Patents

Literature

38results about How to "Feel the same" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

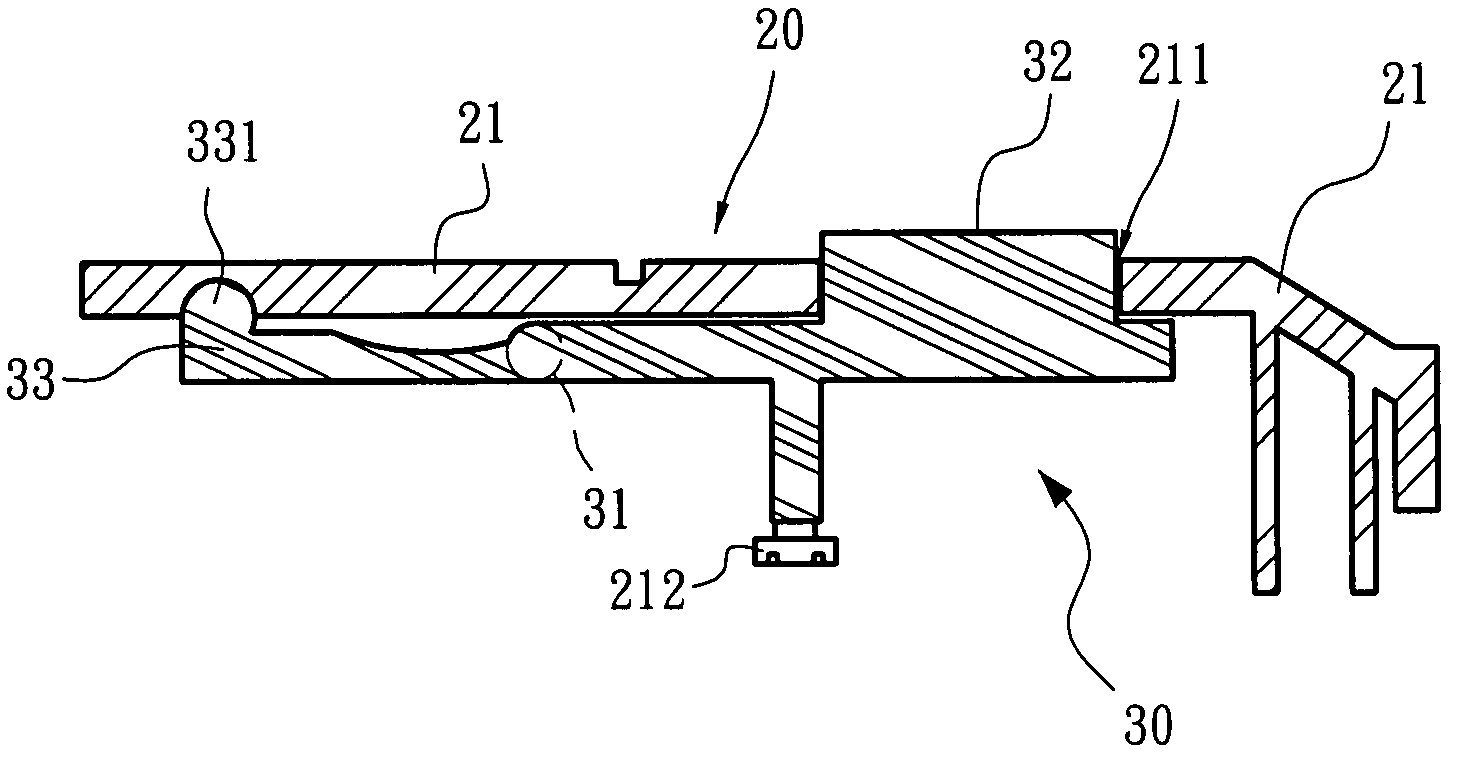

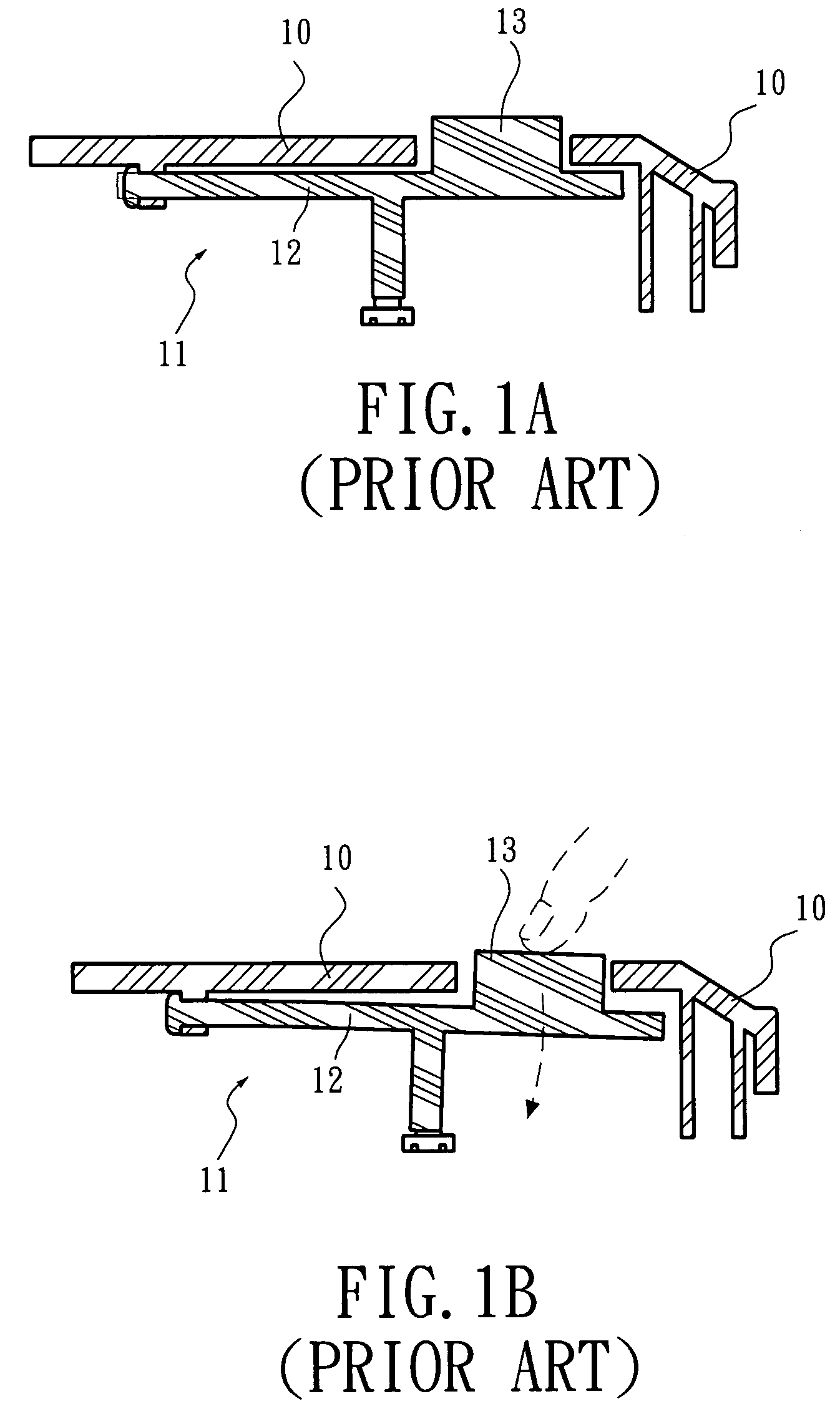

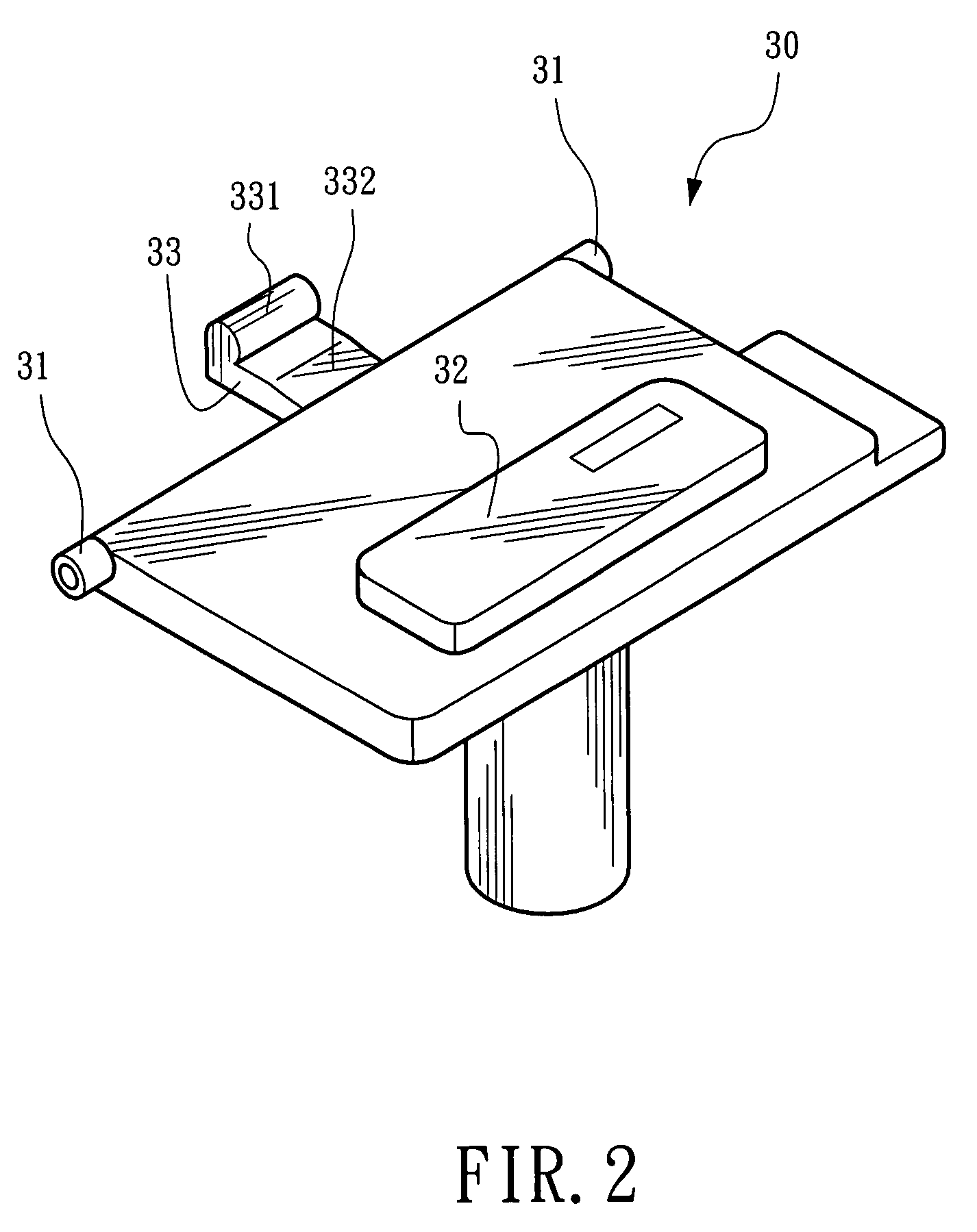

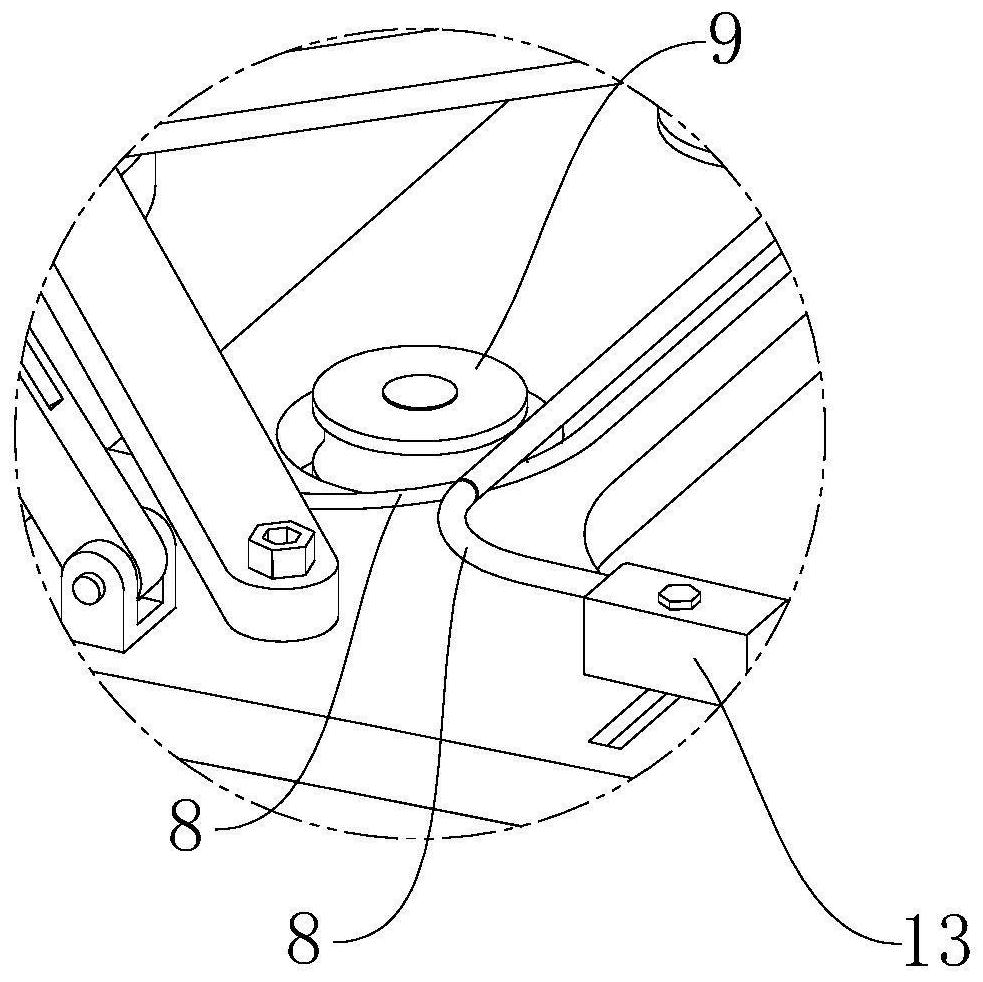

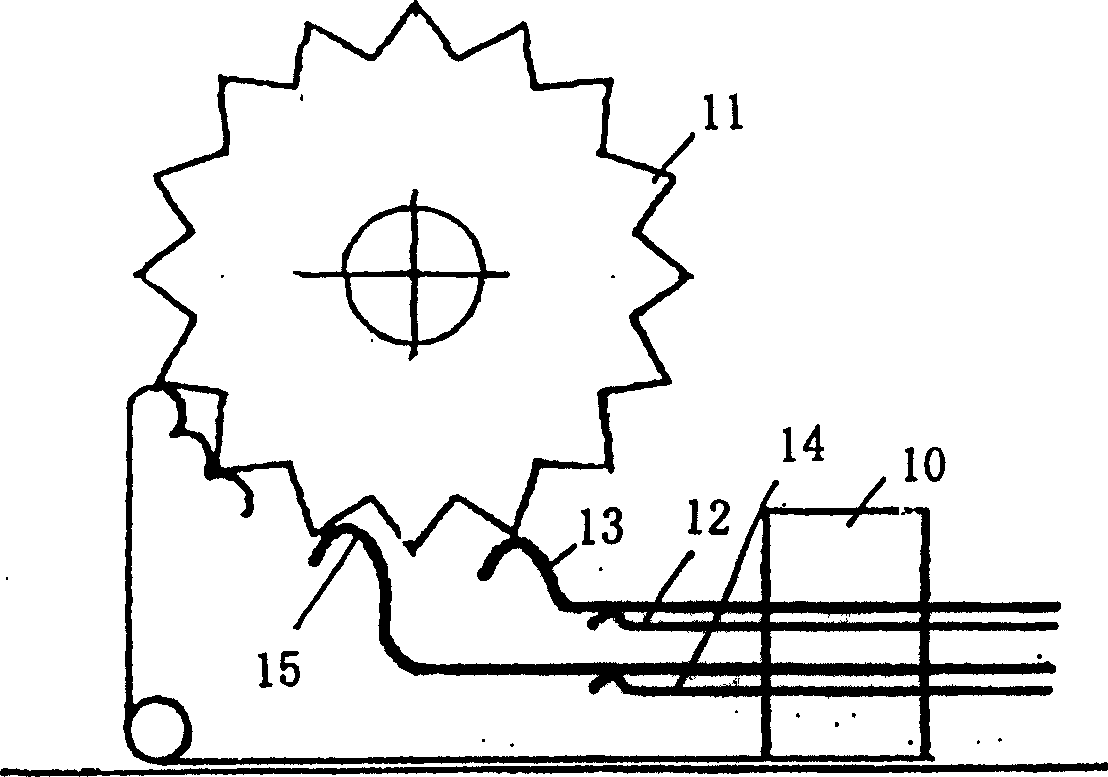

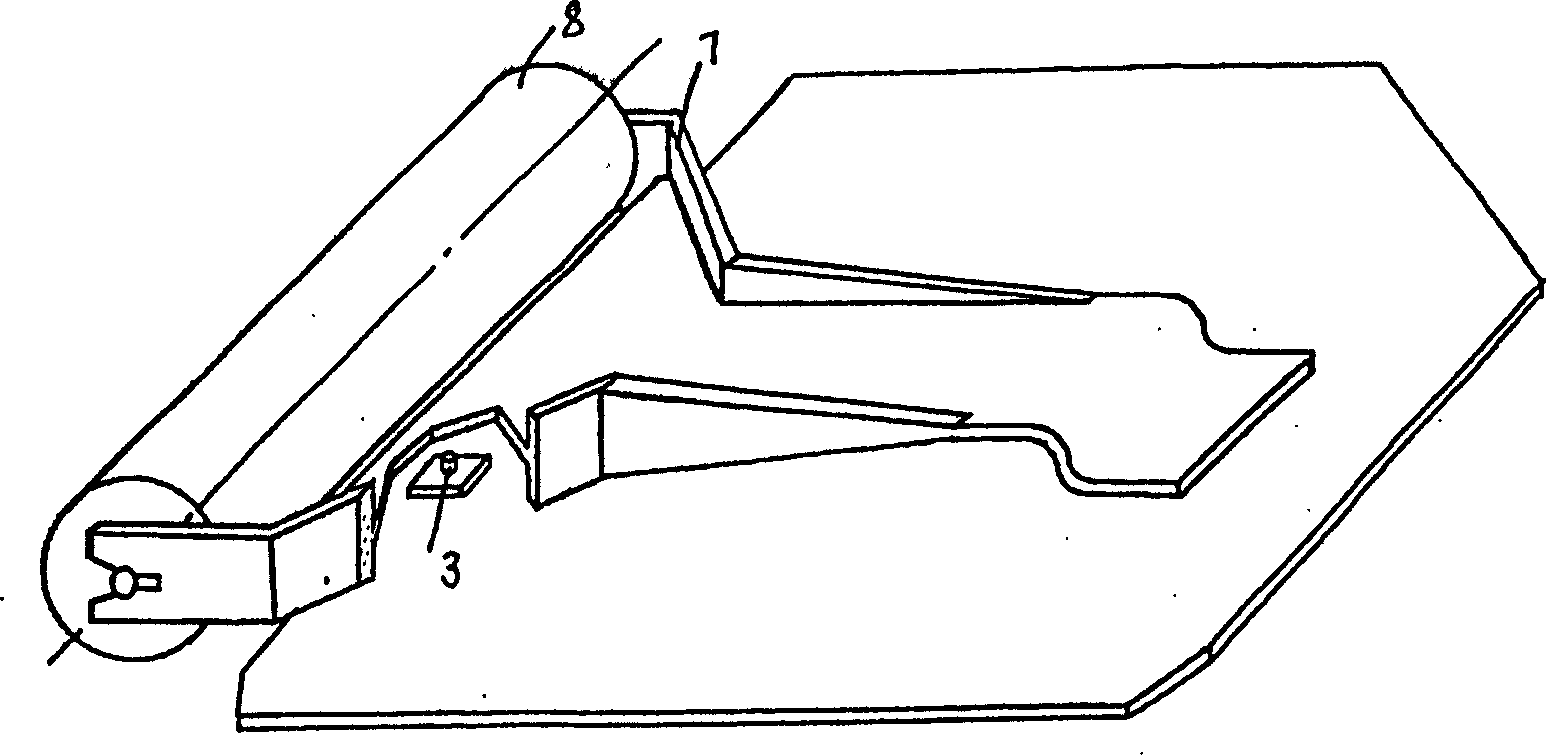

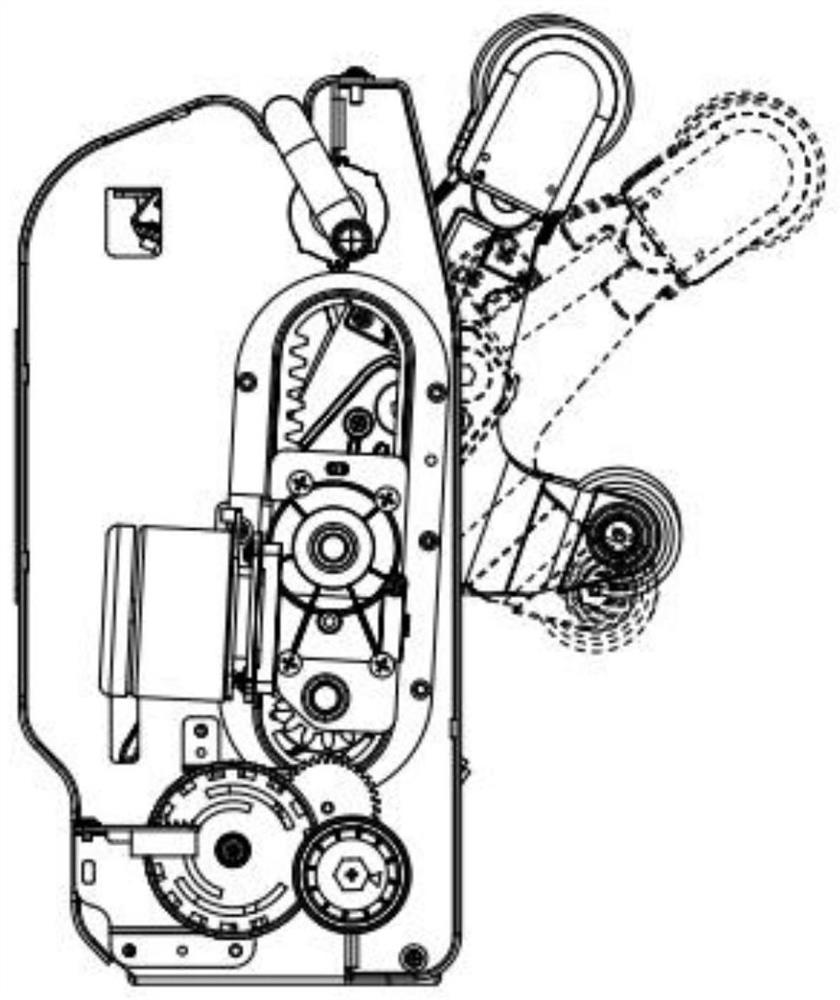

Lever button of electronic product

InactiveUS7381919B1Avoid uneven attachmentFeel the sameElectric switchesCantileverMechanical engineering

A lever button of an electronic product is provided. The lever button is disposed inside a housing, and is deformed under an external force to generate a displacement to press a switch. The lever button includes a fulcrum shaft pivotally disposed in the housing, a pressing section extending from the fulcrum shaft, and at least one suspension arm in the direction opposite to the extending direction of the pressing section. The suspension arm together with the pressing section and the fulcrum shaft forms a lever structure to urge against the housing in the direction opposite to the pressing direction when a user presses the pressing section. The lever button adopts an assembly configuration, and after being assembled, the fulcrum shaft and the suspension arm urge the housing to make the pressing section evenly attached on the housing.

