Automatic accompanying bed

A companion bed, automatic technology, applied in the field of furniture, can solve the problems of easily disturbing the patient, bumping, and exerting a lot of force, and achieves the effect of good thermal insulation, improved utilization, and avoidance of overflow loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

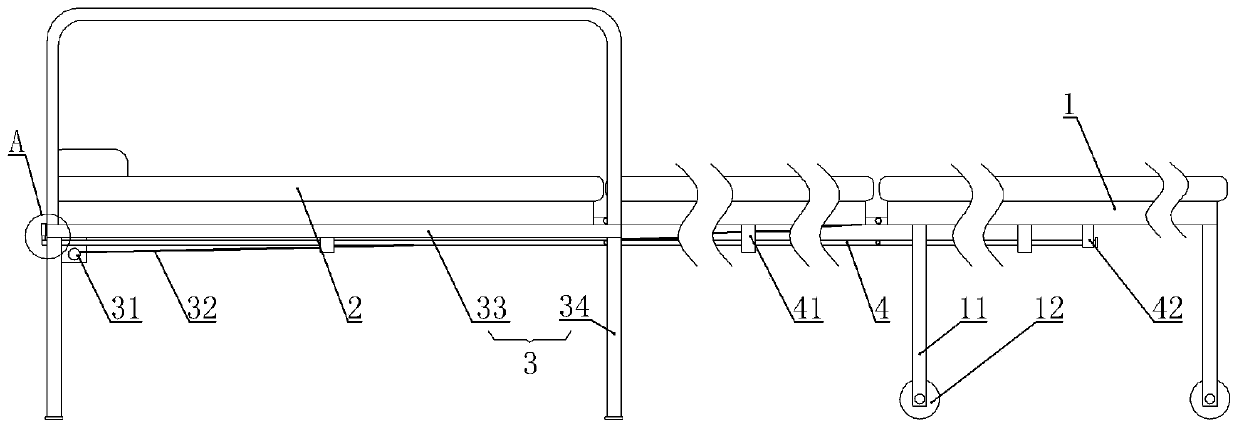

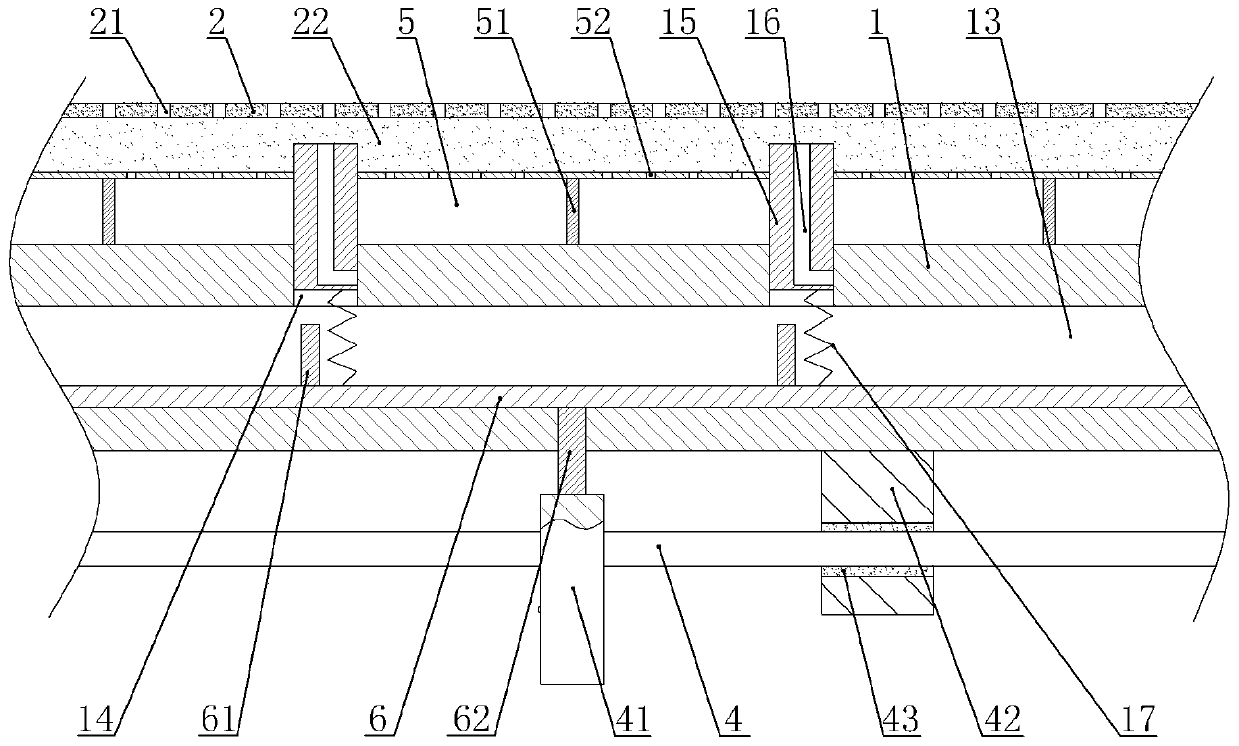

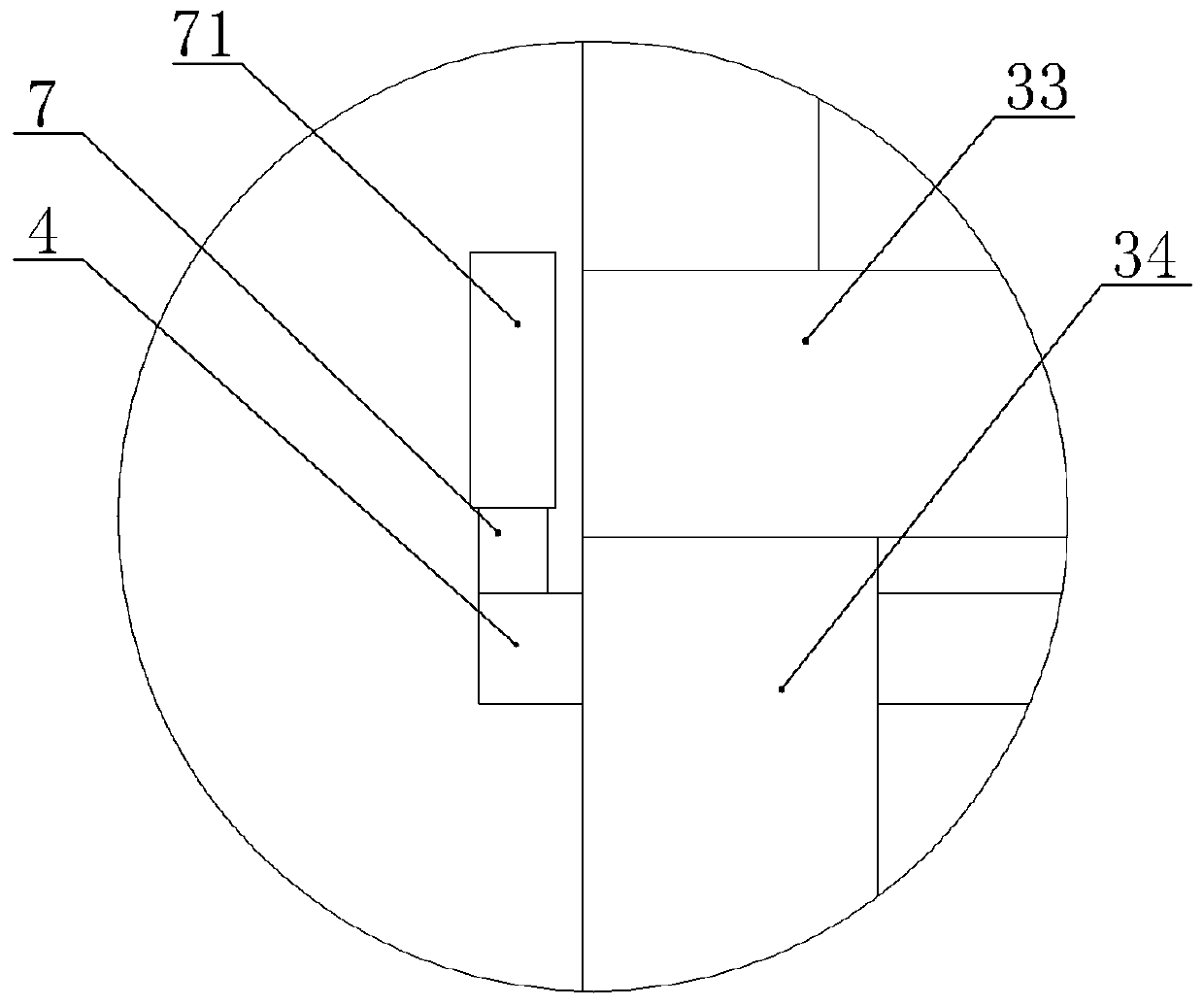

[0037] An automatic companion bed, such as figure 1 , figure 2 with image 3 As shown, it includes at least three bottom plates. The number of bottom plates in this embodiment is three. Adjacent bottom plates are hinged, and from right to left are the first bottom plate 1, the second bottom plate, and the third bottom plate. The first bottom plate 1, Both the second bottom plate and the third bottom plate are provided with a buffer layer on top. Taking the first bottom plate 1 as an example, the buffer layer in this embodiment includes a sponge layer 22 and an outer layer 2 located above the sponge layer 22. The outer layer in this embodiment The layer 2 is made of waterproof and breathable cloth material. The edges of the outer layer 2 and the sponge layer 22 are glued to the side wall of the first bottom plate 1, and the outer layer 2 is provided with a number of through holes 21.

[0038] The bottoms of the left and right ends of the first base plate 1 are vertically welded wi...

Embodiment 2

[0049] The difference from Example 1 is that Figure 4 As shown, the companion bed in this embodiment includes four bottom plates, the fourth bottom plate is located on the left side of the third bottom plate, and the right end of the fourth bottom plate is hinged to the left end of the third bottom plate, and the bottom of the fourth bottom plate is welded with a leg 11, this embodiment The roller 12 is not provided on the leg 11 on the fourth bottom plate in the fourth bottom plate, the rotating rod 4 and the cam 41 are also provided under the fourth bottom plate, and the cross bar 7 is located at the left end of the rotating rod 4 below the fourth bottom plate. In addition, a battery is fixed on the support frame 3 by bolts, and the battery is connected in series with the stepping motor.

[0050] The companion bed in this embodiment is folded in the form of two seat back-to-backs, and there is no need to connect the socket when the stepper motor works. The battery directly sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com