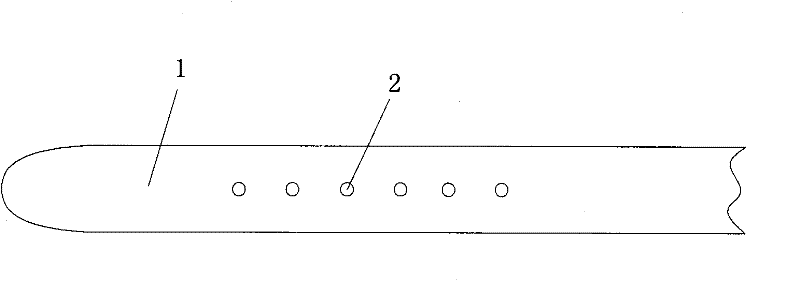

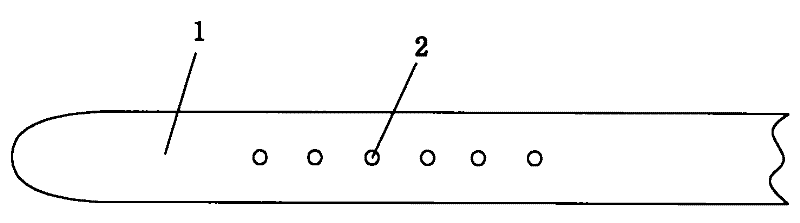

Waist belt and preparation method thereof

A belt and an integrated technology, applied in the field of belts or belts, can solve laborious and time-consuming problems, achieve strong bending and stretching performance, reduce sewage discharge and garbage production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Mix TPU (polyurethane) with the required pigments to obtain a mixed material.

[0045] 2) Put the mixed material into the drying material bucket, and dry it. The drying temperature is 80° C., and the drying time is 3 hours. The dried mixed material is obtained for later use.

[0046] 3) mold is fixed on the injection molding machine, and described injection molding machine is 150 tons, and injection volume is 200g, and the used material of mold is steel, preferably 718# steel.

[0047] 4)) Set various parameters of the injection molding machine and set them aside; the various parameters of the injection molding machine are set as follows:

[0048] Stage 1: 190°C; Stage 2: 180°C; Stage 3: 175°C; Stage 4: 170°C; Stage 5: 170°C; Pressure: 75MPa; Speed: 40mm / s; Injection time: 15s; Back pressure: 6MPa; storage position: 130mm.

[0049] 5) Put the dried mixed material into the storage tank of the injection molding machine, form the main body through plasticization, inje...

Embodiment 2

[0053] Similar to Example 1, the difference is that the artificial rubber material adopts EVA (ethyl acetate); the temperature for putting the mixed material into the drying barrel for drying is 90° C., and the drying time is 2.5 hours; the injection molding machine is 350 tons , the injection volume is 400g; the various parameters of the injection molding machine are set as follows: the first section: 200°C; the second section: 165°C; the third section: 185°C; the fourth section: 180°C; the fifth section: 160°C ℃; pressure: 70MPa; speed: 50mm / s; injection time: 20s; back pressure: 5MPa; storage position: 100mm.

Embodiment 3

[0055] Similar to Example 1, the difference is that the artificial rubber material adopts PVC (polyvinyl chloride); the temperature for putting the mixed material into the drying barrel for drying is 70° C., and the drying time is 4 hours; the injection molding machine is 150 tons, The injection volume is 650g; the various parameters of the injection molding machine are set as follows: first section: 215°C; second section: 195°C; third section: 195°C; fourth section: 160°C; fifth section: 165°C ;Pressure: 80MPa; Speed: 35mm / s; Injection time: 30s; Back pressure: 3MPa; Storage position: 110mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com