Vacuum formation method of lithium ion battery

A technology of lithium-ion batteries and formation methods, applied in the field of vacuum formation of lithium-ion batteries, can solve problems such as corrosion of charging equipment and battery shells, adverse reactions of the skin and respiratory system, and impact on battery performance, and achieve the goal of reducing corrosion and reducing environmental humidity Requirements, the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

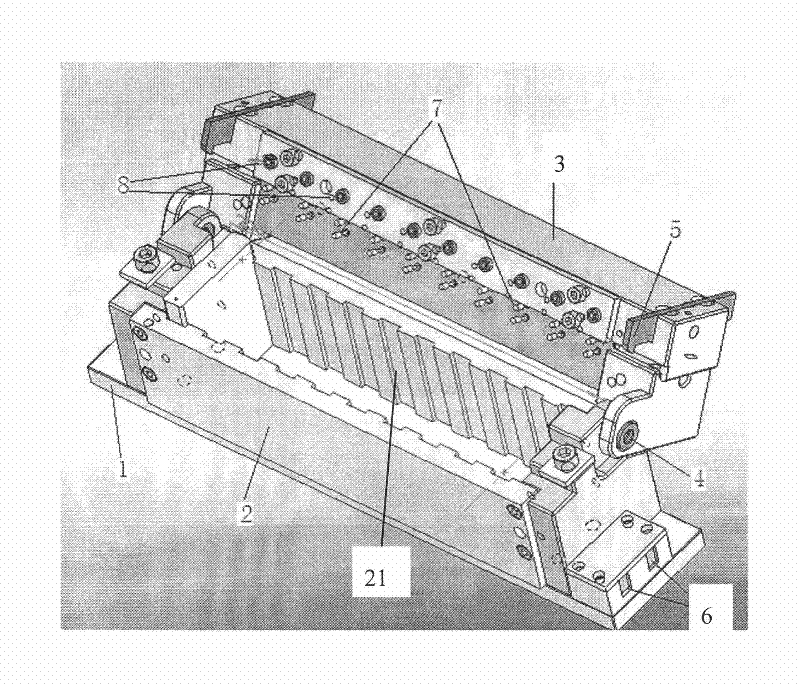

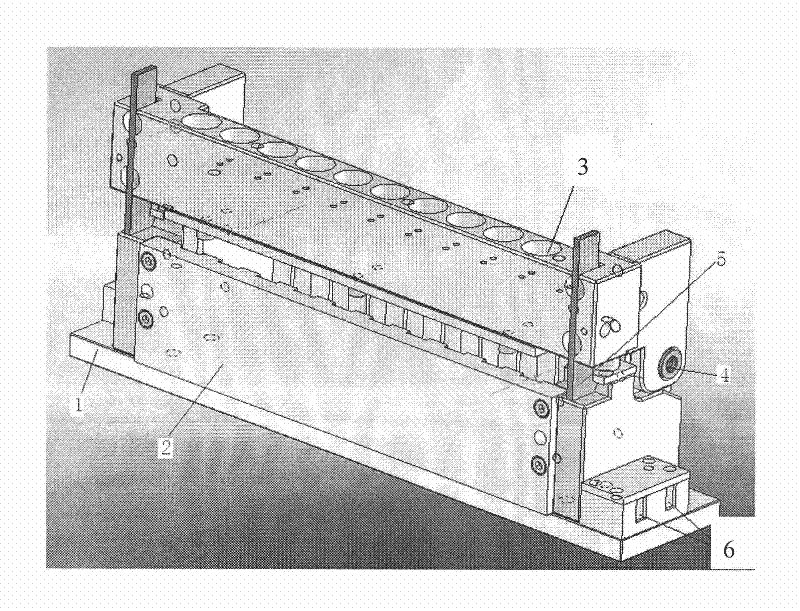

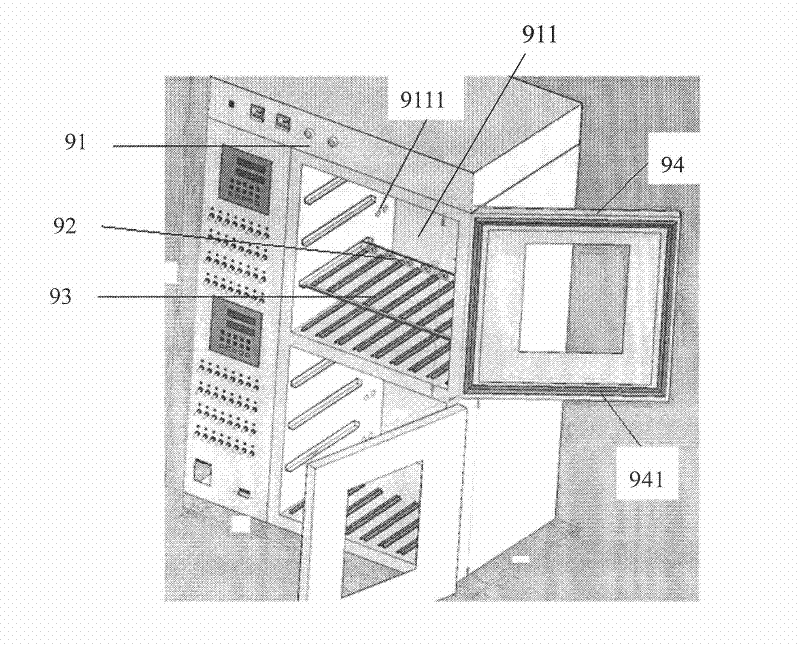

[0029] The 503048A batteries assembled by laser welding are first vacuum baked, then put into the integrated fixture used in the present invention, and the integrated fixture is closed, so that the negative charging probe of the integrated fixture is in contact with the negative terminal of the battery, The positive electrode charging probe of the integrated fixture is in contact with the battery casing (including the cap) except for the negative terminal, and the sealing rubber ring 8 of the integrated fixture corresponds to the liquid injection hole of the battery, and the sealing rubber ring 8 is tightly pressed The outer ring of the battery liquid injection hole ensures the sealing between the battery liquid injection hole and the electrolyte loading container 3 . Then inject 2.2g of lithium-ion organic electrolyte with a volume ratio of EC:EMC:DMC=1:1:1 and a LiPF6 concentration of 1mol / L into the electrolyte loading container 3 of the integrated fixture, and then the batt...

Embodiment approach 2

[0031] In this embodiment, a charging process of a different duration is performed with a current of a different magnitude from that in the first embodiment, and other operation modes are the same as those in the first embodiment. Evacuate the air pressure in the vacuum formation equipment to -0.10MPa, then put in nitrogen with a purity greater than 99.999%, and keep the vacuum at -0.04 to -0.06MPa, use 0.5 rate current to precharge for 40 minutes, then put in nitrogen, and the formation is completed. Table 1 shows the main properties of the battery manufactured in this embodiment.

[0032] Table 1 The main performance of the batteries made by the two embodiments The main performance of the batteries

[0033]

[0034] The present invention has the following advantages: (1), the method can not only perform vacuum liquid injection on the battery, but also can be connected with constant current charging equipment to charge the battery, and two processes of liquid injection and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com