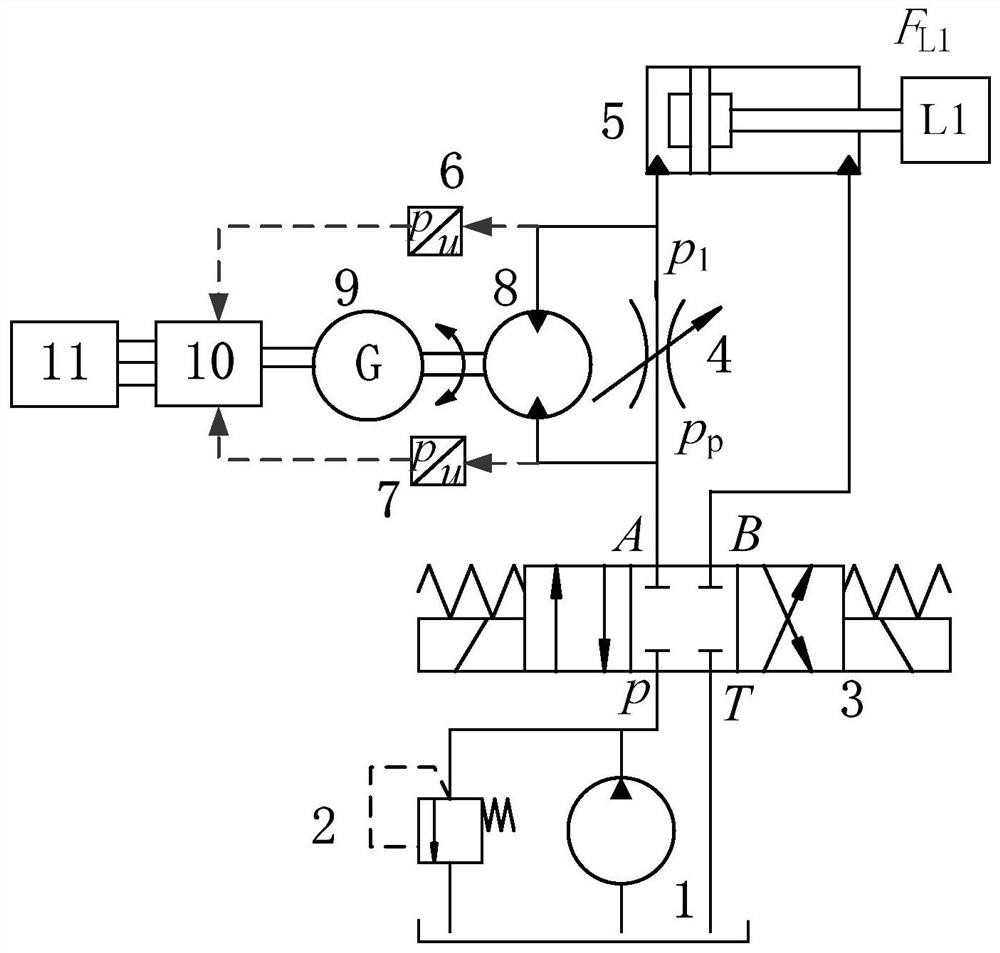

A three-way speed regulating valve based on hydraulic motor-generator pressure compensator

ActiveCN111706563BPlay a role in stabilizing the voltage differenceImprove efficiencyFluid-pressure actuator testingServomotor componentsEngineeringInlet pressure

The invention provides a three-way speed regulating valve based on a hydraulic motor-generator pressure compensator, the oil inlet of the hydraulic motor (8) is connected with the oil inlet of the throttle valve (4); the oil outlet of the hydraulic motor (8) Connect with the oil outlet of the throttle valve (4); connect the first pressure sensor (6) with the oil outlet of the throttle valve (4); connect the second pressure sensor (7) with the oil inlet of the throttle valve (4) connection; the torque input end of the motor controller (10) is connected to the generator (9); the inlet and outlet pressure difference Δp of the throttle valve (4) is obtained through the first pressure sensor (6) and the second pressure sensor (7) , which is also the inlet and outlet pressure difference of the hydraulic motor (8), compare the inlet and outlet pressure difference Δp with the target control pressure difference; when Δp is less than the target control pressure difference, the motor controller (10) adjusts the torque T of the generator (9) Increase, according to the increase of the inlet and outlet pressure difference Δp of the hydraulic motor (8), the inlet pressure Pp also increases accordingly, thereby increasing the pressure difference at both ends of the throttle valve.

