Negative flow hydraulic control oil circuit and hydraulic system and excavator

A technology for controlling oil passage and negative flow, which is applied in earth movers/shovels, fluid pressure actuating devices, mechanical equipment, etc. It can solve the problem of high fuel consumption, reduce oil temperature, save energy, and avoid overflow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

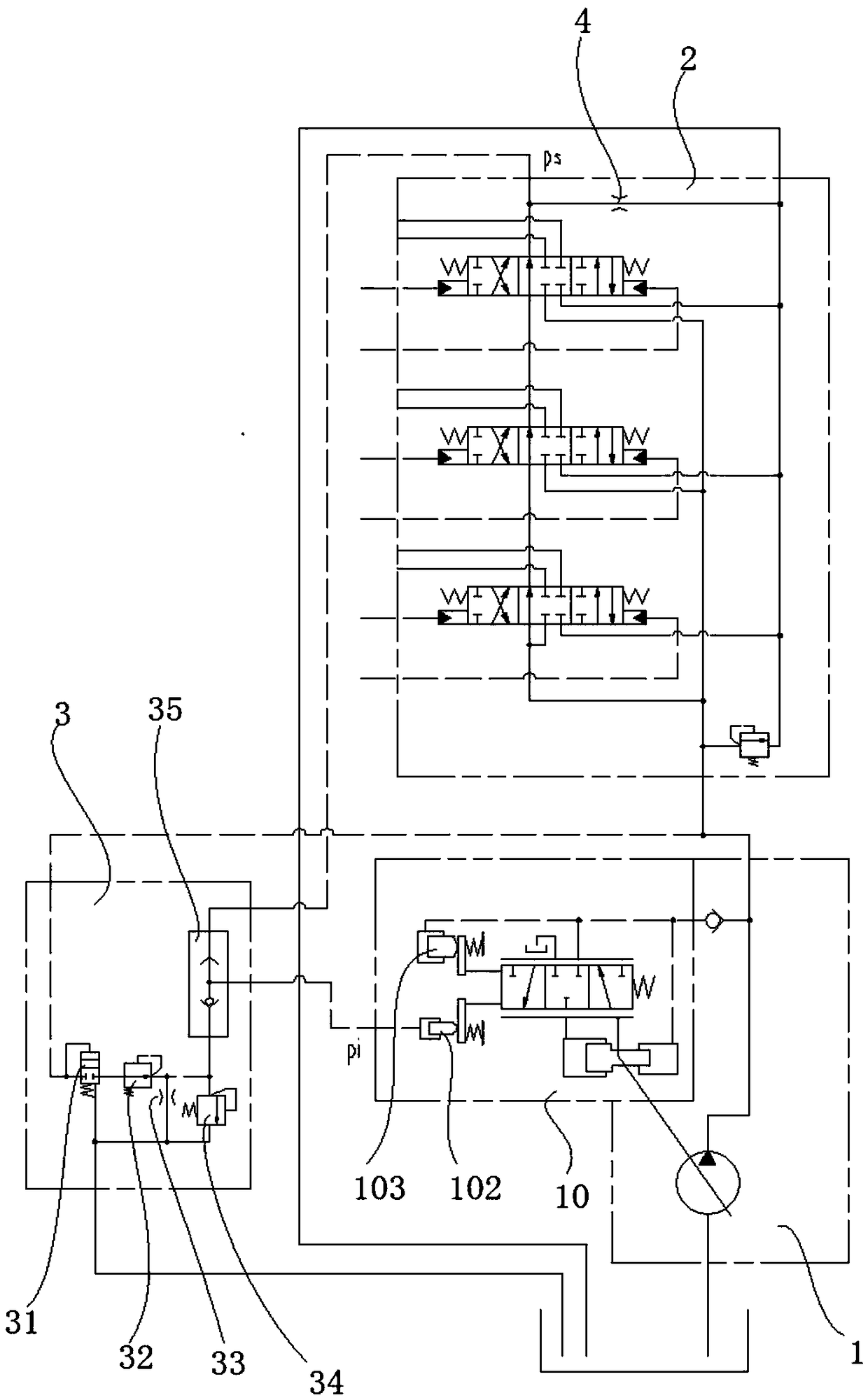

[0019] Such as figure 1 As shown, in this embodiment, the negative flow hydraulic control oil circuit includes the main pump 1, the main control valve 2 connected to the pump port of the main pump 1, and the pressure cut-off valve 3. The middle position oil return channel of the main control valve 2 is provided with The middle oil return orifice 4, the pressure cut-off valve 3 includes a hydraulic control reversing valve 31, a pressure reducing valve 32, and a shuttle valve 35. The hydraulic control end of the hydraulic control reversing valve 31 is connected to the oil inlet and the oil inlet passes through The pipeline is connected to the pump port of the main pump 1, the oil inlet end of the pressure reducing valve 32 is connected to the oil outlet end of the hydraulic control reversing valve 31 and the oil outlet end of the pressure reducing valve is connected to the second oil inlet end of the shuttle valve 35, The first oil inlet end of the shuttle valve 35 is connected ...