Owner:INVENTEC CORP

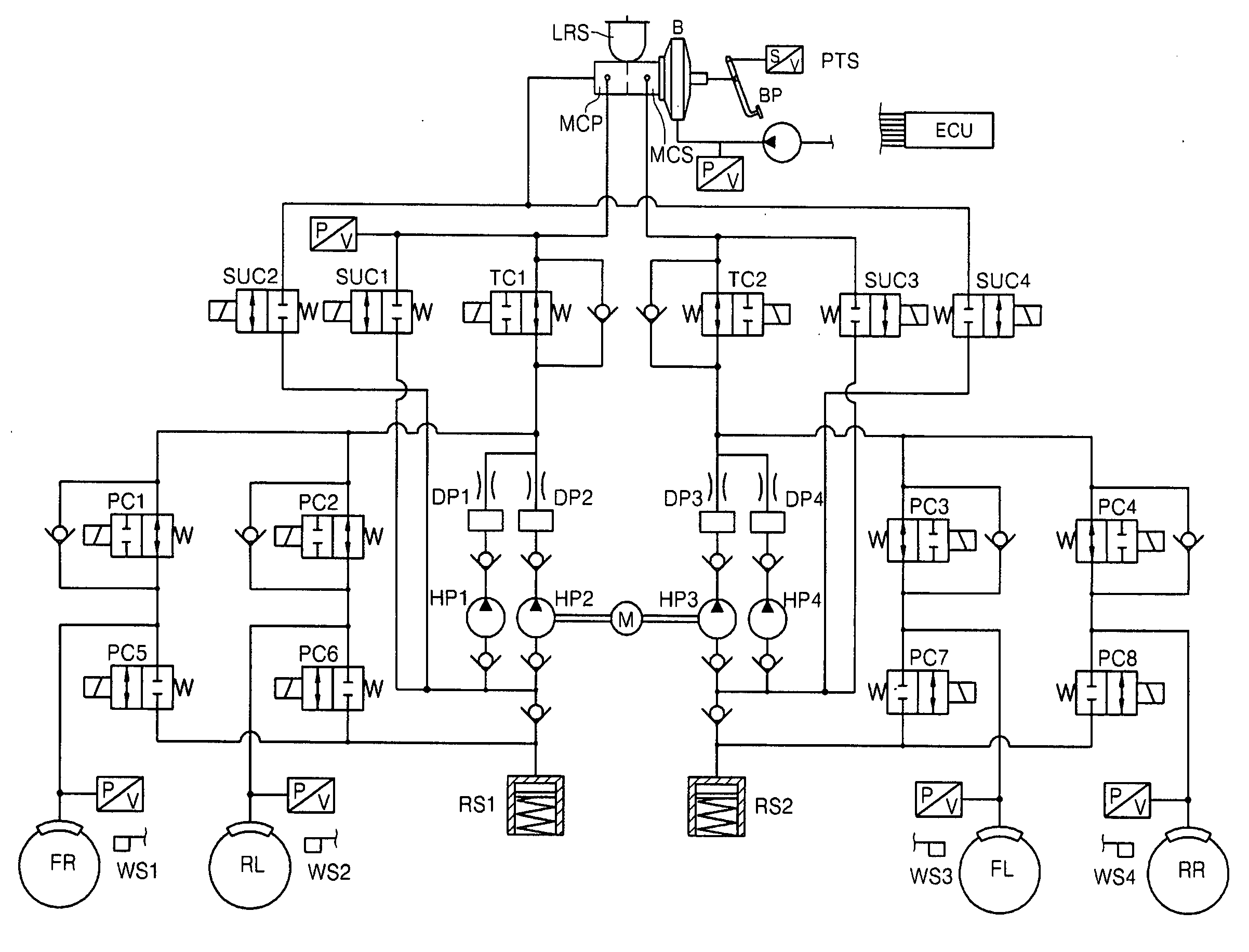

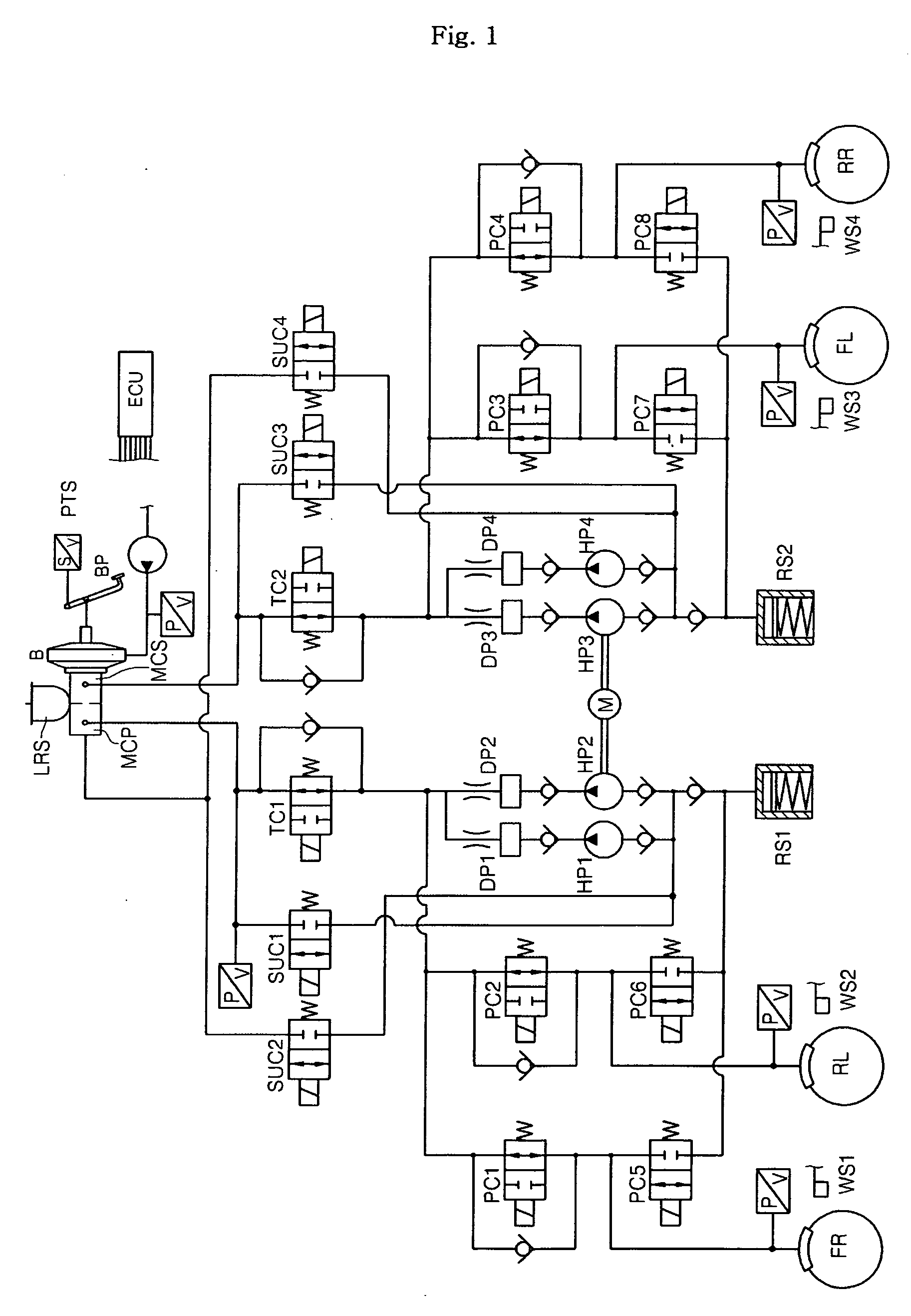

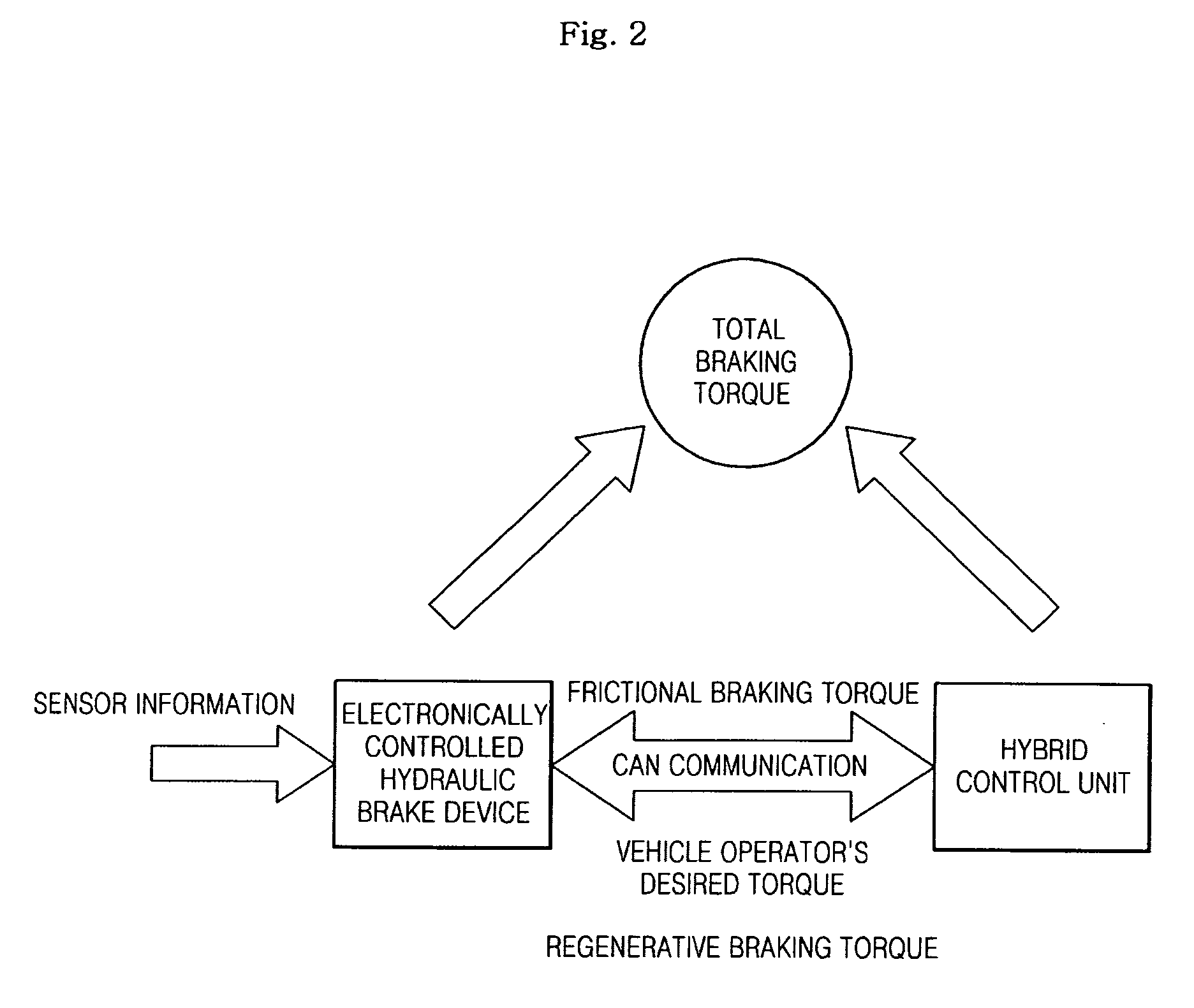

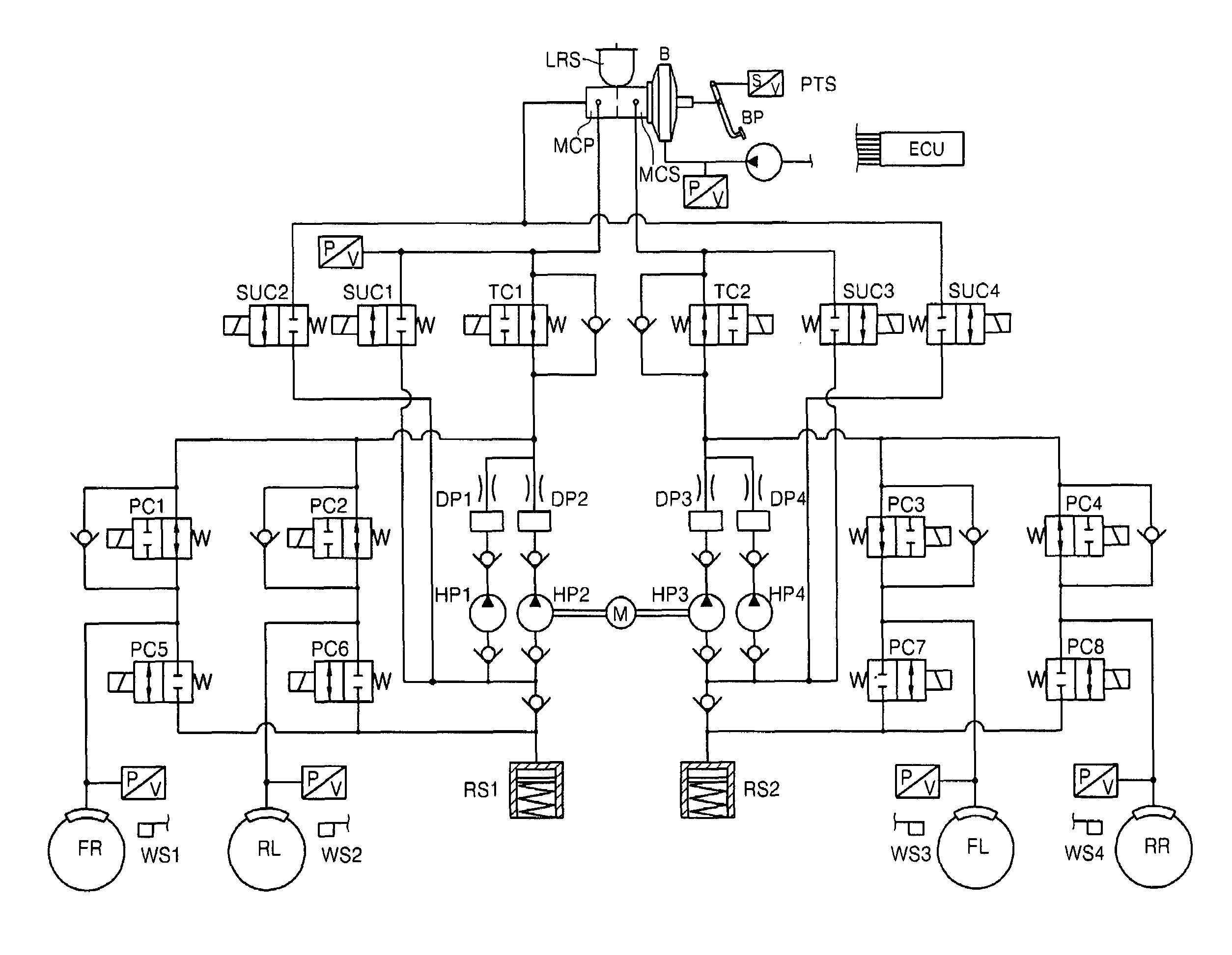

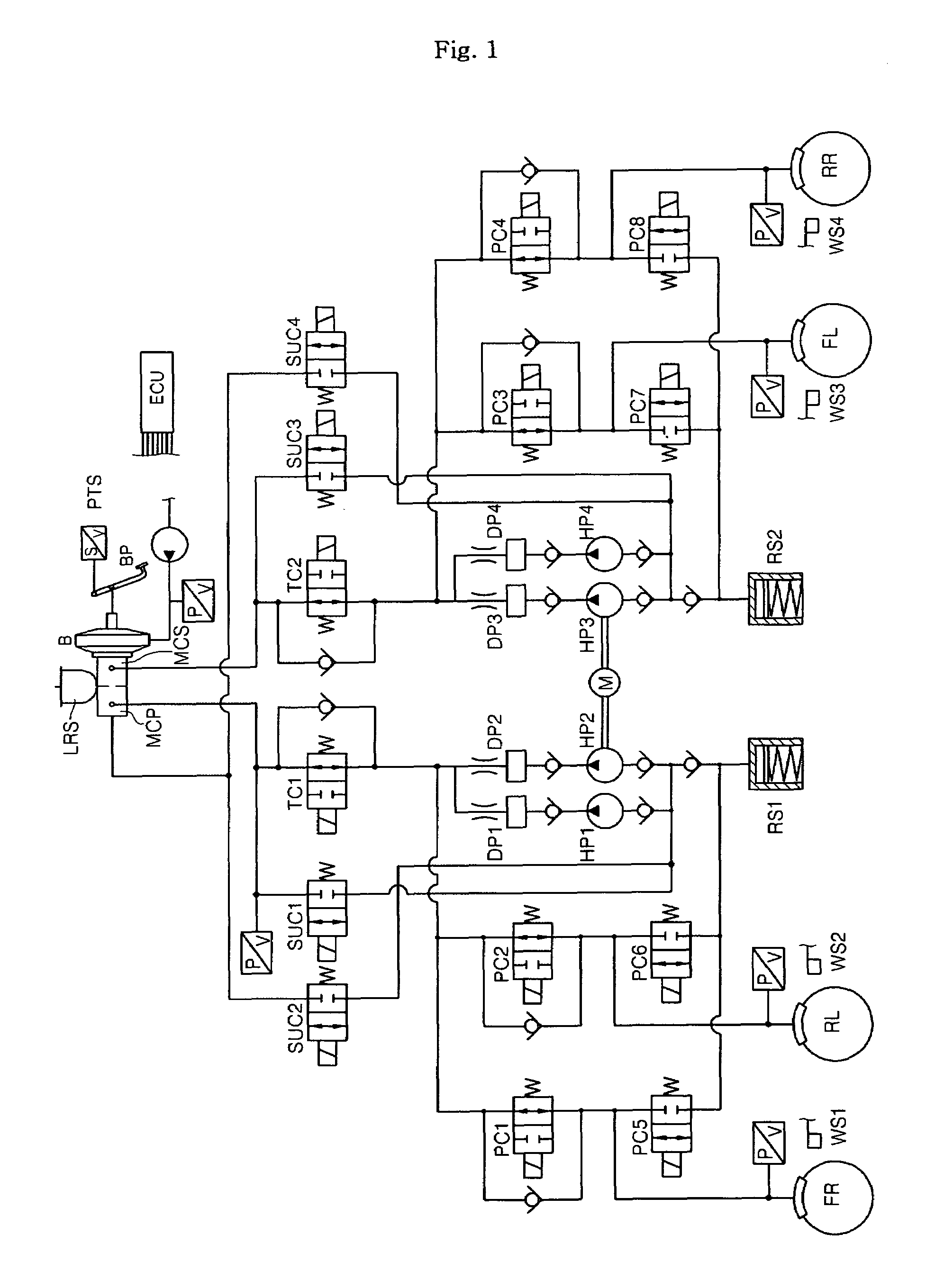

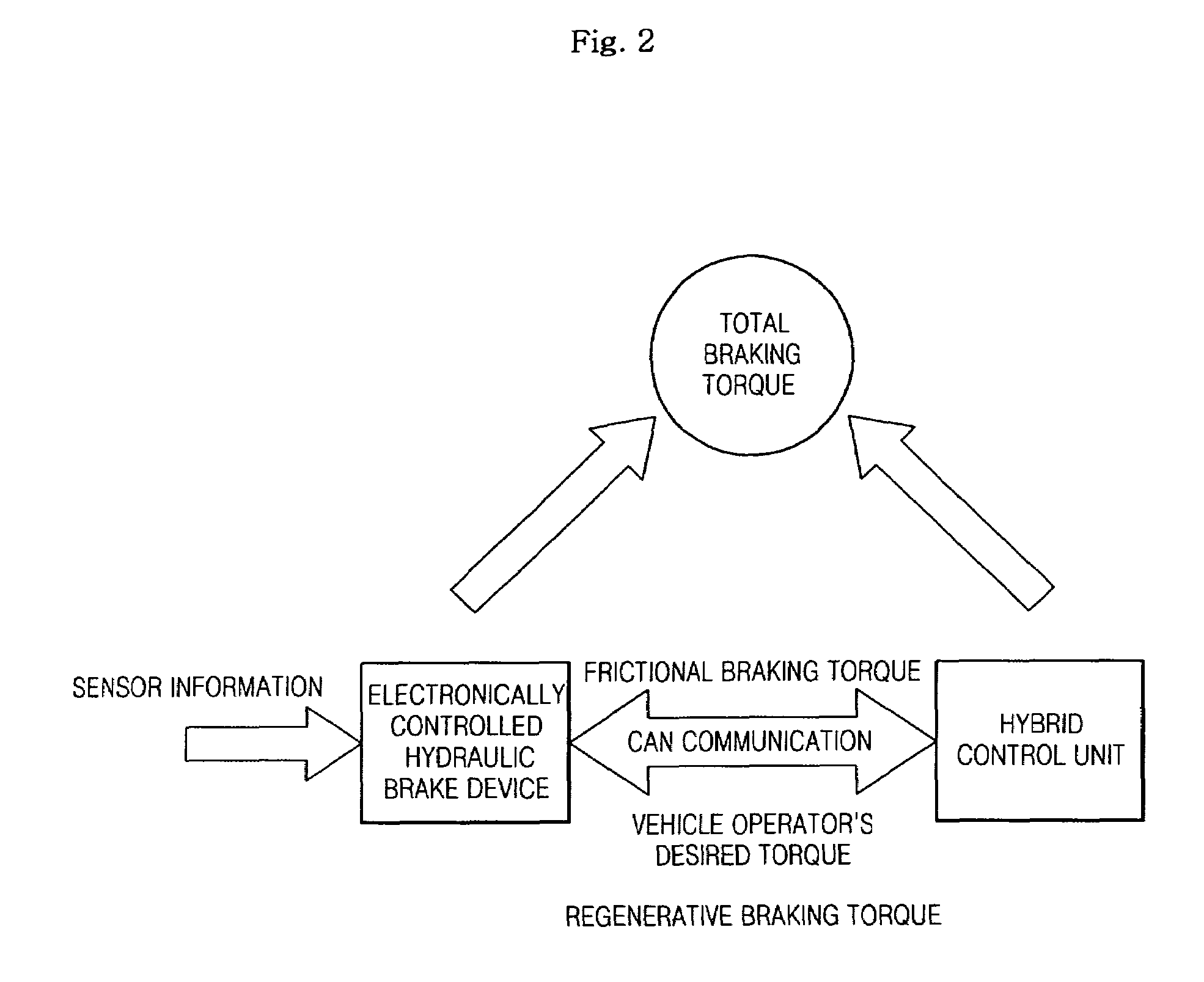

Regenerative braking method for vehicle having electric motor

ActiveUS20070126382A1Feel the sameAvoid problemsDc motor stoppersAsynchronous induction motorsDrive wheelRegenerative brake

A regenerative braking method for a vehicle having an electric motor. During an initial stage of a regenerative braking operation related to the vehicle having the electric motor, a flow rate of brake liquid as much as the amount of regenerative braking is delivered into a reservoir through opened exit valves of non-driving wheels, so as to generate a hydraulic braking force needed after subtracting the amount of regenerative braking from the amount of braking desired by a vehicle operator. When the amount of regenerative braking increases, exit valves of driving wheels are controlled to fulfill the total amount of braking desired by the vehicle operator. Also, when the amount of regenerative braking decreases, wheel pressures have to be increased to fulfill the vehicle operator's desire to brake. In the regenerative braking method for generating a residual amount of braking needed after subtracting the amount of regenerative braking, which corresponds to an amount generated by the electric motor, from the amount of braking desired by the vehicle operator, during the regenerative braking operation, based on a pressure difference between a pressure in the master cylinder and wheel pressures, entrance valves of the driving wheels are controlled to realize an operator's pedal feeling, and the exit valves of the driving wheels are controlled to allow the wheel pressures to follow a target pressure.

Owner:HL KLEMOVE CORP

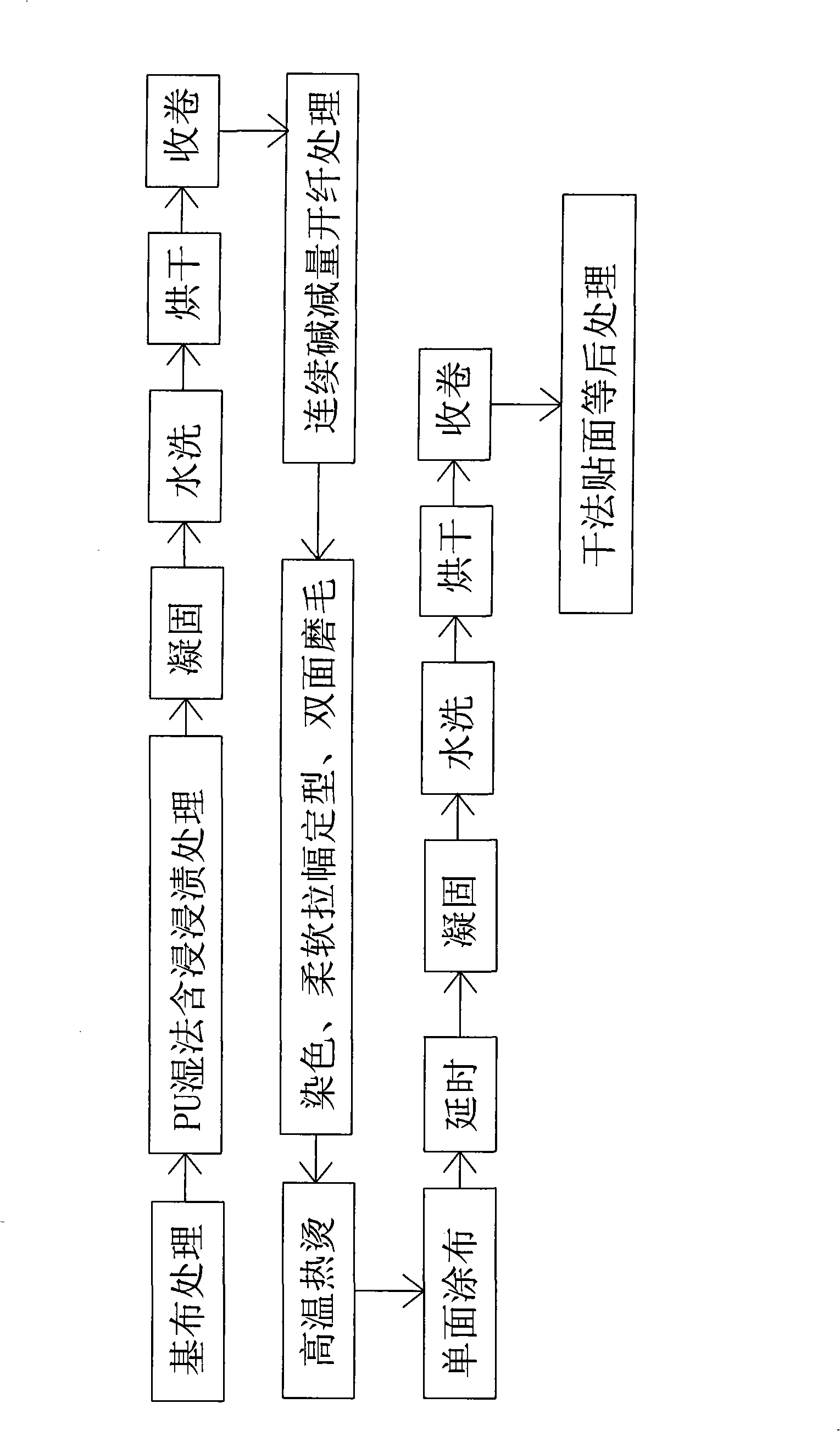

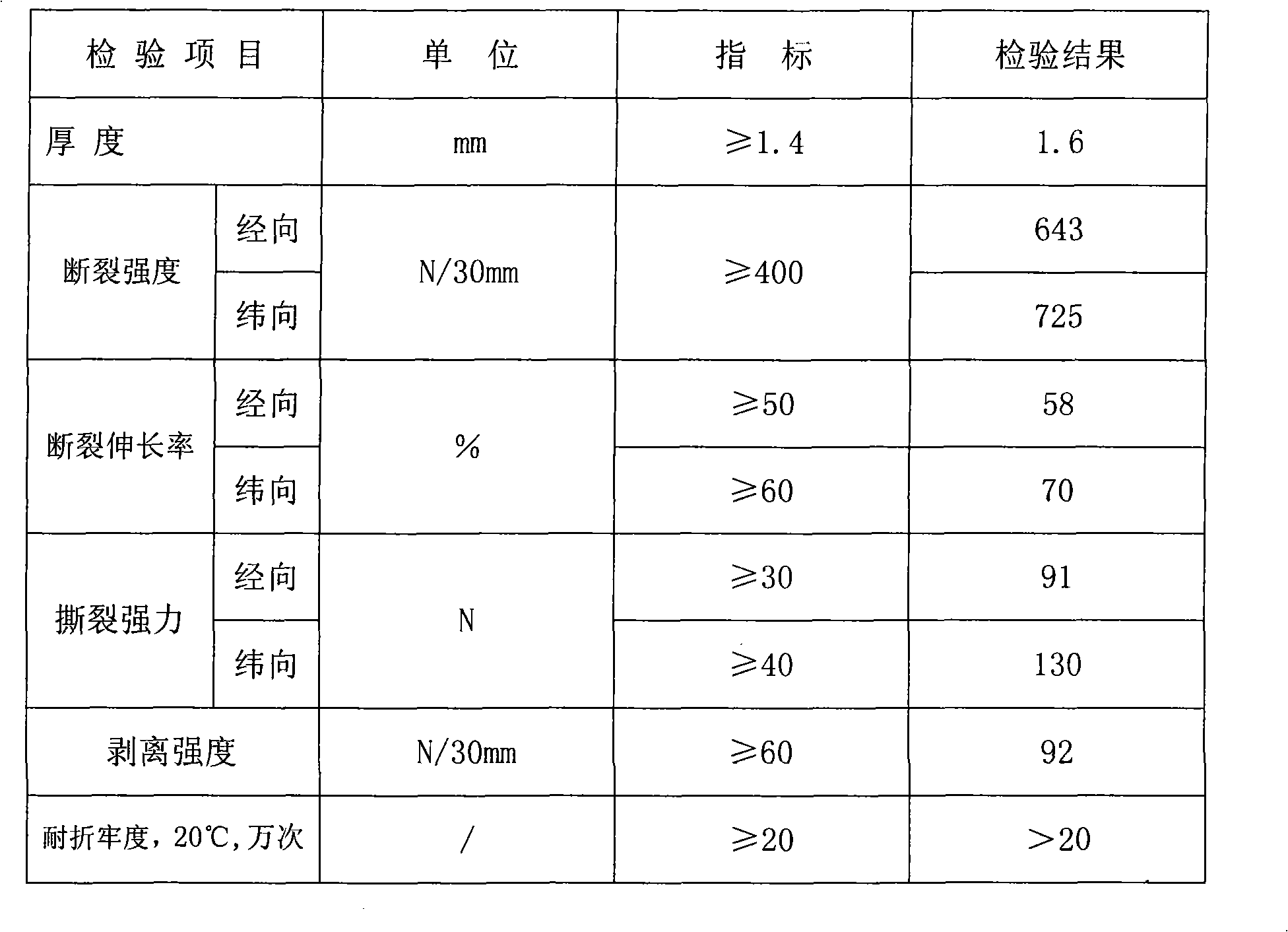

Method for processing island ultra-thin fiber high-density needling non-woven fabrics emulation leather

InactiveCN101260619AUniform thicknessHigh tear strengthFibre treatmentHeating/cooling textile fabricsHigh concentrationTime delays

The invention relates to a method for machining an island superfine fiber high density pinprick non-woven fabrics artificial leather, which is applied to the artificial leather manufacture and comprises the following processes: (1) the foundation process; (2) the PU wet method dipping process; (3) the continuous alkali abatement fiber opening process; (4) the pigmentation, the flexible tentering and shaping, the peached finish on two sides by a roughing-up machine; (5) the post treatments such as the dry method facing. The method is characterized in that the following processes are performed between the (4) process and the (5) process which are as follows: (6) the rolling blanching at a high temperature of 80 to 120 DEG C; (7) the high concentration polyurethane DMF solution with a weight ratio of PU: DMF of 100:50-93 is coated on the single side of the fabrics; (8) the time delay of 30 to 80 seconds; (9) a low temperature of 10 to 15 DEG C high concentration of 15 to 25 percent of DMF solution coagulating basin is coagulated, washed by water, dried and wrapped up. The method has the advantages that the manufactured finished leather has even thickness, excellent anti-tear strength and good ventilation property, the shortcoming that the cross breaks of the fibril synthetic leather is concave is overcome; the single spreading effectively avoids the foaming phenomenon on the coating surface; the section color is constant, etc.