Owner:HUAQIAO UNIVERSITY

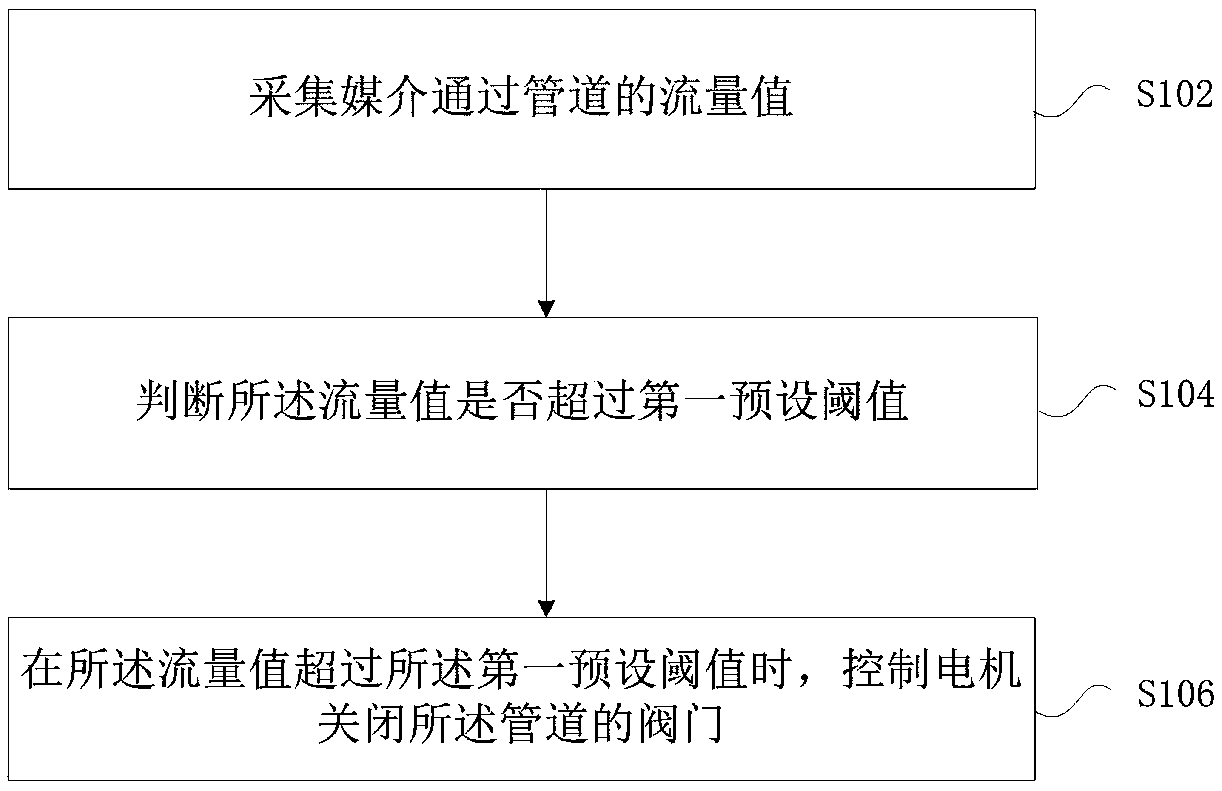

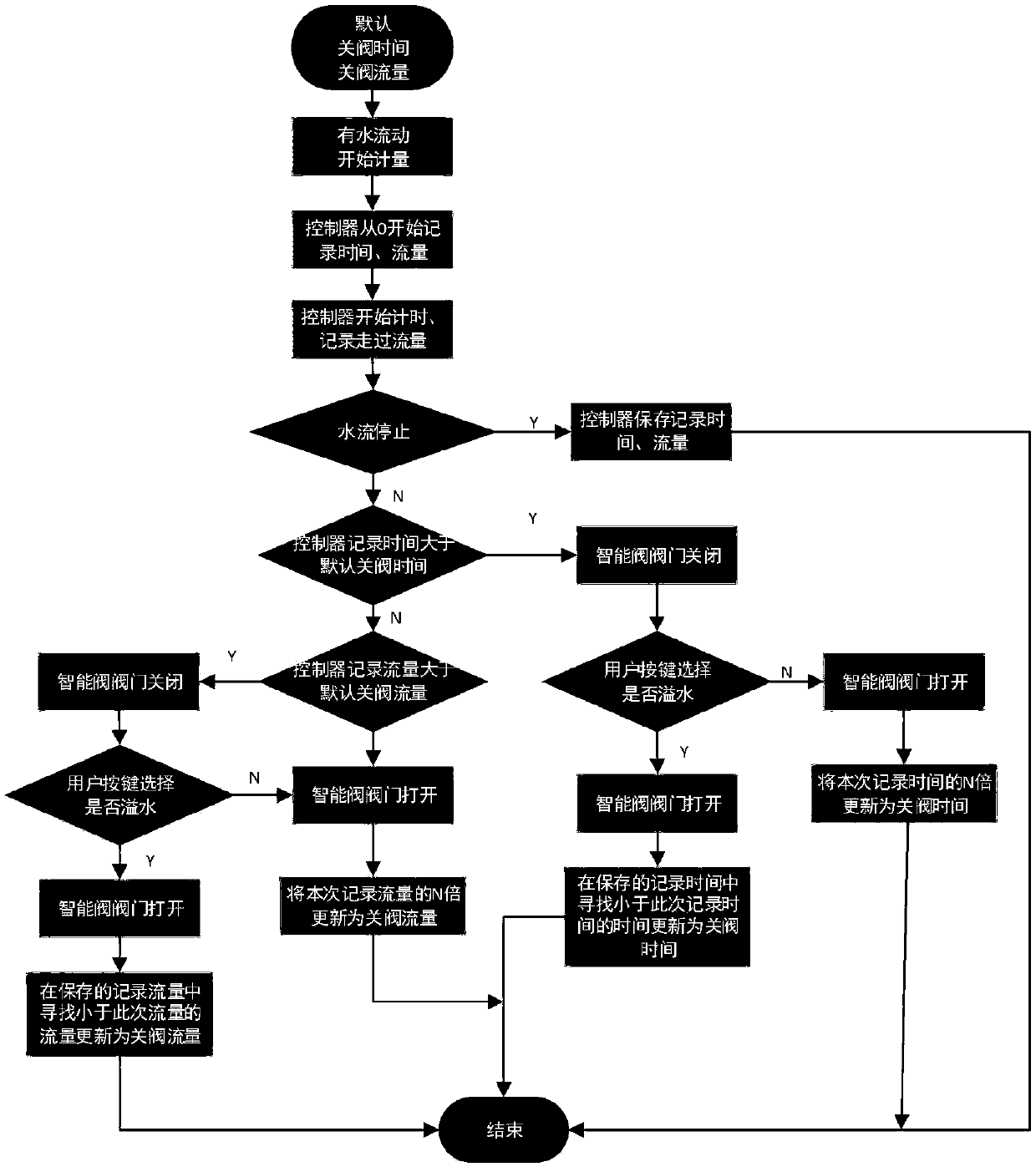

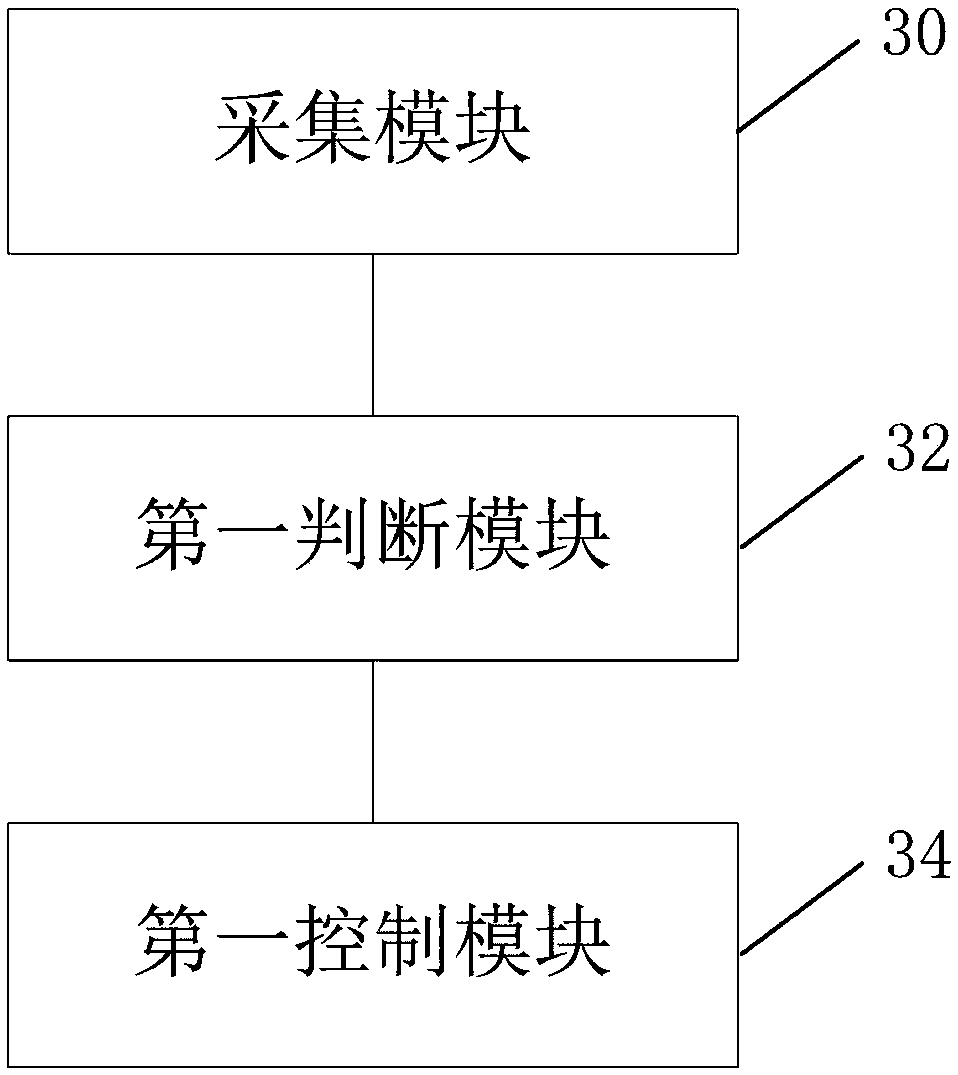

Valve control method and device, valve, storage medium and electronic device

ActiveCN110725989ARealize intelligent controlSolve the technical problem that the valve cannot be automatically controlledOperating means/releasing devices for valvesPipeline systemsAutomatic controlElectric machinery

Owner:ENNEW DIGITAL TECH CO LTD

Hydraulic system of excavator

ActiveCN102304934BReduce output powerGuaranteed output powerSoil-shifting machines/dredgersHigh energyExcavator

The invention provides a hydraulic system of an excavator, belonging to the technical field of engineering machinery and solving the technical problems of high energy consumption, low use stability and the like of the traditional hydraulic system of the excavator. The hydraulic system of the excavator comprises a main oil way subsystem and a pilot oil way subsystem, wherein the main oil way subsystem comprises a main pump and a main oil way communicated with the main pump; the pilot oil way subsystem comprises a pilot valve assembly and an electromagnetic valve assembly communicated with the pilot valve assembly; and an oil inlet of the electromagnetic valve assembly is communicated with the main oil way through an oil supply pipeline. The invention has the advantages of low cost, high stability, low energy consumption, energy saving and emission reduction and the like.