Embodiment 2

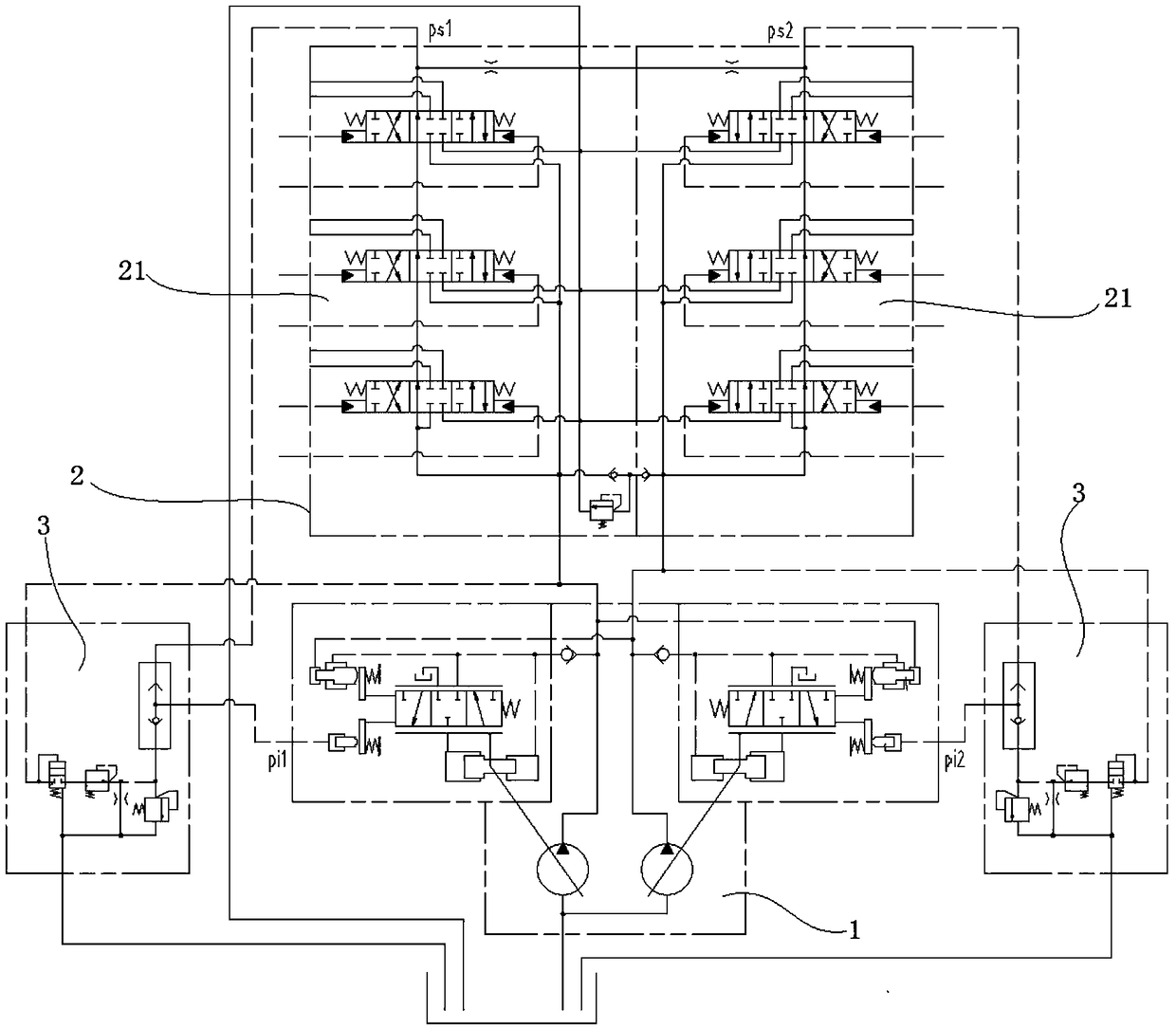

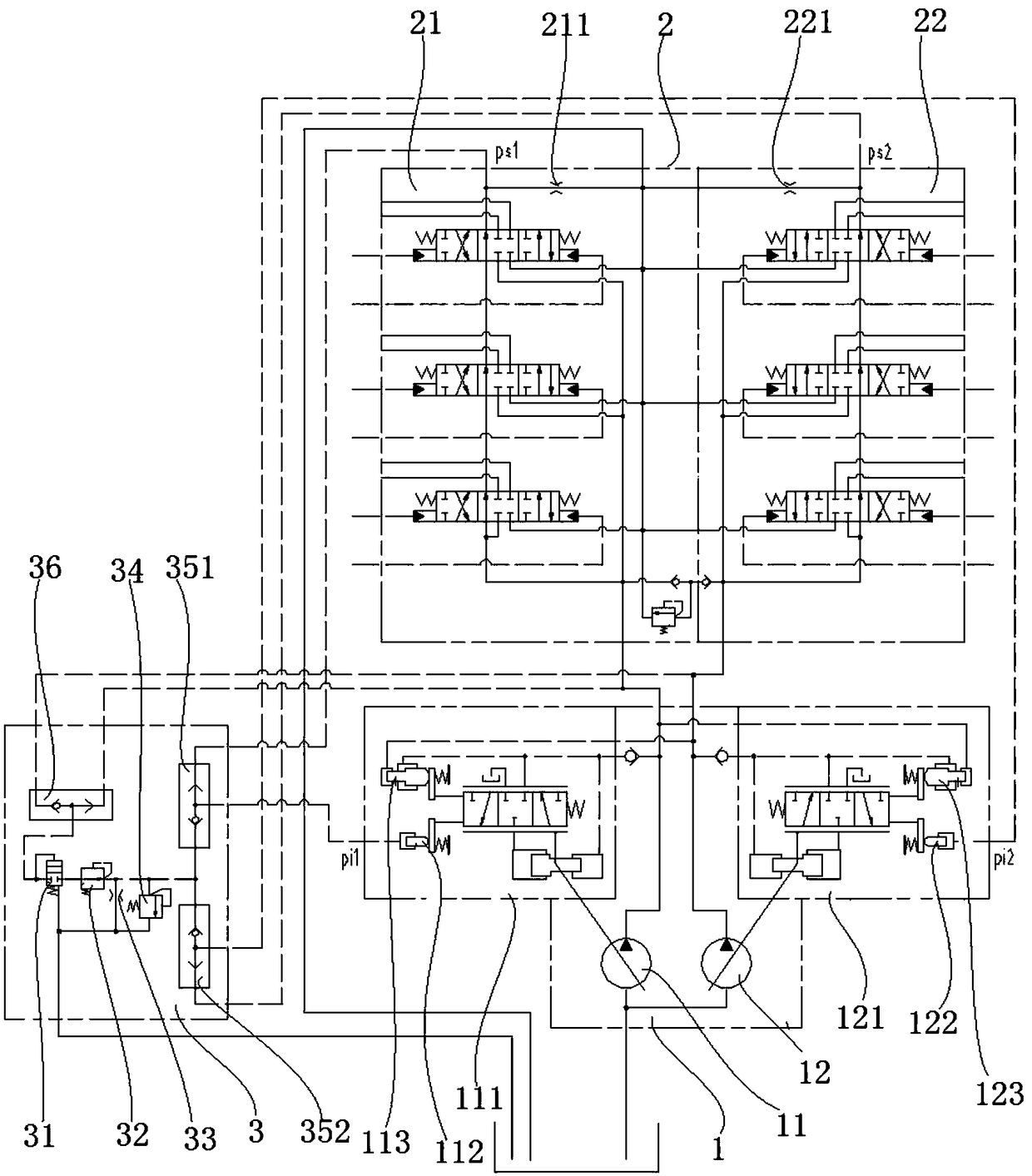

[0022] Such as image 3As shown, the negative flow hydraulic control oil circuit in this embodiment includes a main pump 1 , a main control valve 2 connected to the pump port of the main pump, a neutral oil return orifice, and a pressure cut-off valve 3 . The main pump 1 includes a left pump 11 and a right pump 12, and the main control valve 2 includes a first main control valve group 21 connected to the pump port of the left pump 11 and a second main control valve group 22 connected to the pump port of the right pump 12, each Each main control valve group includes several joint control valves for controlling different hydraulic actuators. The middle oil return orifice includes a first middle oil return orifice 211 arranged on the middle oil return passage of the first main control valve group 21 and a first middle oil return orifice 211 arranged on the middle oil return passage of the second main control valve group 22 The second neutral oil return orifice 221. The pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com