Owner:NANPING JINYUE ARTIFICIAL LEATHER

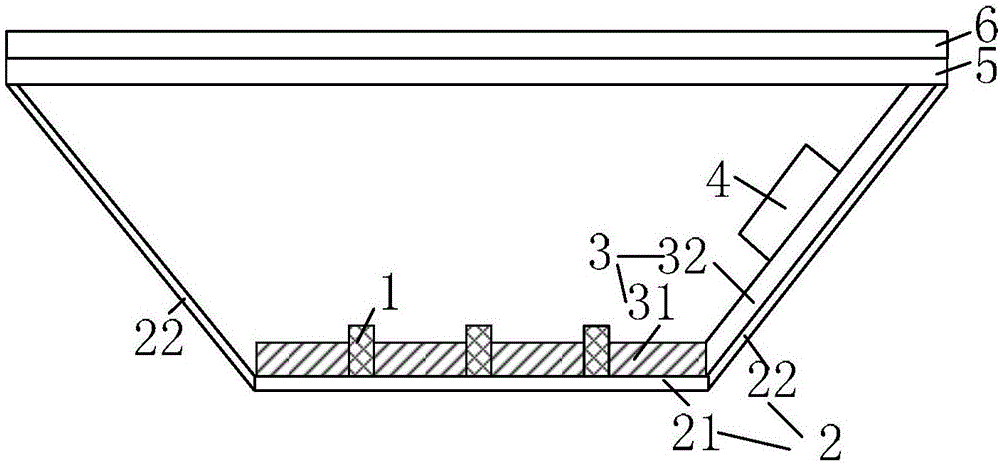

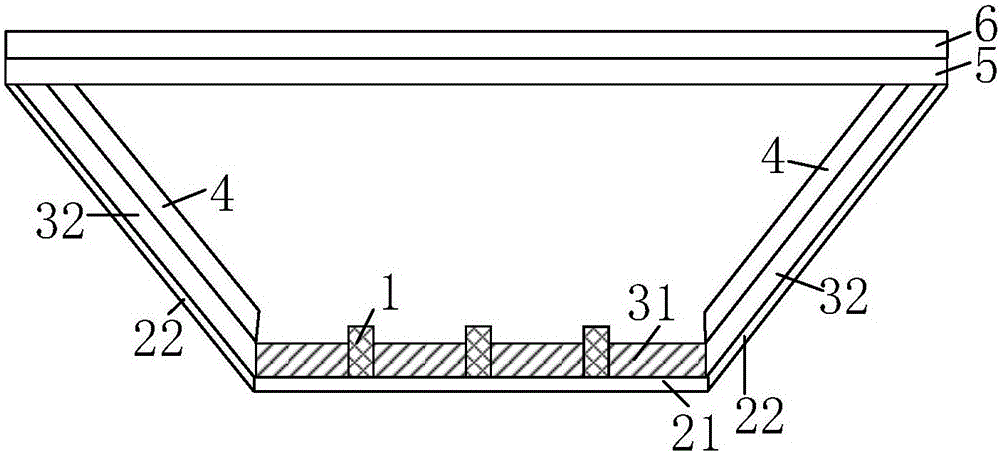

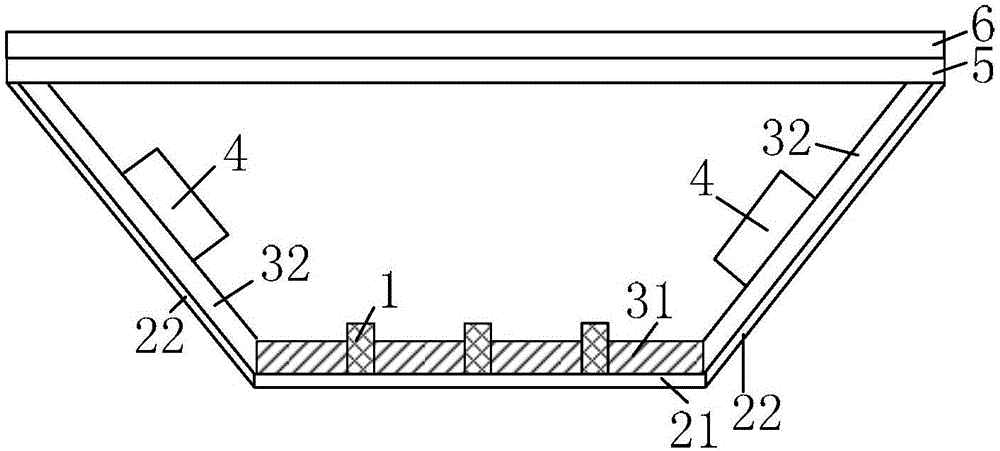

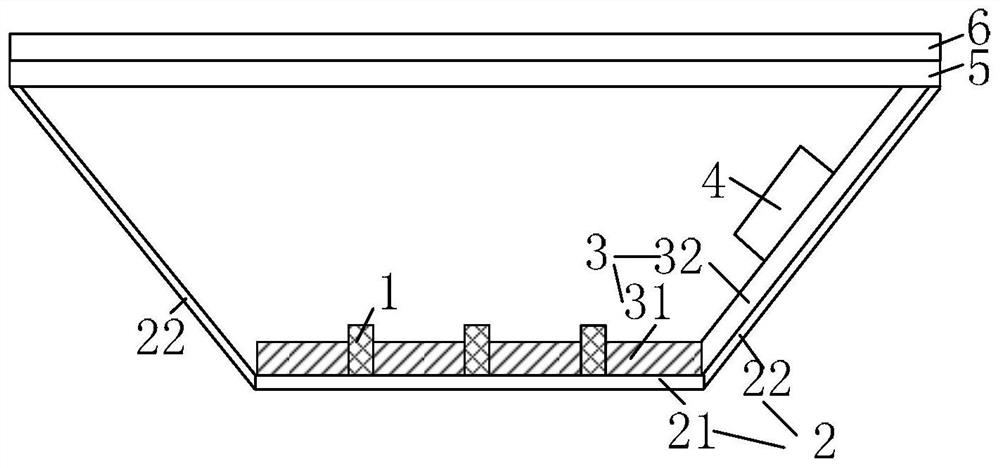

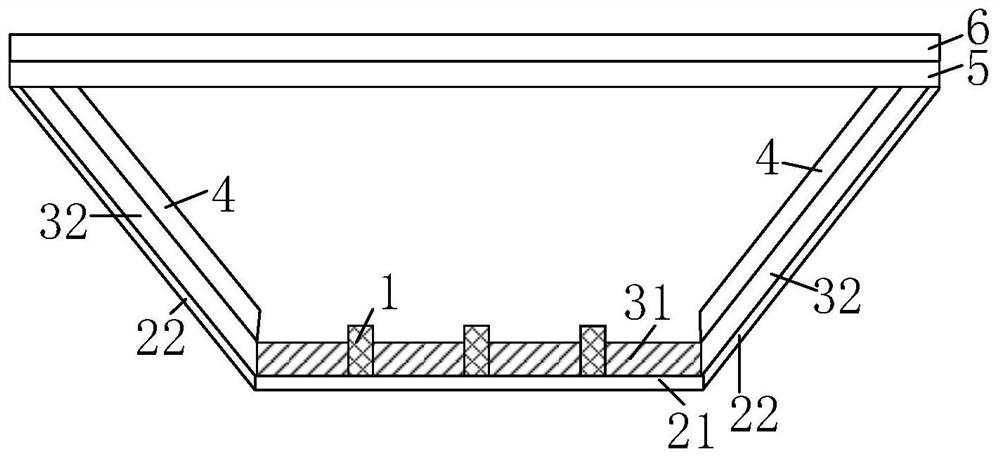

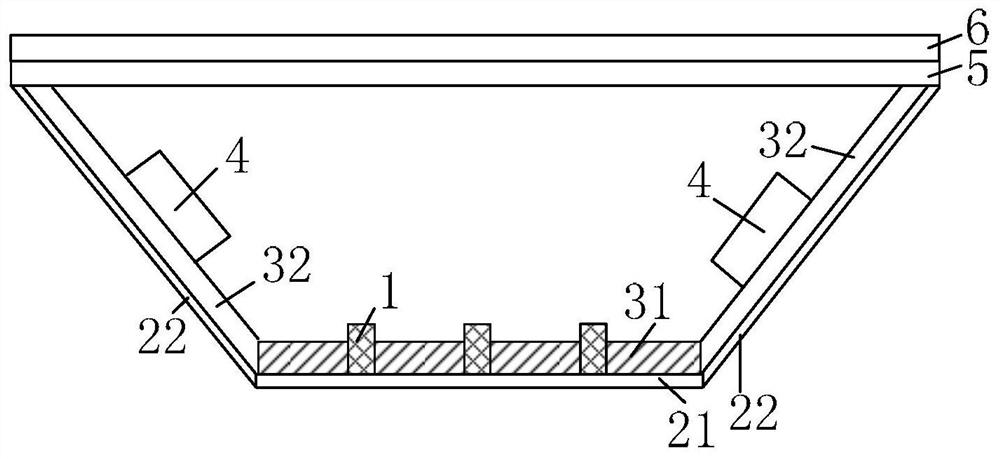

Bottom lighting module and display device including the same

The invention provides a bottom lighting module and a display device including the same. The bottom lighting module comprises at least one LED light source, a reflective film supporter with an opening, a reflective film, a light absorbing film and a light conversion film. The reflective film supporter comprises a bottom plate and at least three side plates. The projection of the bottom plate on the plane of the opening is inside the opening. Each LED light source is arranged on the surface of the bottom plate. The reflective film comprises a bottom reflective film and at least three side reflective films. The bottom reflective film is arranged on the surface of the bottom plate and comprises a plurality of holes in one-by-one correspondence to the LED light source for adaption. Each LED light source is arranged to pass one of the holes. Each side reflective film is installed on each side plate. The light absorption film is arranged on at least a part of the surface of at least one of the side reflective films, the part of the surface being far from the side plate, and the light absorption film is used to absorb light. The light conversion film arranged at the opening is far from the LED light source and is used to convert light emitted by the LED light source into white light.

Owner:NANJING TECH CORP LTD

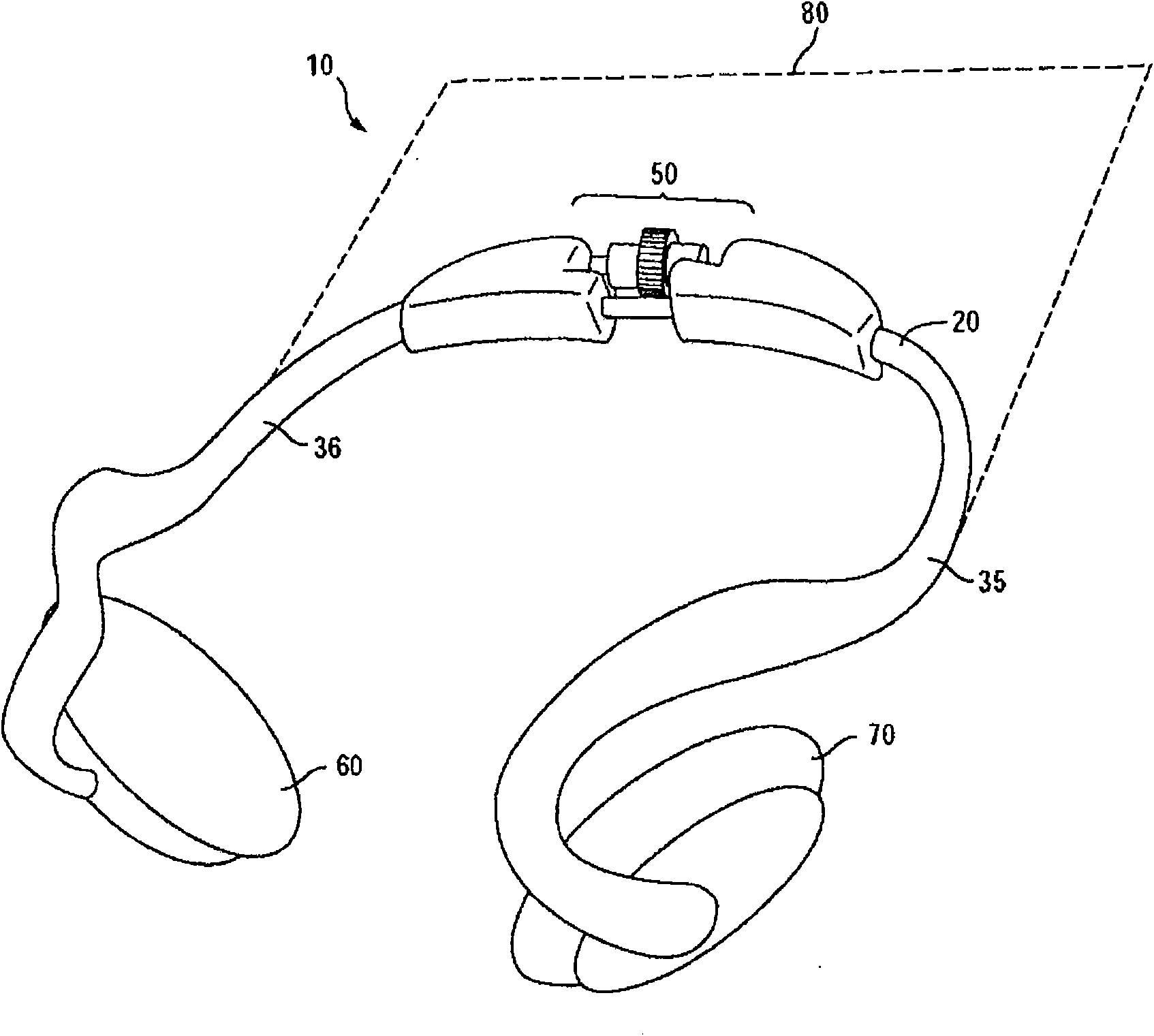

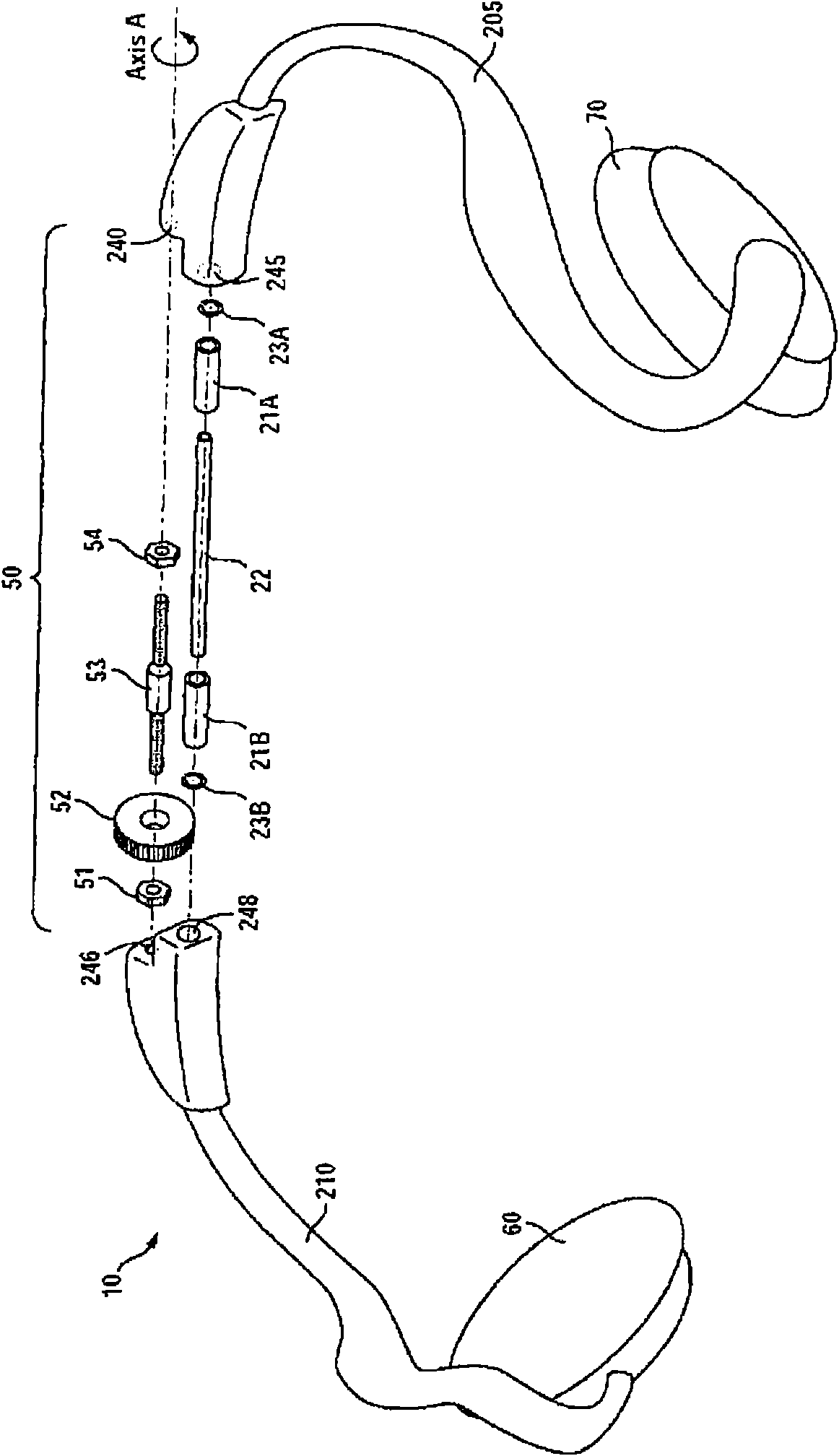

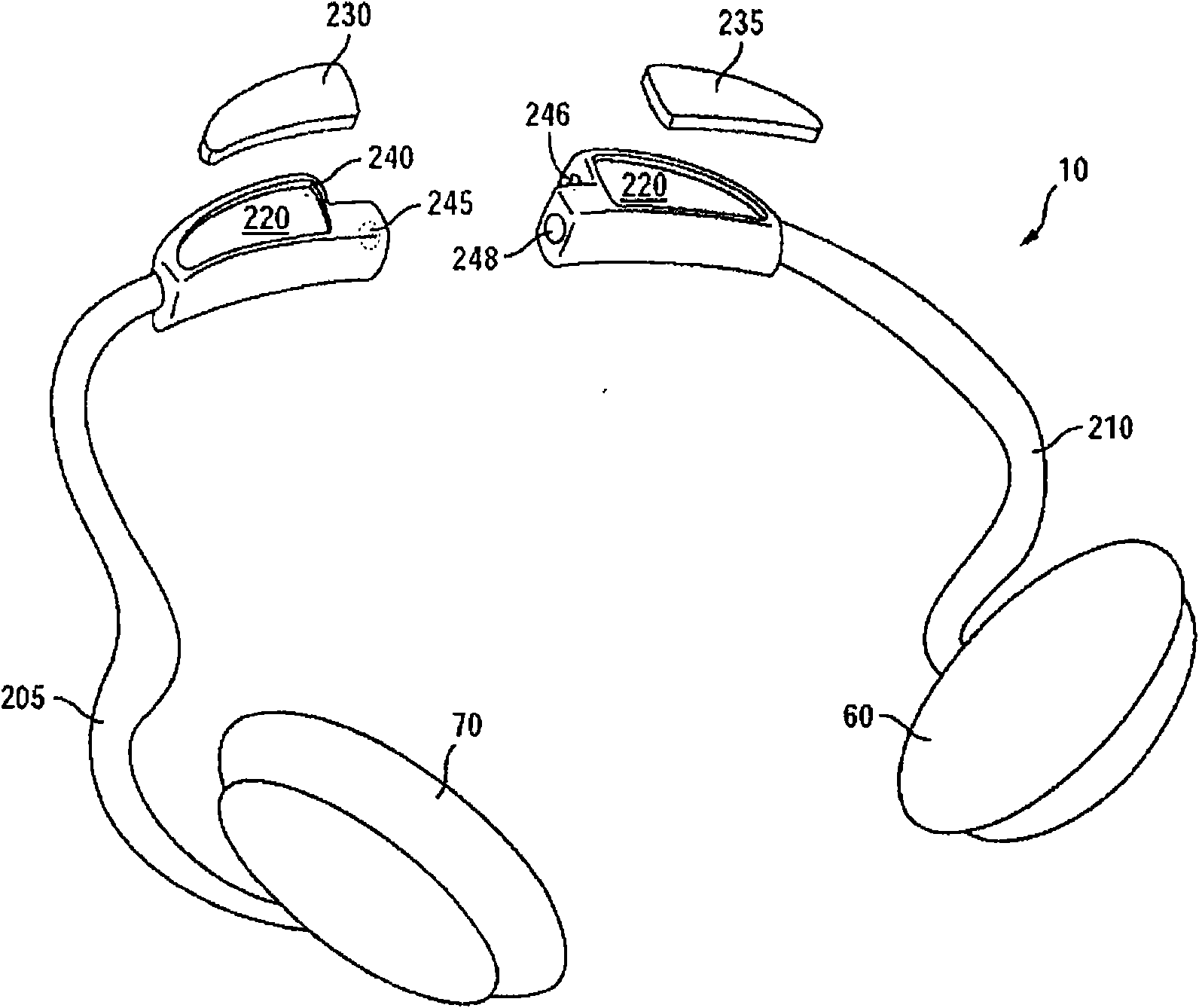

Personal audio set with adjustable force mechanisms

InactiveCN101883302ABest design valueFeel the sameHeadphones for stereophonic communicationSupra/circum aural earpiecesEngineeringHeadphones

