Patents

Literature

36results about How to "Address performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

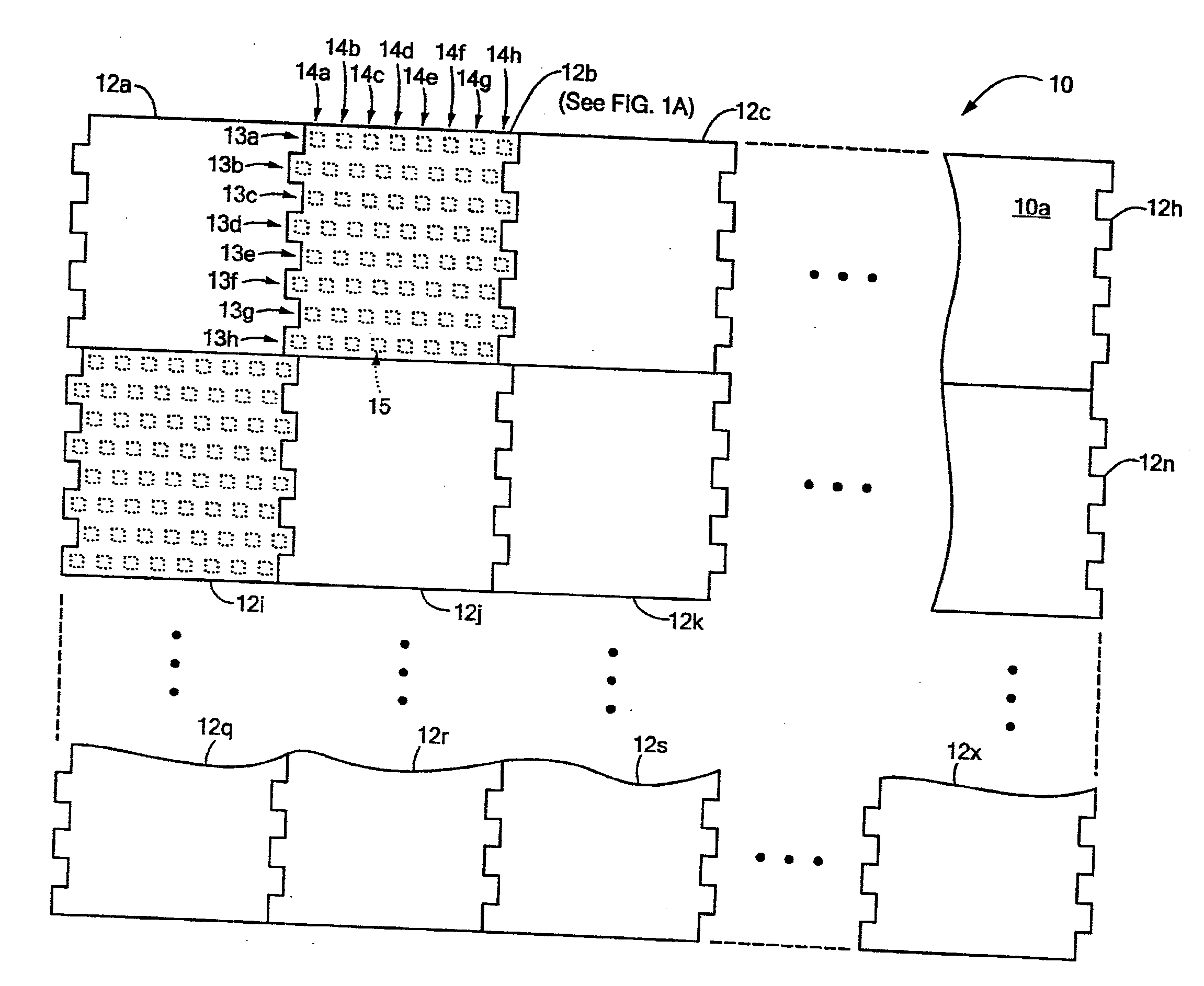

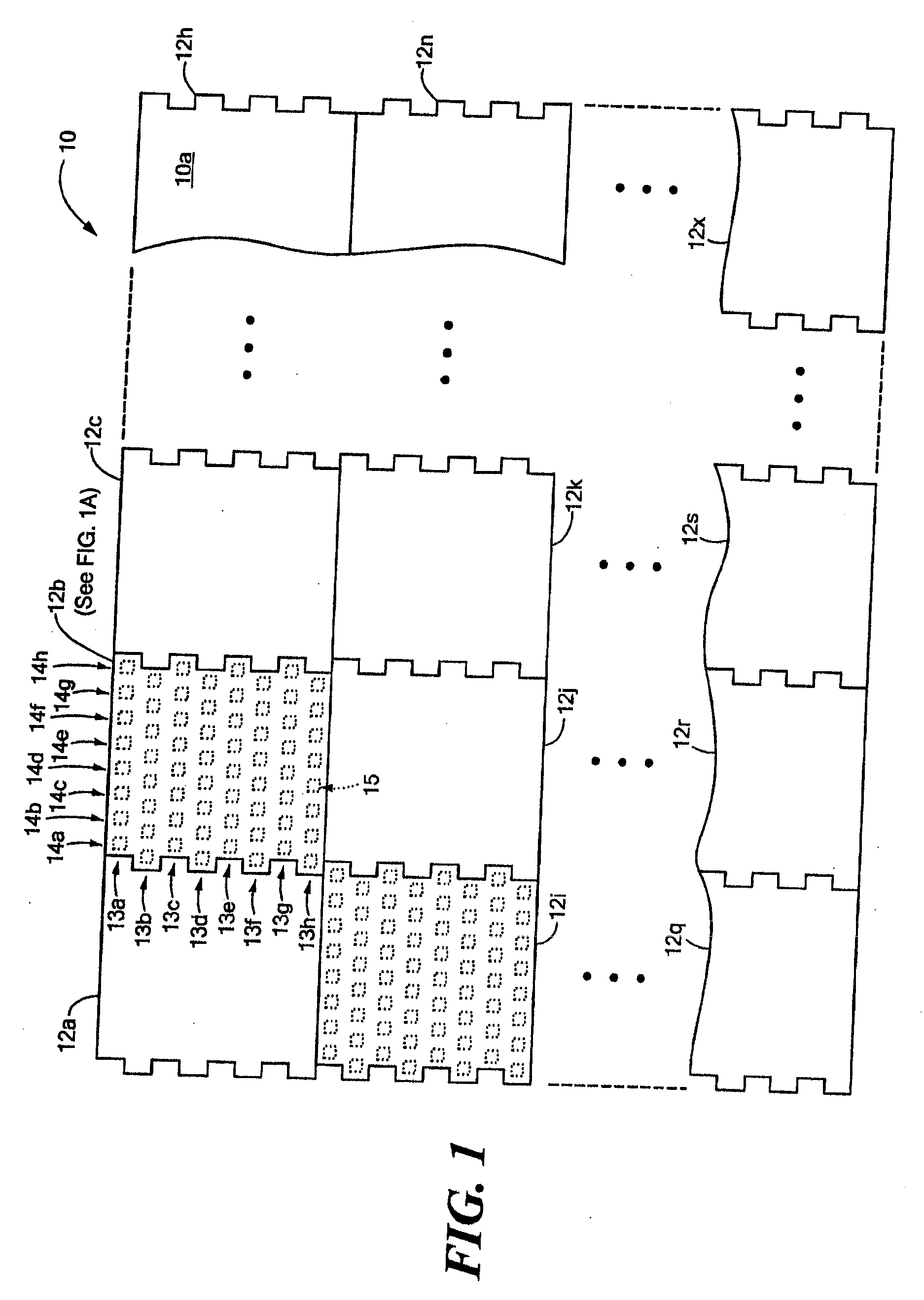

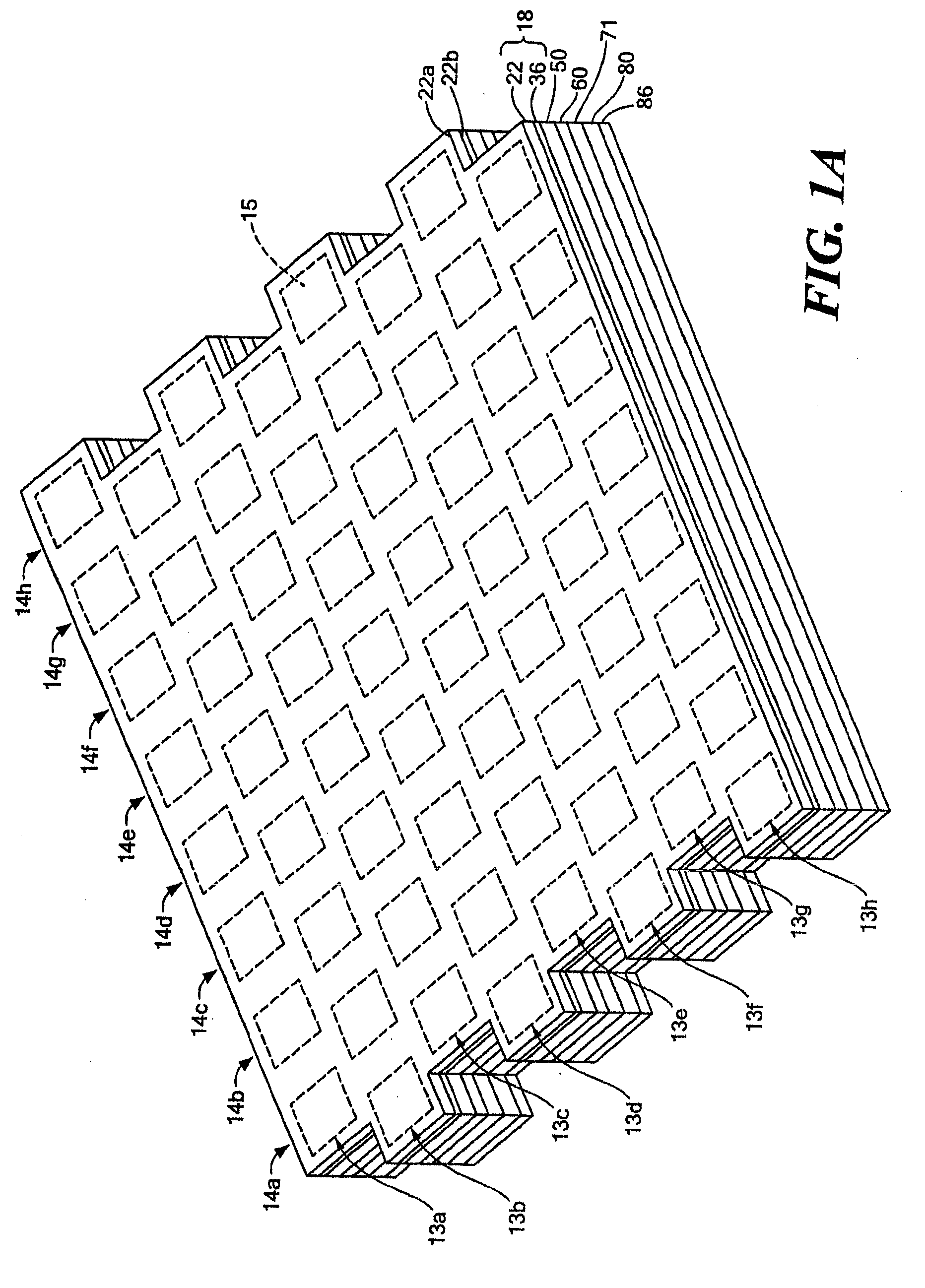

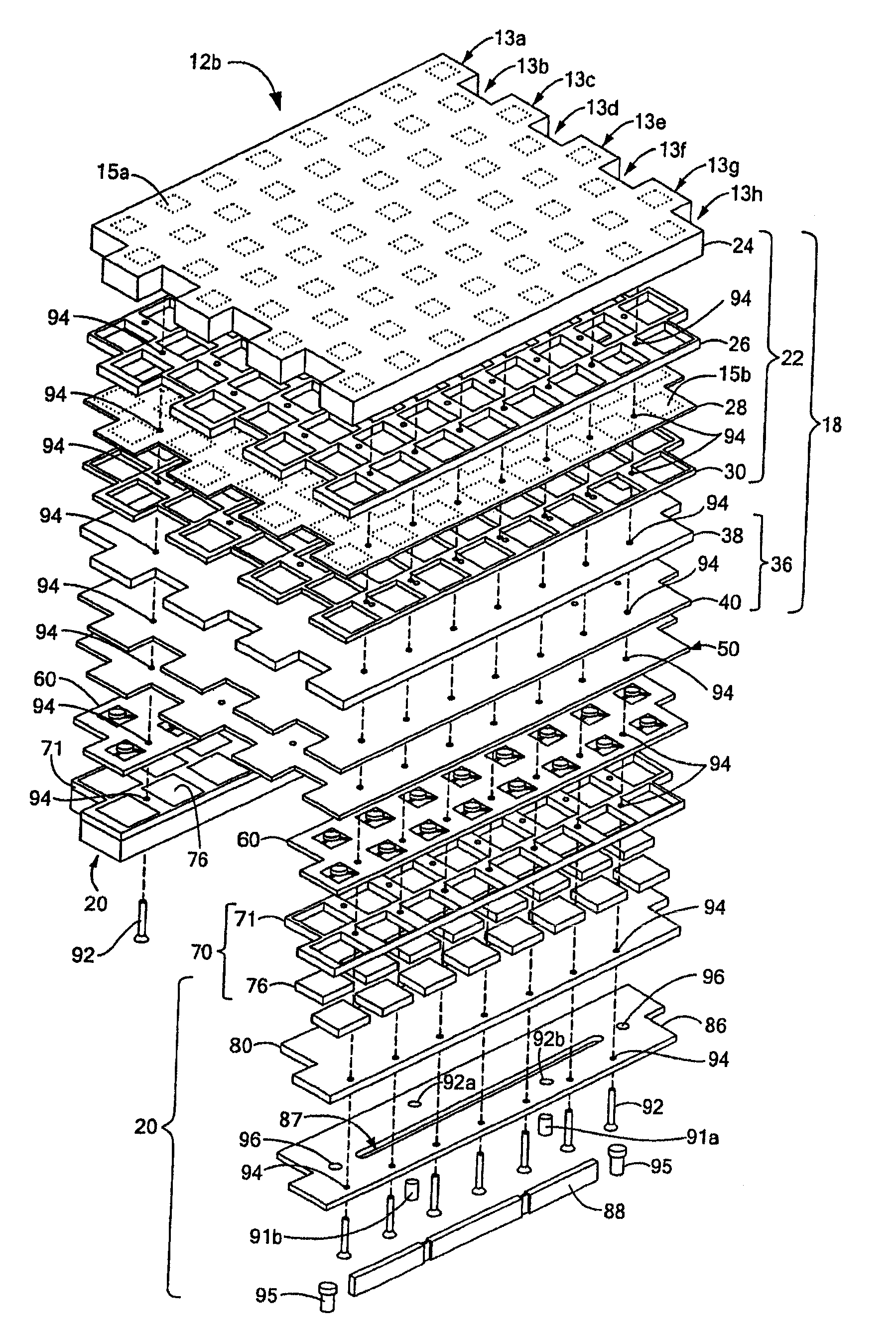

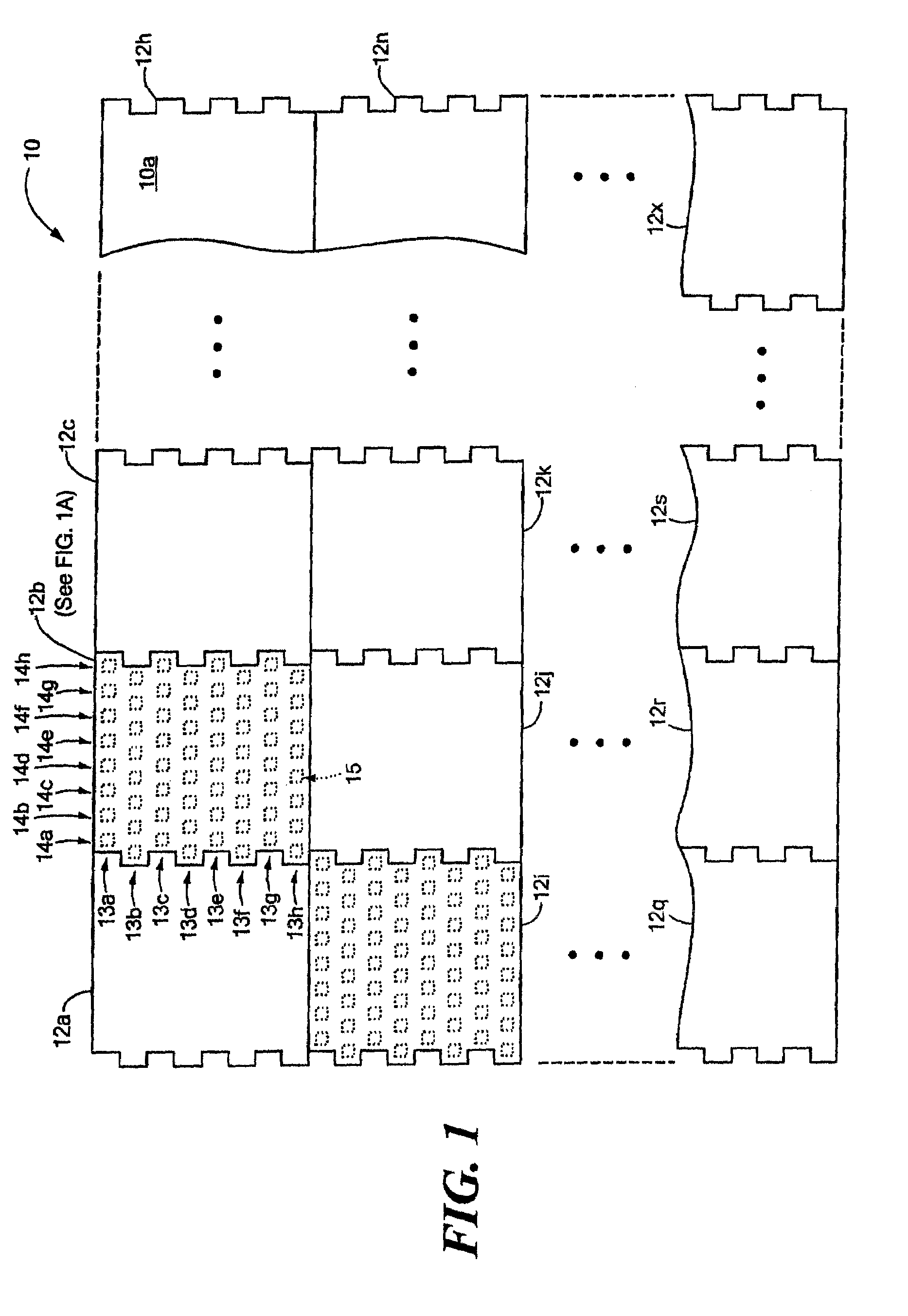

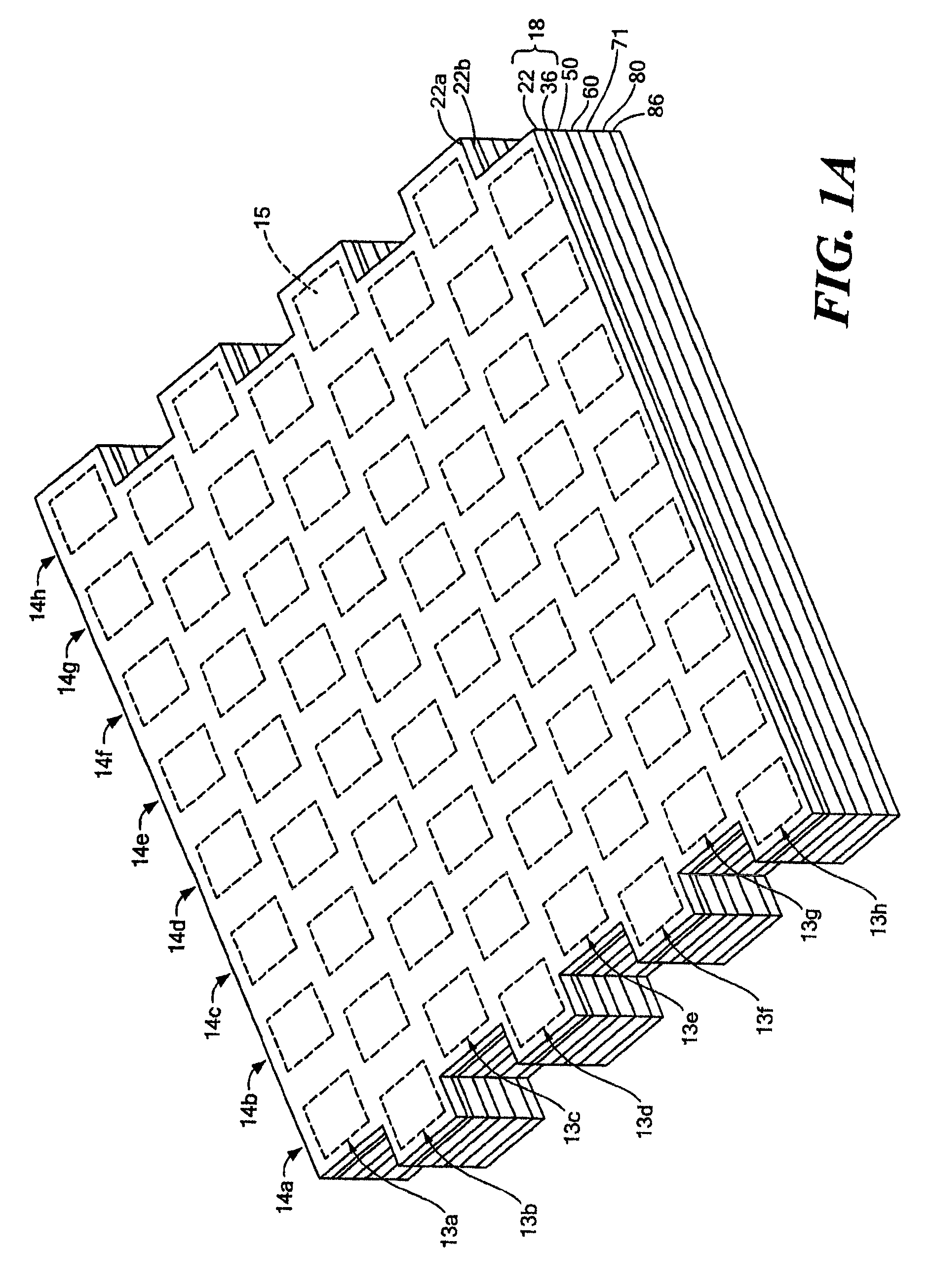

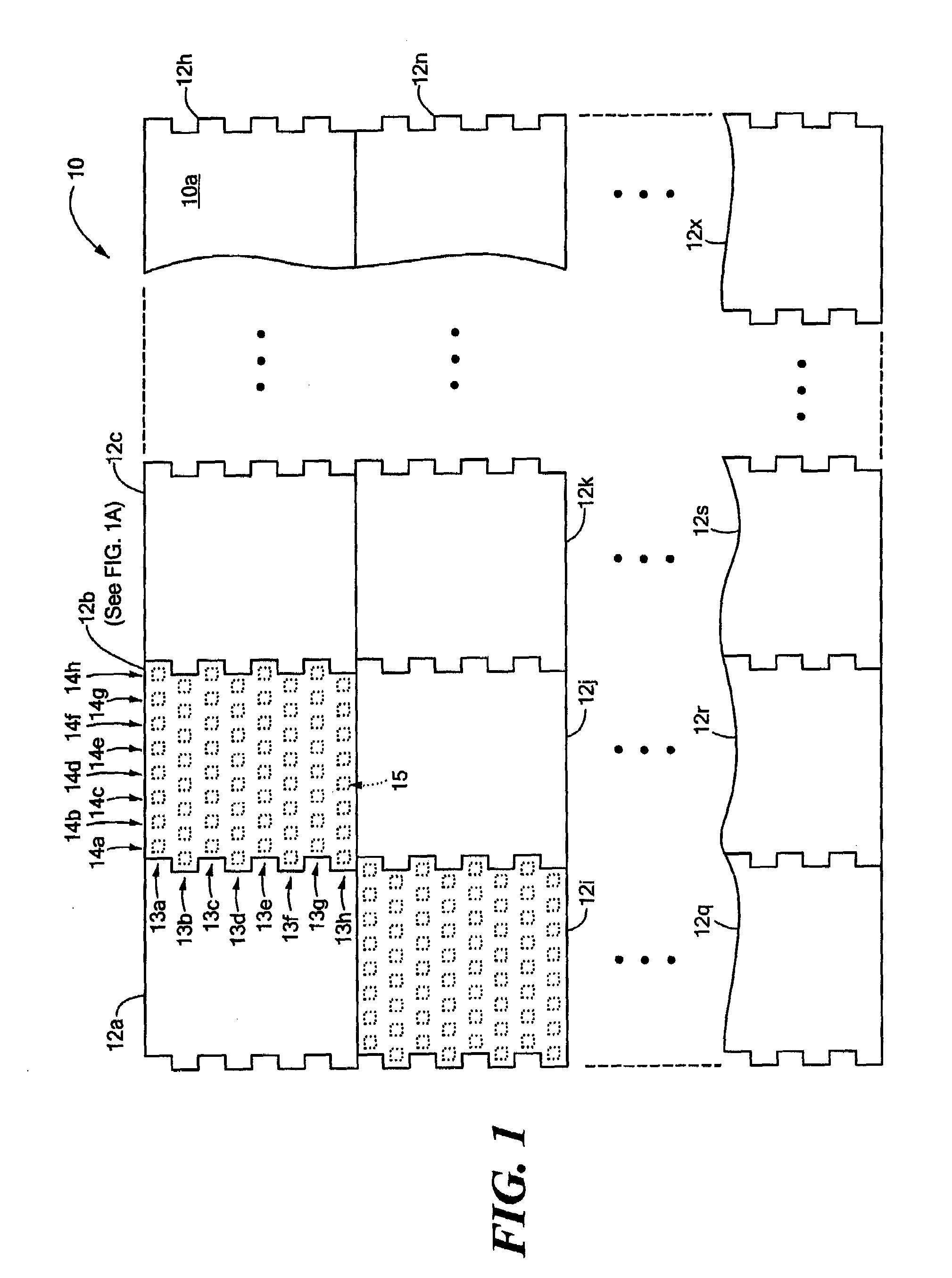