Owner:ZHEJIANG STRONGER HYDRAULIC

A Proportional Valve and Servo Valve Test Bench

ActiveCN109667812BLow powerSolve the noise problemFluid-pressure actuator testingElectric machineryMotor power

Owner:北京凯德福液压技术有限公司

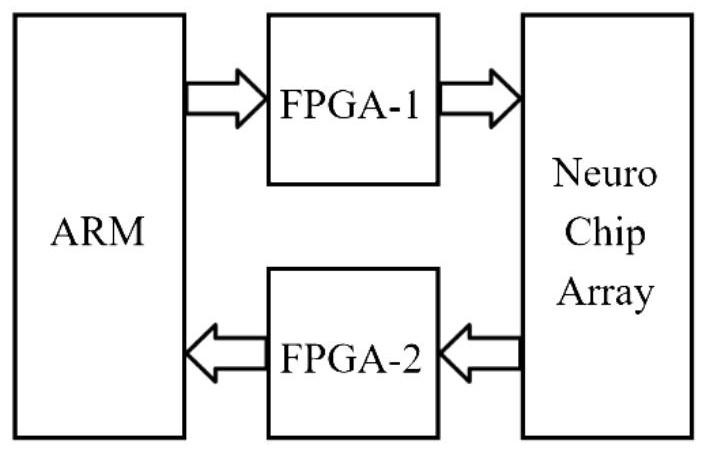

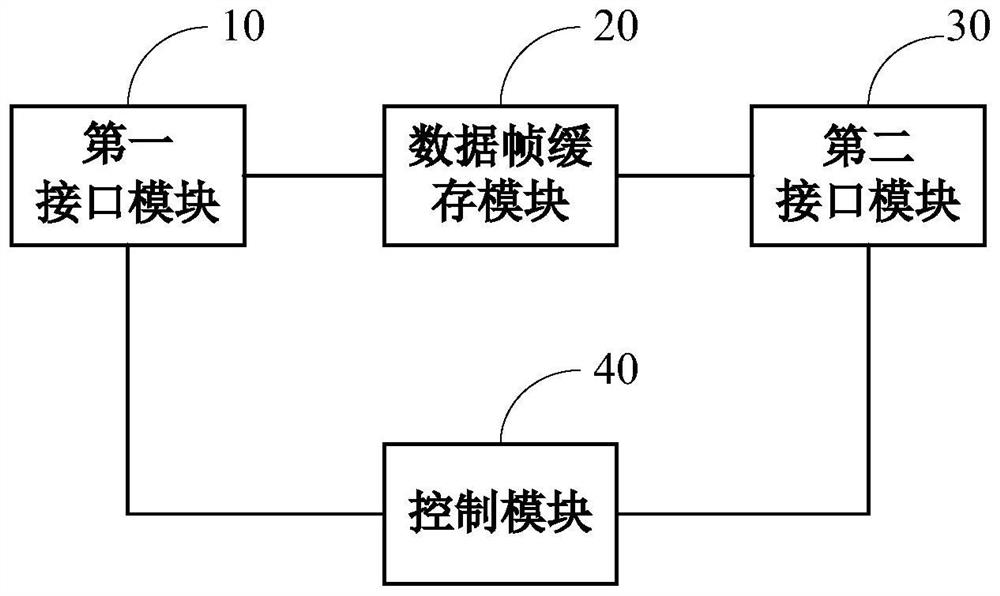

Data communication method and system and spiking neural network operation system

PendingCN114723023AAvoid overflow lossValid conversionNeural architecturesPhysical realisationData transmissionPulse transmission

The invention discloses a data communication method and system and a spiking neural network operation system, and the data communication system comprises a first interface module, a data frame buffer module, a second interface module and a control module. The first interface module is used for receiving data transmitted by an upper computer through the first bus, converting downlink data frames, reading uplink data frames, converting the uplink data frames and sending the uplink data frames to the upper computer through the first bus. The data frame caching module is used for caching downlink data frames and uplink data frames; the second interface module is used for reading the downlink data frame, converting the downlink data frame into a pulse according to a chip protocol, transmitting the pulse to the pulse neural network chip, and converting the received pulse into an uplink data frame according to the chip protocol; the control module is used for controlling data transmission interaction between the first interface module and the upper computer and data transmission interaction between the second interface module and the pulse neural network chip. According to the invention, data transmission of large data volume can be realized.

Owner:PEKING UNIV

Vacuum formation method of lithium ion battery

ActiveCN101887994BImprove exhaust efficiencyShield negative influenceFinal product manufactureSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention discloses a vacuum formation method of a lithium ion battery. In the method, an electrolyte injection process and a formation process of the battery are completed by adopting an integrated fixture with electrolyte-injecting and charging functions and a vacuum formation device with charging and vacuumizing functions. The vacuum formation device charges the battery arranged in the integrated fixture, and the battery is electrically connected with the vacuum formation device by the integrated fixture. The vacuum formation method of the invention provides an enclosed and controllable microenvironment, thereby reducing electrolyte waste, avoiding overflow loss of electrolyte and corrosion on a battery casing, the fixture or charging equipment, and effectively reducing environmental pollution.

