Hydraulic system of excavator

A hydraulic system and excavator technology, applied in the field of excavator and excavator hydraulic system, can solve the problems of hydraulic system heating, energy waste, low pressure, etc., and achieve the effects of reducing heat generation, reducing cost, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

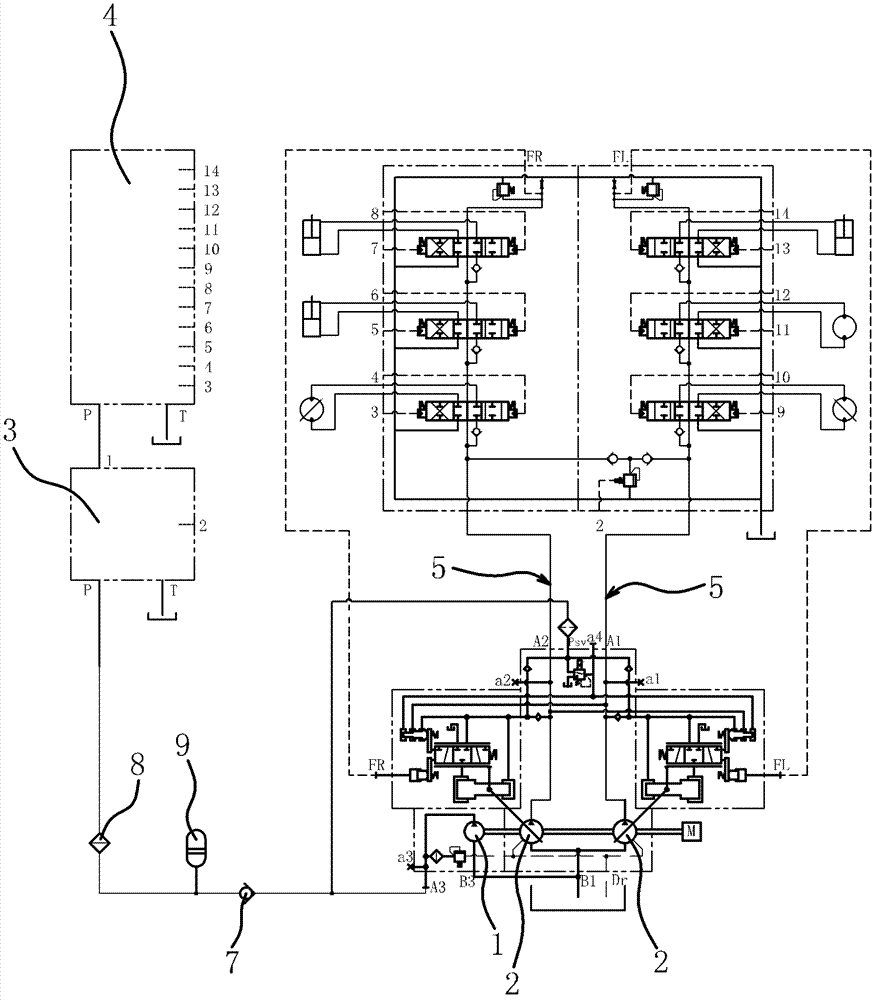

[0027] like figure 2 As shown, the hydraulic system of the excavator includes the main oil circuit subsystem and the pilot oil circuit subsystem. The main oil circuit subsystem includes two main pumps 2 and a main oil circuit 5 communicating with the main pumps 2 one by one. The pilot oil circuit subsystem includes a pilot valve assembly 4 and a solenoid valve assembly 3 communicating with the pilot valve assembly 4 .

[0028] The oil inlet of the solenoid valve assembly 3 communicates with the two main oil circuits 5 through the oil supply pipeline 6 and the shuttle valve 10; that is, the two inlets of the shuttle valve 10 communicate with the two main oil circuits 5 respectively , The oil supply pipeline 6 communicates with the outlet of the shuttle valve 10 .

[0029] More specifically, the communication pipeline 11 between the two inlets of the shuttle valve 10 and the corresponding main oil passage 5 is provided with a throttle valve capable of reducing the influence o...