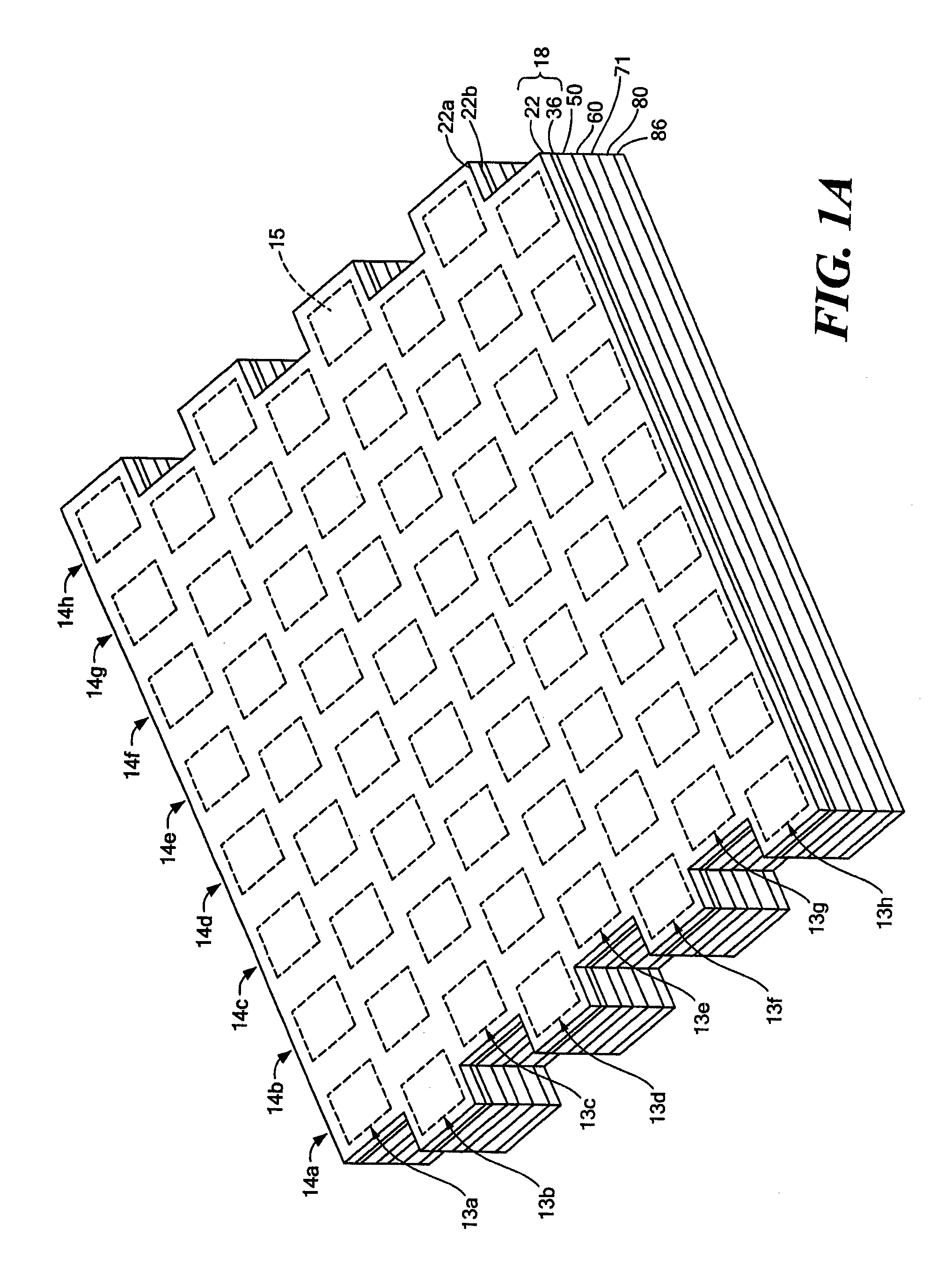

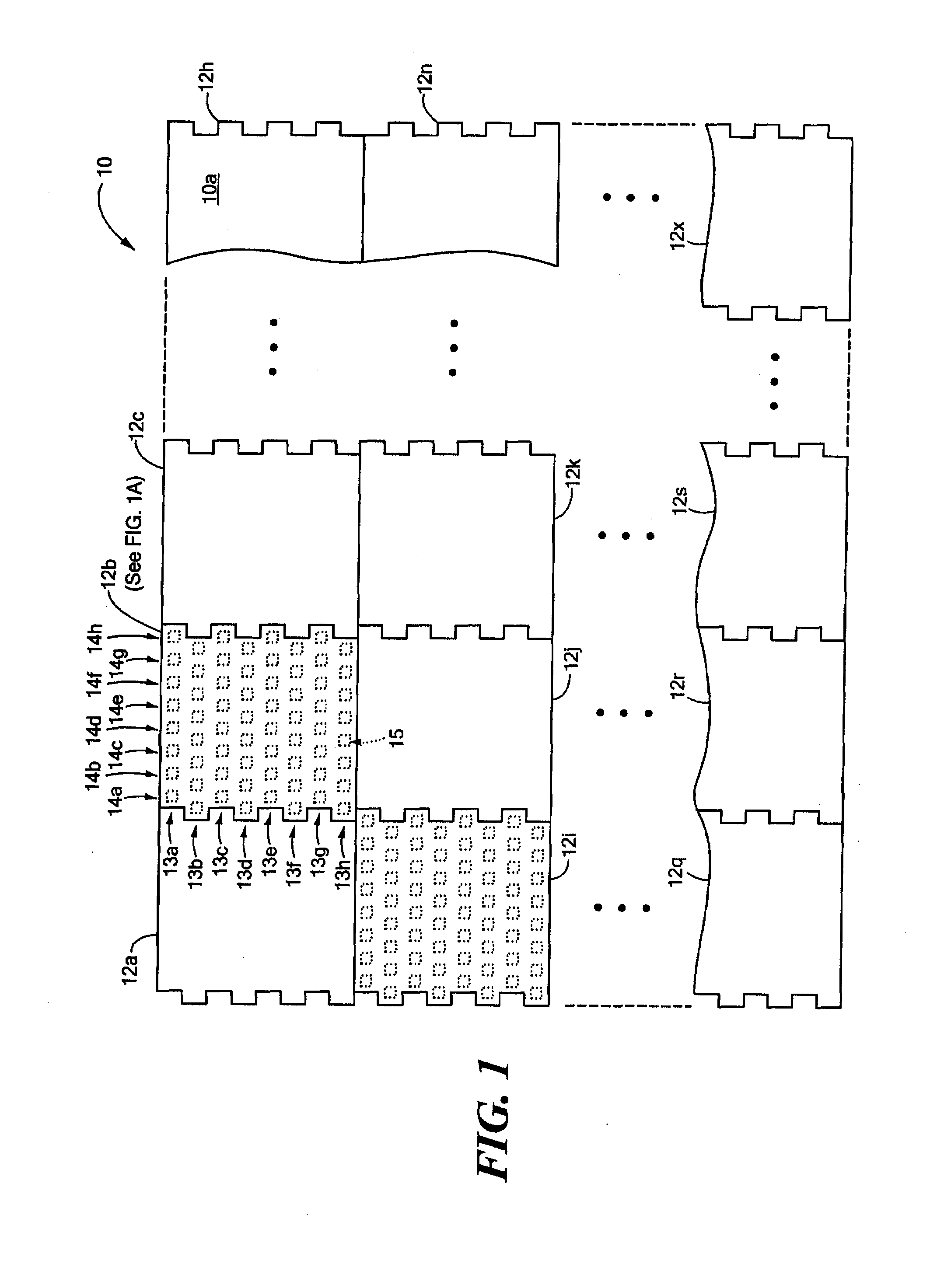

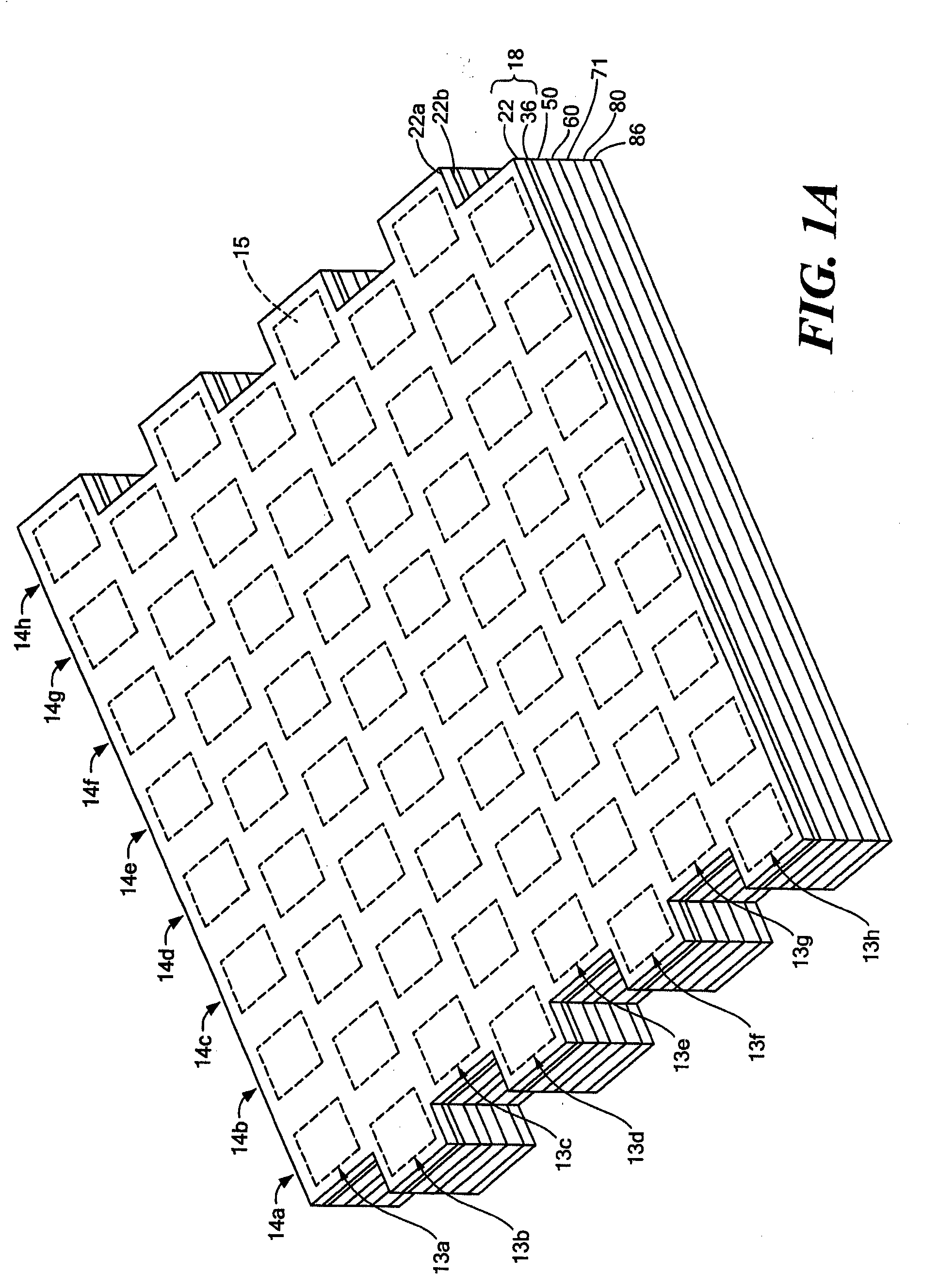

Tile sub-array and related circuits and techniques

ActiveUS20080074324A1Lower acquisition and life cycle costs of phased arraysLow costSimultaneous aerial operationsRadiating elements structural formsWaveguideHeat spreader

A radiator includes a waveguide having an aperture and a patch antenna disposed in the aperture. In one embodiment, an antenna includes an array of waveguide antenna elements, each element having a cavity, and an array of patch antenna elements including an upper patch element and a lower patch element disposed in the cavity.

Owner:RAYTHEON CO

Tile sub-array and related circuits and techniques

ActiveUS7348932B1High bandwidthImproving polarization diversitySimultaneous aerial operationsRadiating elements structural formsWaveguideHeat spreader

A radiator includes a waveguide having an aperture and a patch antenna disposed in the aperture. In one embodiment, an antenna includes an array of waveguide antenna elements, each element having a cavity, and an array of patch antenna elements including an upper patch element and a lower patch element disposed in the cavity.