Owner:东莞市鸿德电池有限公司 +1

A kind of laser welding method of galvanized steel sheet

ActiveCN107030382BImprove stabilityAvoid overflow lossLaser beam welding apparatusShielding gasSpray nozzle

The invention relates to a laser splicing welding method for a galvanized steel sheet. The laser splicing welding method is characterized by comprising the following steps: step 1, base metal is provided and located; step 2, a laser welding system is provided; step 3, the laser welding system is started up, a protective gas sprayer nozzle blows a protective gas, and a laser beam transmitted by a laser welding head is perpendicularly irradiated onto the upper surface of a workpiece; step 5, a temperature sensor acquires the temperature of the back side of the base metal in real time, and the laser welding head and a high-pressure gas column nozzle are rotated when the acquired temperature reaches or exceeds the gasification temperature value of the base metal to ensure that the laser welding head is inclined relative to the upper surface of the workpiece and the high-pressure gas column nozzle is perpendicularly aligned with the upper surface of the workpiece; step 6, a gas supply valve of the high-pressure gas column nozzle is controlled to ensure that inert gas columns jetted by the high-pressure gas column nozzle penetrate welding pores and the laser welding head continues to perform welding; and step 7, the welding process is finished. The high-pressure tiny gas column assist in maintaining the pores, so that the stability of the welding pores and a weld pool is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Detection method for constant-flow oil return channel

InactiveCN102966630AReduce lossesAvoid overflow lossFluid-pressure actuator testingHydraulic pumpEngineering

The invention discloses a detection method for a constant-flow oil return channel. A throttling port is formed in an oil return channel in a multi-path reversing valve in a hydraulic system; pressure difference of oil is generated through the throttling port; pressure in front of the throttling port is guided to a hydraulic pump displacement mechanism for controlling the displacement of a hydraulic pump; a bypass oil return channel of a multi-path valve is provided with a flow detection element; the bypass oil return flow is set and controlled to be a smaller constant value; a connecting section between the displacement pump and an operating valve in the hydraulic system is provided with a fluidic sensor for performing flow detection, and control over the displacement of the hydraulic pump is completed in cooperation with a negative flow control valve existing in a pipeline; the outlet pressure of the negative flow control valve is used for controlling a servo oil cylinder of the displacement pump; and meanwhile, a pressure cutoff valve is arranged at adjacent positions of every each negative flow control valve respectively. The detection method has the beneficial effects that: overflow loss and system heating in the conventional hydraulic excavator are avoided, the fuel oil consumption is lowered, and the aim of saving energy is fulfilled.

Owner:无锡汇虹机械制造有限公司

Interrupt operation method of tte end system adapter card pcie controller

ActiveCN108763121BAvoid overflow lossGuaranteed low latency requirementsElectric digital data processingDirect memory accessEnd system

The invention discloses an interrupt operation method of a TTE terminal system adapter card PCIe controller, which is used to solve the problem in the prior art that data is overflowed and lost due to insufficient adapter card buffer space due to a read interrupt initiated by a host. The technical solution is: 1) requesting to read and write data; 2) periodically requesting to read and write data to the PCIe bus controller; 3) the PCIe bus controller generates an interrupt sequence and configures the read and write cache registers; 4) the PCIe driver Identify the interrupt type and determine the amount of data to be moved; 5) The PCIe driver configures the read and write related registers and starts the direct memory access operation to complete the data transfer and end the direct memory access operation. The present invention initiates direct memory access read and write operations through the adapter card to realize flow control. The present invention utilizes the adapter card to actively issue interrupts, which improves the time accuracy of the end system and can be used for time triggering in the adapter card of the Ethernet TTE end system. Interrupt module design.

