Hinging-type dump truck chassis

A dump truck and articulated technology, which is applied in the field of mining machinery, can solve problems such as complex frame structure design, insufficient suspension comfort, and low transmission efficiency, so as to improve transmission efficiency and service life of components, improve braking safety, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

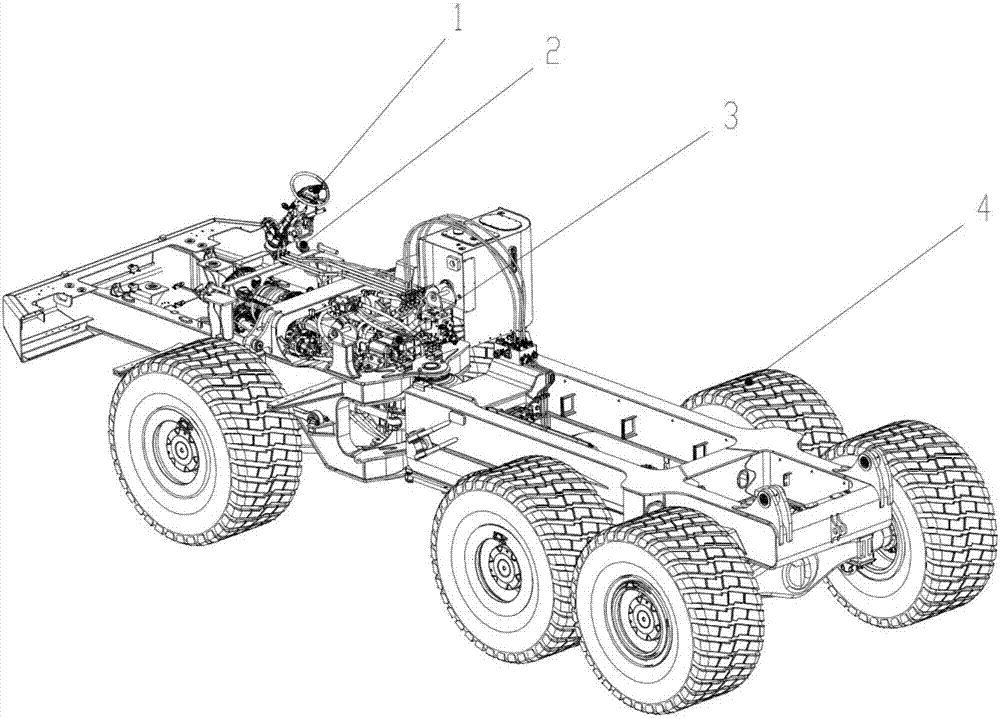

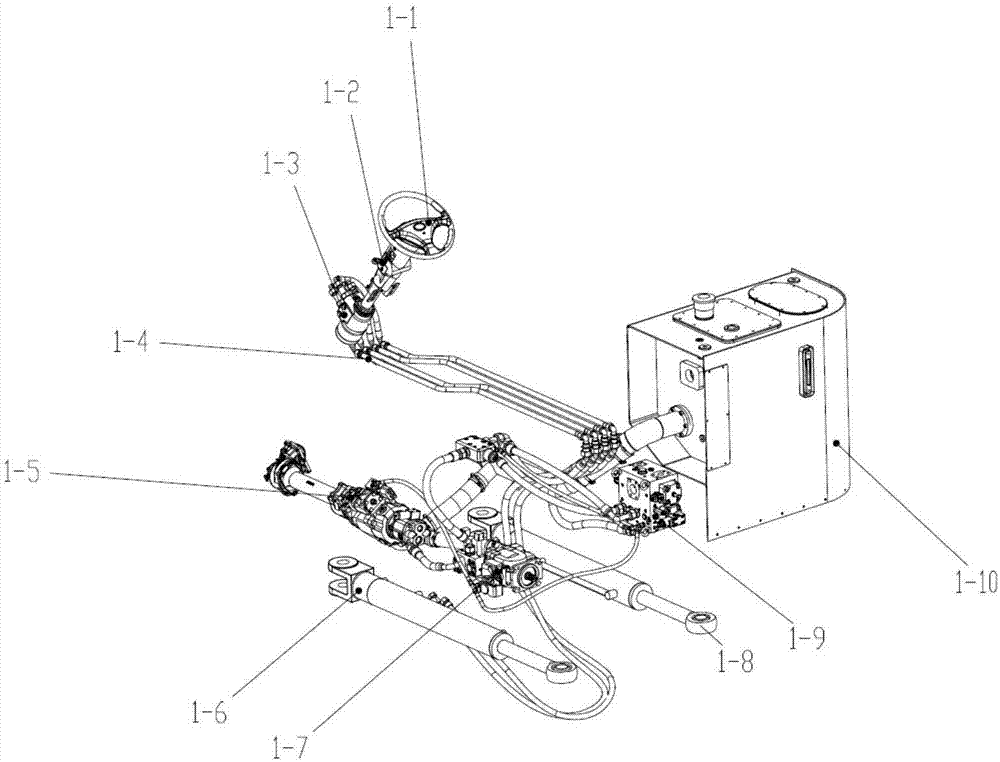

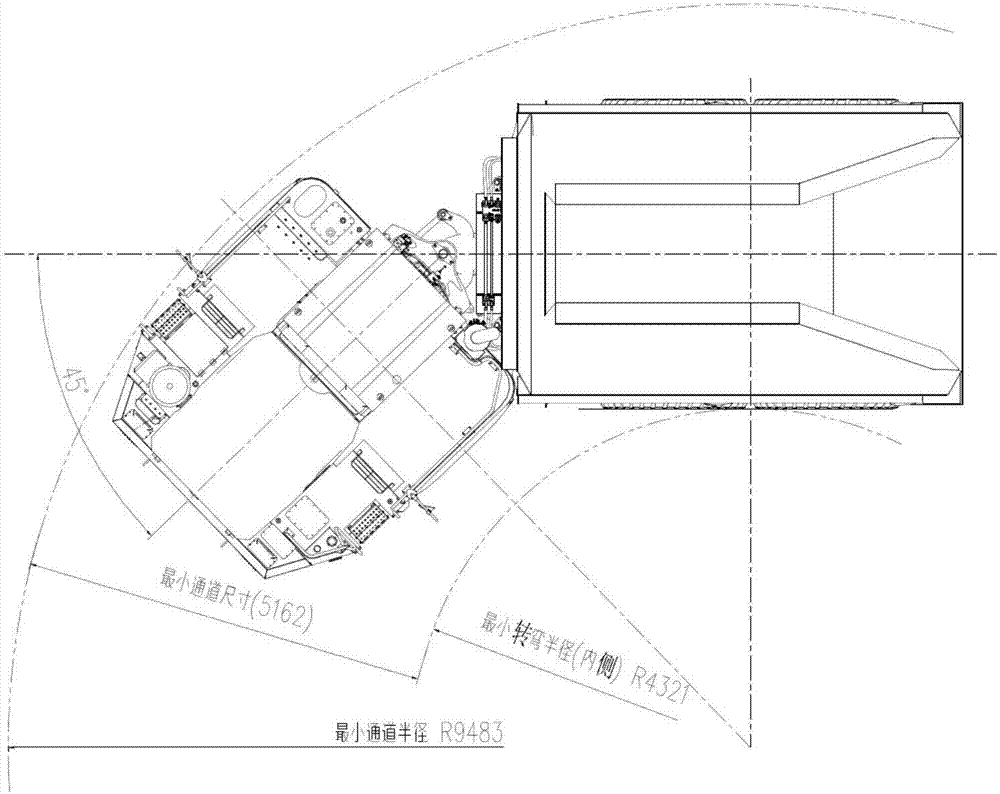

[0026] A kind of articulated dump truck chassis of the present invention is applied to the overall effect of articulated dump truck as follows Figure 12 shown. likefigure 1 As shown, an articulated dump truck chassis includes a steering system 1 , a braking system 2 , a transmission system 3 and a driving system 4 . Driving system 4 comprises front vehicle frame 4-1, articulated body 4-2, rear vehicle frame 4-3, left front tire 4-4, left middle tire 4-5, left rear tire 4-6, front axle 4-7, Right front tire 4-8, middle axle 4-9, right middle tire 4-10, rear axle 4-11. like Figure 8 as shown in Figure 8 As shown, the frame assembly includes a front frame 4-1, a hinged body 4-2 and a rear fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com