Local exhaust ventilator with rotating swirler

a local exhaust and swirler technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of affecting the efficiency of pollutant removal, and raising the possibility of spreading pollutants farther in the space by blowing flow, so as to achieve the effect of enhancing energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which various embodiments of the invention are shown.

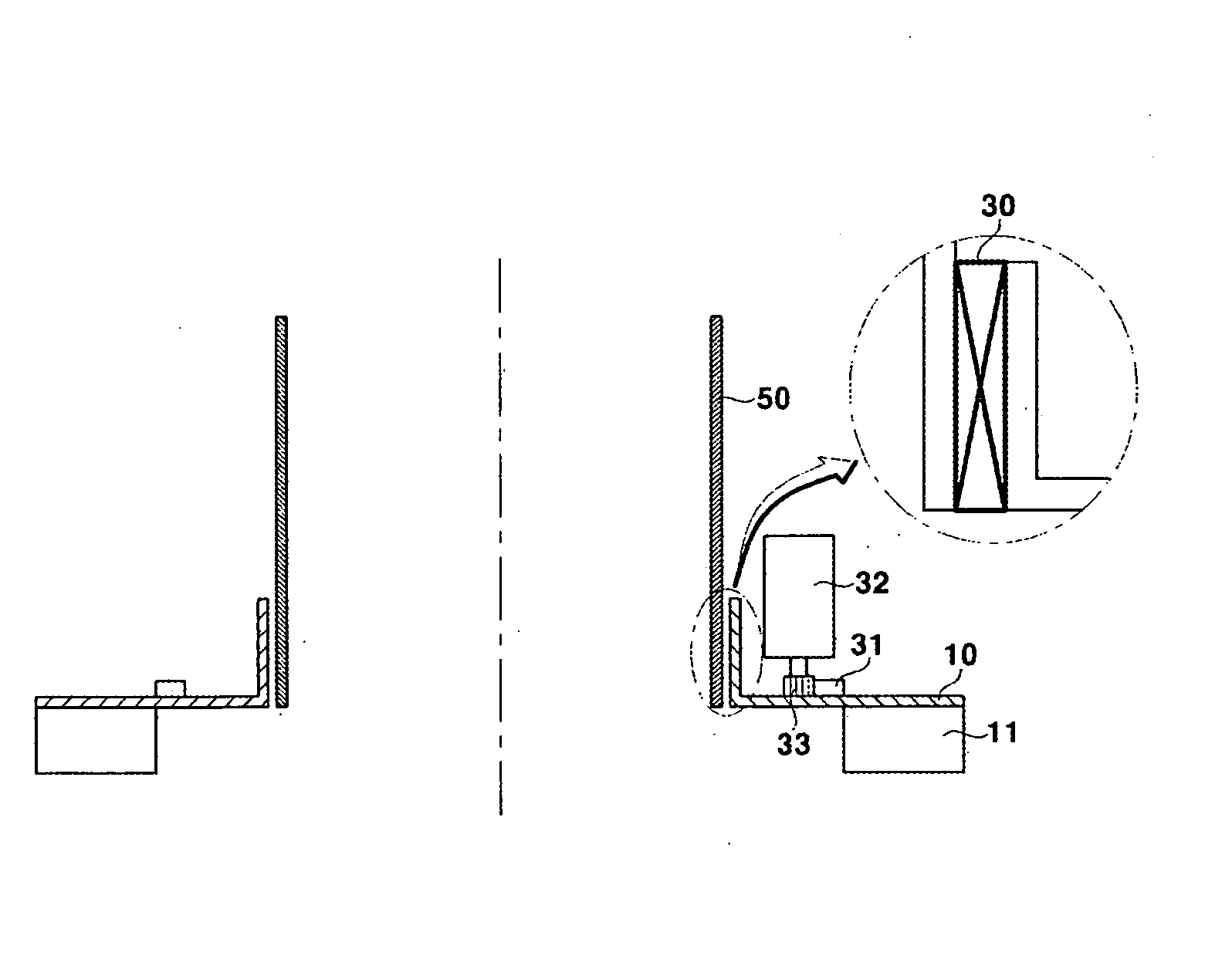

[0037] As shown in FIG. 1, the local exhaust ventilator includes a swirler 10 installed at an exhaust tube 50 to form a swirl flow, and a driving unit for rotating the swirler 10.