Owner:ROGERTECH EUROPE GMBH

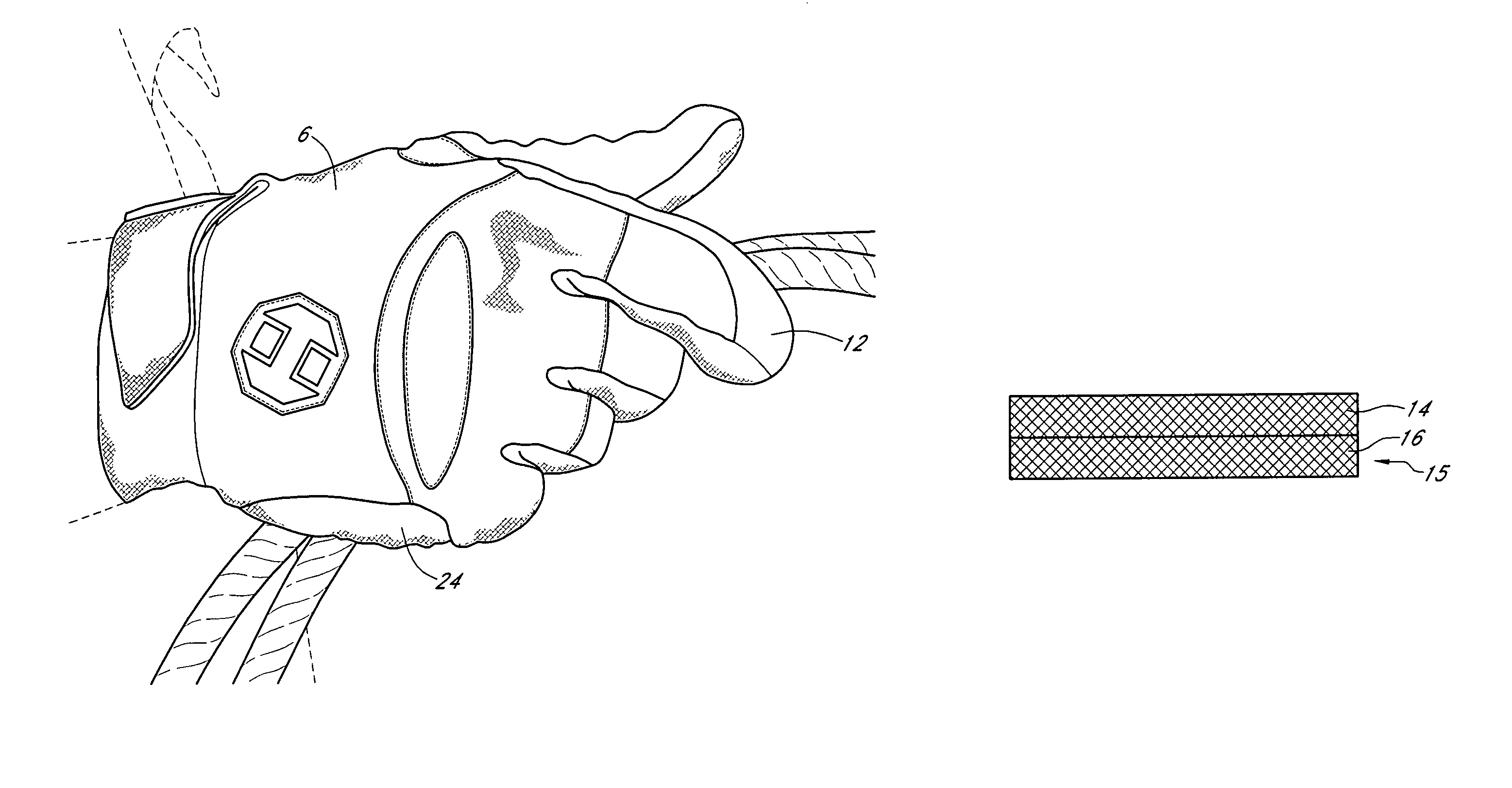

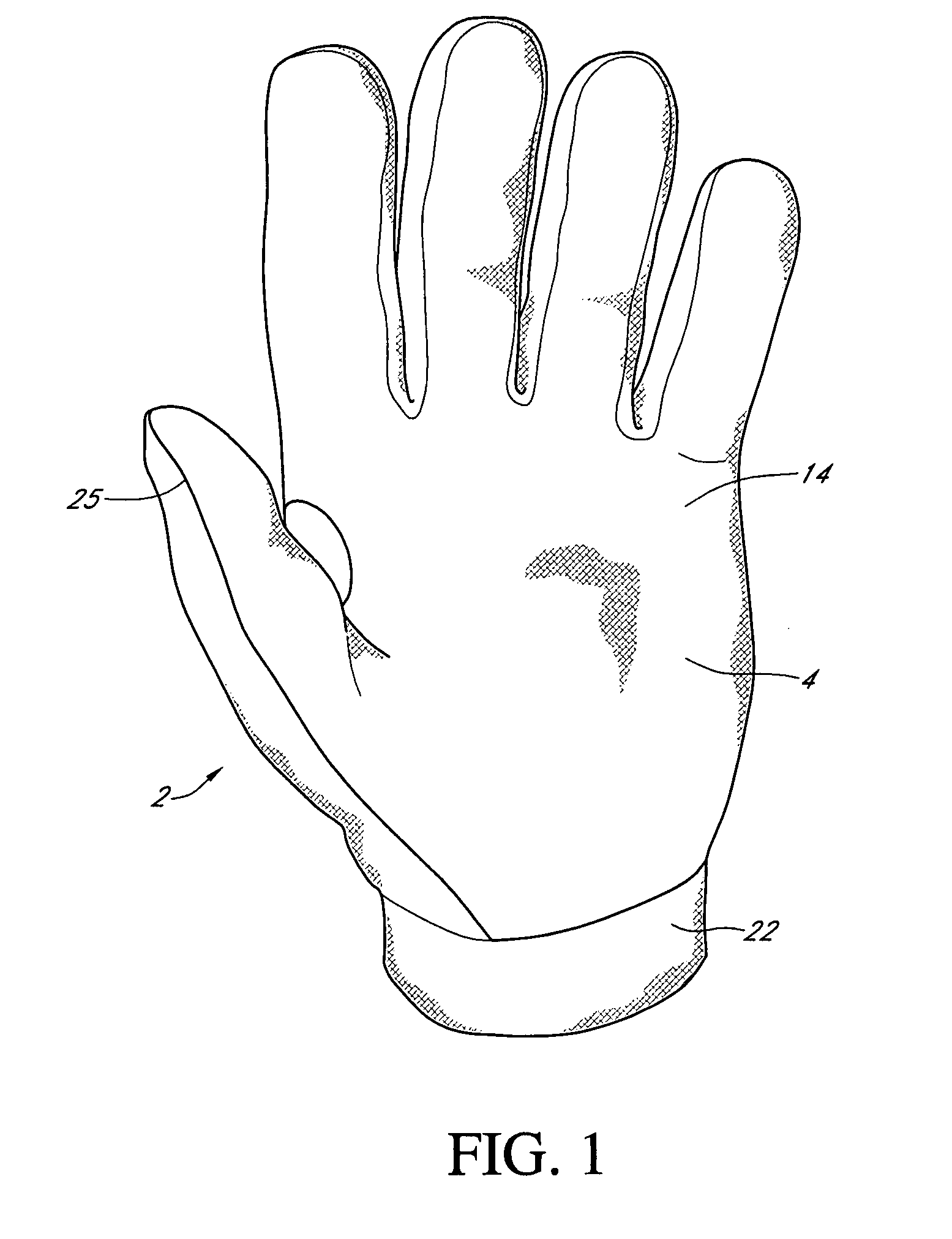

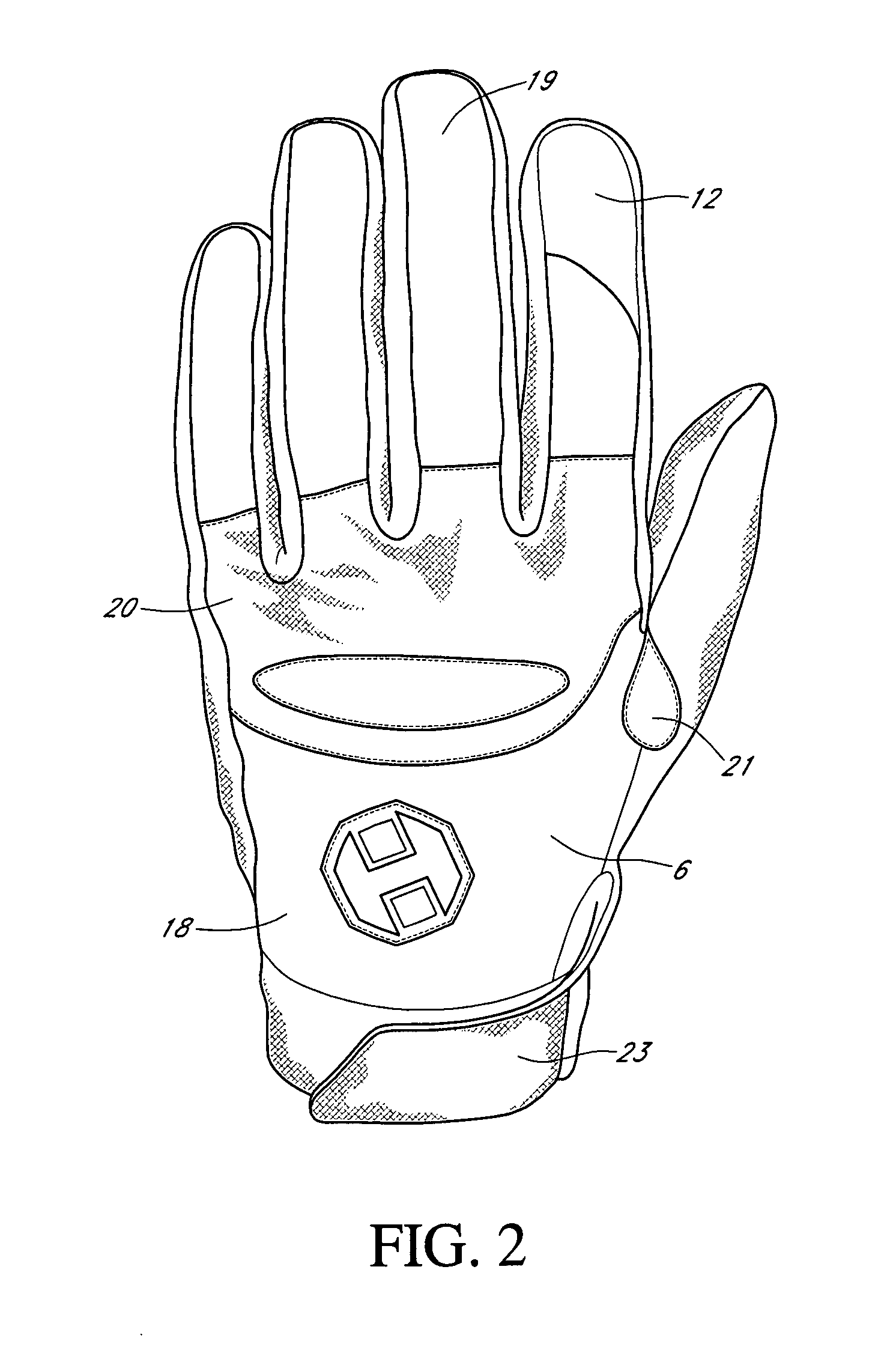

Glove with soft feel and high wear resistance

A glove used for roping steer and other animals such as in rodeo competition and ranching has a front side, which covers a wearer's palm and a palm side of the wearer's fingers, and a back side, which covers the wearer's hand and the back of the wearer's fingers. The front and rear sides of the glove are joined by thread. The front side is made of a woven fabric that has an outer layer of one hundred percent aramid fiber such as Kevlar®, and an inner layer of a woven and breathable fiber, the inner layer and outer layer being joined by glue. The fibers are preferably in yarn form. Both the inner and outer layer along with the glue have a weight of about 245 gm / m2 of material, plus or minus 50 gm / m2 of material. The wearer holds the rope having it rest on the middle finger and guides the rope with the index finger and thumb.

Owner:BITZER ROBERT

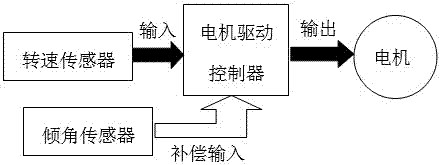

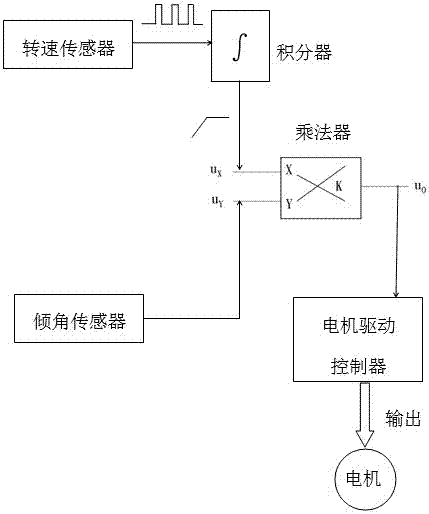

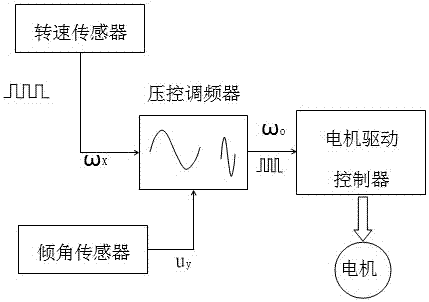

Moped speed induction type power-assisted control method

The invention discloses a moped speed induction type power-assisted control method which is used in the technical field of mopeds. According to the moped speed induction type power-assisted control method, based on an original speed induction type power-assisted control method, the inclined degree of the road surface is measured in real time by additionally arranging an inclined angle sensor, the output of the inclined angle sensor serves as the compensation input of a system, and thus the system has the capacity that different power-assisted output is achieved under the same speed and different road conditions, wherein the capacity is not achieved by the original speed induction type power-assisted control method; and power assistance is optimized, and experience and / or rising experience of a client are / is improved.

Owner:深圳前海优时科技有限公司

Regenerative braking method for vehicle having electric motor

ActiveUS7567042B2Feel the sameAvoid problemsDc motor stoppersAsynchronous induction motorsRegenerative brakeDrive wheel

A regenerative braking method for a vehicle having an electric motor. During an initial stage of a regenerative braking operation related to the vehicle having the electric motor, a flow rate of brake liquid as much as the amount of regenerative braking is delivered into a reservoir through opened exit valves of non-driving wheels, so as to generate a hydraulic braking force needed after subtracting the amount of regenerative braking from the amount of braking desired by a vehicle operator. When the amount of regenerative braking increases, exit valves of driving wheels are controlled to fulfill the total amount of braking desired by the vehicle operator. Also, when the amount of regenerative braking decreases, wheel pressures have to be increased to fulfill the vehicle operator's desire to brake. In the regenerative braking method for generating a residual amount of braking needed after subtracting the amount of regenerative braking, which corresponds to an amount generated by the electric motor, from the amount of braking desired by the vehicle operator, during the regenerative braking operation, based on a pressure difference between a pressure in the master cylinder and wheel pressures, entrance valves of the driving wheels are controlled to realize an operator's pedal feeling, and the exit valves of the driving wheels are controlled to allow the wheel pressures to follow a target pressure.

Owner:HL KLEMOVE CORP

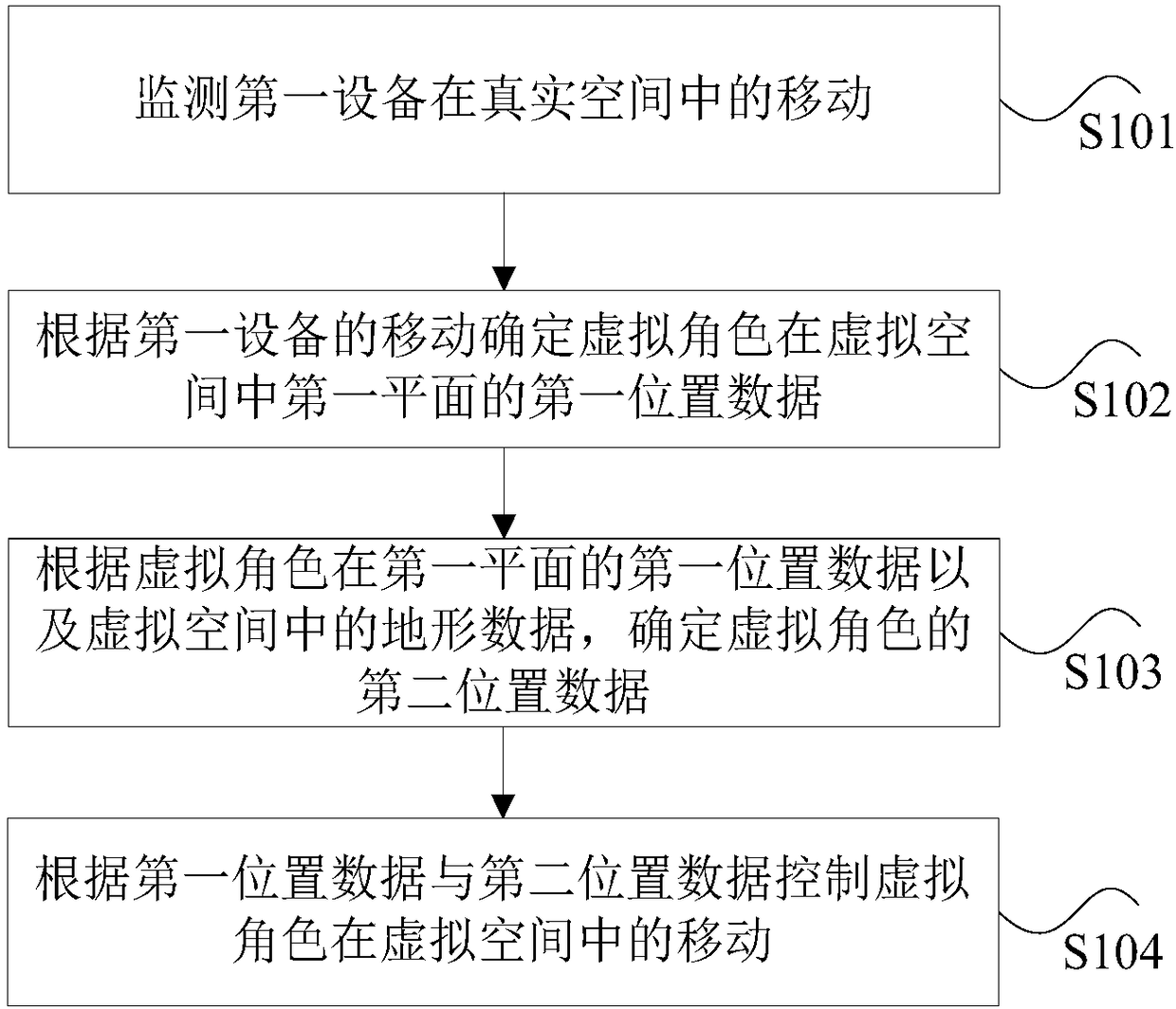

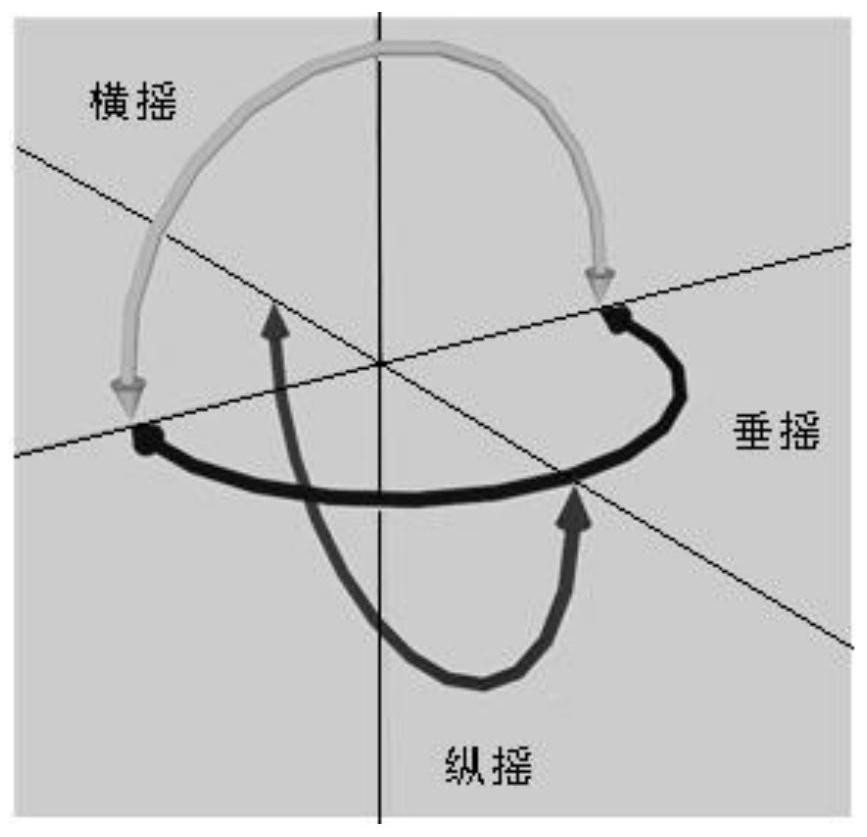

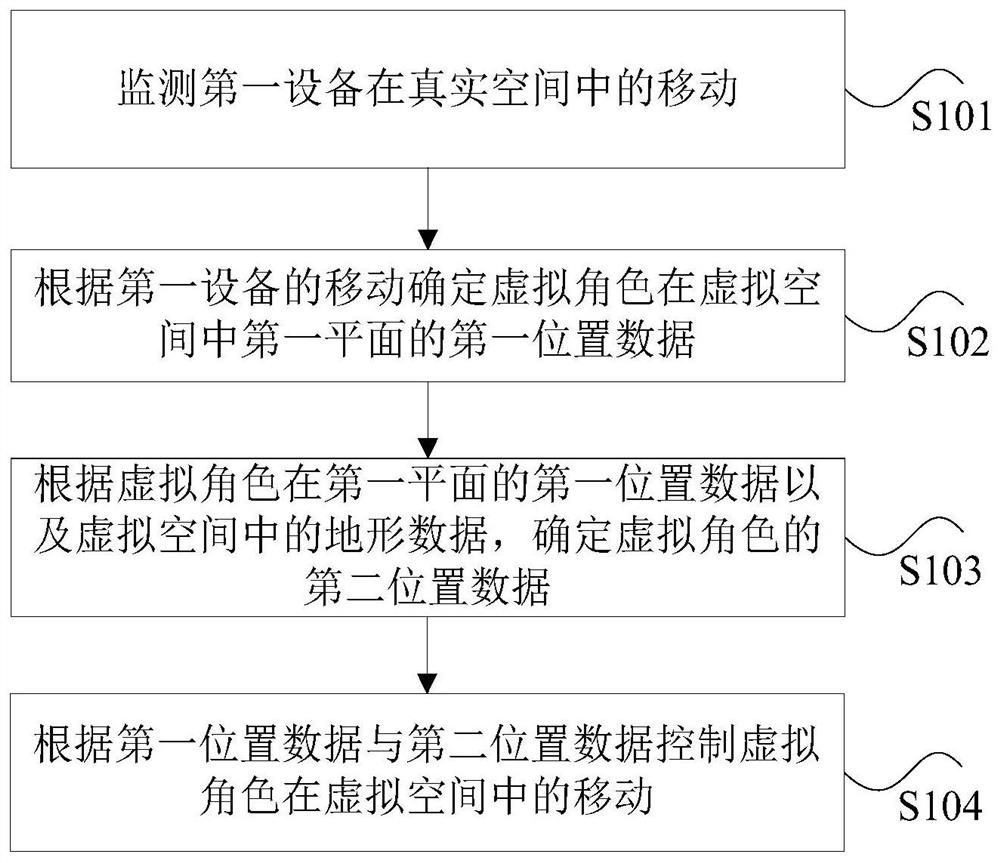

Mobile control method and apparatus in virtual reality

ActiveCN108427501AImprove immersionSolve the problem of low experienceInput/output for user-computer interactionGraph readingTerrainVirtual space

The invention discloses a mobile control method and apparatus in virtual reality. A virtual space in virtual reality includes a virtual character. The method includes the steps of monitoring the movement of a first device in a real space; determining, according to the movement of the first device, first location data of the virtual character in a first plane the in the virtual space; determining second location data of the virtual character according to the first location data of the virtual character in the first plane and terrain data in the virtual space, wherein the second location data includes height data of the virtual character relative to the first plane; and controlling the movement of the virtual character in the virtual space according to the first location data and the secondlocation data. Through the mobile control method and apparatus in virtual reality, the problems that a target object is likely to cause dizziness in the moving process in the virtual space and the user experience is low are solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

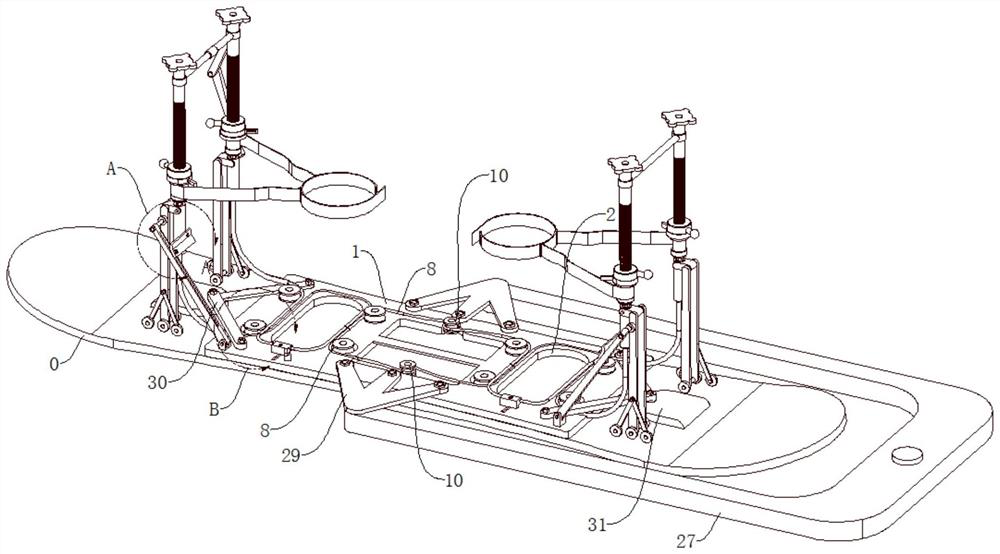

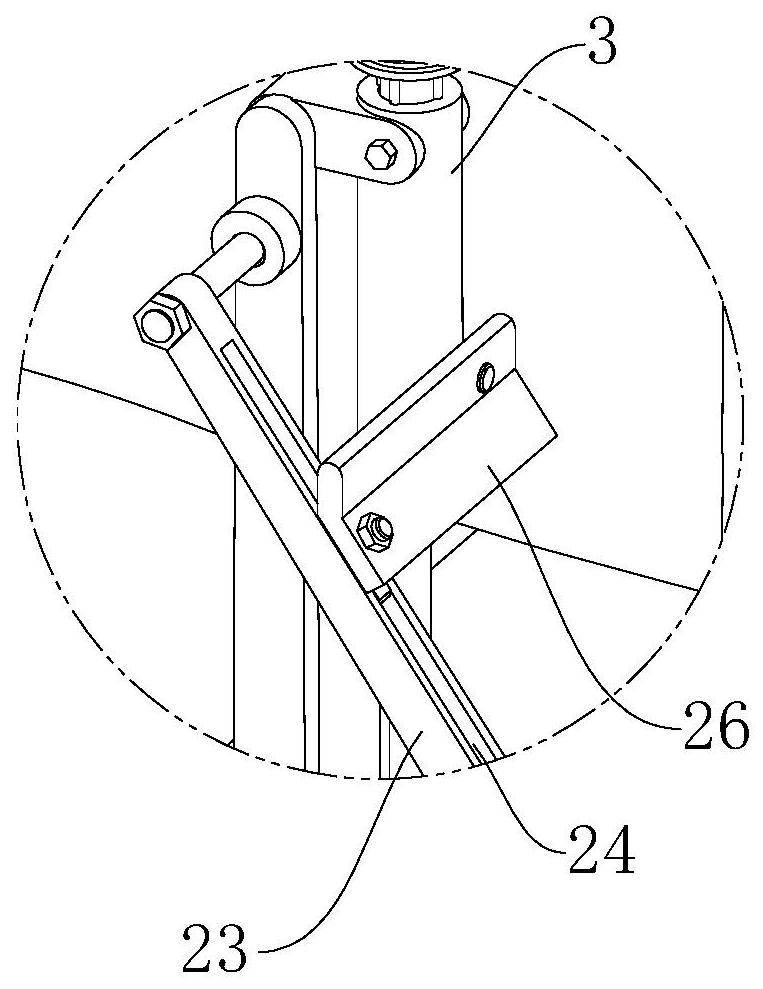

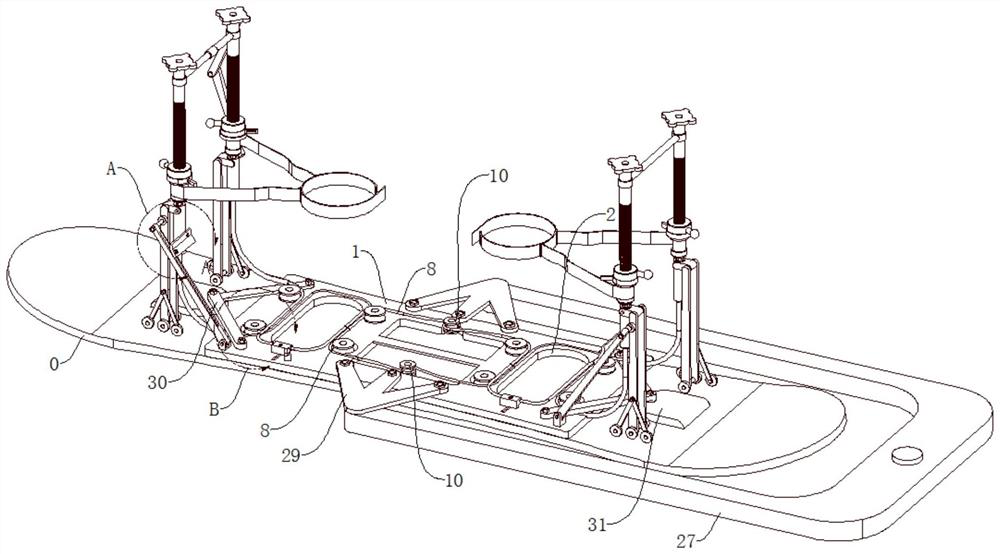

Gravity center auxiliary stabilization teaching aid for single-board skiing

The invention relates to the technical field of skiing equipment, in particular to a gravity center auxiliary stabilizing teaching aid for single-board skiing, which comprises a skateboard body, two skateboard boots are symmetrically arranged on the skateboard body, a teaching aid board is detachably mounted at the top of the skateboard body, and avoiding grooves for avoiding the skateboard boots are formed in the teaching aid board, a traction mechanism is arranged outside each of the two ends of the teaching aid plate, the two traction mechanisms are elastically connected with the teaching aid plate through first elastic components, the two traction mechanisms can move in the same direction or back to back, and a grabbing mechanism capable of being vertically and movably adjusted is arranged in the upper area of each traction mechanism, and a detachable boosting mechanism is arranged at the tail part of the skateboard body. The skiing trainer can stably assist a beginner in skiing exercise, the falling frequency is reduced, and abandoning caused by too high difficulty in the early stage is prevented.