Owner:RAYTHEON CO

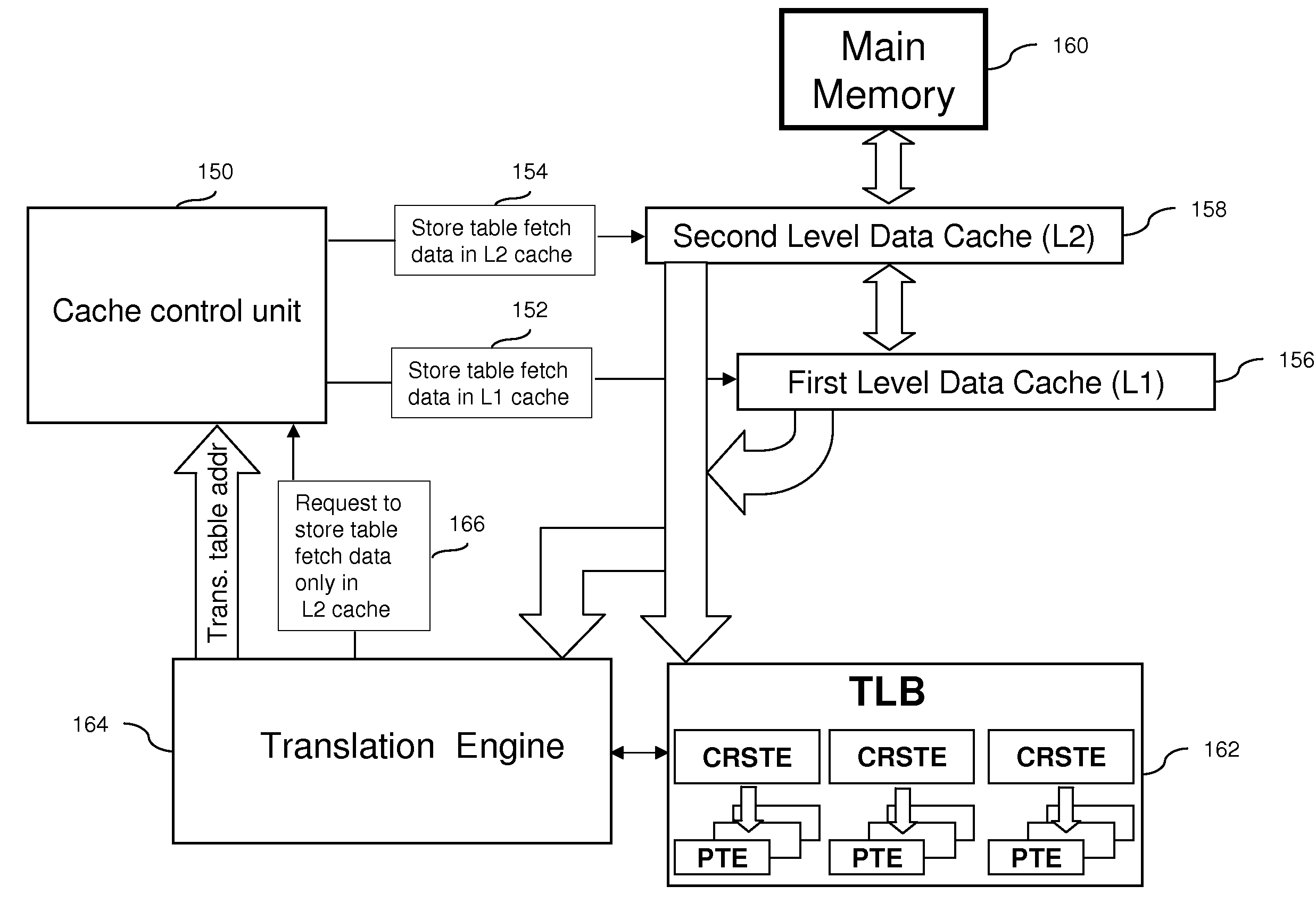

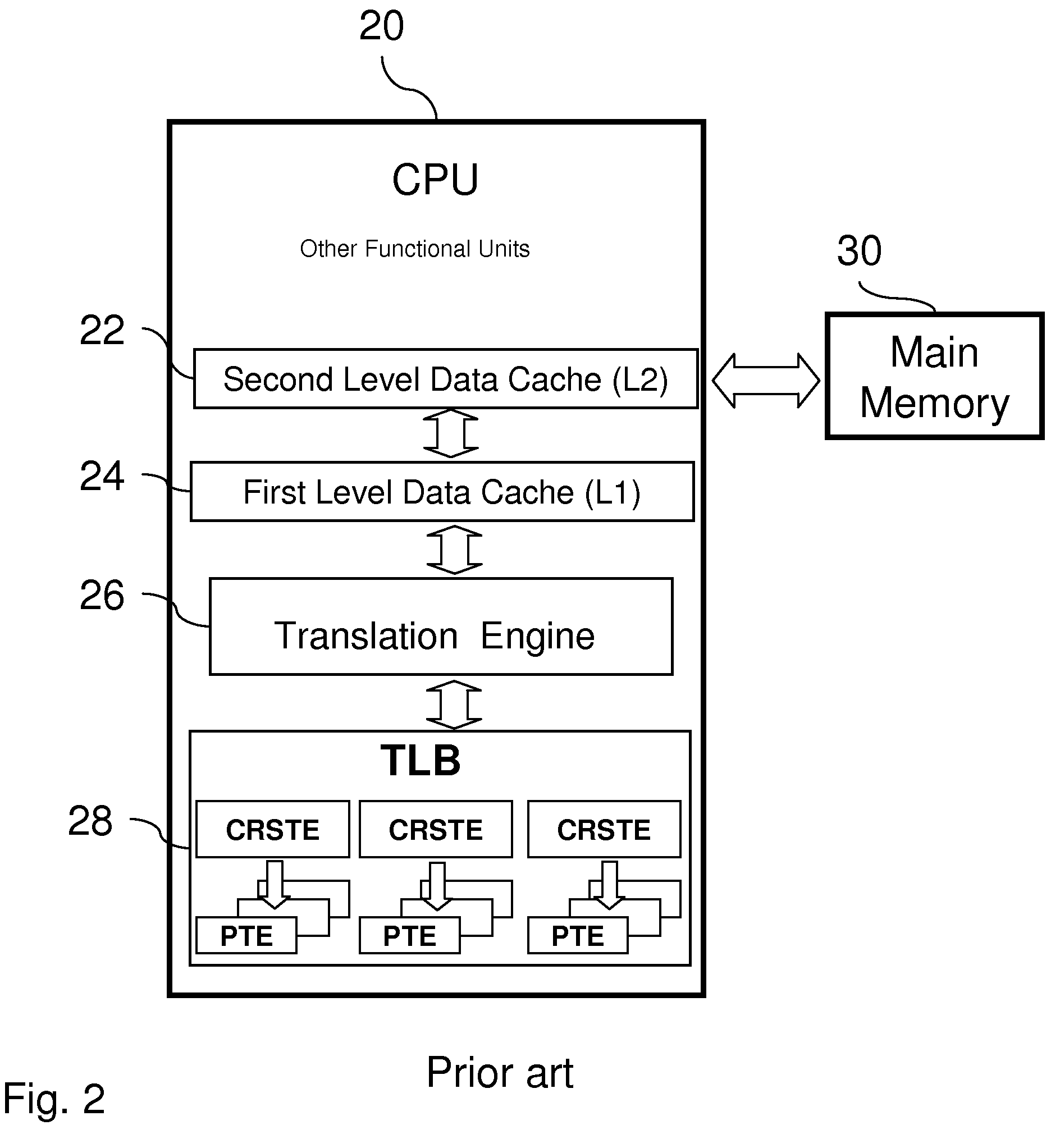

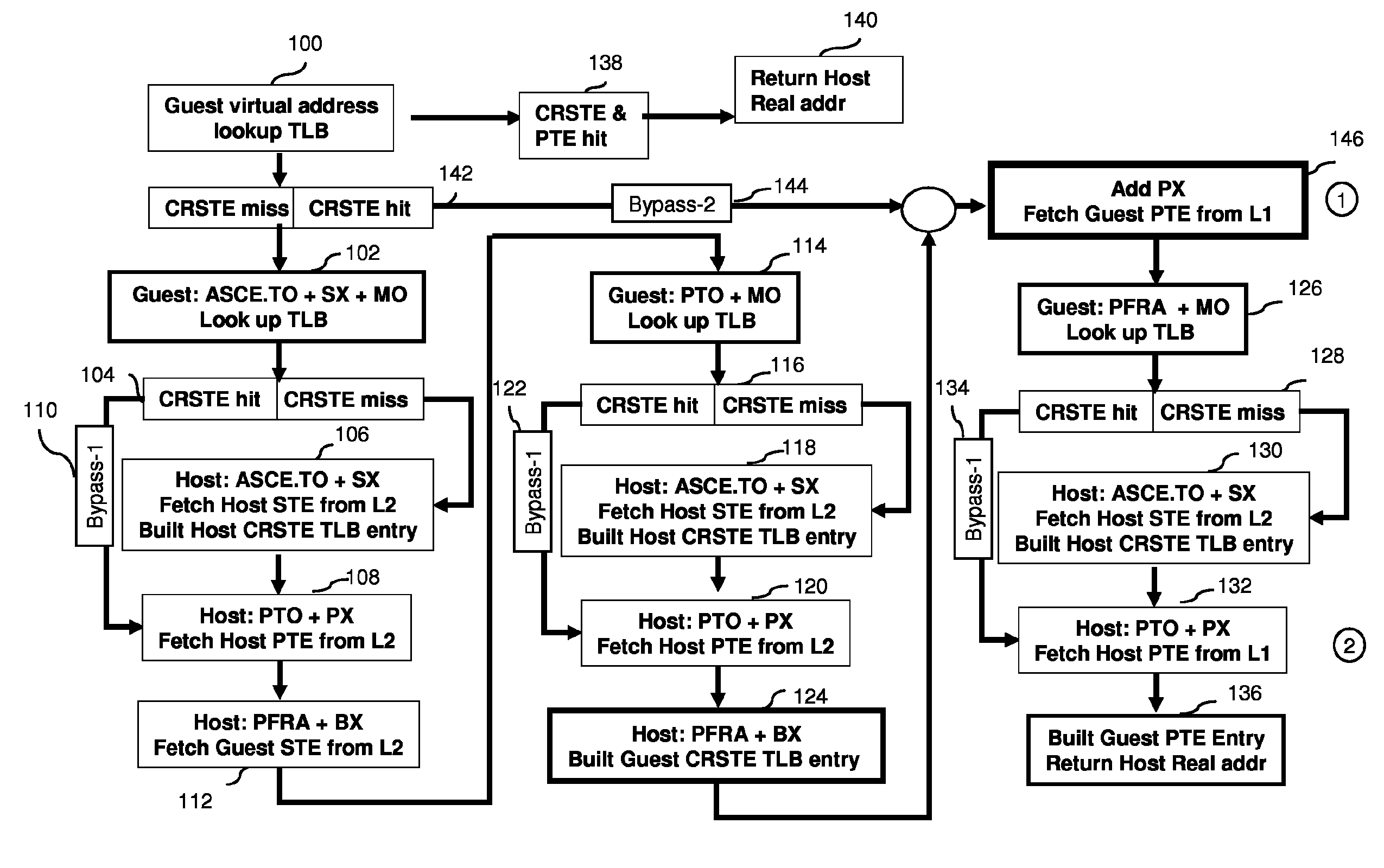

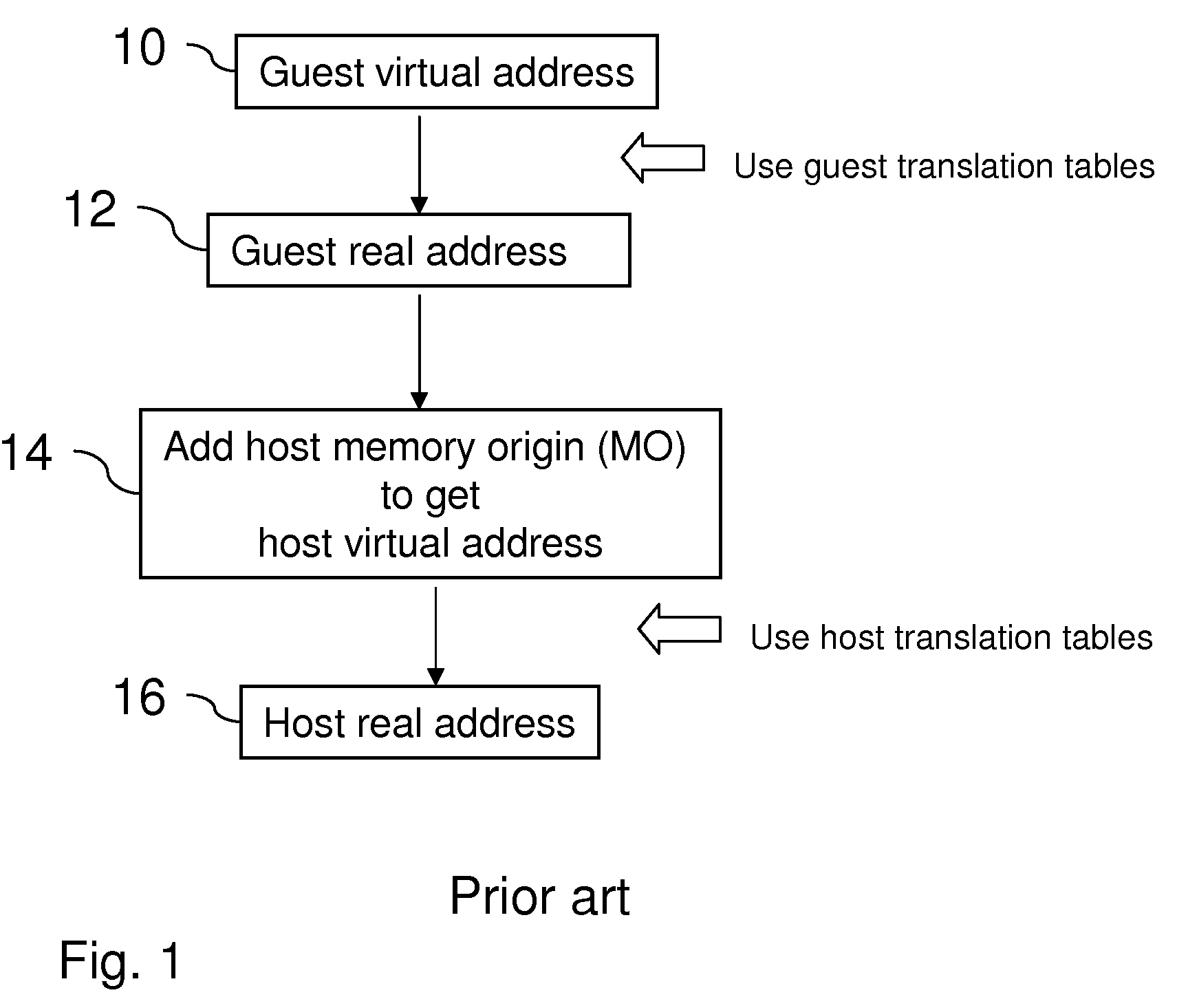

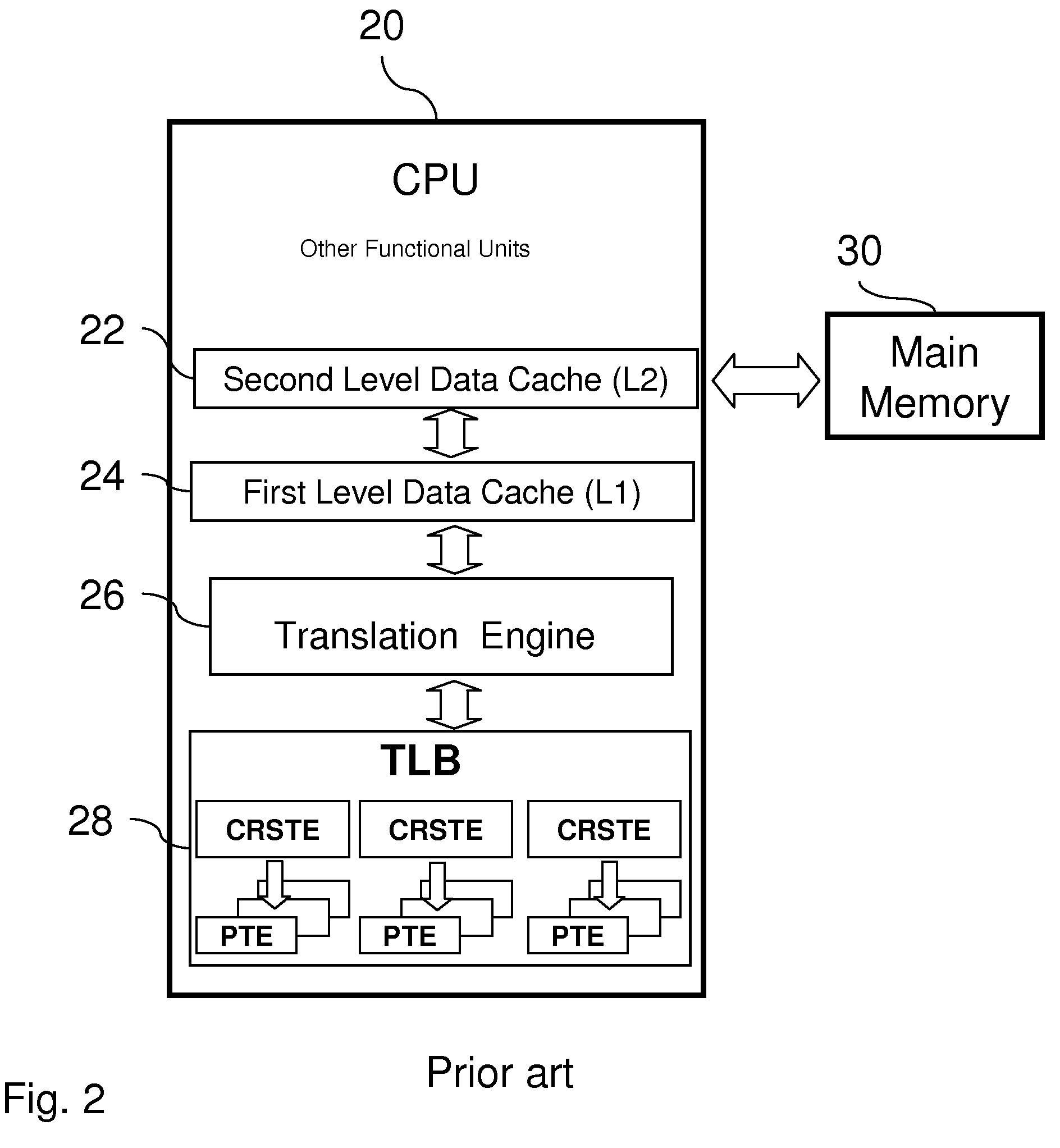

Method for Address Translation in Virtual Machines

InactiveUS20090187731A1Improve performanceAddress performance requirementsMemory adressing/allocation/relocationSoftware simulation/interpretation/emulationTranslation lookaside bufferVirtual machine

The invention relates to a method for address translation in a system running multiple levels of virtual machines containing a hierarchically organized translation lookaside buffer comprising at least two linked hierarchical sub-units, a first sub-unit comprising a lookaside buffer for some higher level address translation levels, and the second sub-unit comprising a lookaside buffer for some lower level address translation levels, and said second sub-unit being arranged to store TLB index address information of the upper level sub-unit as tag information in its lower level TLB structure, comprising the steps of collecting intermediate address translation results on different virtual machine levels; and buffering the intermediate translation results in the translation lookaside buffer.

