Sealed smoke hood suitable for rotary electrode vacuum electroslag remelting technology

A rotating electrode, electroslag remelting technology, applied in the direction of process efficiency improvement, waste heat treatment, lighting and heating equipment, etc., can solve problems such as increased sealing requirements, reduce ingot pores, reduce element burning loss, and avoid overflow The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

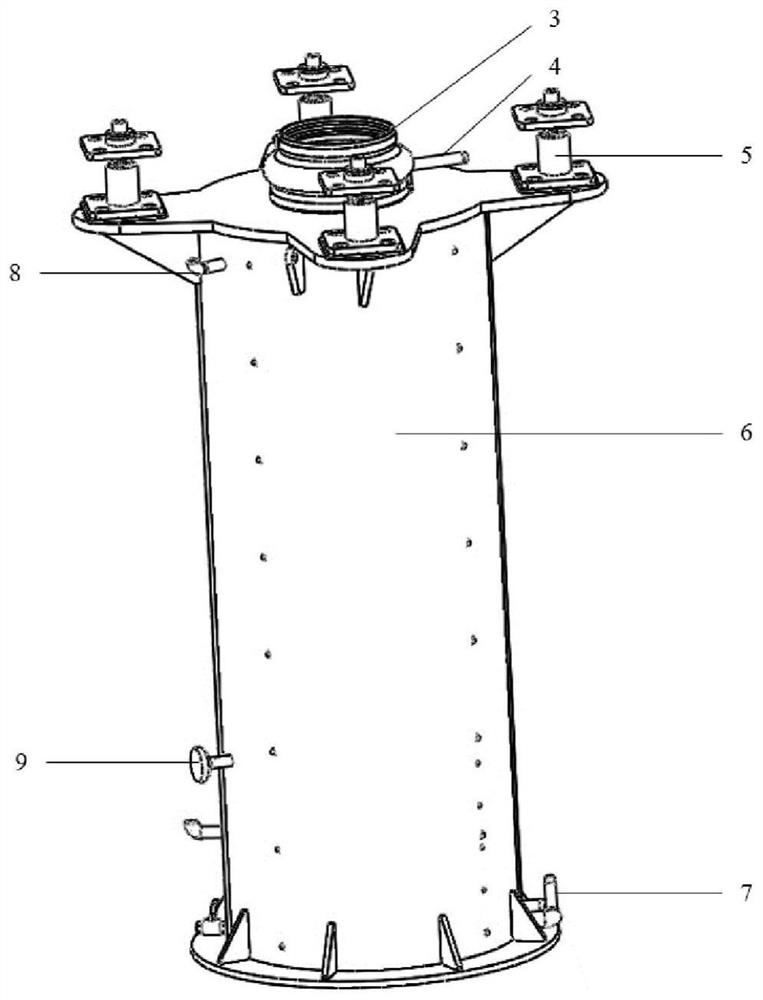

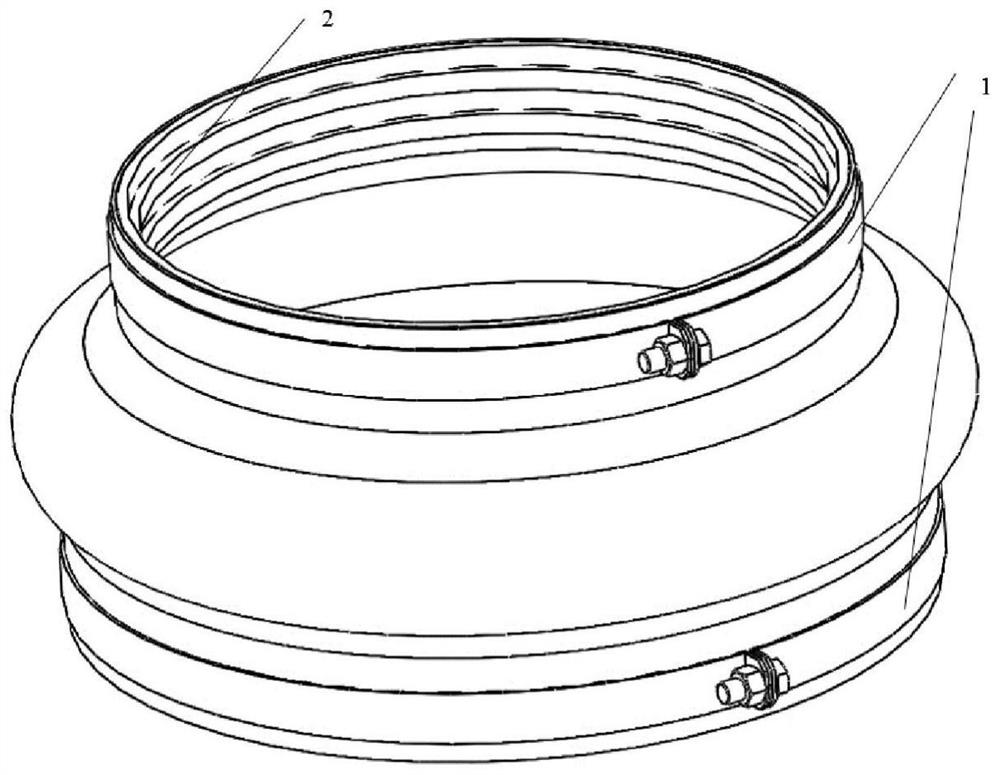

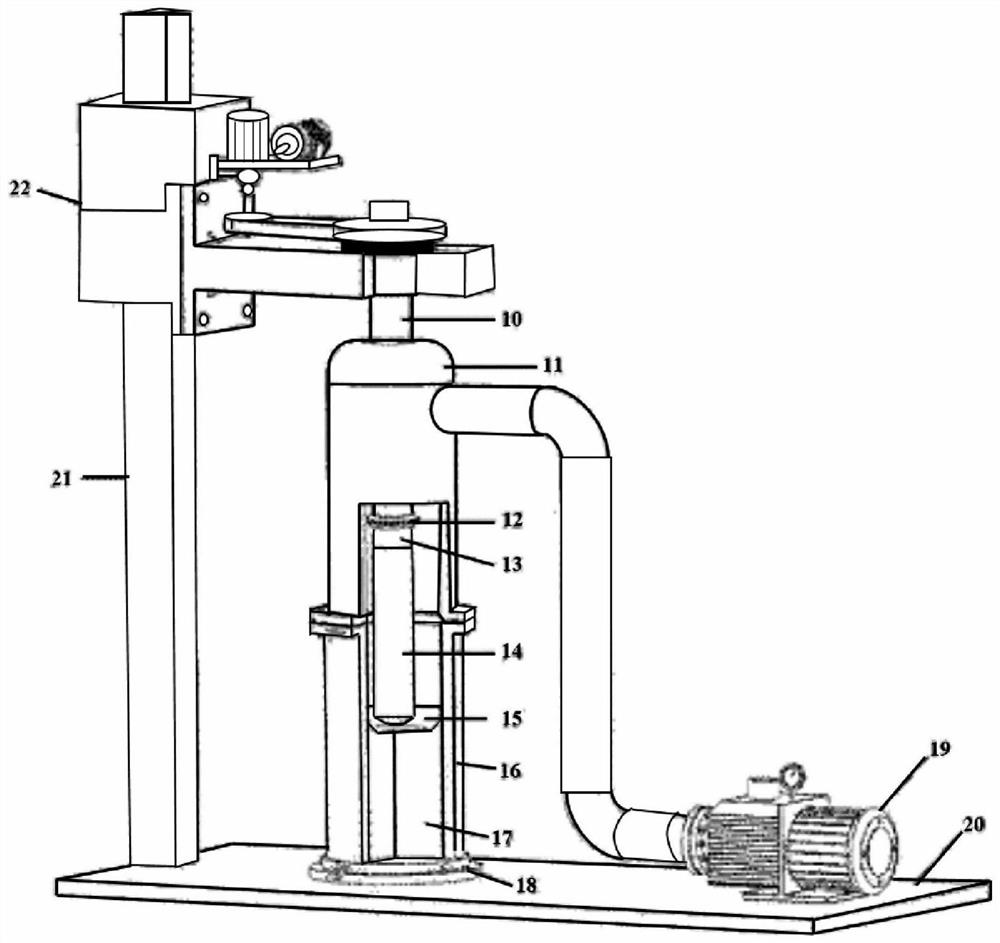

[0018] Such as figure 1 , 2 As shown, the present invention provides a sealed fume hood suitable for rotating electrode vacuum electroslag remelting technology, including a sealing sleeve 3, a fume hood suspension device 5, a fume hood main body 6, a water inlet pipe 7, a water outlet pipe 8 and an air extraction The pipeline 4, wherein the fume hood main body 6 is connected with the lifting platform of the rotating electrode vacuum electroslag remelting equipment in the rotating electrode vacuum electroslag remelting equipment through the fume hood suspension device 5 arranged at the upper end, and the rotating electrode vacuum electroslag remelting equipment rotates The rotating shaft of the electrode vacuum electroslag furnace passes through the upper port of the fume hood and enters the interior of the fume hood main body 6, the lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com