Owner:HARBIN INST OF PHYSICAL EDUCATION

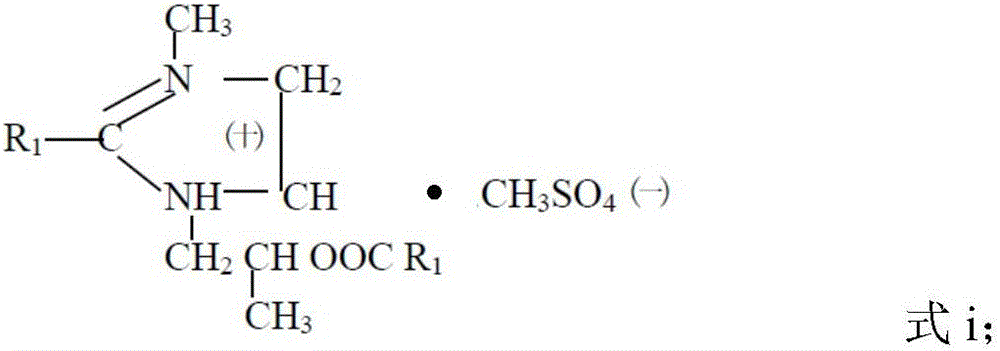

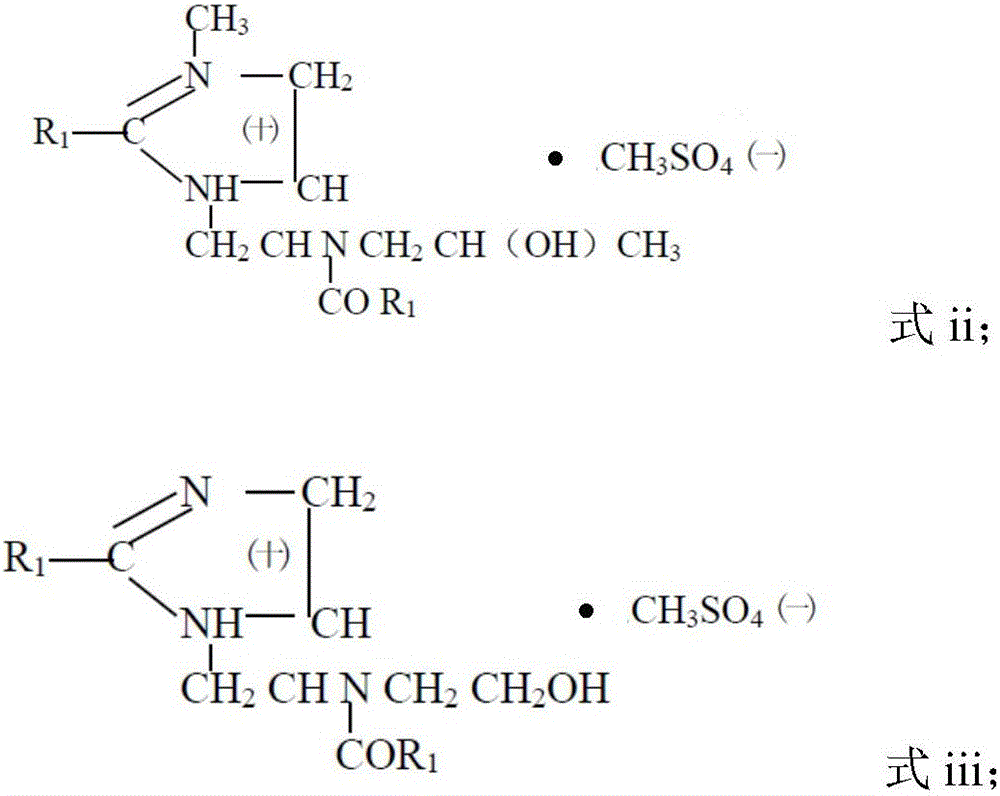

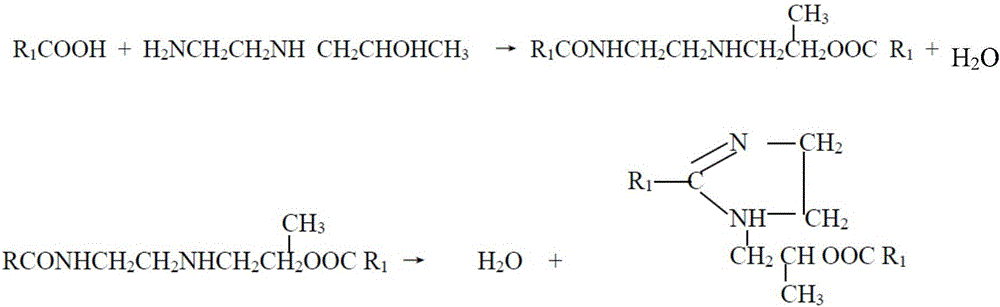

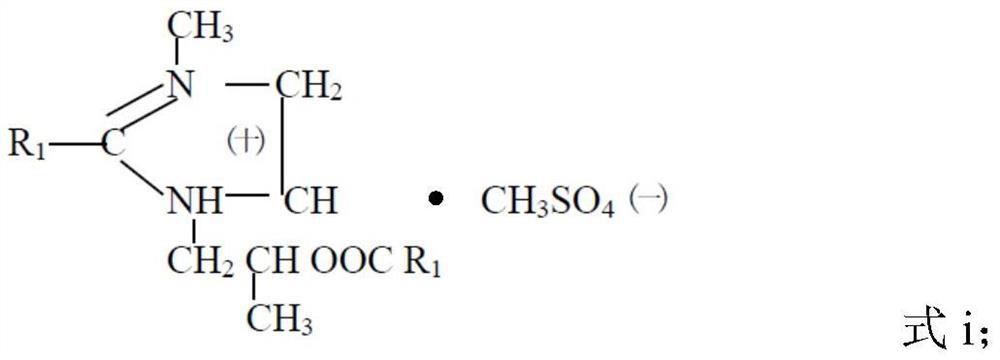

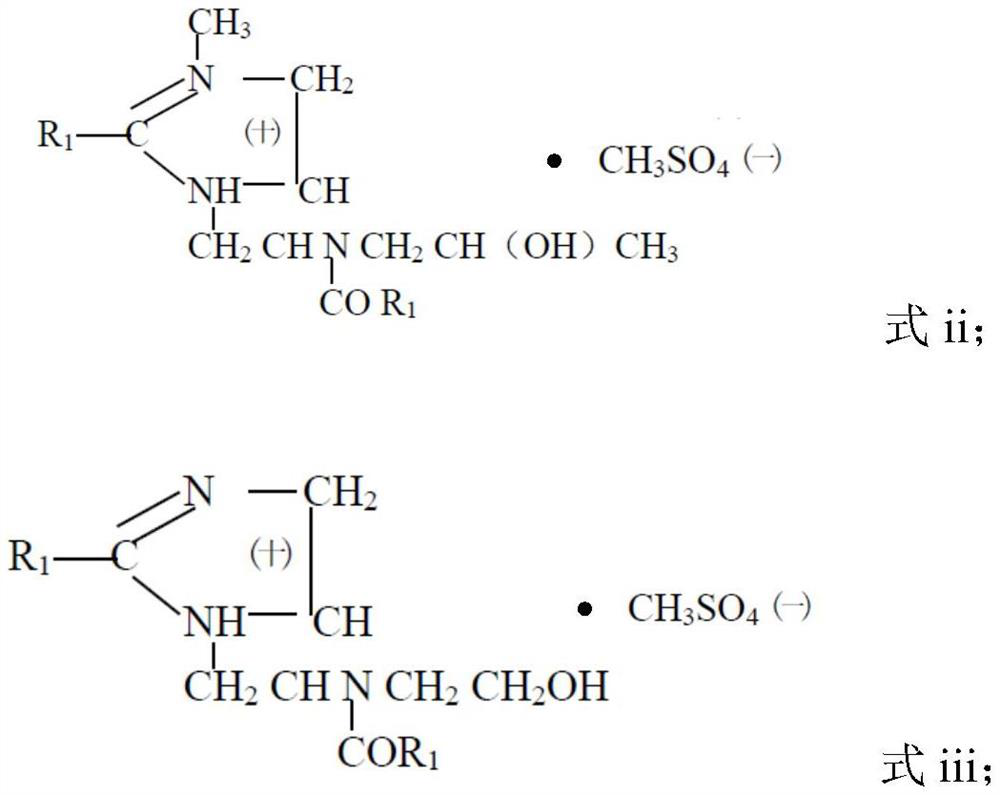

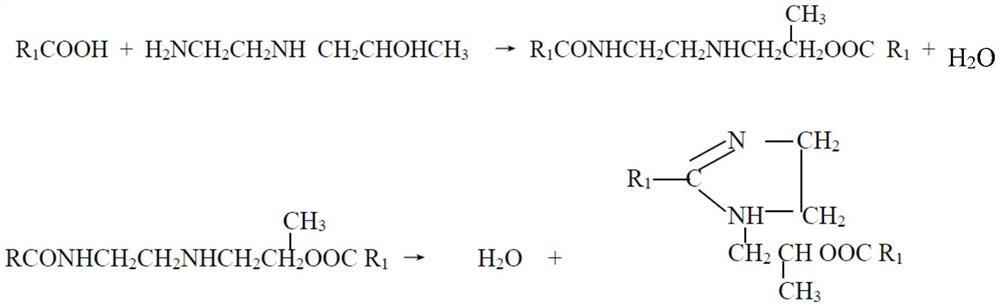

Environment-friendly softening agent and preparation method thereof

ActiveCN106758211AReduce yellowingIncrease steric hindranceOrganic chemistryLight resistant fibresEthylenediamineNitrogen atmosphere

The invention provides an environment-friendly softening agent which is used for hand feeling finishing of fabric. The softening agent is a product obtained through the following steps: dehydrating raw materials: organic amine and fatty acid in nitrogen atmosphere with phosphorous as a catalyst at the temperature of 180-200 DEG C and then dehydrating under the vacuum condition at the temperature of 200-240 DEG C; and finally, performing quaterisation and acidification. According to the invention, the softening agent, which has good hand feeling and low yellowing performances consistent with those of a softening agent commonly used at present, can be obtained by replacing a raw material: AEEA (aminoethylethanolamine) of the softening agent commonly used at present with a series of organic amine such as hydroxy-propyl-ethylenediamine and the like under the condition that the molar ratio is not changed, so that the environment and health problems caused by AEEA can be solved.

Owner:苏州联胜化学有限公司

High-flow EPDM material and preparation method thereof

The invention relates to a high-flow EPDM material and a preparation method thereof. The material is prepared from the following raw materials in percentage by weight: 0 to 30 percent of polypropylene; 40 to 80 percent of EPDM; 1 to 5 percent of compatilizer; 5 to 15 percent of SEBS; 5 to 30 percent of white oil; and 0.1 to 0.5 percent of antioxidant. The preparation method comprises the following steps: weighing the raw materials in percentage by weight; putting the SEBS and the white oil in a high mixing machine for uniformly mixing, then adding other raw materials into the mixture for mixing for 2 to 5 minutes, discharging the obtained product; and putting the raw materials which are uniformly mixed in a screw machine to carry out extrusion granulation. The method and the material are characterized in that: the prepared EPDM material is granules; not only the hardness can be adjusted, but also the fluidness is obviously superior to that of the common EPDM material; and the EPDM material prepared by the method has almost the same appearance and handfeel as the commercial grade EPDM material and can be directly injected into the finished product.