[0038] Swirlers are largely classified into an inner drive type and an outer drive type. With the inner drive type shown in FIG. 1, the driving unit is formed with a driving motor 20 fixed to the inner circumference of the exhaust tube 50 via a bracket 21. The swirler 10 rotates around the rotation shaft of the driving motor 20 extended external to the exhaust tube 50 while being fixed thereto.

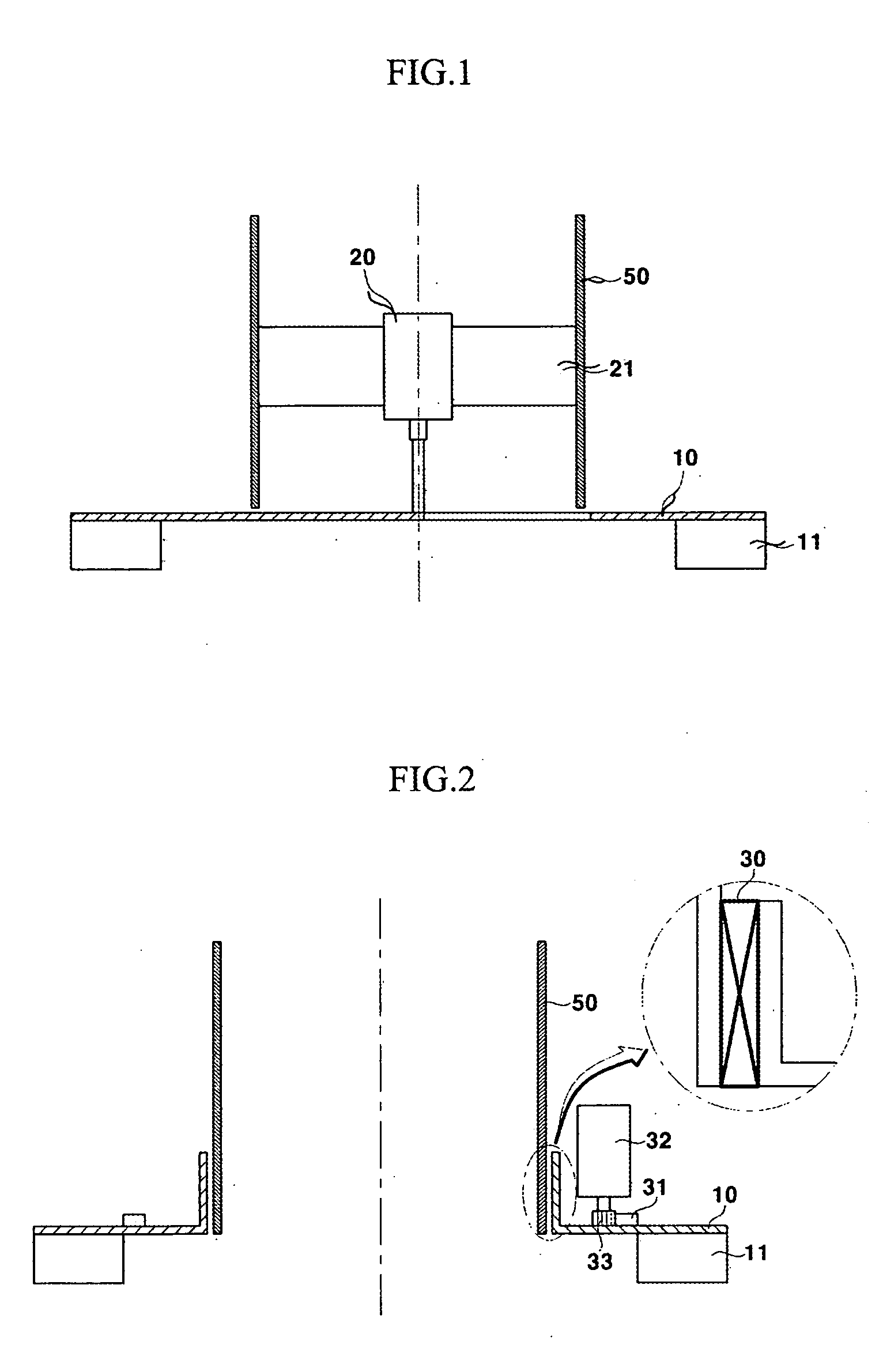

[0039] Furthermore, with the outer drive type shown in FIG. 2, the swirler 10 is installed at the outer circumference of the exhaust tube 50 via a bearing 30 such that it can be rotated. A circular rack 31 is mounted on the top of the swirler 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com