Owner:XIDIAN UNIV

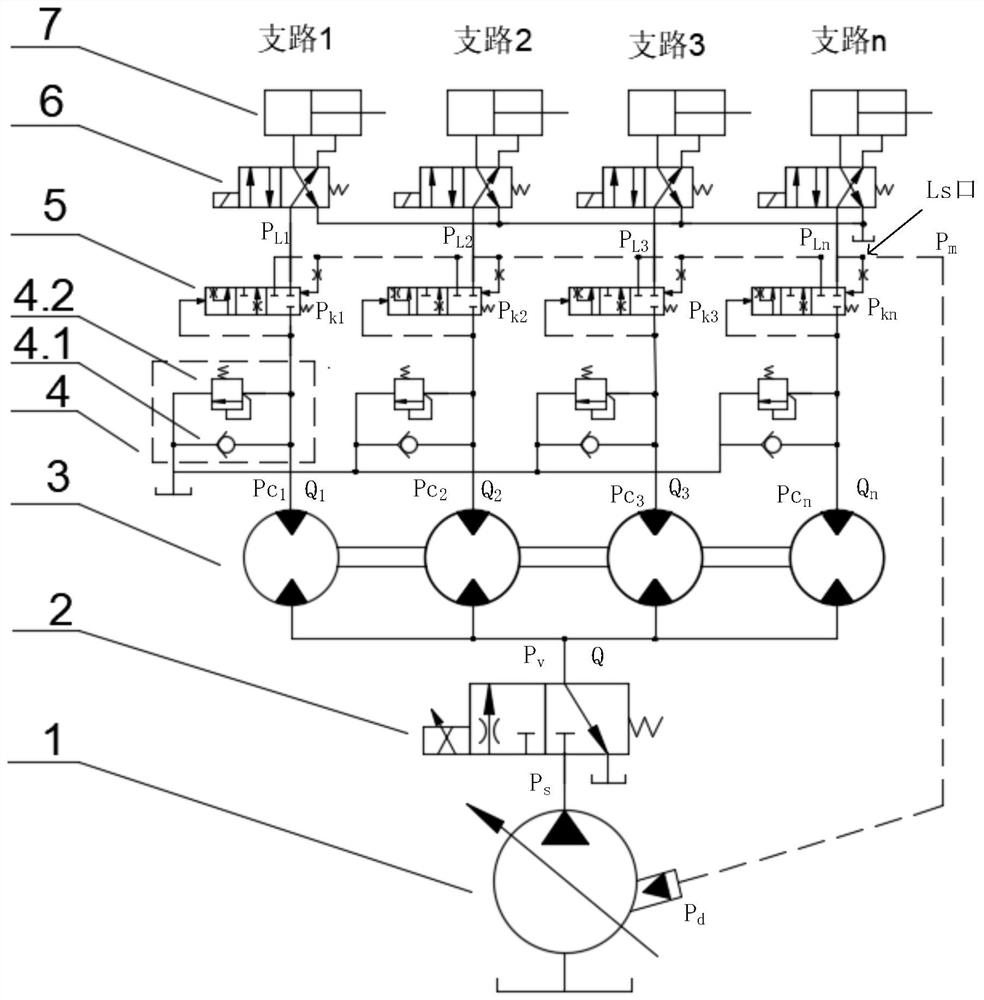

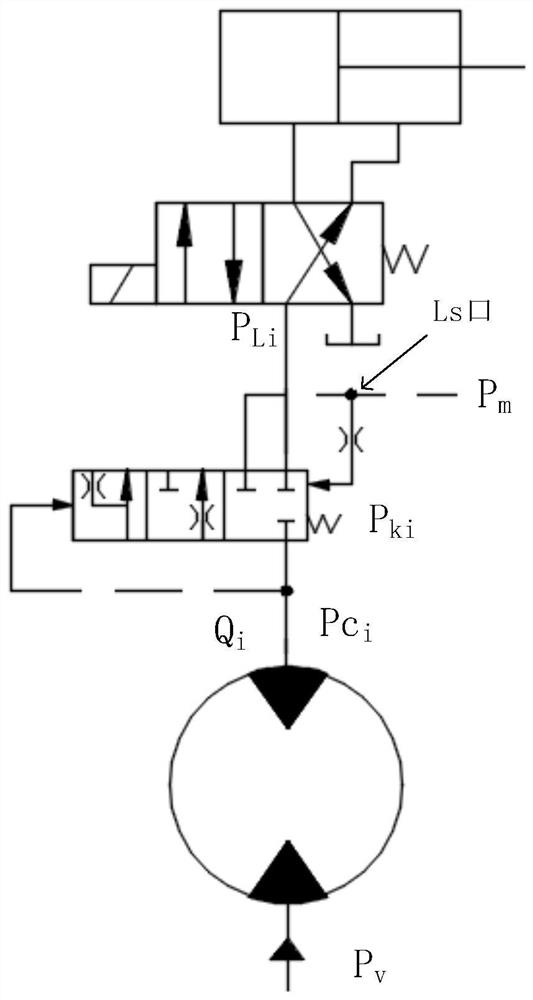

Shunting motor speed change synchronizing system resisting time-varying large eccentric load and working method

ActiveCN111734698AImprove efficiencyIncrease loadServomotor componentsServomotorsMotor speedSynchronous control

The invention discloses a shunting motor speed change synchronizing system resisting the time-varying large eccentric load and belongs to the field of hydraulic synchronous control. The system comprises a load sensing variable pump, a proportional direction valve, shunting motors, a pressure compensating valve, a reversing valve and an execution element which are connected sequentially. The shunting motors are arranged in a multi-line manner. An oil outlet of each line of shunting motor is connected with an executor branch. Speed change synchronous driving of multiple hydraulic executors is achieved. The invention further discloses a working method of the speed change synchronizing system. By means of the four links of speed changing, shunting, pressure compensating and load sensing, high-precision and high-efficiency speed change synchronous driving control under the working circumstances of the large eccentric load or the time-varying load can be achieved, the system is simple in structure, high in reliability and particularly applicable to synchronous driving in a severe environment, the influence on the shunting precision from the eccentric load can be eliminated thoroughly, and the interference of the time-varying load can be resisted.