Owner:SHANGHAI SUNNY

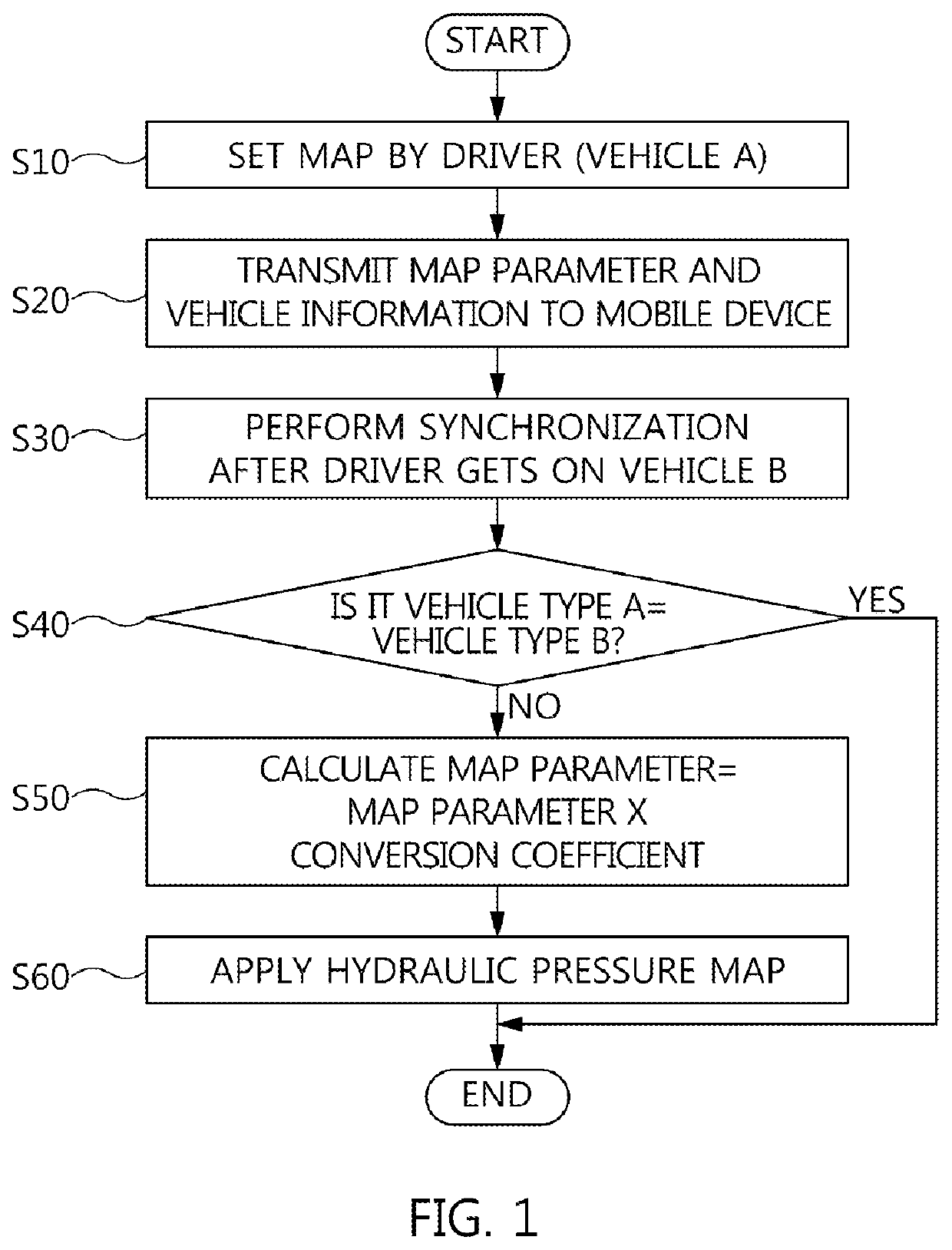

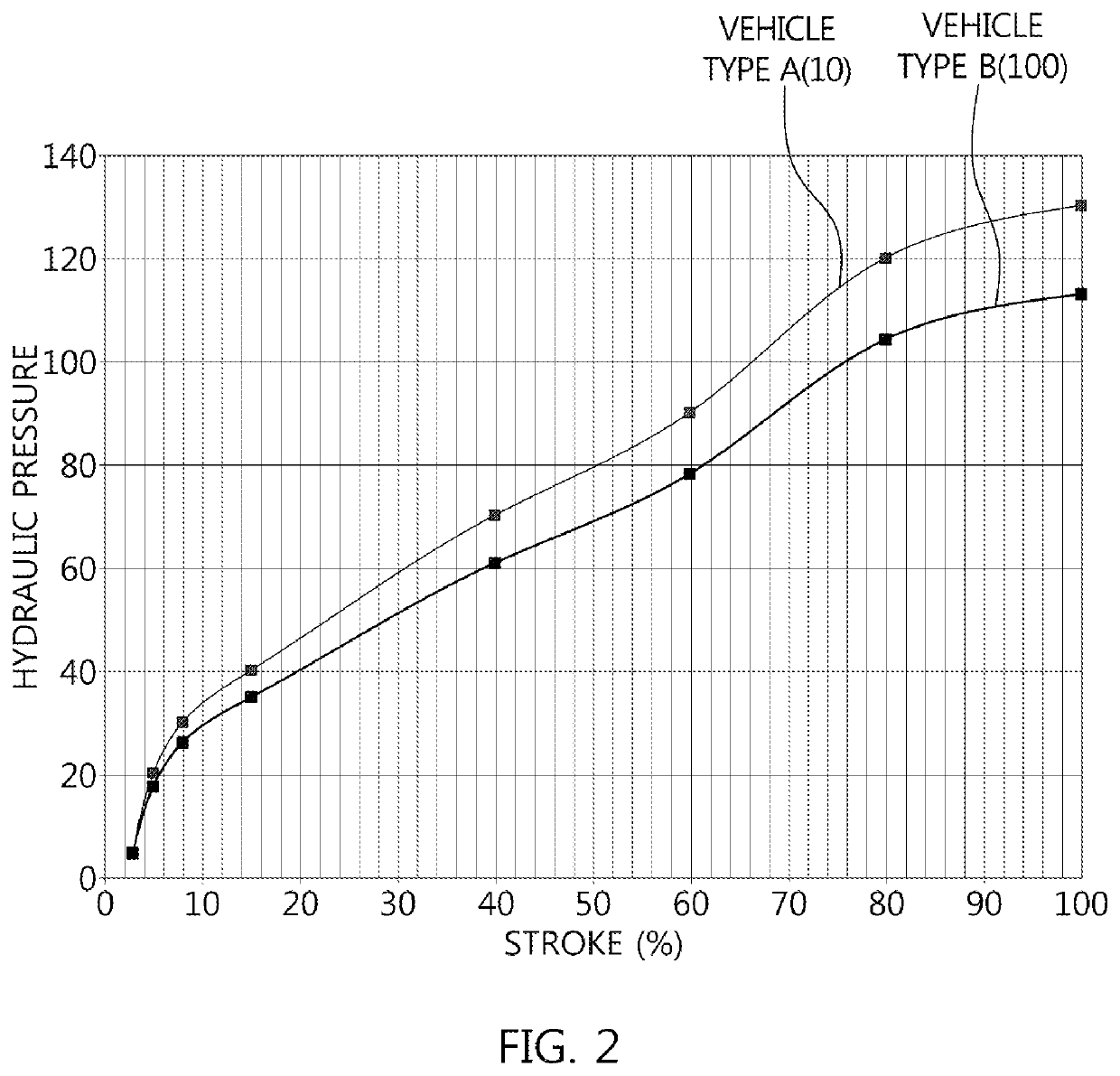

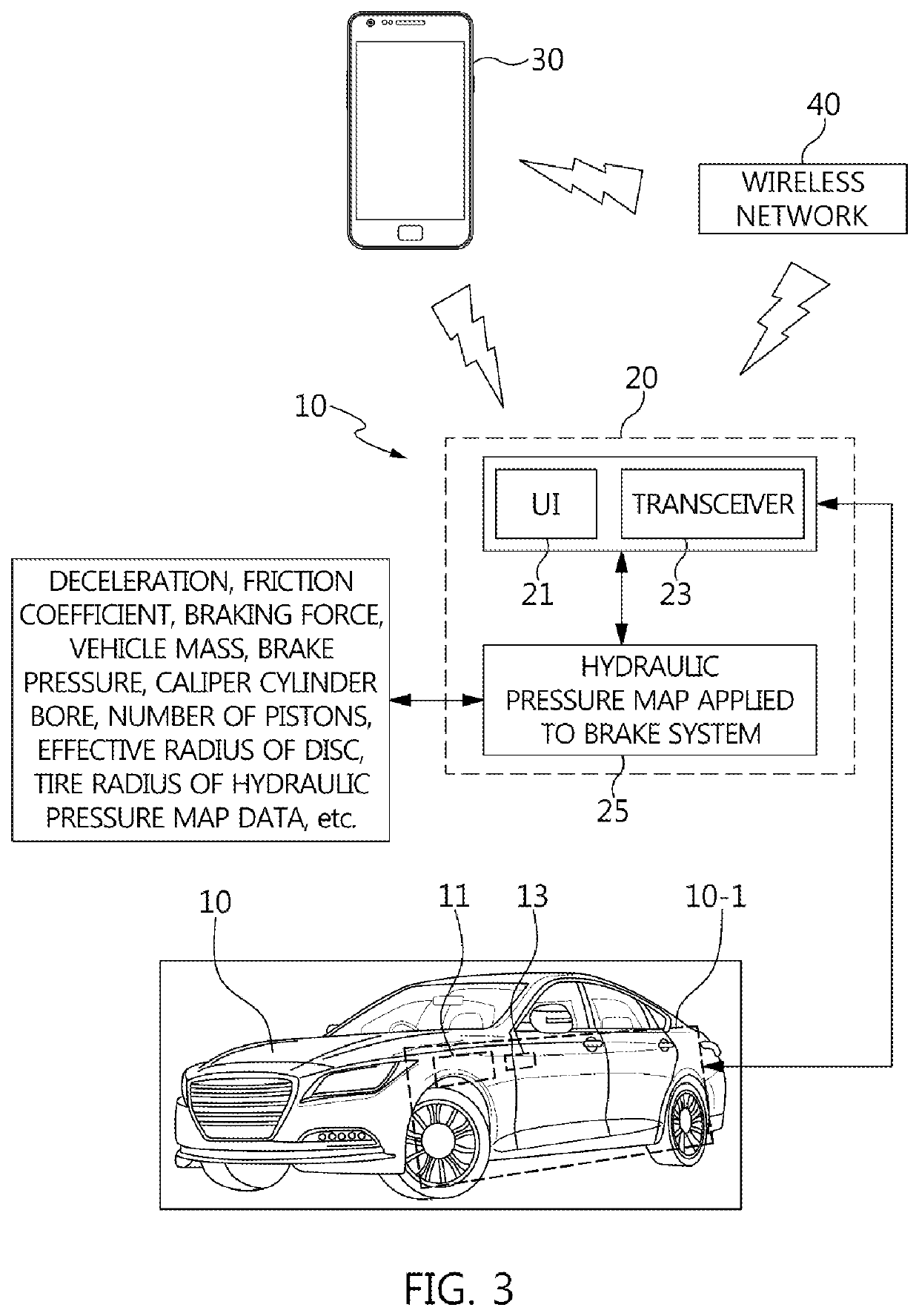

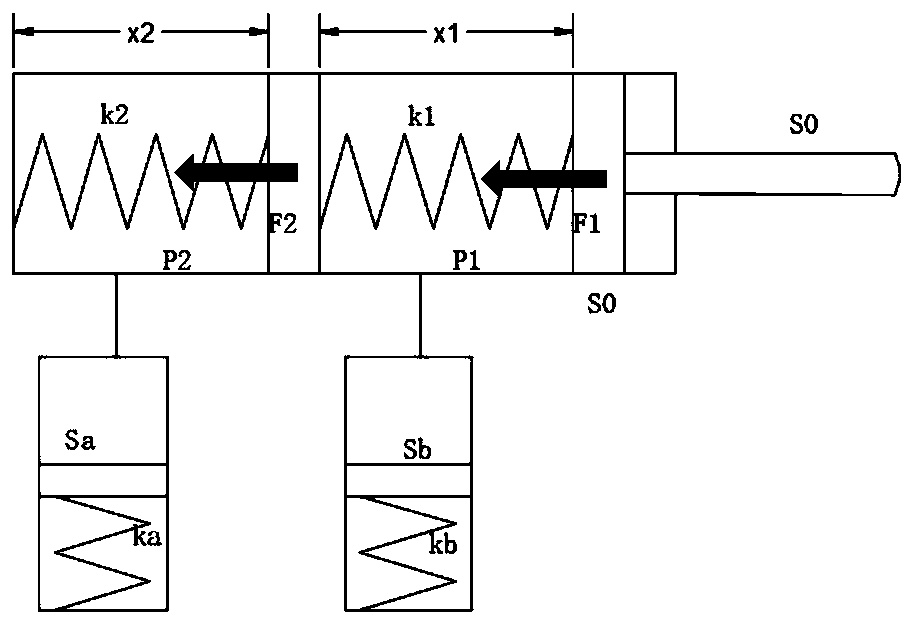

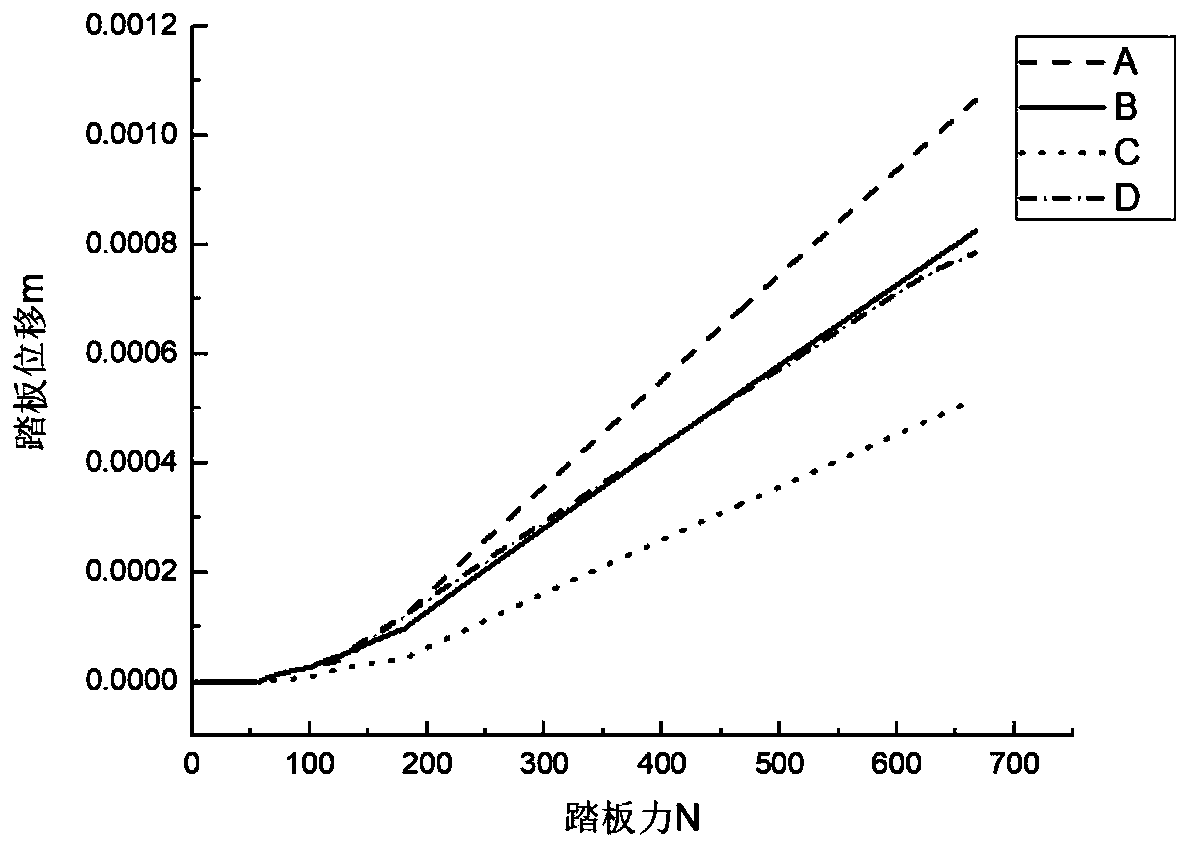

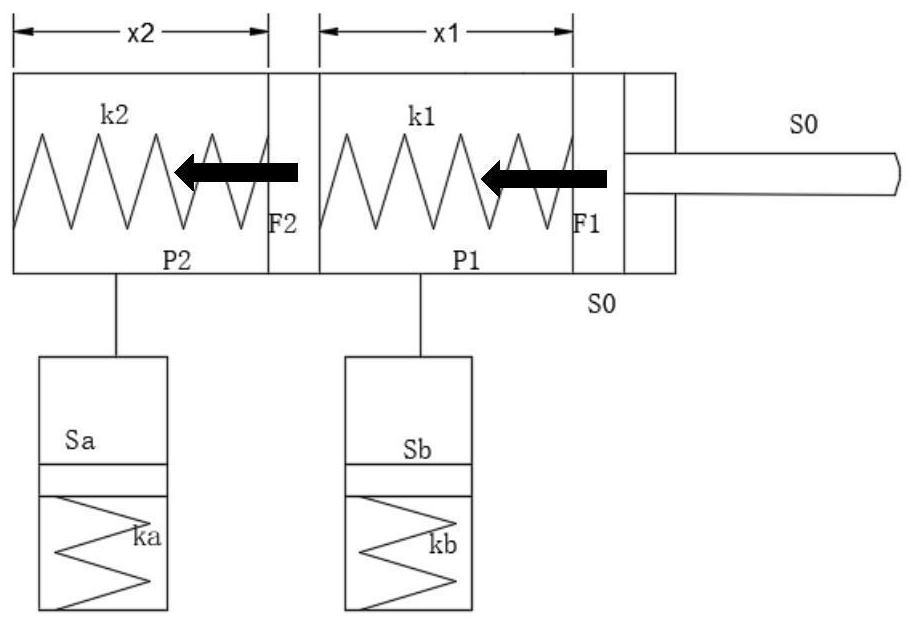

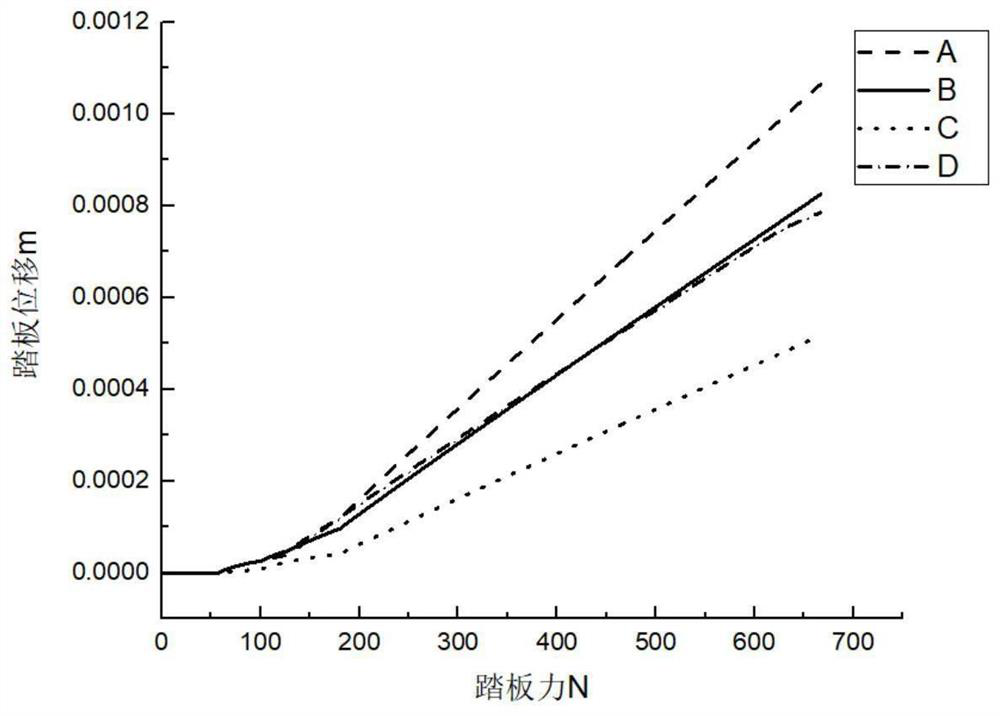

Advance driver brake customizing method and system thereof

ActiveUS20200262402A1Feel the sameParticular environment based servicesVehicle sub-unit featuresDriver/operatorControl engineering

An advance driver brake customizing method applied to a brake customizing system is provided to identically implement a braking feeling set according to a driver's vehicle regardless of a vehicle type by transplanting driver braking feeling information of a driver's vehicle into a braking feeling matching vehicle. A braking characteristic of a brake of a brake system, which is applied to the braking feeling matching vehicle, is directed to follow the braking characteristic of a brake of the brake system, which is applied to the braking feeling matching vehicle, through driver matching control in conjunction with a wireless network. In particular, even when the same driver changes a vehicle or a driver for the same vehicle is changed, the same braking feeling is maintained.

Owner:HYUNDAI MOTOR CO LTD +1

Method for spray coating of crackle lacquer

InactiveCN100581658CImprove adhesionSame adhesionPretreated surfacesArtistic surface treatmentPolymer scienceCrazing

The invention relates to a method for plating crack paint, which comprises a, plating the polypropylene bottom paint on the surface of product made from modified polypropylene material, the bottom paint can be grey, black, or grey-white bottom paint; b, drying said bottom paint and plating the acroleic acid bottom paint that diluted by dimethylbenzene solvent, drying; c, plating the polypropylene crack paint diluted by the crack solution on the acroleic acid bottom paint, drying; d, plating the polyurethane paint diluted by polyurethane solvent and added with solidifier on the polypropylene crack bottom, and drying. The invention has low cost.

Owner:BYD CO LTD

Mute equipment capable of controlling a breath pressure and an adapter thereof

ActiveUS20180033415A1Impact tone interval toneImpact tone tone qualityOcarinasWind instrumentControl of respiration

Owner:OFFICE ITSUKI AGENCY CO LTD

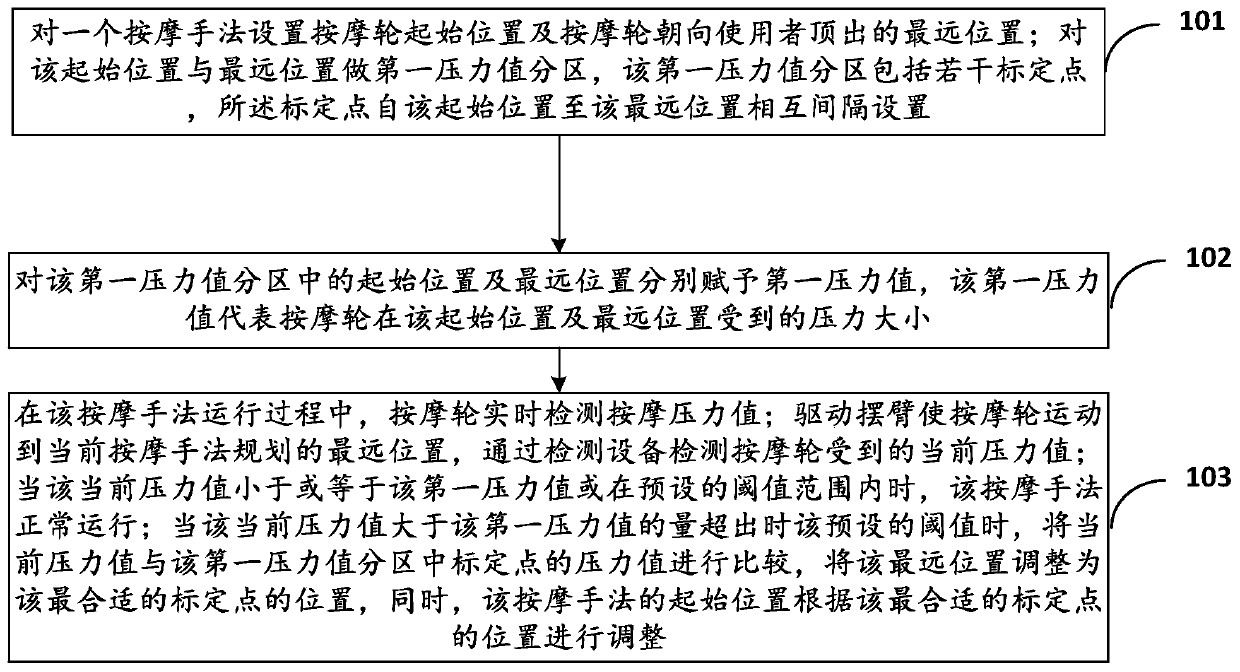

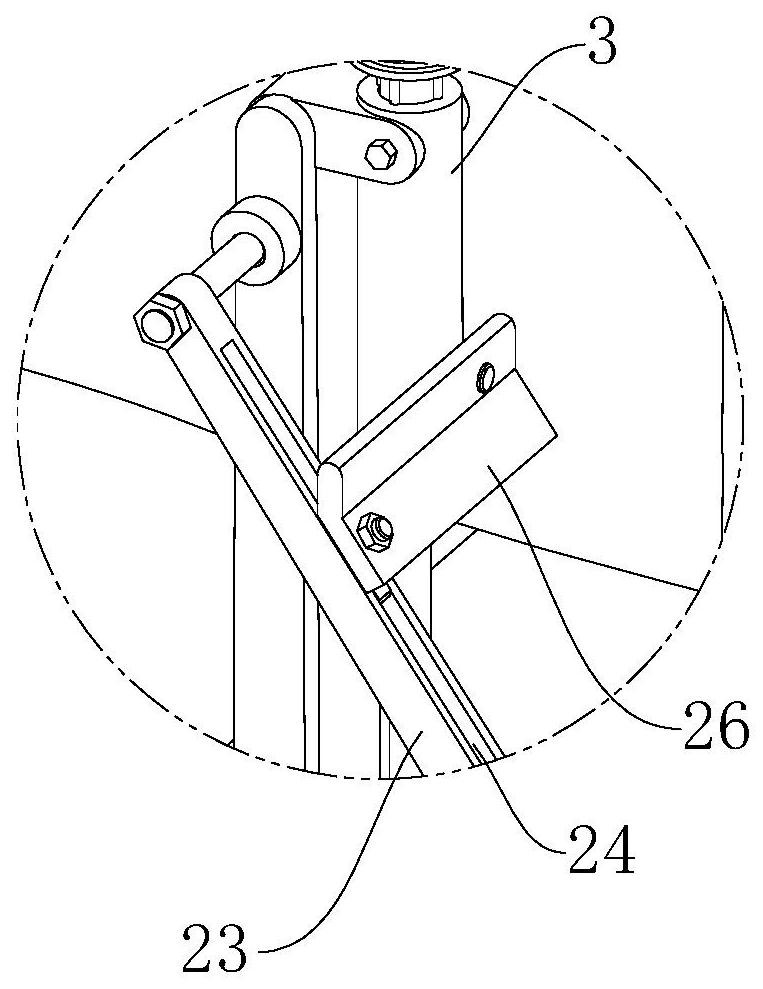

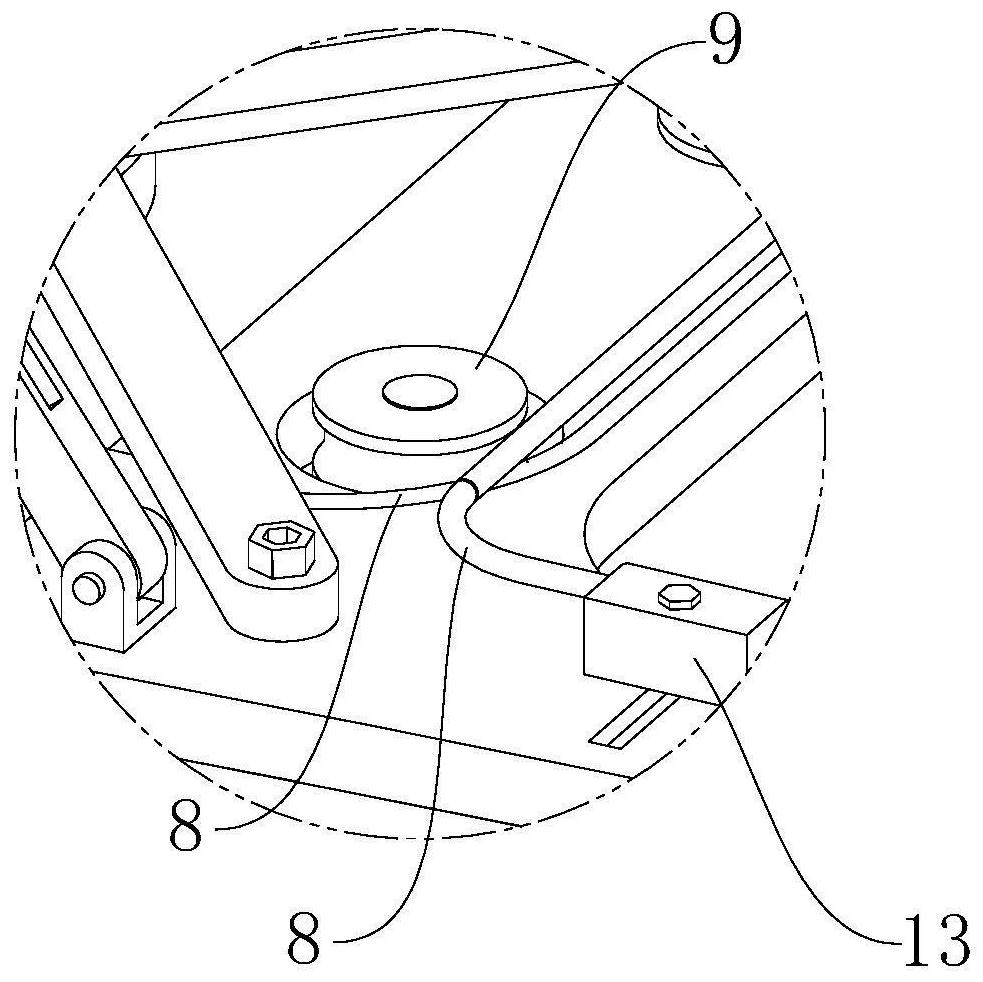

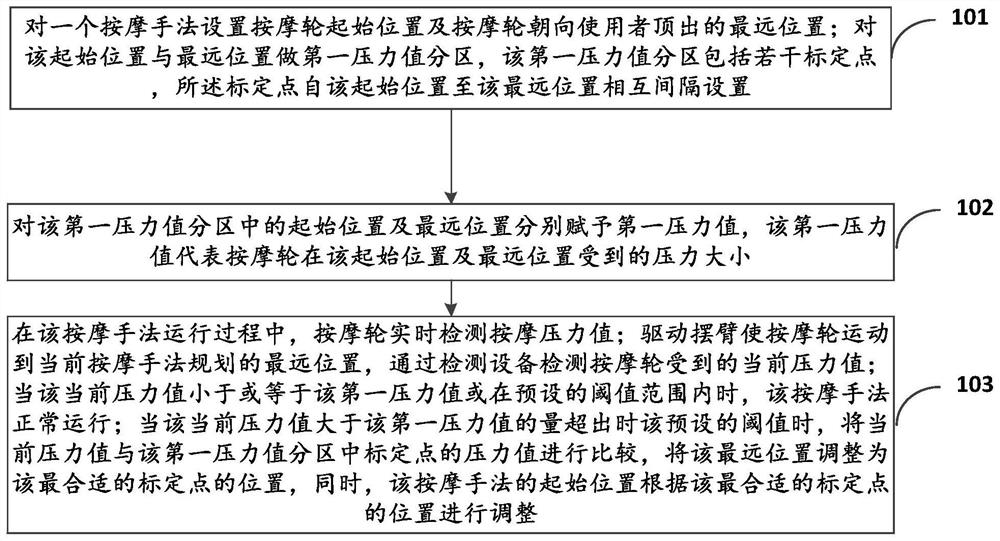

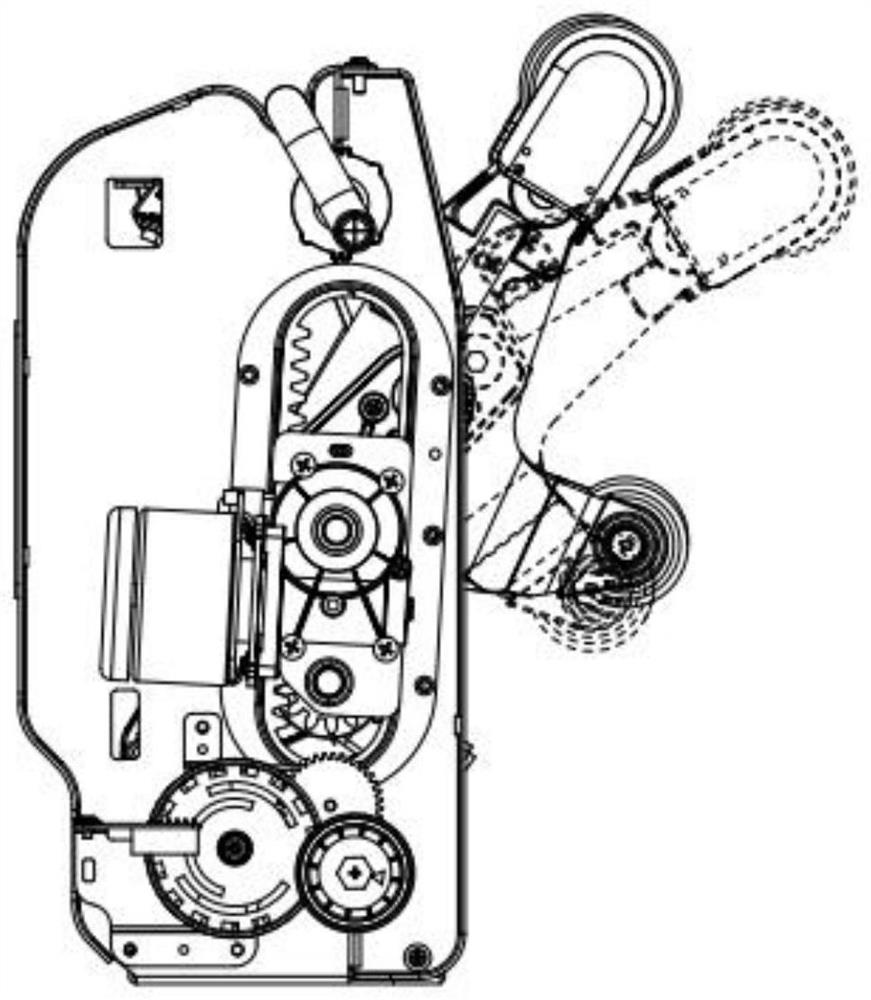

Massage manipulation force self-adapting method

The invention discloses a massage manipulation force self-adapting method. According to the massage manipulation force self-adapting method, the change of a pressure value of a massage wheel is detected; when the exceeding amount of the current pressure value to a first pressure value is determined to be larger than a preset threshold value, the current pressure value is compared with the pressurevalue of a marked point in a first pressure value partition, the farthest position is adjusted to be the position of a most appropriate marked point, and meanwhile, the initial position of the massage manipulation is adjusted according to the position of the most appropriate marked point, so that accuracy of massage action is improved, and experience of a force self-adapting user is better. In addition, when the user adjusts the sitting posture, self-adaptive adjusting can be carried out according to the adjusted sitting posture, and consistent body feeling is kept.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD

