Shunting motor speed change synchronizing system resisting time-varying large eccentric load and working method

A shunt motor and synchronous system technology, applied in the direction of servo motors, servo motor components, fluid pressure actuators, etc., can solve the problems of large start-up braking pressure shock, inevitable overflow loss, and non-adjustable synchronous speed, etc., to achieve Resistance to interference from time-varying loads, ability to improve efficiency and resistance to load changes, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

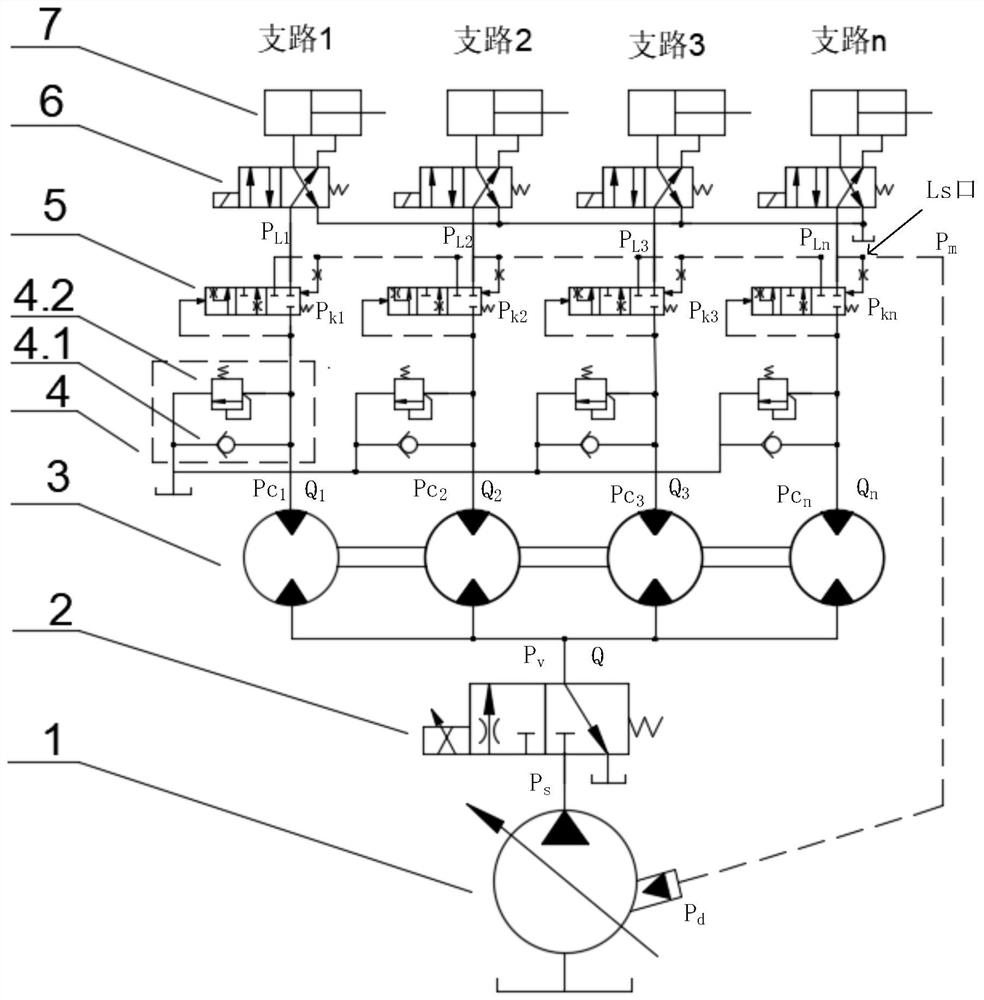

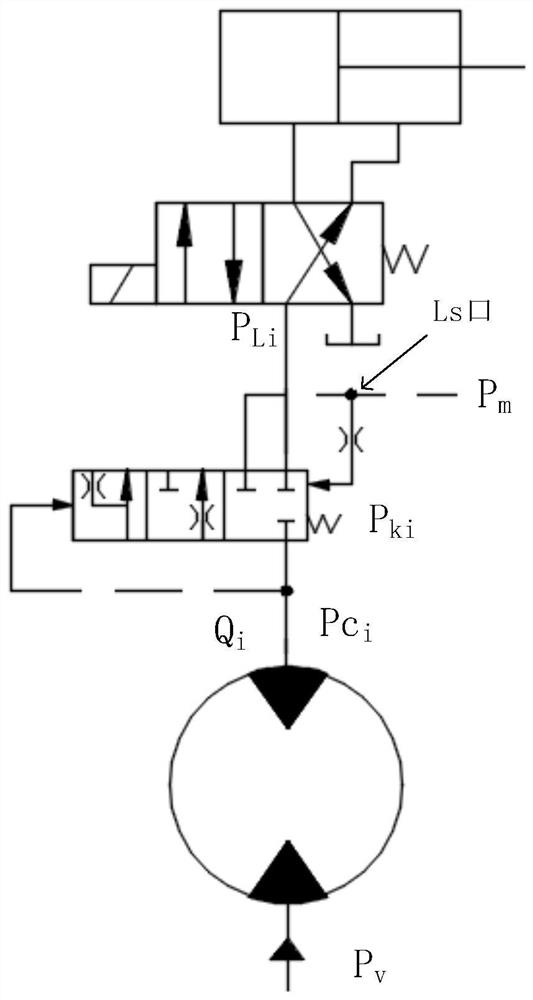

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, the shunt motor variable speed synchronization system of the present invention that resists time-varying and large eccentric loads includes a sequentially connected load-sensitive variable pump 1, a proportional directional valve 2, and multiple shunt motors 3 arranged in multiple connections, and the proportional directional valve 2 is a three-way structure, its oil inlet is connected to the oil outlet of the load sensing pump 1 through a pipeline, its oil return port is connected to the oil tank, and the oil outlet pipeline of each shunt motor 3 is connected to a hydraulic actuator through an actuator branch 7 connections, so as to realize the variable speed synchronous drive of multiple hydraulic actuators;

[0025] The proportional directional valve 2 is preferably a two-position three-way type, its P port is connected to the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com