Embodiment 2

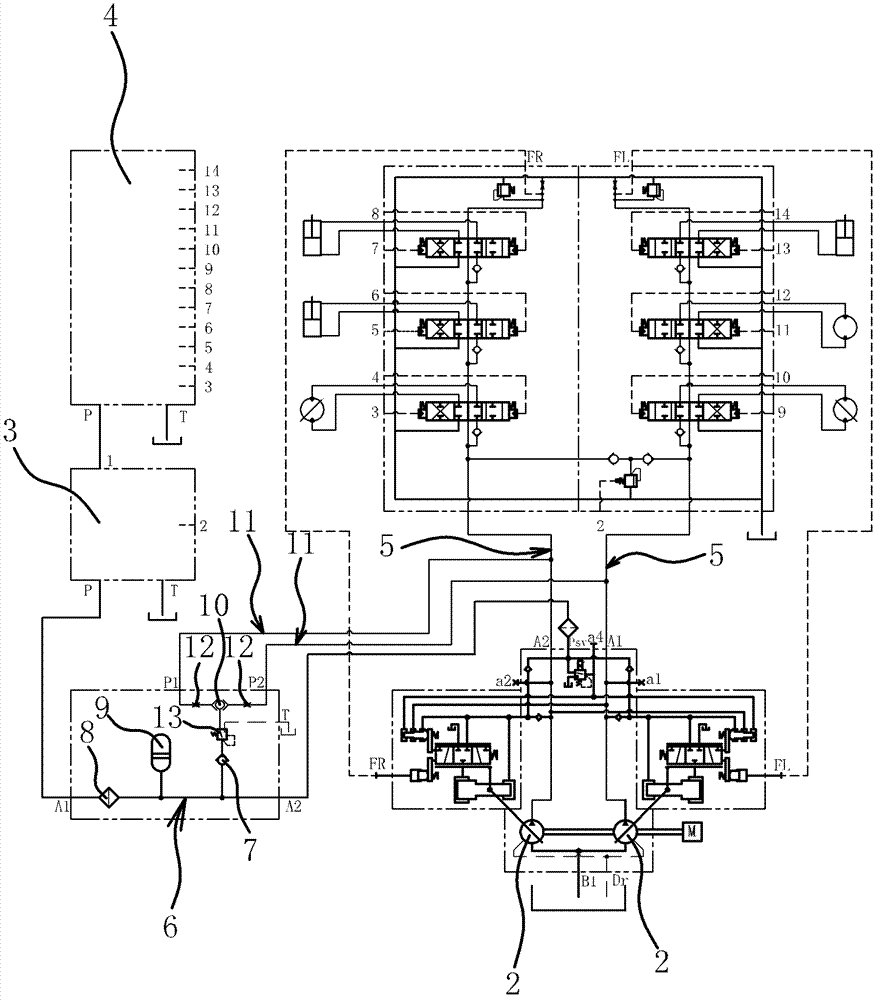

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: the connecting pipeline 11 between the two inlets of the shuttle valve 10 and the corresponding main oil circuit 5 is provided with a one-way throttle valve, The one-way throttle valve can not only reduce the influence of the pressure fluctuation of the main oil circuit 5 on the pressure of the oil supply pipeline 6 , but also prevent the hydraulic oil from flowing back to the main oil circuit 5 . A relief pressure reducing valve 13 and a filter 8 are sequentially provided on the oil supply pipeline 6 from the outlet of the shuttle valve 10 to the oil inlet of the solenoid valve assembly 3 .

Embodiment 3

[0036] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the oil inlet of the solenoid valve assembly 3 communicates with any one of the main oil circuits 5 through the oil supply pipeline 6 . A throttle valve 12, a relief pressure reducing valve 13, a one-way valve 7 and a filter 8 are sequentially arranged on the oil supply line 6 from the main oil line 5 to the solenoid valve assembly 3, and the relief of the relief pressure relief valve 13 The orifice communicates with the fuel tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com