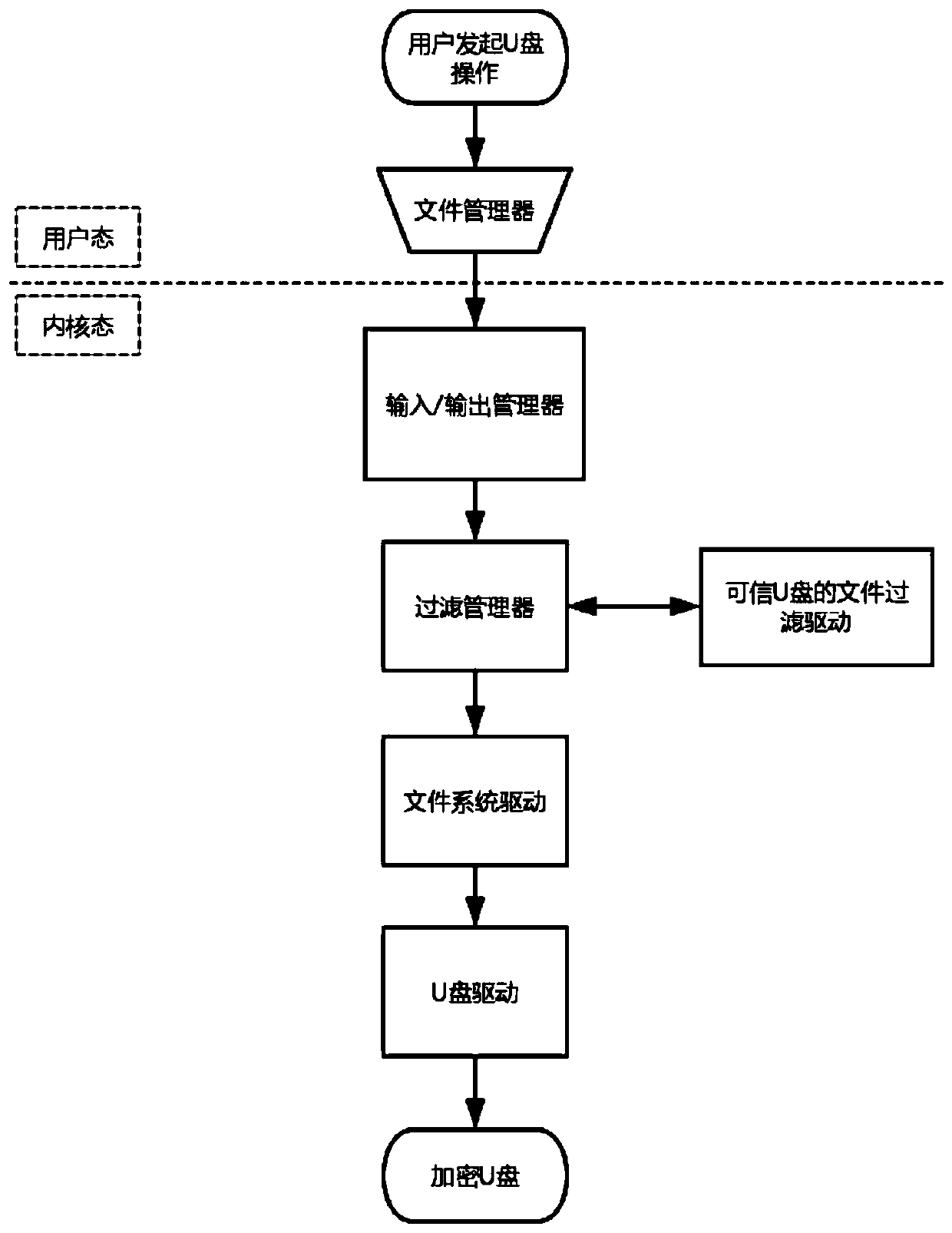

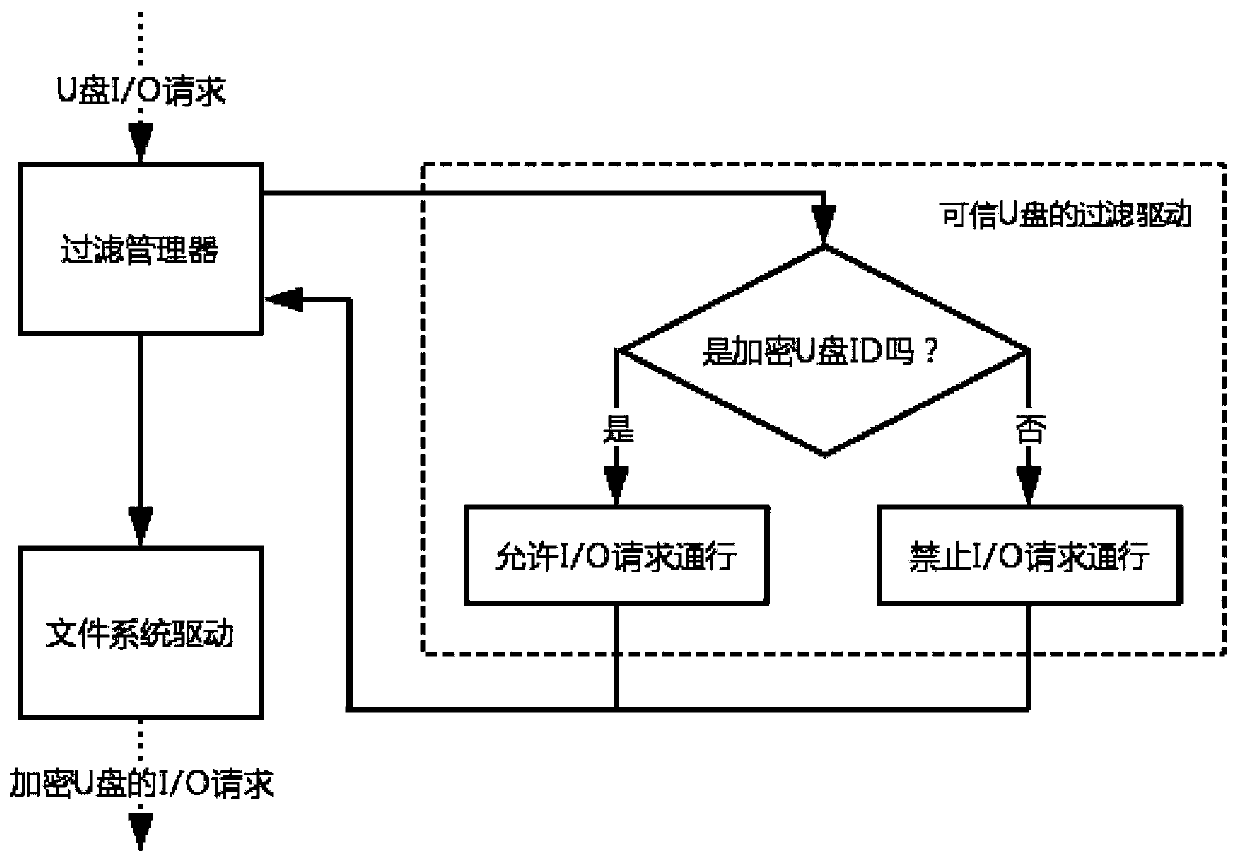

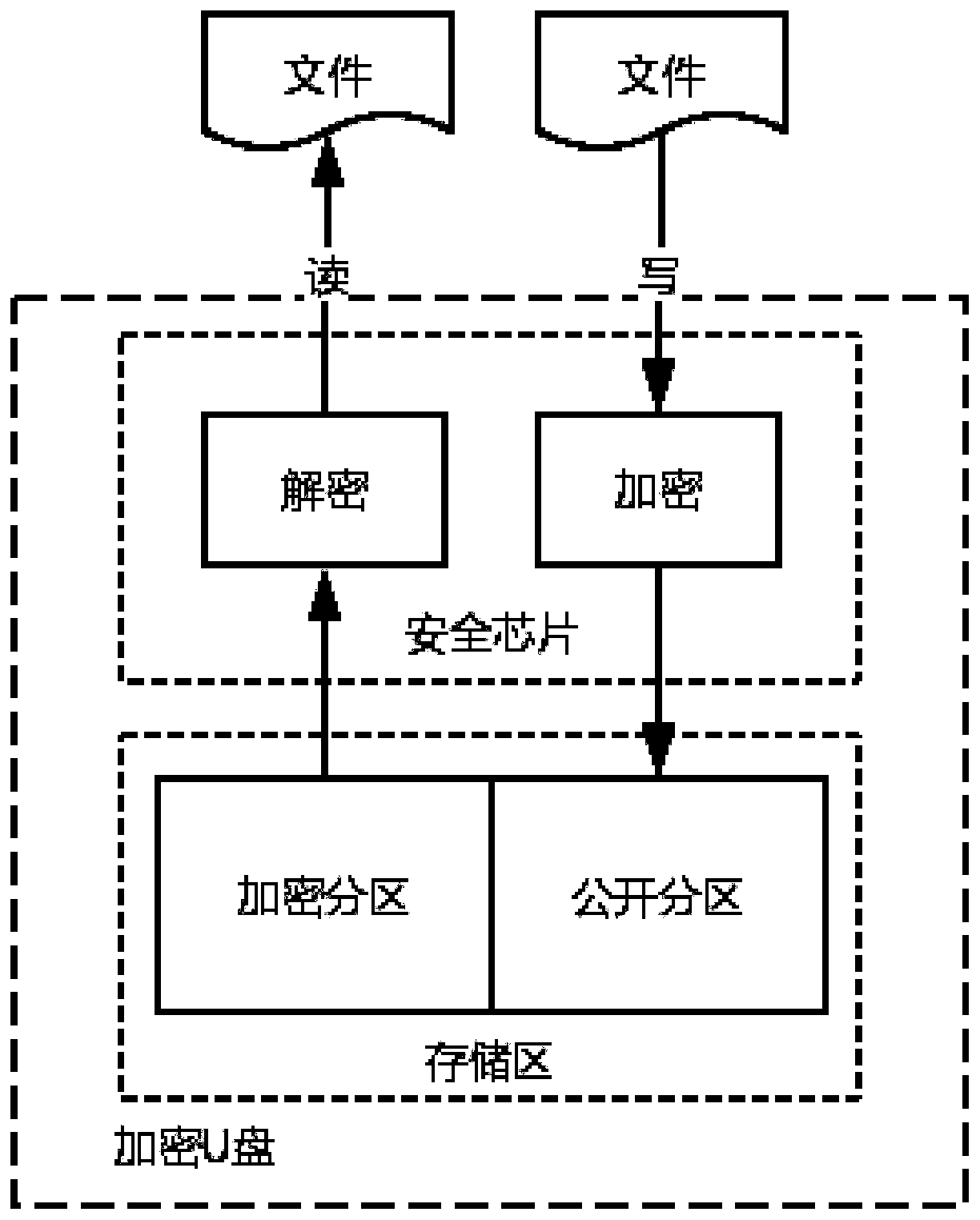

Credible USB flash disk implementation method based on file filtering driver

InactiveCN110096910ADisable read and write accessEasy accessInternal/peripheral component protectionOperational systemConfidentiality

The invention discloses a credible USB flash disk implementation method based on a file filtering driver, which comprises the following steps that: S1, a user initiates a USB flash disk operation, andan access request of the user to the USB flash disk is forwarded to a kernel layer by a Windows operating system and is intercepted by an input / output manager; s2, the input / output manager activatesa filtering manager according to the intercepted request type, and loads and calls a corresponding file filtering driver to process the request; s3, after receiving the passing message, the filteringmanager forwards the USB flash disk access request to a file system driver at a lower layer for further processing, so that access to the authorized encrypted USB flash disk is allowed; on the contrary, if it is detected that the ID is not matched, further issuing of the input and output request is stopped in the filtering driver, and therefore read-write access to the unauthorized USB flash diskis forbidden. According to the invention, only the designated computer is allowed to access the designated USB flash disk in an environment requiring high data confidentiality.

Owner:北京天地和兴科技有限公司

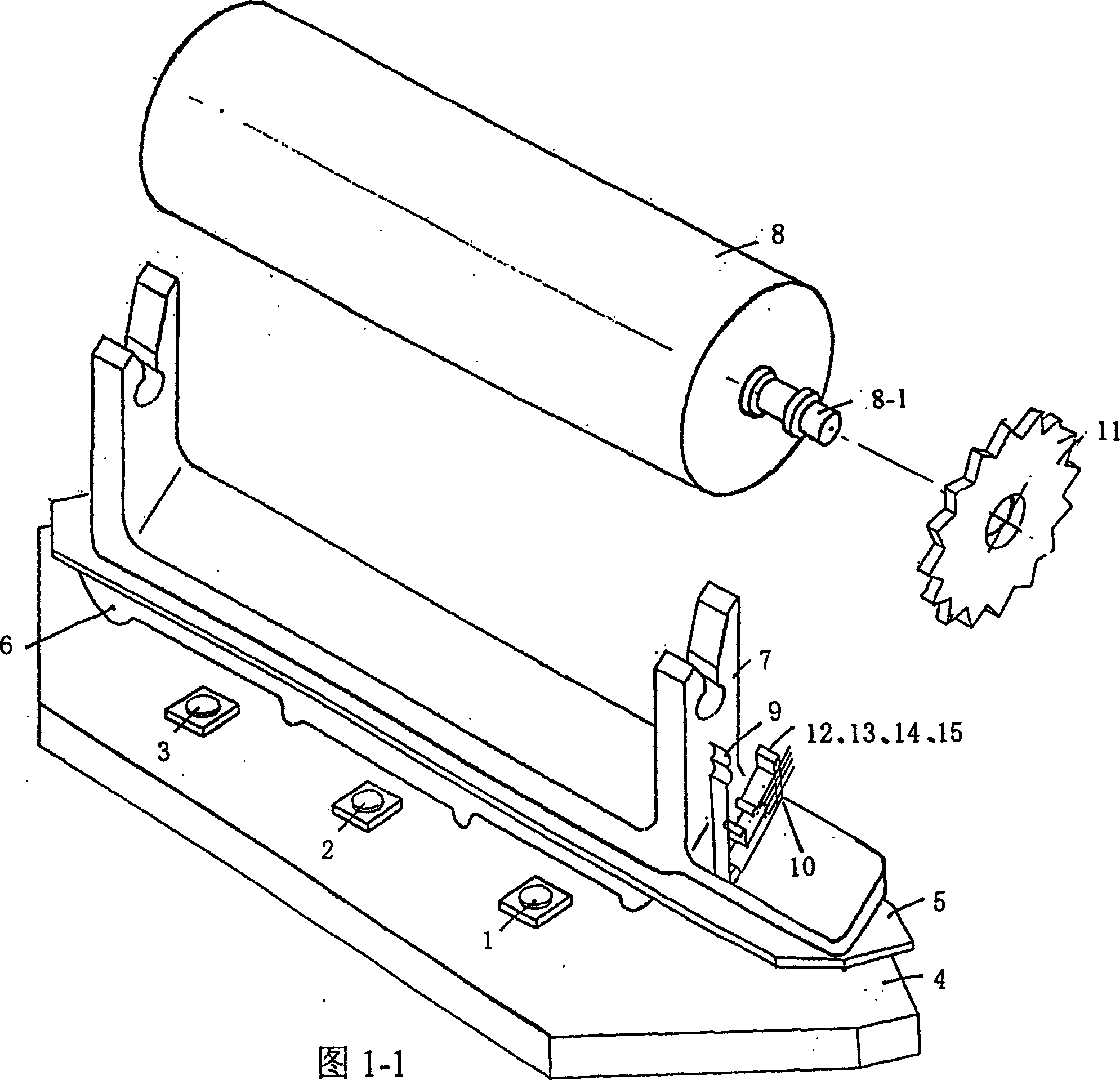

Information input set-up method and device

InactiveCN1194283CTake full advantage of the interactive featuresQuick feedbackInput/output for user-computer interactionElectrical impulseRotation sensor

An information input method and device for the electronic equipment containing processor, memory and display screen is characterized by that a roller-shaped knob is used, pressing the left, right and middle of said roller-shaped knob can trigger 2-3 hidden keys, and turning the knob can generate and electric pulse sequence by a rotation sensor. Said key signals and said electric pulses can be combined.

Owner:张海舡

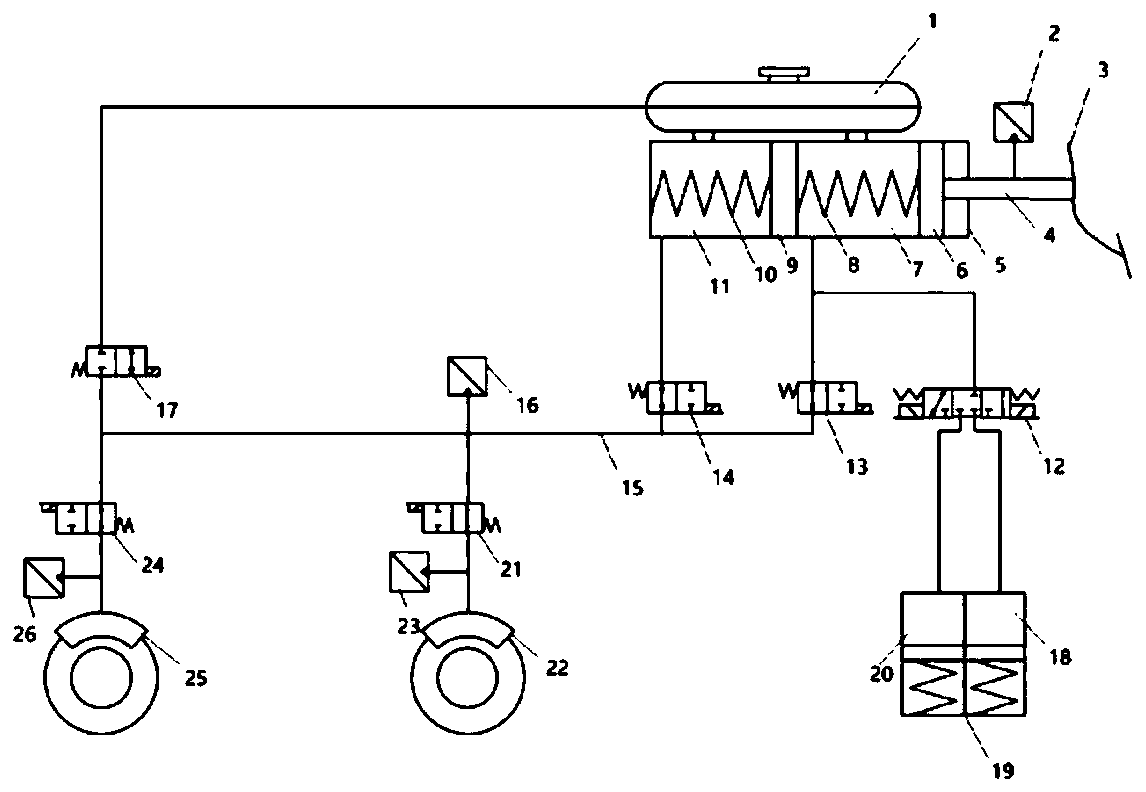

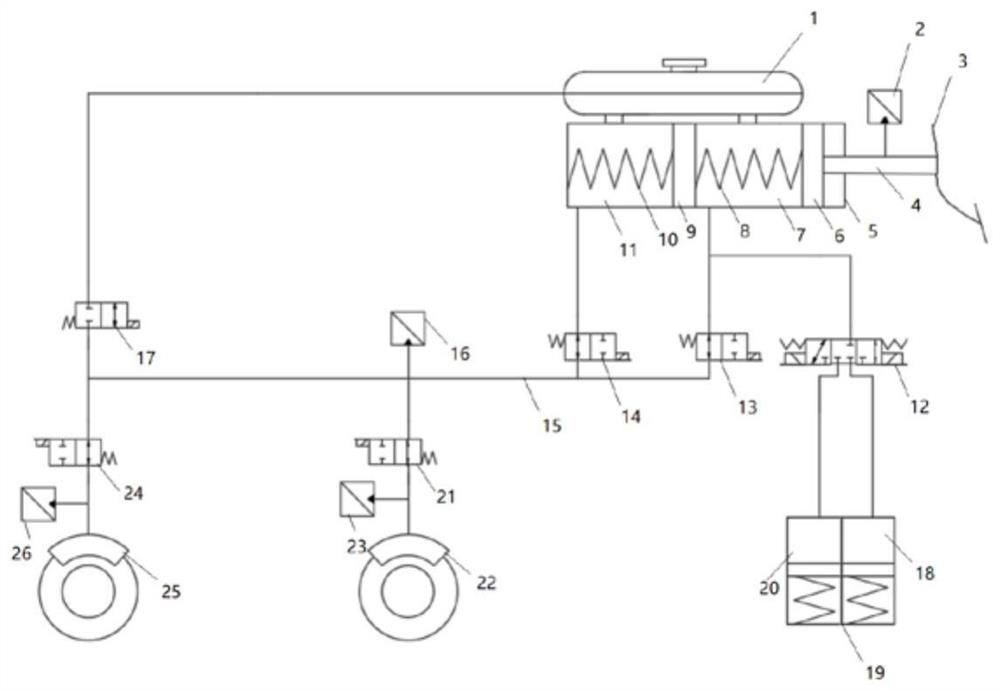

Hybrid braking system of electric wheel automobile and control method thereof

ActiveCN111231910ASimple structureIncreased unsprung massBraking action transmissionFoot actuated initiationsDrive wheelEngineering

The invention discloses a hybrid braking system of an electric wheel automobile and a control method thereof. The invention relates to the field of electric automobile brake systems. According to thehybrid braking system of the electric wheel automobile, on the premise that safety is guaranteed and the general braking function requirement of the electric automobile is met, the structure is simplified. The hybrid braking system comprises a hydraulic braking subsystem and a motor braking subsystem. The hydraulic brake subsystem comprises an oil storage cup, a brake pedal mechanism, a brake master cylinder, a pedal simulator, a public pipeline, a right brake wheel cylinder and a left brake wheel cylinder. The motor braking subsystem comprises a control unit and a pair of driving motors connected to the pair of driving wheels, the pair of driving motors are controlled through the control unit, and therefore the driving force and the braking force of the pair of driving wheels are adjusted. According to the system, the maximum total brake pressure requirement can be ensured. And the brake pedal feelings can be ensured to be consistent under different brake modes such as low-adhesion road surfaces, high-speed vehicle conditions and medium-low-speed vehicle conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of environment-friendly softener and preparation method thereof

ActiveCN106758211BReduce yellowingIncrease steric hindranceOrganic chemistryLight resistant fibresPhosphorous acidPtru catalyst