Owner:CHINA UNIV OF MINING & TECH

A method for joining dissimilar materials by laser deep penetration-brazing

ActiveCN106964899BImprove mechanical propertiesImprove spreading uniformityLaser beam welding apparatusShielding gasProduct gas

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

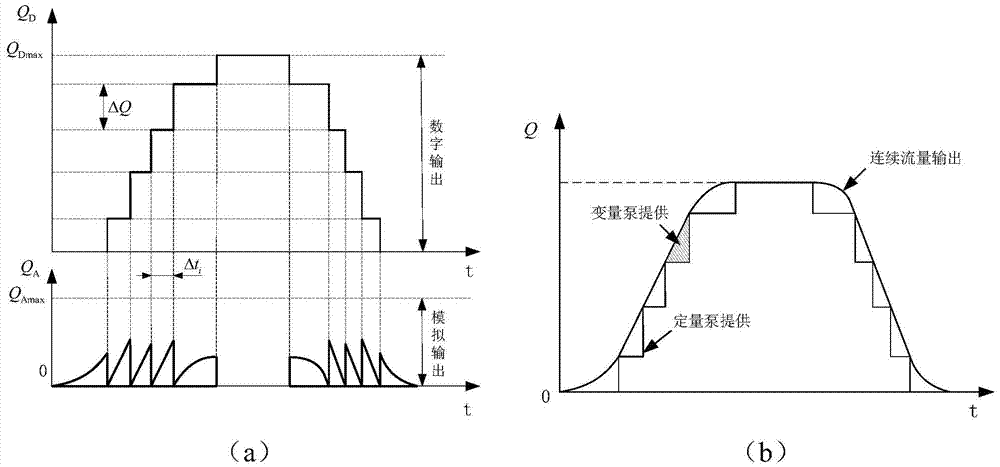

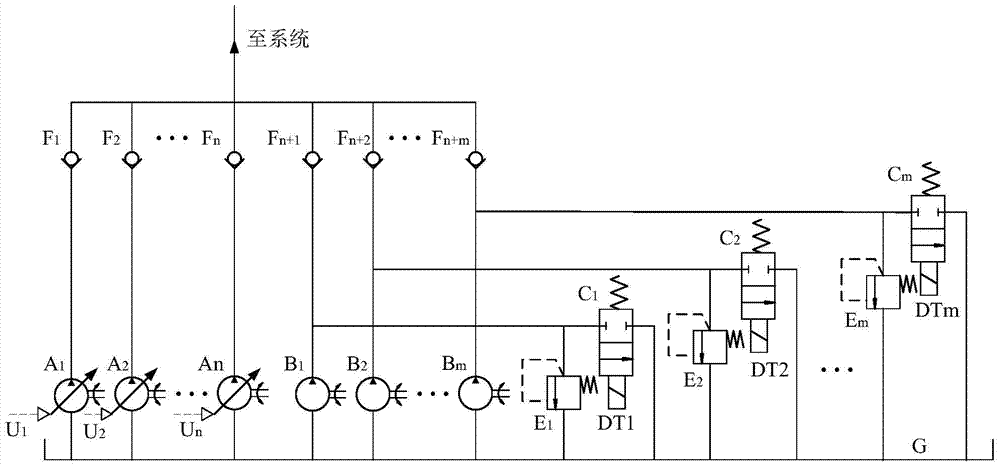

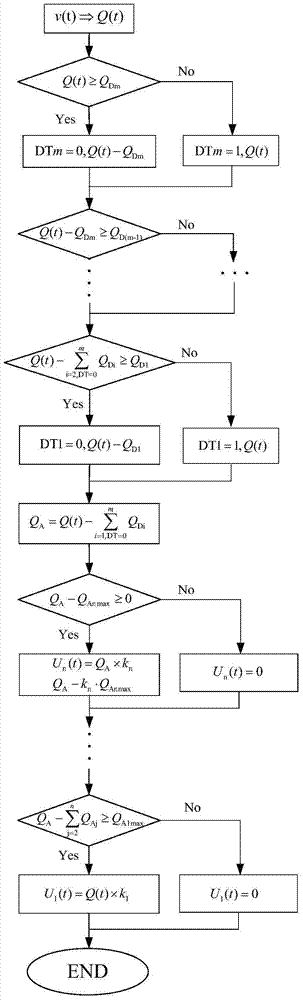

A configuration design method of digital and analog combined control hydraulic system multi-pump source

ActiveCN105138714BTo achieve the purpose of matchingAvoid overflow lossServomotorsSpecial data processing applicationsConfiguration designControl system

The invention relates to a configuration design method for controlling multiple pump sources of a hydraulic system through digital and analogue combination. The configuration design method mainly comprises the following steps: (1), obtaining a flow demand Q(t), a maximal flow value Qmax and an absolute value h of a maximal flow change rate required by the hydraulic system according to action requirements of hydraulic equipment; (2), determining an optimal combination coefficient lamdaof a quantitative pump set and the discharge capacity D1 of a minimal pump in the quantitative pump set according to a theoretical formula provided by the invention; (3), determining the number m of quantitative pumps and the maximal discharge capacity Dk of the pumps according to the theoretical formula provided by the invention; and (4), determining the number n and the full discharge capacity gammaj of variable pumps. According to the invention, flow matching of a load is realized; the configuration design method has the advantages of being rapid to respond, free from overflow loss, high in transmission efficiency and continuous and adjustable in output flow; the configuration design method has the advantages of the traditional valve control system and pump control system; and furthermore, the disadvantages of being high in investment of the pump control system and high in maintenance cost are avoided.

