A configuration design method of digital and analog combined control hydraulic system multi-pump source

A hydraulic system and combined control technology, which is applied in the hydraulic field, can solve the problems of low precision of continuous quantity simulation, difficult to meet engineering requirements, difficult high-frequency switching, etc., achieve obvious energy saving effect, continuously adjustable output flow, and less overflow loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

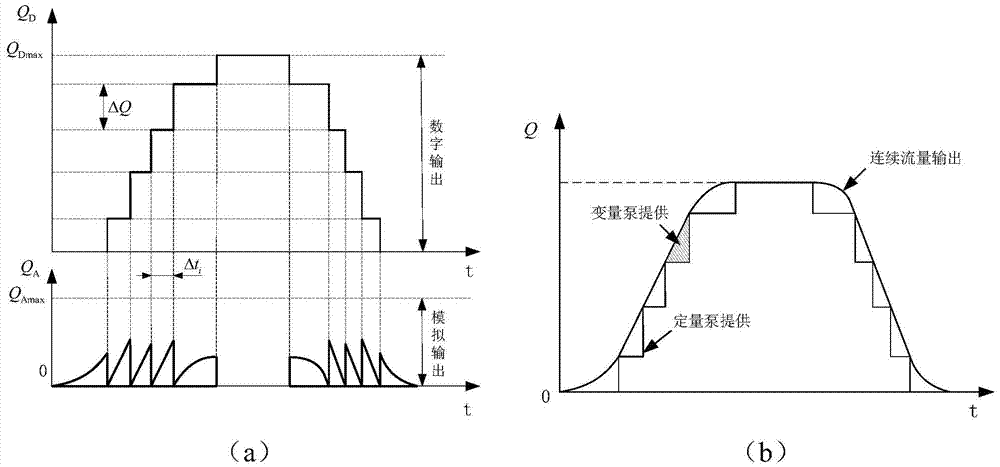

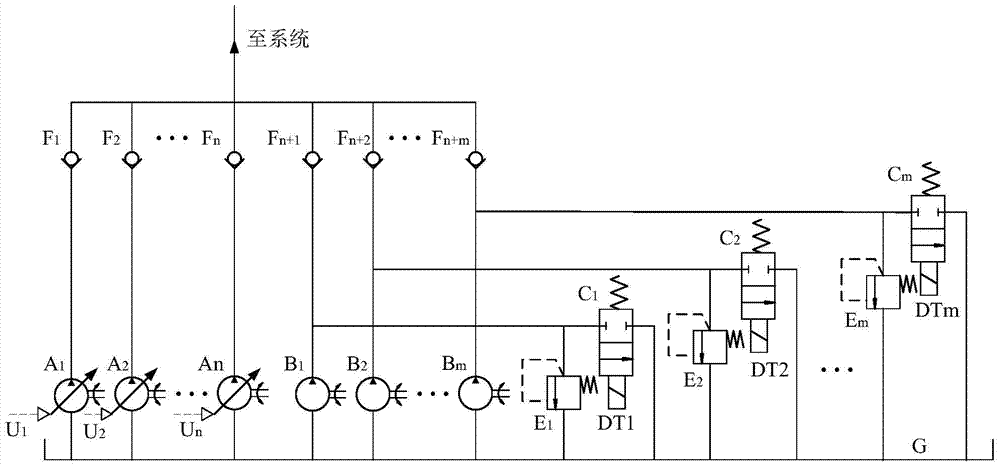

[0031] exist figure 1 Figure (a) shows the respective output flow curves of the constant pump group and the variable pump group, and figure (b) shows the quantitative The sum of the output flow of the pump group and the variable pump group. Quantitative pumps controlled indirectly by digital quantities can output stepped flow, and variable pumps controlled by analog can output continuously changing flow.

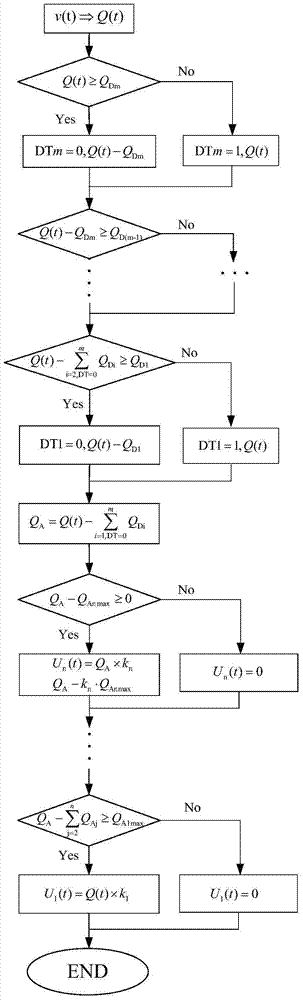

[0032] The number and displacement of quantitative pumps and variable pumps in the multi-pump source system are determined by the method of flow area division. Set the number of pumps as m and the displacement as D i , the corresponding output flow is Q Di , and Q Di ≤Q D(i+1) , 1≤i≤m; the number of variable pumps is n, and the maximum displacement is γ j , the output flow at full displacement is Q Ajmax , 1≤j≤n; the principle of equidistant segmentation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com