Owner:苏州联胜化学有限公司

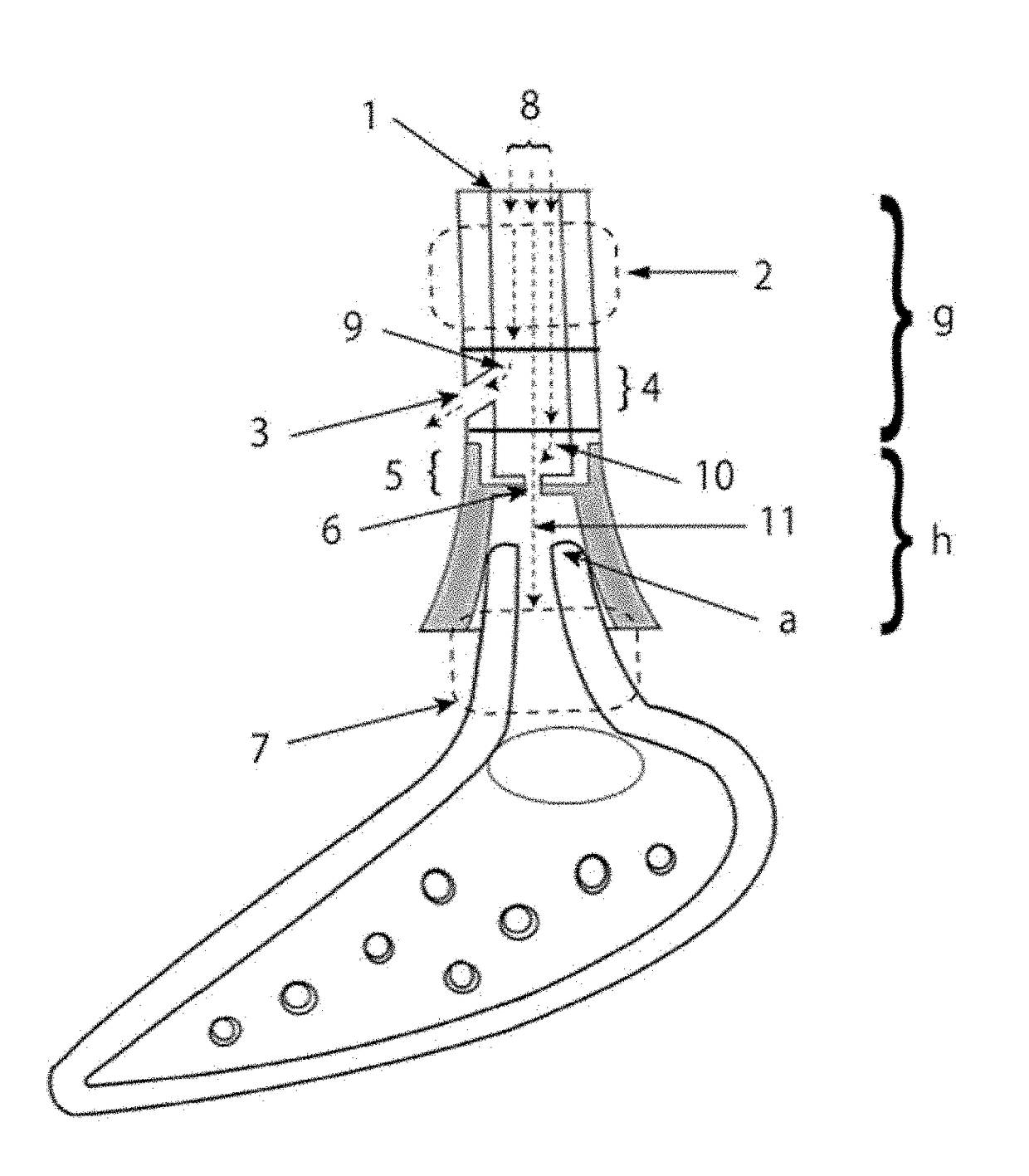

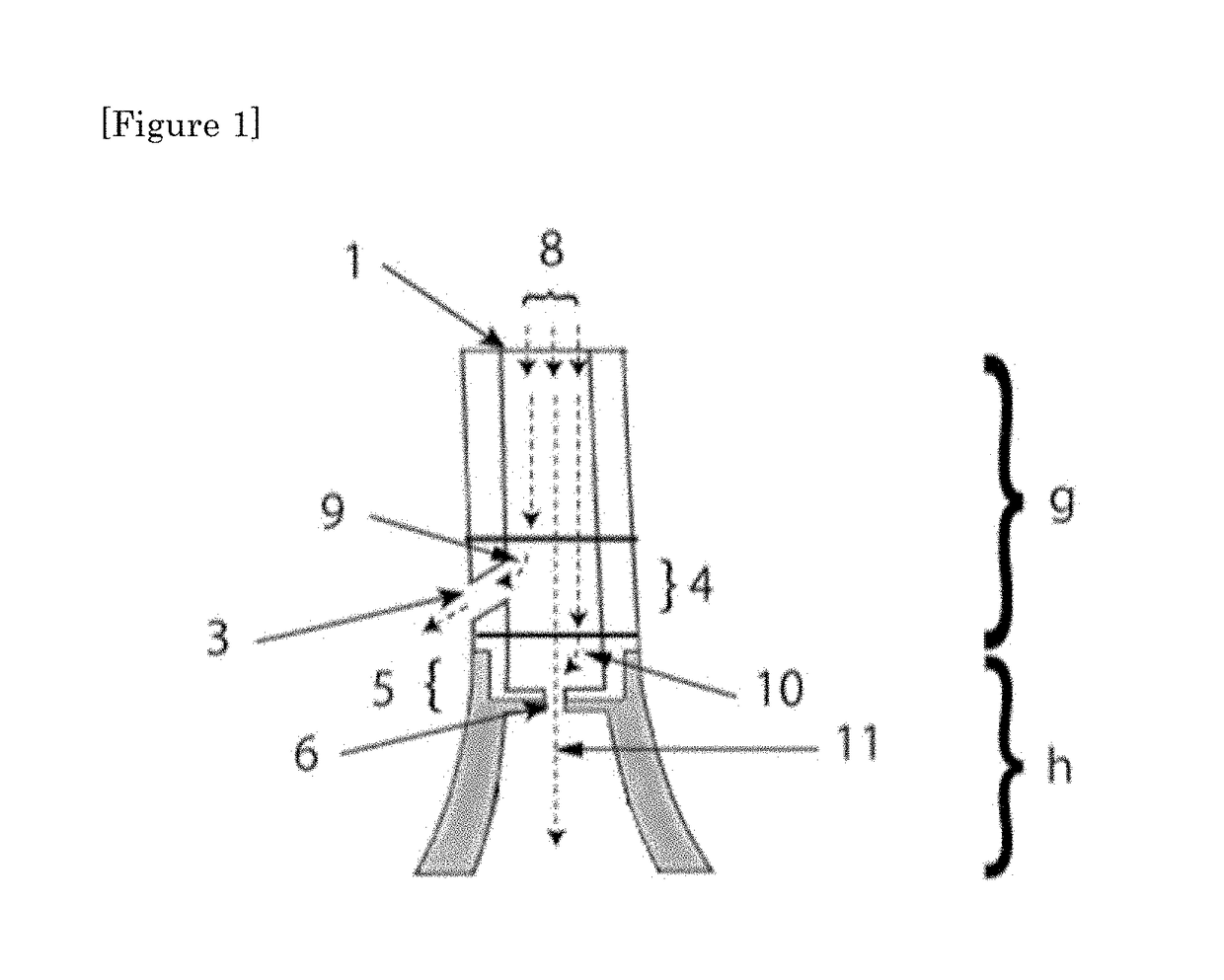

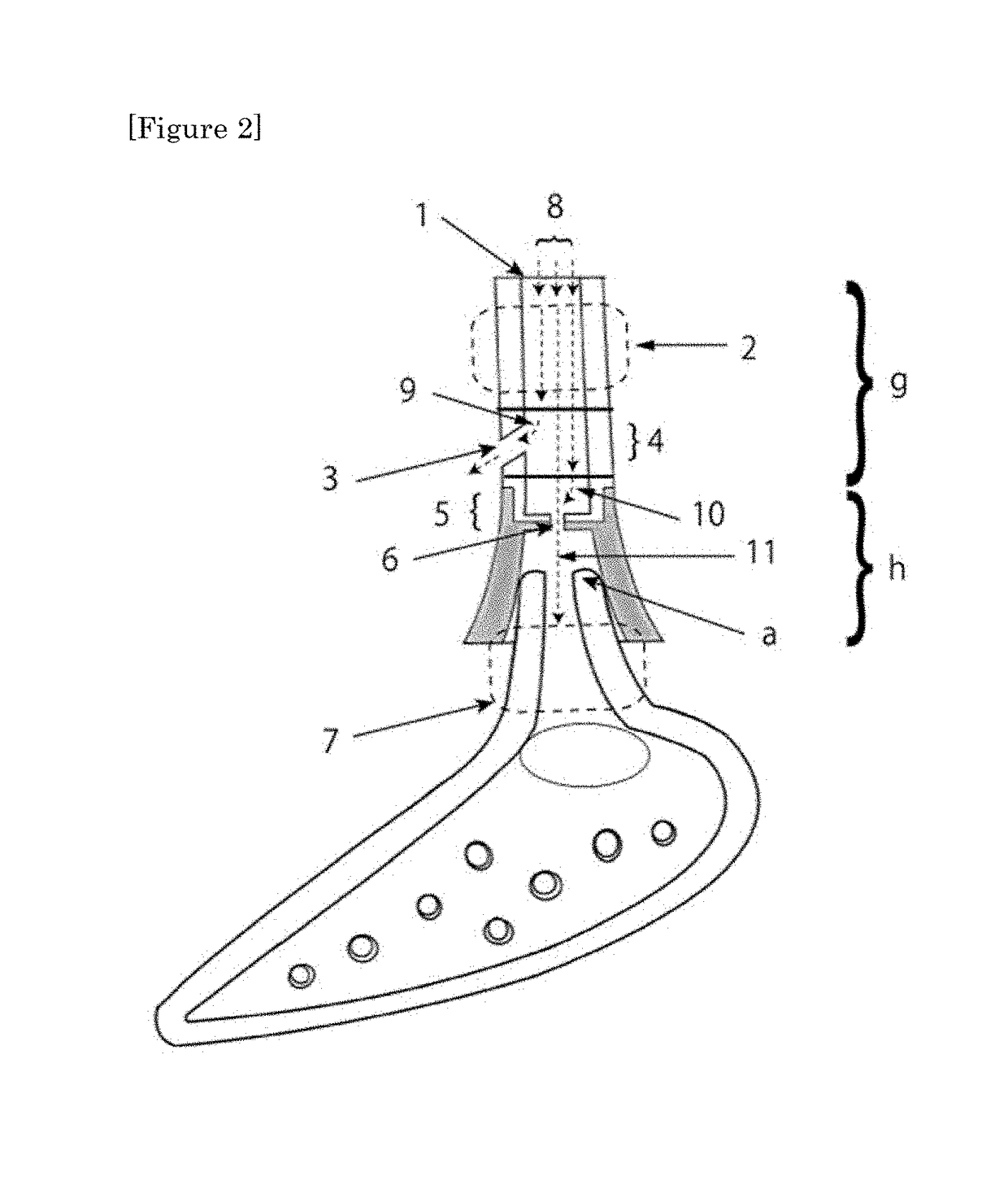

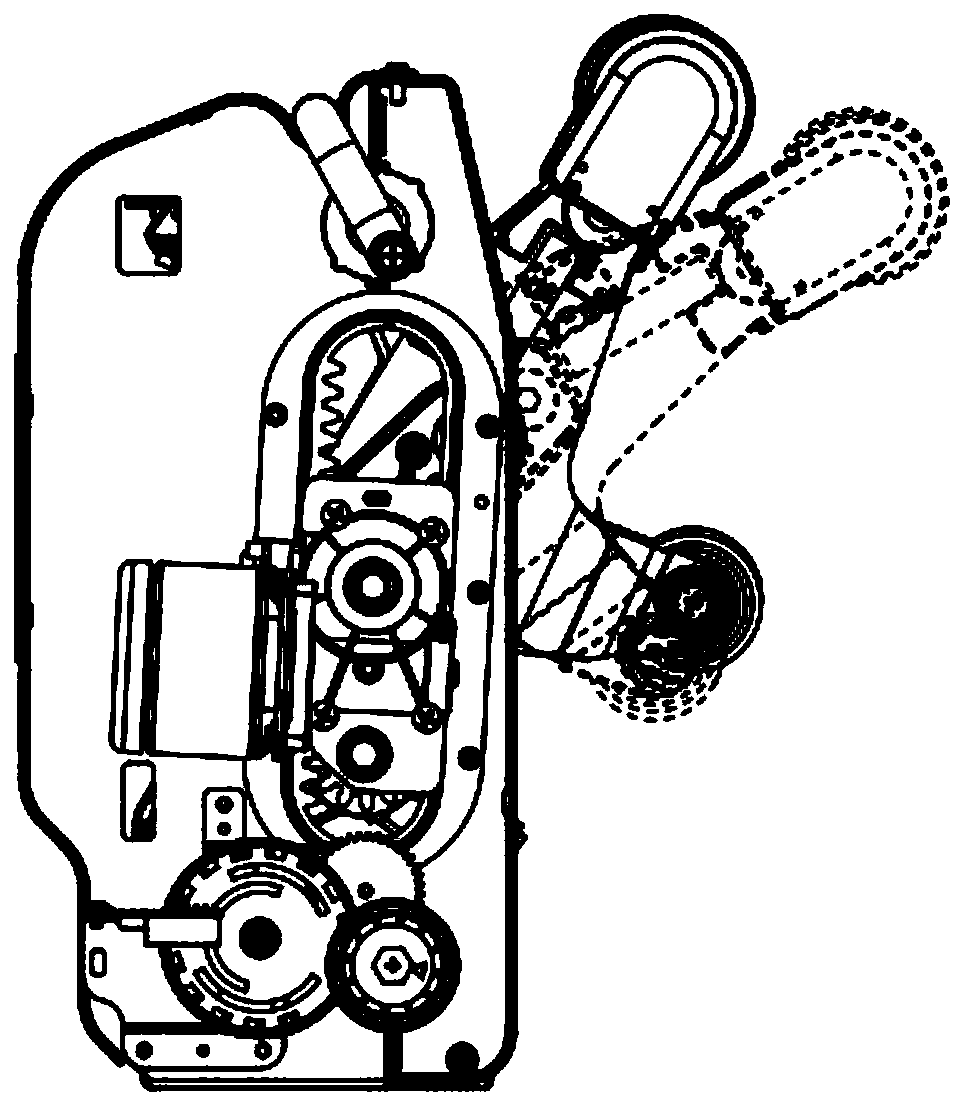

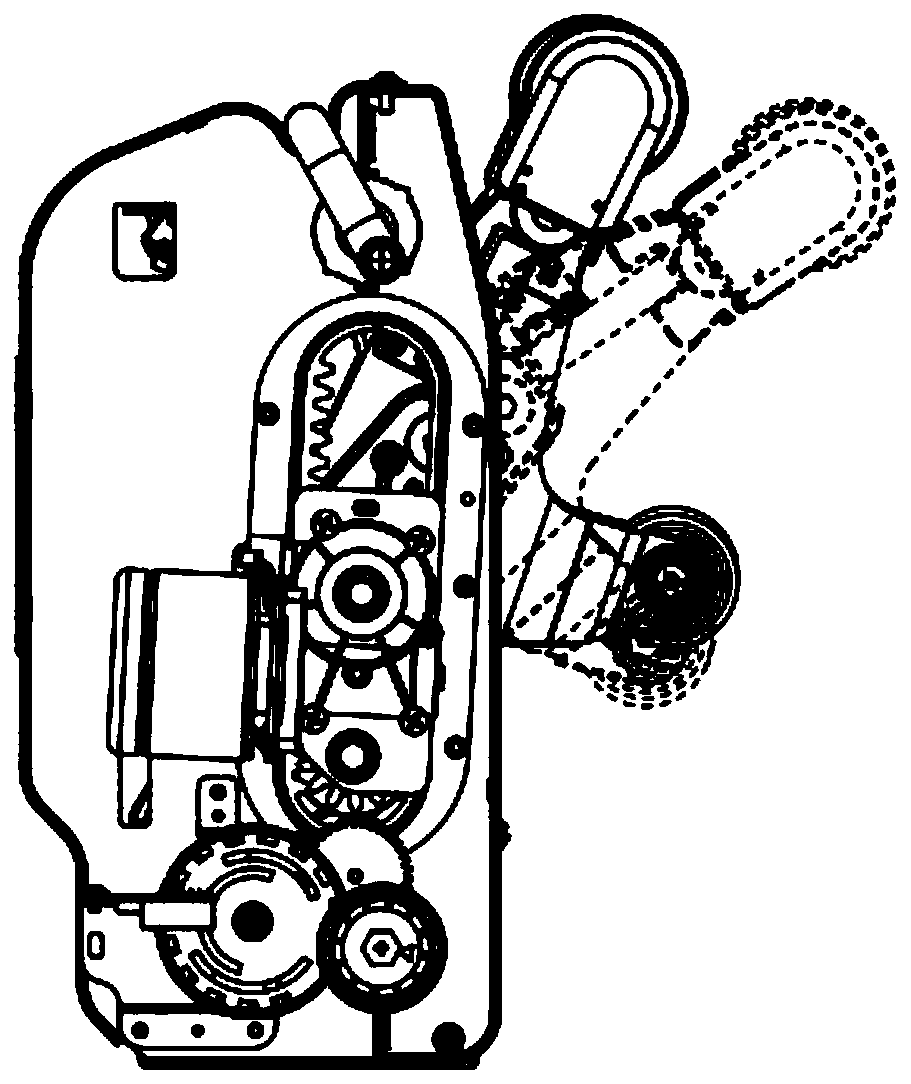

One-hand lever cartridge

The invention relates to a one-hand lever cartridge, comprising a head piece (1), which receives a floor piece (8), and a disc control having a control disc (5) which is rotatably and / or movably arranged via a spindle (2), which is rotatably and / or swivel-mounted in a spindle receptacle (3), wherein the spindle receptacle is produced from a material which is different from the head piece (1) and has a feed-through for the spindle (2), wherein at least one slot is introduced into the spindle receptacle (3) in the region of the feed-through, by which the inside contour of the feed-through is interrupted in an end-side section of the spindle receptacle (3).

Owner:FLUHS DREHTECHN

Center of gravity auxiliary stability teaching aid for snowboarding

ActiveCN113082669BUnlimited useUnrestricted useSnowboardsSkisClassical mechanicsStructural engineering

The present invention relates to the technical field of skiing equipment, in particular to a center of gravity auxiliary stabilization teaching aid for snowboarding, comprising a skateboard body, two skateboard boots are arranged symmetrically on the skateboard body, and teaching aids are detachably installed on the top of the skateboard body The teaching aid board is provided with an avoidance groove for avoiding skateboard boots, and a traction mechanism is respectively arranged outside the two ends of the teaching aid board, and the two traction mechanisms are respectively elastically connected to the teaching aid board through a first elastic member , the two traction mechanisms can move toward each other or back, the upper area of each traction mechanism is provided with a grasping mechanism that can be adjusted vertically, and the tail of the skateboard body is provided with a detachable booster mechanism. The invention can stably assist beginners to practice skiing, reduce the number of falls, and prevent giving up due to excessive difficulty in the early stage.

Owner:HARBIN INST OF PHYSICAL EDUCATION

A kind of massage technique force adaptive method

ActiveCN111419666BHigh precisionImprove experienceRoller massagePhysical medicine and rehabilitationEngineering

The invention discloses a method for self-adapting massage manipulative force. In the method for self-adapting massage manipulative force, by detecting the change of the pressure value of the massage wheel, it is determined that the current pressure value is greater than the first pressure value when the amount exceeds the preset threshold value. , compare the current pressure value with the pressure value of the calibration point in the first pressure value partition, adjust the farthest position to the position of the most suitable calibration point, and at the same time, the starting position of the massage technique is based on the most suitable The position of the calibration point is adjusted, thereby improving the accuracy of the massage action, and the force adaptive user experience is better. In addition, when the customer adjusts the sitting posture, it can also be adaptively adjusted according to the adjusted sitting posture to keep the body feeling consistent.

Owner:XIAMEN COMFORT SCIENCE & TECHNOLOGY GROUP CO LTD

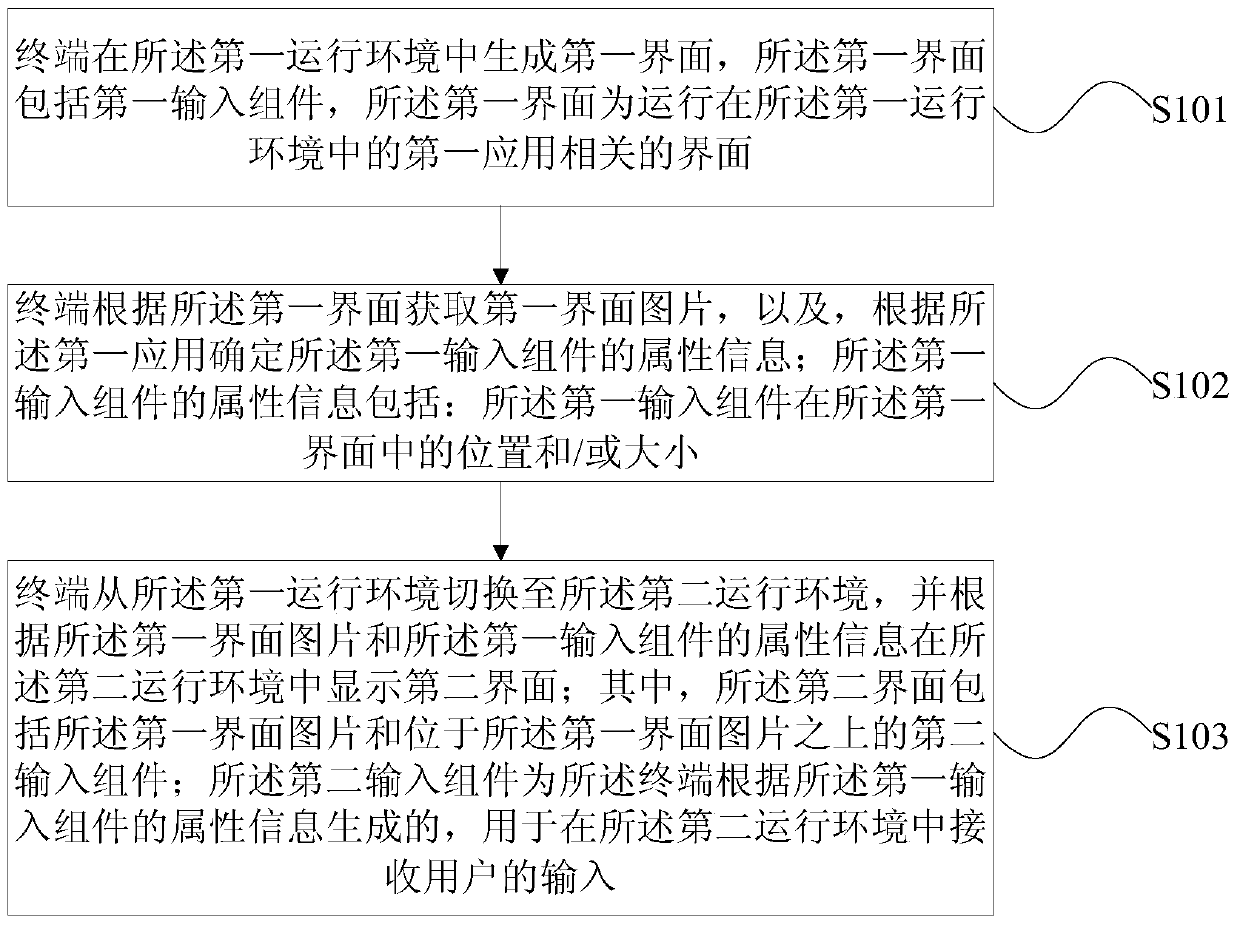

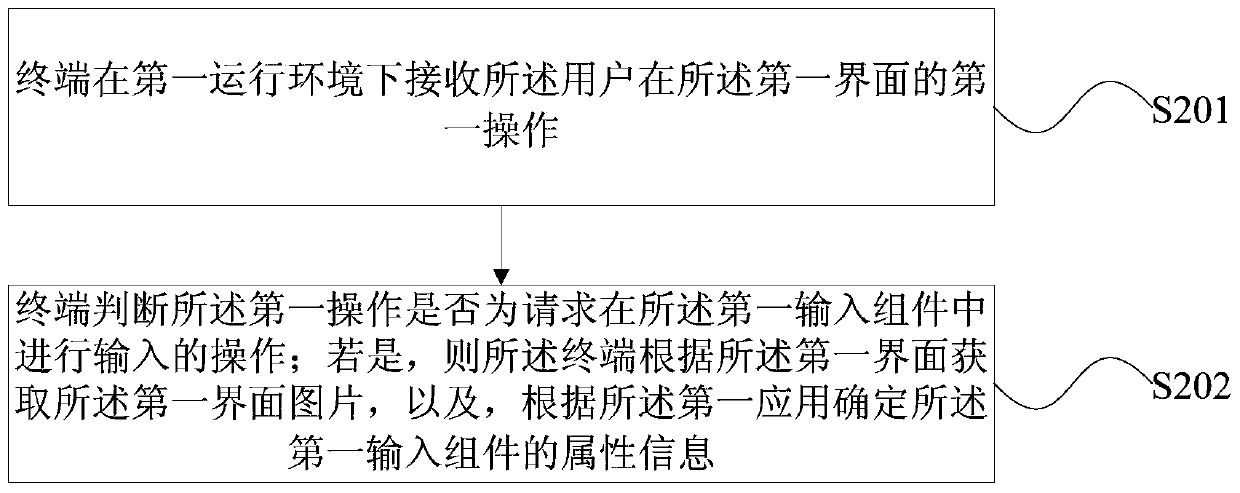

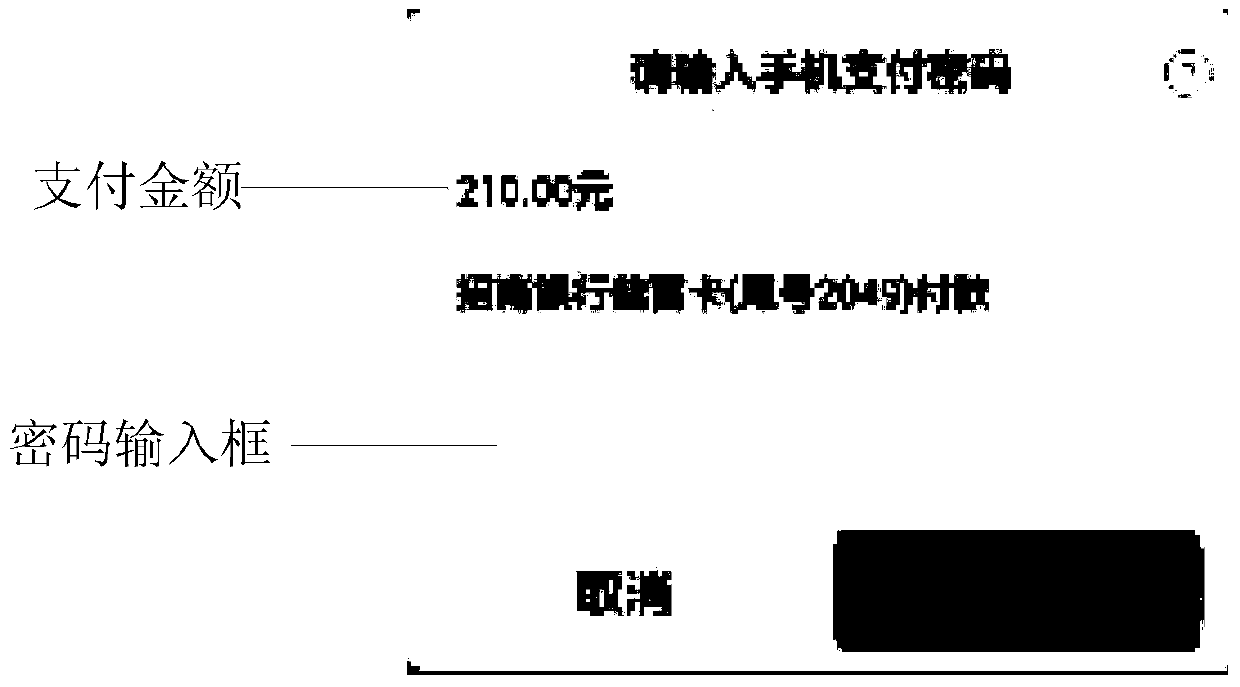

Terminal interface display method and terminal

ActiveCN106462713BFeel the sameImprove intelligenceDigital data protectionInternal/peripheral component protectionHuman–computer interactionUser interface

The present invention provides a user interface display method for a terminal, and a terminal, and the method includes: generating, by a terminal in a first operating environment, a first user interface that includes a first input component, obtaining a first user interface picture according to the first user interface, and determining attribute information of the first input component according to a first application; and switching, by the terminal, to a second operating environment, and displaying a second user interface in the second operating environment according to the first user interface picture and the attribute information of the first input component, thereby reducing processing overheads of the terminal.

Owner:HUAWEI TECH CO LTD

Nitrocellulose varnish and preparation method thereof

ActiveCN102020916BAddress performance requirementsSame hardnessPolyester coatingsPolymer scienceNitrocellulose

The invention discloses a nitrocellulose varnish and a preparation method thereof. The raw material formula of the nitrocellulose varnish contains two components, namely main agent and electrostatic thinner; by reasonably selecting materials and adjusting the proportions of the materials, the nitrocellulose varnish has the same performance requirement on hardness, luster, hand feeling, adhesive force and the like as the conventional product; and by adjusting the formulas of the main agent and the electrostatic thinner, the nitrocellulose varnish disclosed by the invention has good conductivity, volatile speed, anti-sagging property, elevation levelling property and other performances. The nitrocellulose varnish disclosed by the invention is suitable for the electrostatic spraying process;compared with the air spraying nitrocellulose varnish, the utilization rate of the paint can be greatly increased; the nitrocellulose varnish is suitable for special-shaped pieces such as guitars andornaments; and the cost of the paint is greatly reduced, the loss is reduced and the pollution to the environment is lowered.

Owner:HUIZHOU CHANGRUNFA PAINT

An electronic cigarette liquid with a roasted aroma

ActiveCN104026728BImproves intrinsic suction qualityFeel the sameTobacco treatmentTobacco devicesBiotechnologyLiquid smoke

The invention discloses an electronic cigarette liquid with a toasted aroma, which comprises mixing tobacco powder, shredded tobacco or soot with a solvent at a mass-volume ratio of 1:5-10, and distilling at 120-200°C for 1-4 hours. During the distillation process, an inert gas is introduced to sweep the distillate to the absorption liquid, and then the e-cigarette liquid is obtained. The present invention selects tobacco powder, shredded tobacco or soot as raw materials, and uses a distillation device to extract and separate substances with roasted aroma from tobacco powder, shredded tobacco or soot at a certain temperature. The similarity of the components of the roasted aroma substances produced in the product is very high. After the roasted-flavored e-liquid is atomized by the atomizer, the smoker feels that the e-liquid is consistent with the burning process of traditional cigarettes. There is a roasted aroma from the burning process of cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

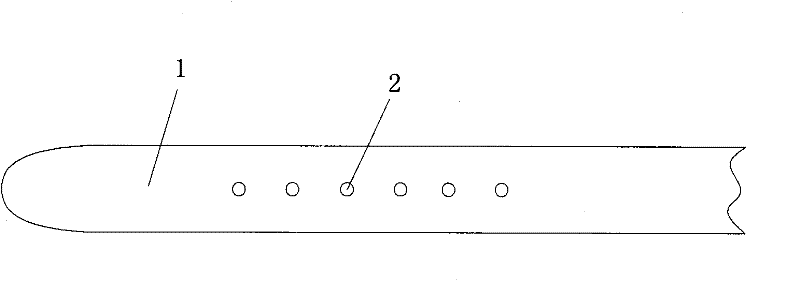

Waist belt and preparation method thereof

The invention provides a waist belt and a preparation method thereof, and relates to a belt or the waist belt, and provides the waist belt which is formed in one step by an injection molding machine and has the advantages of difficult extension of belt holes, better bending and stretching resistance and difficult deformation and the preparation method thereof. The waist belt is a one-step molded belt made of artificial rubber, wherein the artificial rubber can be TPU, EVA, PVC and the like. The method comprises the following steps of: mixing an artificial rubber material and required pigment to obtain a mixed material; putting the mixed material into a material drying barrel for drying to obtain the dried mixed material for later use; fixing a die on the injection molding machine; setting each parameter of the injection molding machine for later use; putting the dried mixed material into a storage barrel of the injection molding machine to form a body through plasticizing, ejecting, cooling and other molding processes; and cleaning and airing the body to obtain the waist belt. The waist belt and a waist belt buckle can be assembled into a waist belt finished product.

Owner:王晓文

Direct type backlight module and display device including same

The invention provides a bottom lighting module and a display device including the same. The bottom lighting module comprises at least one LED light source, a reflective film supporter with an opening, a reflective film, a light absorbing film and a light conversion film. The reflective film supporter comprises a bottom plate and at least three side plates. The projection of the bottom plate on the plane of the opening is inside the opening. Each LED light source is arranged on the surface of the bottom plate. The reflective film comprises a bottom reflective film and at least three side reflective films. The bottom reflective film is arranged on the surface of the bottom plate and comprises a plurality of holes in one-by-one correspondence to the LED light source for adaption. Each LED light source is arranged to pass one of the holes. Each side reflective film is installed on each side plate. The light absorption film is arranged on at least a part of the surface of at least one of the side reflective films, the part of the surface being far from the side plate, and the light absorption film is used to absorb light. The light conversion film arranged at the opening is far from the LED light source and is used to convert light emitted by the LED light source into white light.

Owner:NANJING TECH CORP LTD

Method and device for mobile control in virtual reality

ActiveCN108427501BImprove immersionSolve the problem of low experienceInput/output for user-computer interactionGraph readingData controlComputer graphics (images)

The present application discloses a movement control method and device in virtual reality. Wherein, a virtual character is included in the virtual space of the virtual reality, and the method includes: monitoring the movement of the first device in the real space; determining the first position data of the virtual character on the first plane in the virtual space according to the movement of the first device; According to the first position data of the virtual character on the first plane and the terrain data in the virtual space, determine the second position data of the virtual character, the second position data includes the height data of the virtual character relative to the first plane; according to the first position data The movement of the virtual character in the virtual space is controlled with the second position data. The present application solves the problems in the related art that the target object easily causes dizziness when moving in the virtual space and the user experience is low.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

Hybrid brake system and control method for electric wheel vehicle

ActiveCN111231910BSimple structureIncreased unsprung massBraking action transmissionFoot actuated initiationsDrive wheelEngineering

A hybrid braking system and a control method for an electric wheel vehicle. It relates to the field of electric vehicle braking system. A hybrid braking system for electric wheel vehicles with simplified structure is proposed under the premise of ensuring safety and meeting the general braking function requirements of electric vehicles. The hybrid braking system includes a hydraulic braking subsystem and a motor braking subsystem; the hydraulic braking subsystem includes an oil storage cup, a brake pedal mechanism, a brake master cylinder, a pedal simulator, a public pipeline, a right Brake wheel cylinder, left brake wheel cylinder; the motor brake subsystem includes a control unit and a pair of driving motors connected to a pair of driving wheels, and the control unit controls a pair of driving motors respectively, thereby respectively adjusting a pair of driving wheels driving force and braking force. The invention can guarantee the maximum total braking pressure requirement. It can ensure that the brake pedal feels consistent under different braking modes such as low-adhesion road surfaces, high-speed vehicle conditions, and medium and low-speed vehicle conditions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com