Method for spray coating of crackle lacquer

A technology of crack paint and primer, which is applied in the direction of surface coating liquid device, coating, special art surface treatment, etc., can solve the problem of high production cost, achieve high practicability, reduce production cost, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

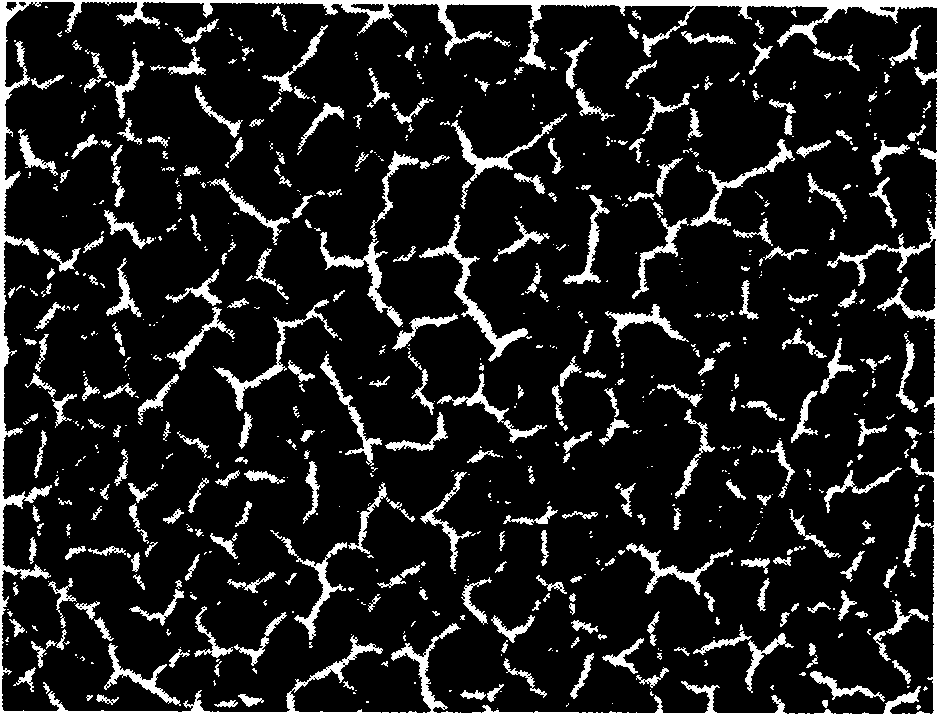

[0026] The method for spraying crack paint of the present invention comprises the steps:

[0027] a. Dilute the PP gray polypropylene primer with PP (polypropylene) solvent at a ratio of 1:0.85 (parts by weight) for 12 minutes, control the viscosity of the paint by controlling the time, and then spray it on the product made of modified polypropylene material surface.

[0028] b. Dry the sprayed polypropylene primer at a temperature of 68° C. for 20 minutes to volatilize the solvent. Dilute the 206 type acrylic black primer with X3 (xylene solvent) in a ratio of 1:1 (parts by weight) for 15 minutes. Seconds, dry at 70°C for 15 minutes and then spray on the dried polypropylene primer, then let it cool until the surface is dry.

[0029] This step is used to strengthen the intermediate coating interface, the joint bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com