A kind of environment-friendly softener and preparation method thereof

A kind of softener and environment-friendly technology, applied in the field of environment-friendly softener and its preparation, can solve the problems that AEEA cannot be completely replaced, and the yellowing and discoloration of products become larger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

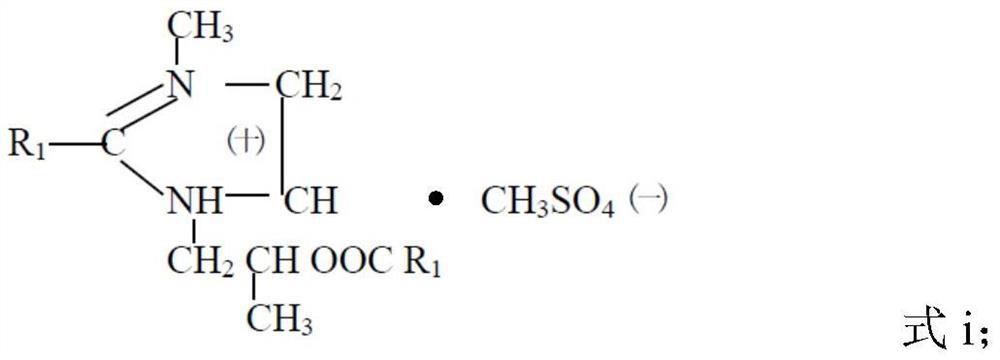

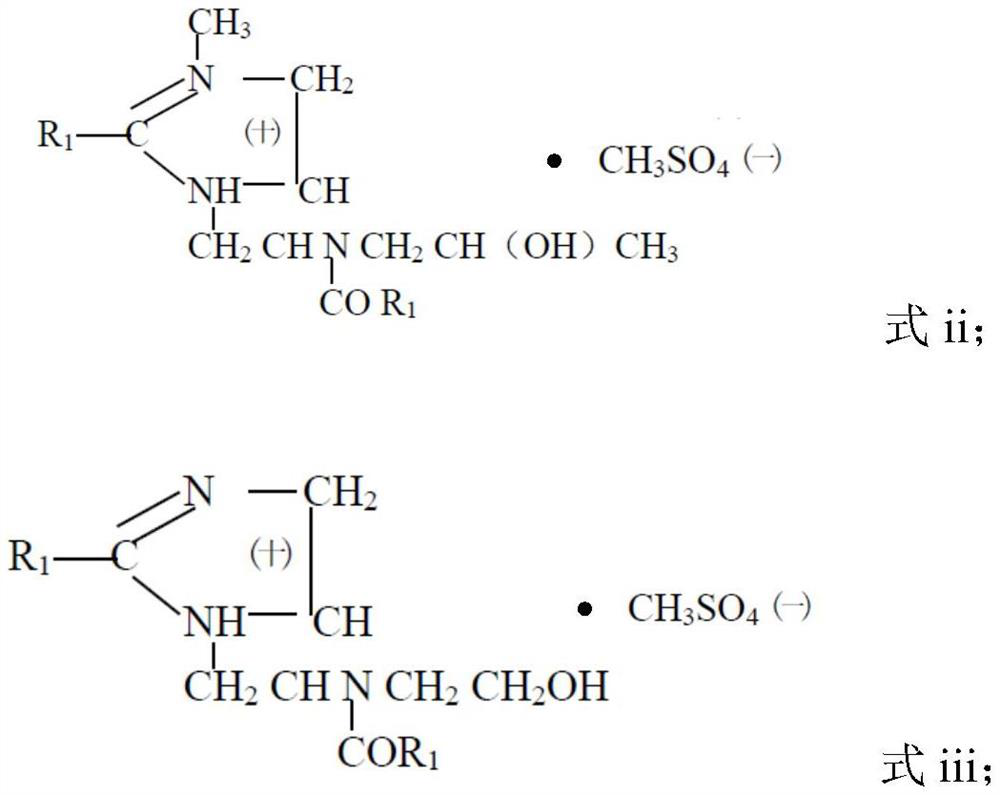

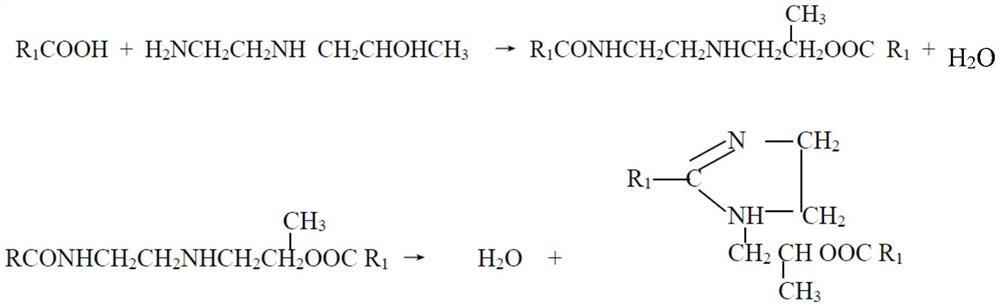

Image

Examples

Embodiment 1

[0032] Embodiment 1. Preparation of hydroxypropyl ethylenediamine

[0033] In this example, hydroxypropyl ethylenediamine as one of the softener raw materials was prepared. Refer to the technical scheme and reactor described in the patent ZL200910032856.6 "Continuous Production of Hydroxyethylethylenediamine Production Process and Reactor". Specifically, in this example, the reaction tower of this patent is used to replace the ethylene oxide in this patent with propylene oxide, and other process conditions are basically unchanged. After synthesis and rectification, the purity obtained is above 99%. Hydroxypropylethylenediamine (AEPA).

Embodiment 2

[0034] Embodiment 2. Preparation of N-hydroxypropyldiethylenetriamine

[0035] In this example, N-hydroxypropyldiethylenetriamine (hydroxypropyldiethylenetriamine) as one of the raw materials of the softener was prepared. Using a reaction kettle, under the protection of nitrogen, under the conditions of 80-150°C and 0-0.5MPa, add propylene oxide to diethylenetriamine by continuous feeding method; the molar ratio of diethylenetriamine to propylene oxide is 1 1, the product that obtains is N-hydroxypropyldiethylenetriamine (being called for short hydroxypropyldiethylenetriamine).

Embodiment 3

[0036] Example 3. Preparation of N-hydroxyethyldiethylenetriamine and N, N'-dihydroxyethyldiethylenetriamine

[0037] In this example, N-hydroxyethyldiethylenetriamine and N,N'-dihydroxyethyldiethylenetriamine were prepared as one of the softener raw materials. Using a reaction kettle, under the protection of nitrogen, under the conditions of 80-150°C and 0-0.5MPa, add ethylene oxide to diethylenetriamine by continuous feeding method; wherein, when diethylenetriamine and ethylene oxide When the molar ratio is 1:1, the obtained product is N-hydroxyethyldiethylenetriamine; when the molar ratio of diethylenetriamine and ethylene oxide is 1:2, the obtained product is N,N'- Dihydroxyethyldiethylenetriamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com