Transmission device for improving transmission efficiency of intermediate shaft type gear box

A technology of gearbox transmission and transmission, applied in transmission, gear transmission, transmission control and other directions, can solve the problems of oil churning loss, wind resistance loss, oil churning loss and wind resistance loss unavoidable, etc. Life, improve temperature rise, improve the effect of overall transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

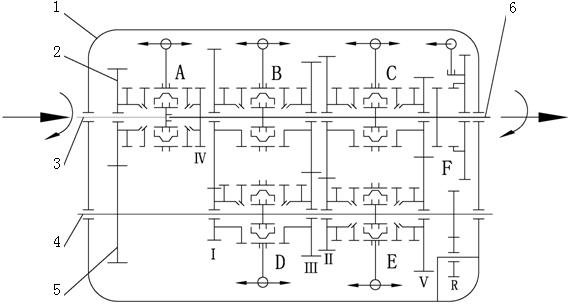

[0028] Please refer to the accompanying drawings and take the five-speed countershaft gearbox as an example to further describe the present invention.

[0029] Such as figure 1 As shown, the present invention provides a transmission device for improving the transmission efficiency of an intermediate shaft type gearbox, including a gearbox case 1, an input shaft 3, an intermediate shaft 4, an output shaft 6, a first-stage transmission driving gear 2, a first Stage drive driven gear 5, direct gear engaging ring gear IV, corresponding transmission gears for each gear except direct gear and reverse gear (I, II, III, V), reverse gear R, synchronizers A-E and bearings, Except for the direct gear, other gears are all two-stage gear transmission, and share the first-stage transmission gears 2 and 5. The front end of the gearbox input shaft 03 is supported on the gearbox case 1 through a bearing, and the end is connected to the splined hub of the synchronizer A through a spline. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com