gear reducer

A technology of gear reduction and gear box, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

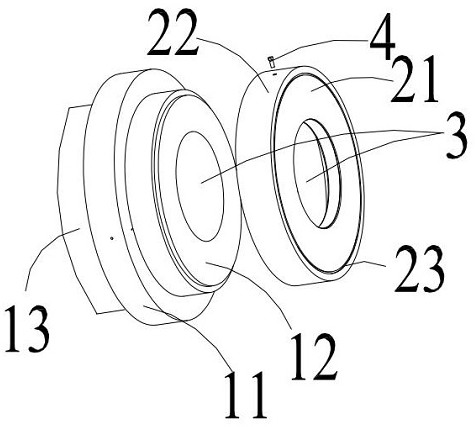

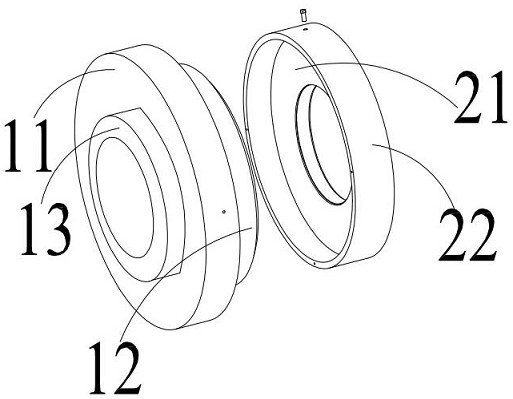

[0044] see Figure 1 to Figure 10 As shown, this embodiment provides a gear reducer, including: a gear box and a reduction gear assembly disposed in the gear box; wherein the reduction gear assembly includes a pair of transmission shafts 5 that pass through the side wall of the gear box at intervals and a plurality of gears 7 respectively sheathed on the transmission shaft 5 ; and a matching hole for rotating with the transmission shaft 5 is provided on the side wall of the gear box; and an oil baffle is sleeved on the transmission shaft 5 .

[0045] The oil baffle includes: a large eccentric wheel 1 and a small eccentric wheel 2 which are adapted to be locked and fixed by bolts 4 for example but not limited to; wherein the outer diameter of the large eccentric wheel 1 is greater than the outer diameter of the small eccentric wheel 2; and the large eccentric wheel 1 and the small eccentric 2 are provided with a through hole 3 that runs through but is not coaxial; the through h...

Embodiment 2

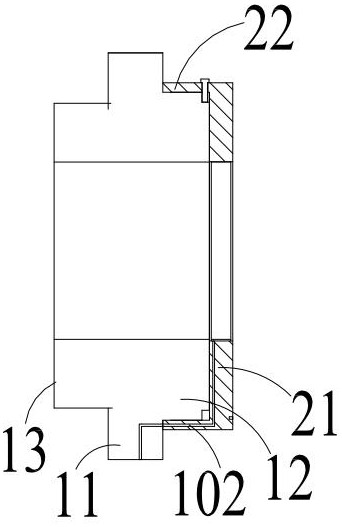

[0065] see Figure 1 to Figure 10 As shown, on the basis of the gear reducer in Embodiment 1, it is considered that the transmission shaft 5 and the through holes 3 of the large eccentric wheel 1 and the small eccentric wheel 2 are clearance fit, that is to say, there is a clearance, even if It is a very small gap, and lubricating oil may leak from the gap. Therefore, based on this problem, the gear reducer provided in this embodiment is also embedded with a sleeve in the through hole 3 of the small eccentric wheel 2. The washer 10 on the transmission shaft 5 is arranged coaxially with the through hole 3 . Through the cooperation of the washer 10 and the transmission shaft 5, the above-mentioned gap is blocked.

[0066] Here, between the circumferential side wall of the gasket 10 and the hole wall of the through hole 3 of the small eccentric wheel 2, for example but not limited to, sealing colloid can be used to achieve an effective sealing fit, so as to prevent the lubricati...

Embodiment 3

[0068] see Figure 1 to Figure 10 As shown, on the basis of the gear reducer of Embodiment 2, the washer 10 used in the gear reducer of this embodiment has a hollow storage chamber 101, and the hollow storage chamber 101 is wound around the outer circumference of the transmission shaft 5 and at least one oil inlet is provided on the contact surface between the washer 10 and the hole wall of the through hole 3 of the small eccentric wheel 2, and the large eccentric wheel 1 and the small eccentric wheel 2 are respectively provided with a The oil passage 102 communicated with the oil port. Here, the oil inlets correspond to the oil passages one by one, that is, the number of oil inlets corresponds to the number of oil passages, which is not absolutely limited in this embodiment.

[0069] To be more specific, the oil passage 102 provided on the large eccentric 1 includes the oil inlet hole provided on the circumferential side wall of the base 11 of the large eccentric 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com