Owner:YANSHAN UNIV

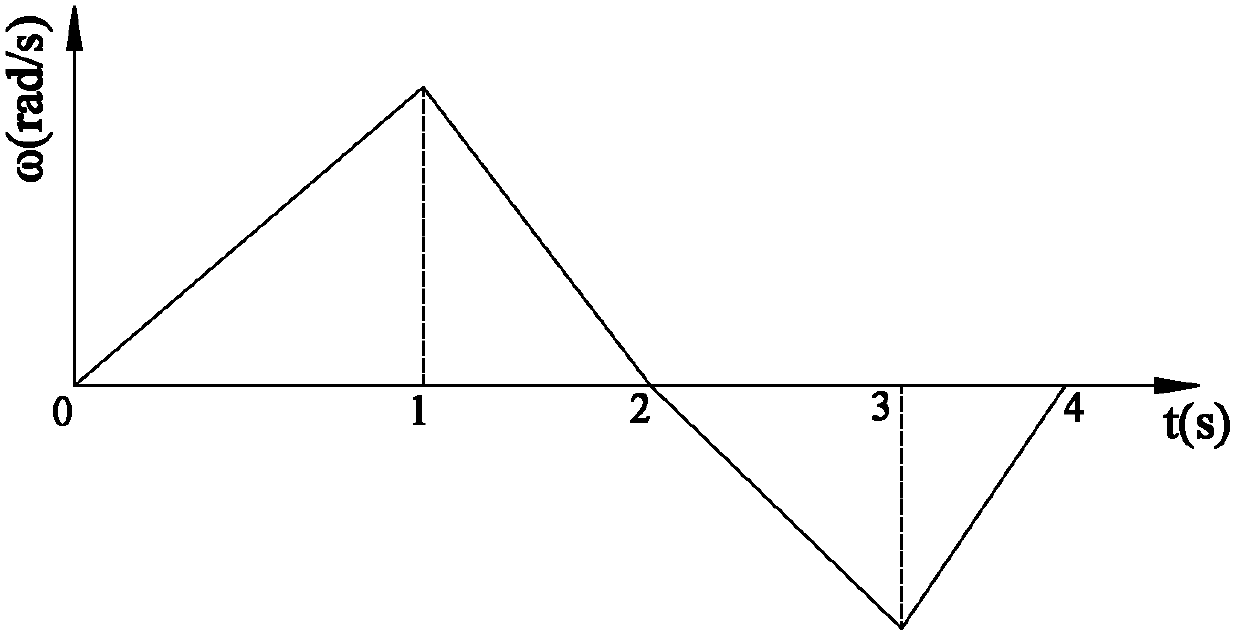

Energy-saving turntable drive system for excavators based on dual motors and hydraulic accumulators

ActiveCN104358285BAvoid overflow lossReduce shockSoil-shifting machines/dredgersHydraulic motorHydraulic pump

The invention discloses an energy-saving rotary table driving system of an excavator based on dual motors and a hydraulic energy accumulator. When a rotary table decelerates and brakes, an auxiliary hydraulic pump / motor works in a pump mode, oil is charged to the hydraulic energy accumulator, rotary brake kinetic energy is converted into hydraulic energy, and the hydraulic energy is stored in the hydraulic energy accumulator, so that the overflow loss of the rotary table in the braking process is avoided; furthermore, due to the fact that the pressure of the hydraulic energy accumulator cannot be suddenly changed, the impact on the rotary table in the braking process is reduced. When the rotary table of a hydraulic excavator accelerates and rotates, the auxiliary hydraulic pump / motor works in a motor mode, the hydraulic energy accumulator releases hydraulic oil, the auxiliary hydraulic pump / motor is driven to assist a hydraulic motor to drive the rotary table to accelerate, and the energy loss of an engine is reduced; the auxiliary hydraulic pump / motor converts the pressure change of the hydraulic energy accumulator into torque change and is coupled to the hydraulic motor through torque, so that the influence on the operation performance of the rotary table caused by the pressure change of the hydraulic energy accumulator when a single hydraulic motor drives the rotary table and the rotary table decelerates and brakes is eliminated.

Owner:HUAQIAO UNIVERSITY

Combined control system of quantitative pump and variable pump of loader

ActiveCN104895139BReduce lossesAvoid overflow lossSoil-shifting machines/dredgersControl systemControl valves

The invention relates to a composite control system of a loader with a quantitative pump and a variable pump. The problem of large overflow energy loss and low system efficiency of the existing loader control system is solved. It includes a flow amplifying valve, a pilot control valve, and a working device main valve. The flow amplifying valve includes a priority valve and a reversing valve, and also includes a quantitative pump, a variable pump, an unloading control valve and a confluence control valve. The quantitative The pump communicates with the main valve of the working device through the unloading control valve. The confluence control valve includes a confluence valve, a selection shuttle valve and a signal shuttle valve. The variable variable pump communicates with the confluence valve through a priority valve. The confluence valve has a At this time, the priority valve is disconnected from the first position of the main valve of the working device, and the second position is driven by the pressure oil of the selection shuttle valve so that the priority valve is connected to the main valve of the working device. The invention is provided with a confluence control valve and an unloading control valve, adopts a quantitative pump and a variable pump to output pressure oil at the same time to avoid overflow loss of the system, and improves the efficiency of the system.

Owner:SHENGBANG GRP +3

Hydraulic system of quadruped robot based on two-stage energy supply and independent valve control of load port

ActiveCN111828410BImprove efficiencyReduce energy consumptionServomotor componentsAccumulator installationsControl engineeringLegged robot

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com