Water guide bearing

A water guide bearing and water guide tile technology, applied in the field of water turbine components, can solve the problems of uneven distribution of lubricating oil, unreasonable overall design, and insufficient oil retaining effect, etc., achieving good oil retaining effect, simple structure, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

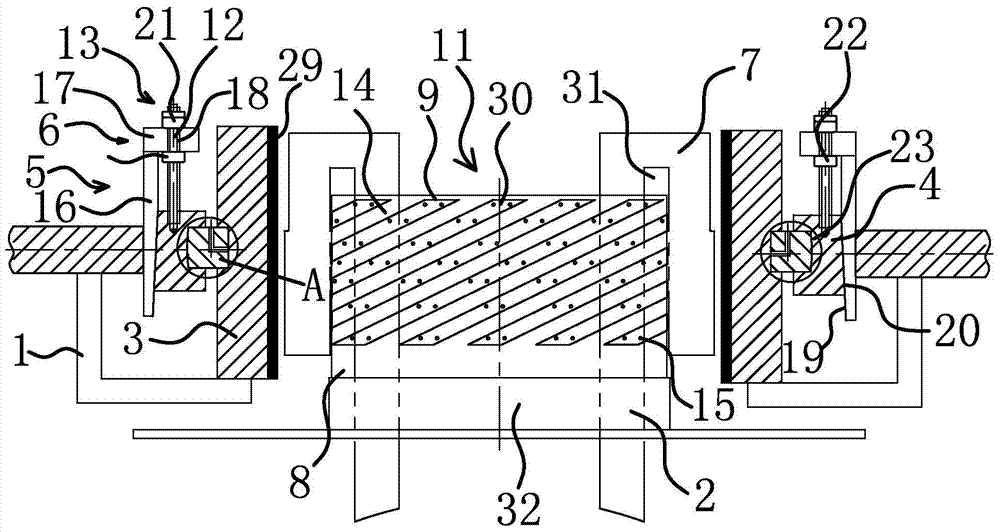

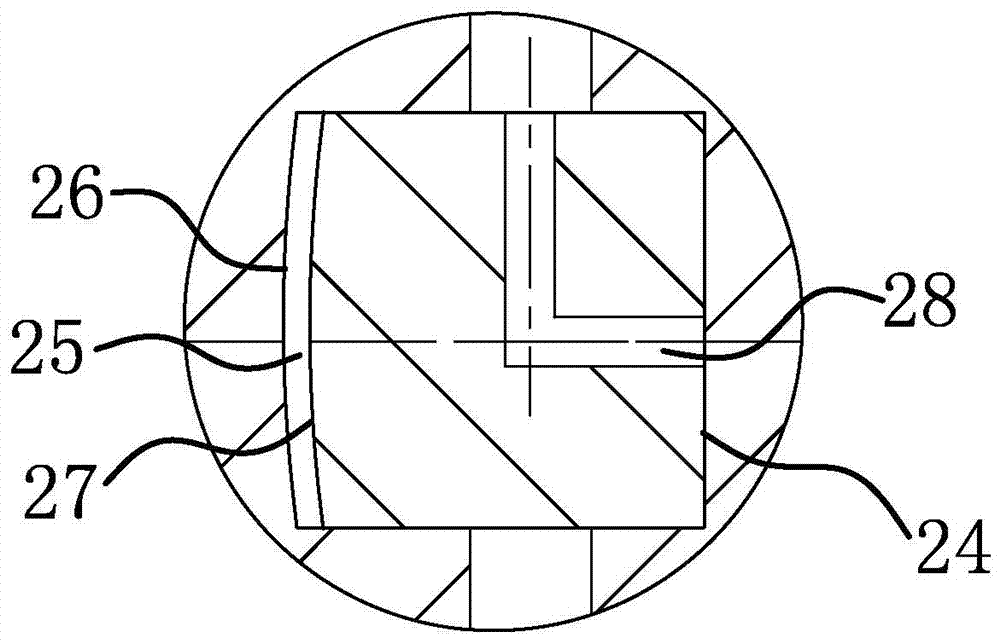

[0027] Such as Figure 1-2 As shown, the water guide bearing includes a bearing seat 1 and a main shaft 2, the main shaft 2 is covered with a water guide pad 3 and the water guide pad 3 is rotationally connected with the main shaft 2, and the water guide pad 3 and the bearing seat 1 are provided with a water guide pad to adjust device, an oil retaining mechanism is provided between the water guide shoe 3 and the main shaft 2, and the feature is that the oil retaining mechanism includes an annular space 8 that is arranged at the main shaft 2 with the collar 7 and is formed between the main shaft 2 and the collar 7 In the cylindrical body 9, the shaft collar 7 is externally connected with the water guide pad 3 and the water guide pad 3 is connected to the main shaft 2 in rotation. The main body 9 is provided with a pressure that can form a positive pressure when the main shaft 2 rotates to prevent the loss of lubricating oil. Structure 11 is formed. The pressure forming structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com