Owner:IBM CORP

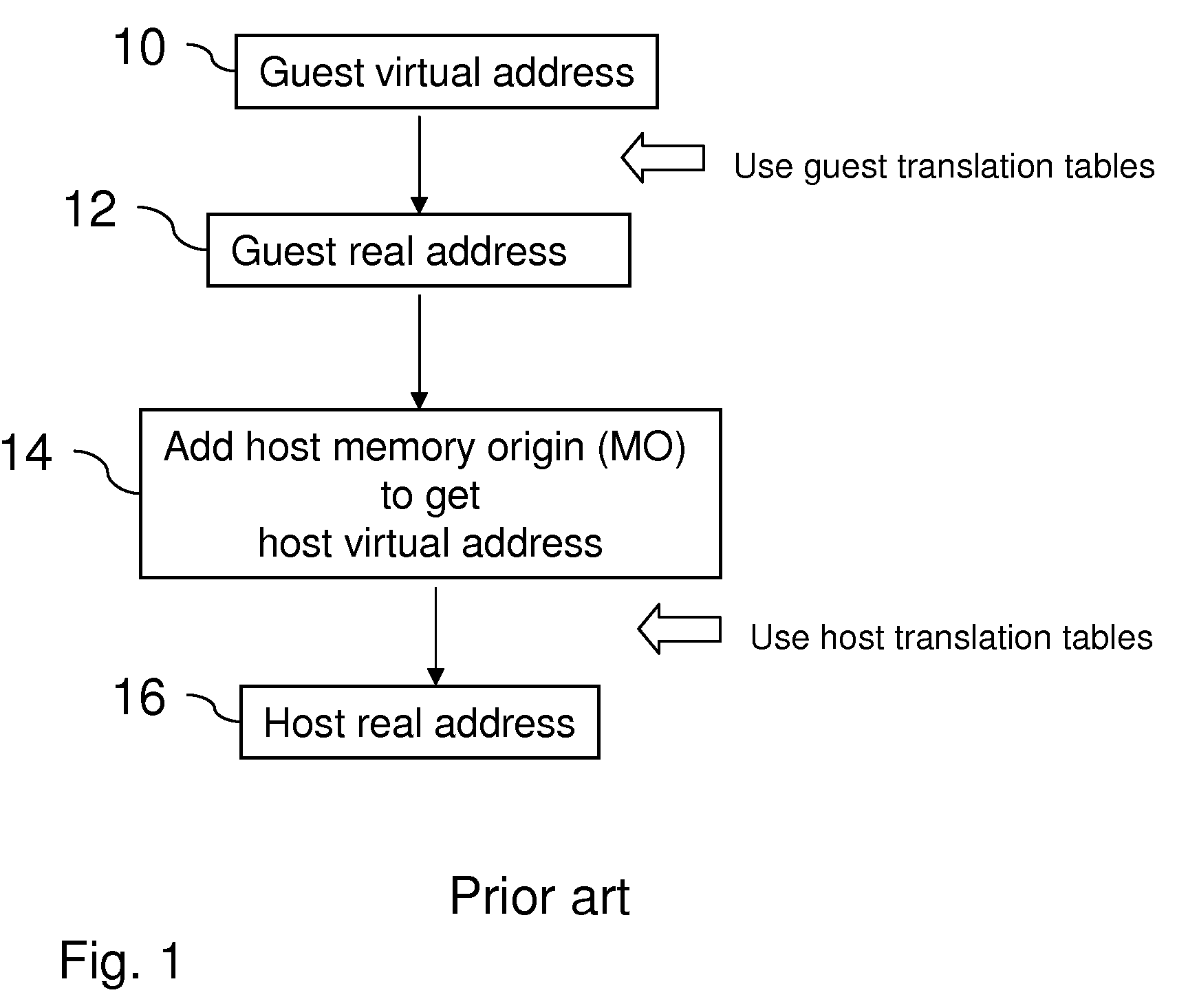

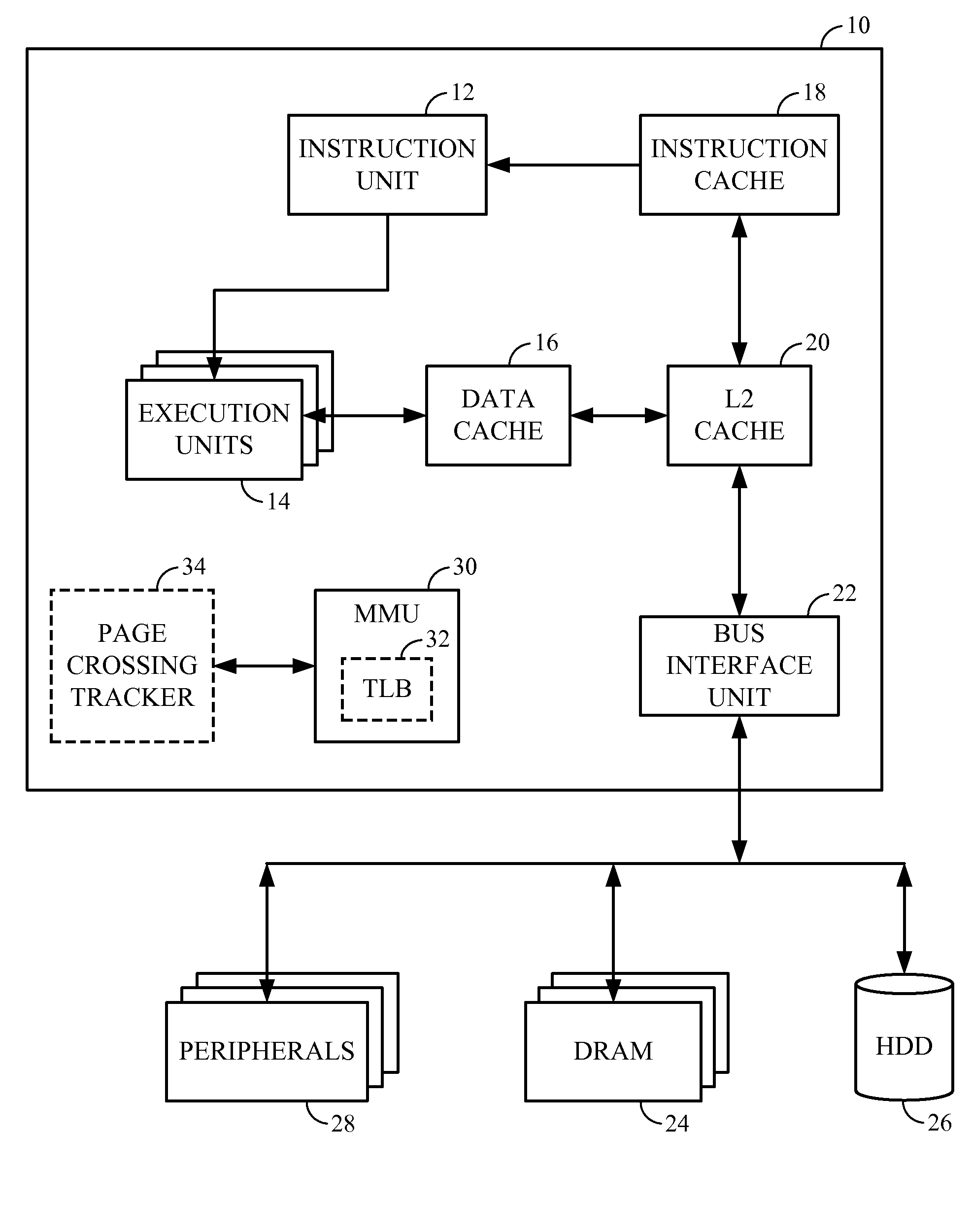

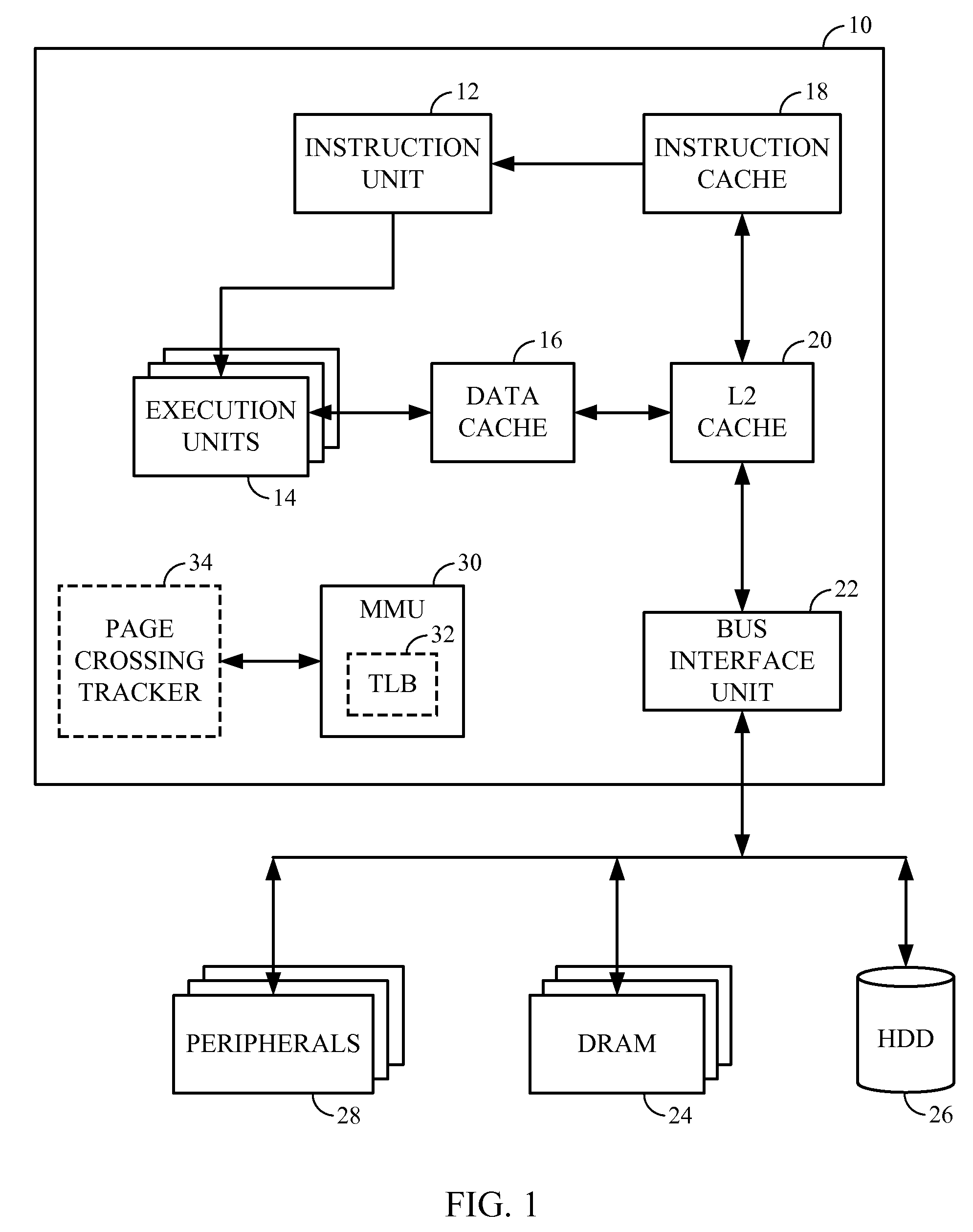

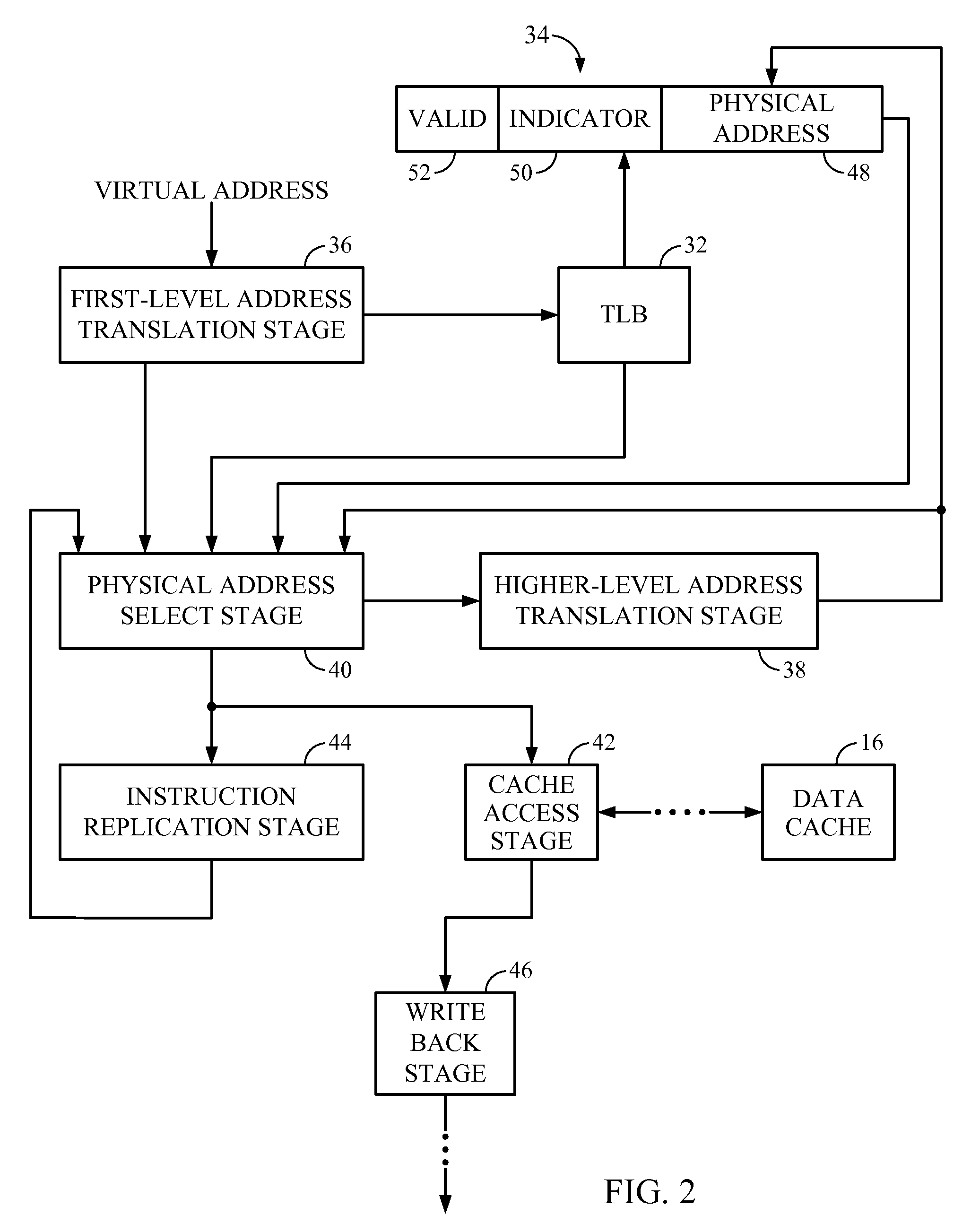

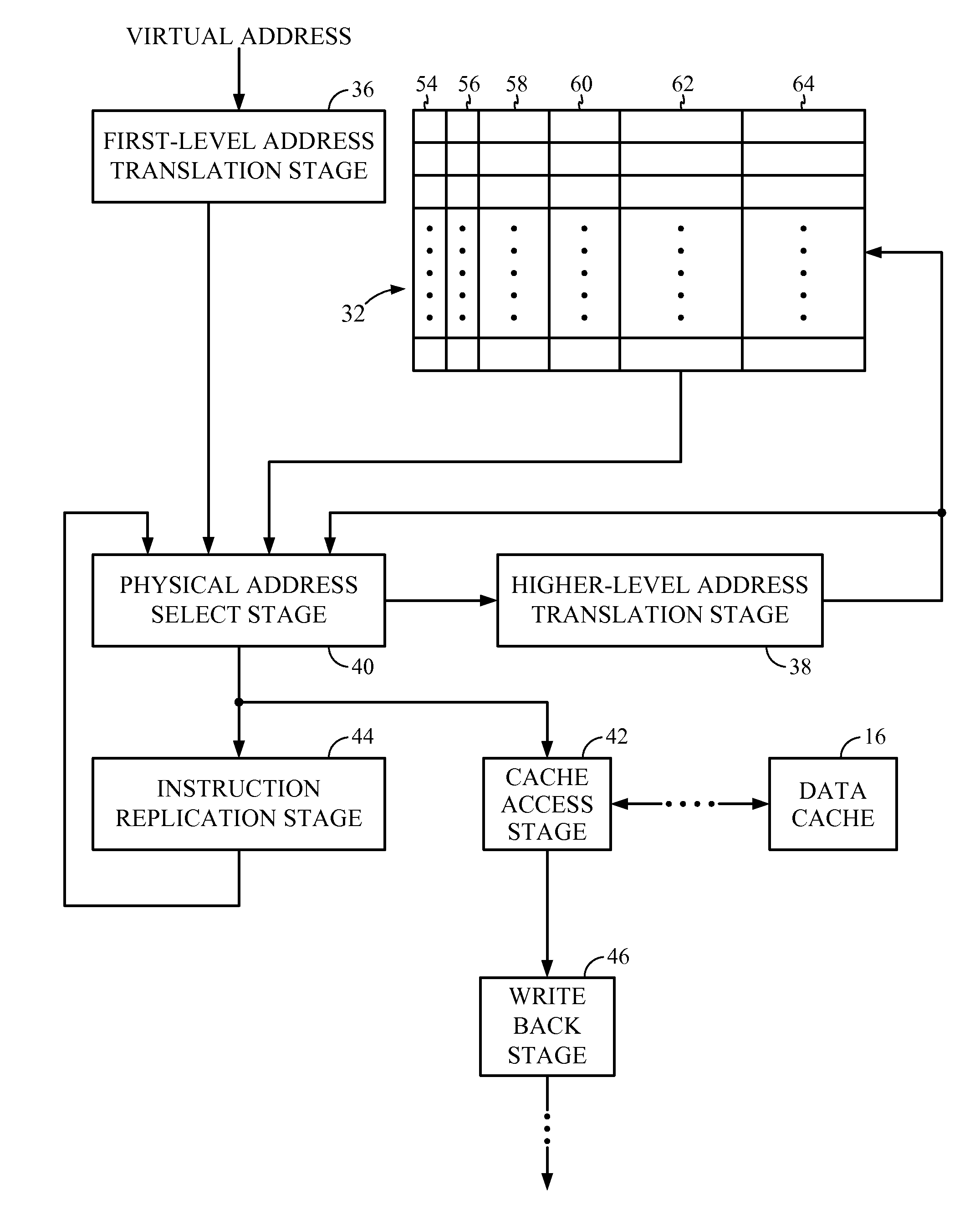

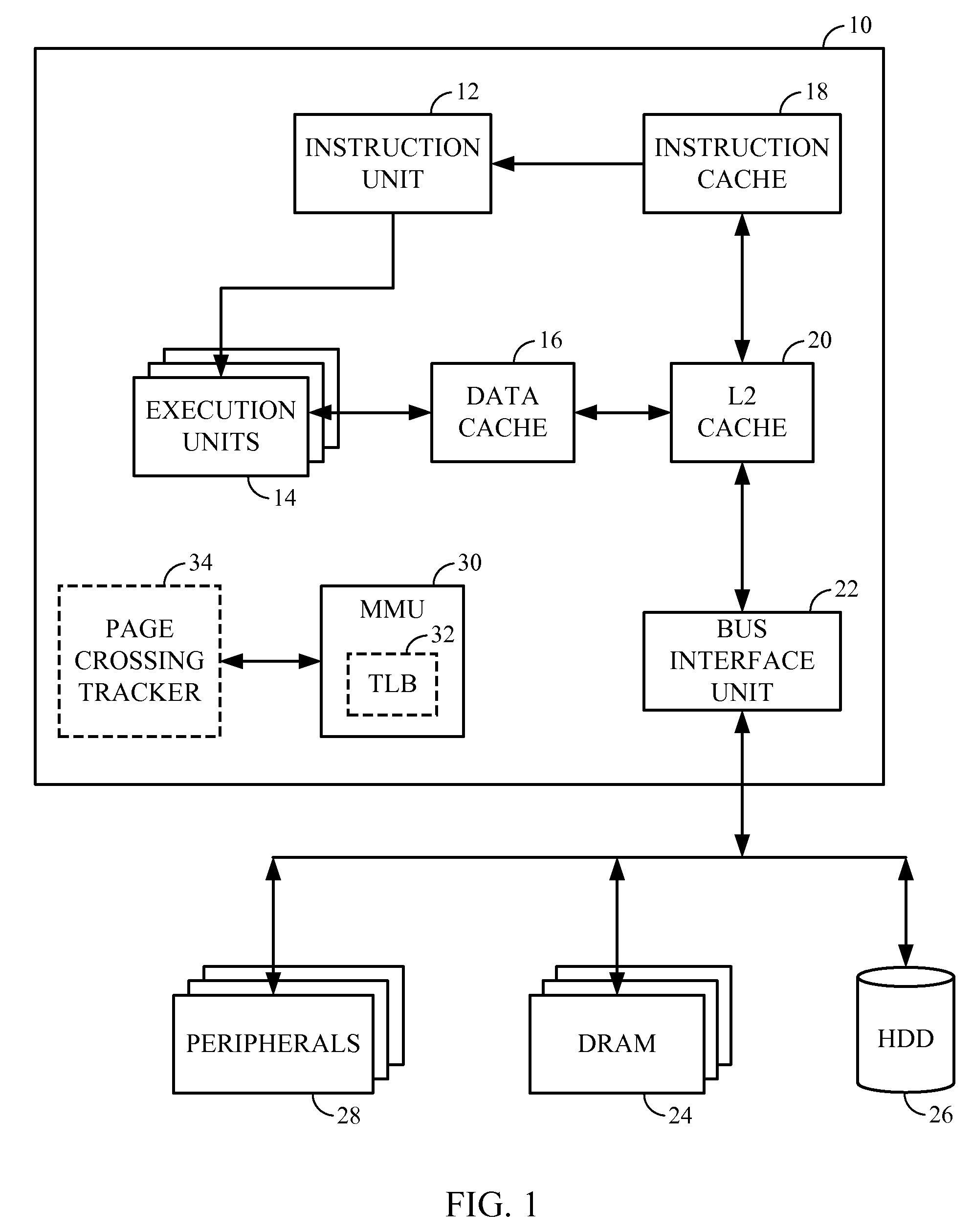

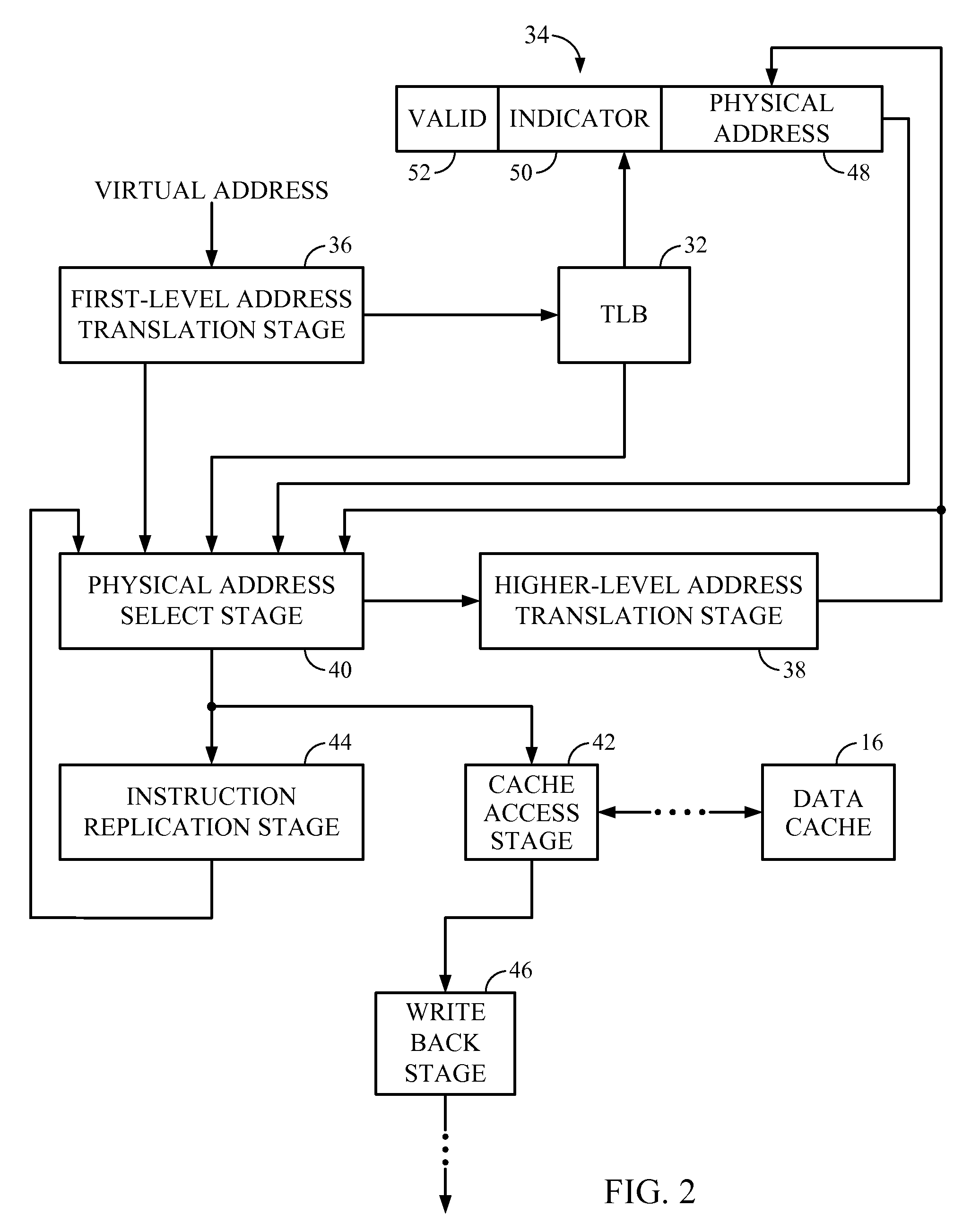

Address Translation Method and Apparatus

ActiveUS20080189506A1Address performance requirementsMultiple address translationMemory architecture accessing/allocationEnergy efficient ICTBoundary crossingOperating system

Address translation performance within a processor is improved by identifying an address that causes a boundary crossing between different pages in memory and linking address translation information associated with both memory pages. According to one embodiment of a processor, the processor comprises circuitry configured to recognize an access to a memory region crossing a page boundary between first and second memory pages. The circuitry is also configured to link address translation information associated with the first and second memory pages. Thus, responsive to a subsequent access the same memory region, the address translation information associated with the first and second memory pages is retrievable based on a single address translation.

Owner:QUALCOMM INC

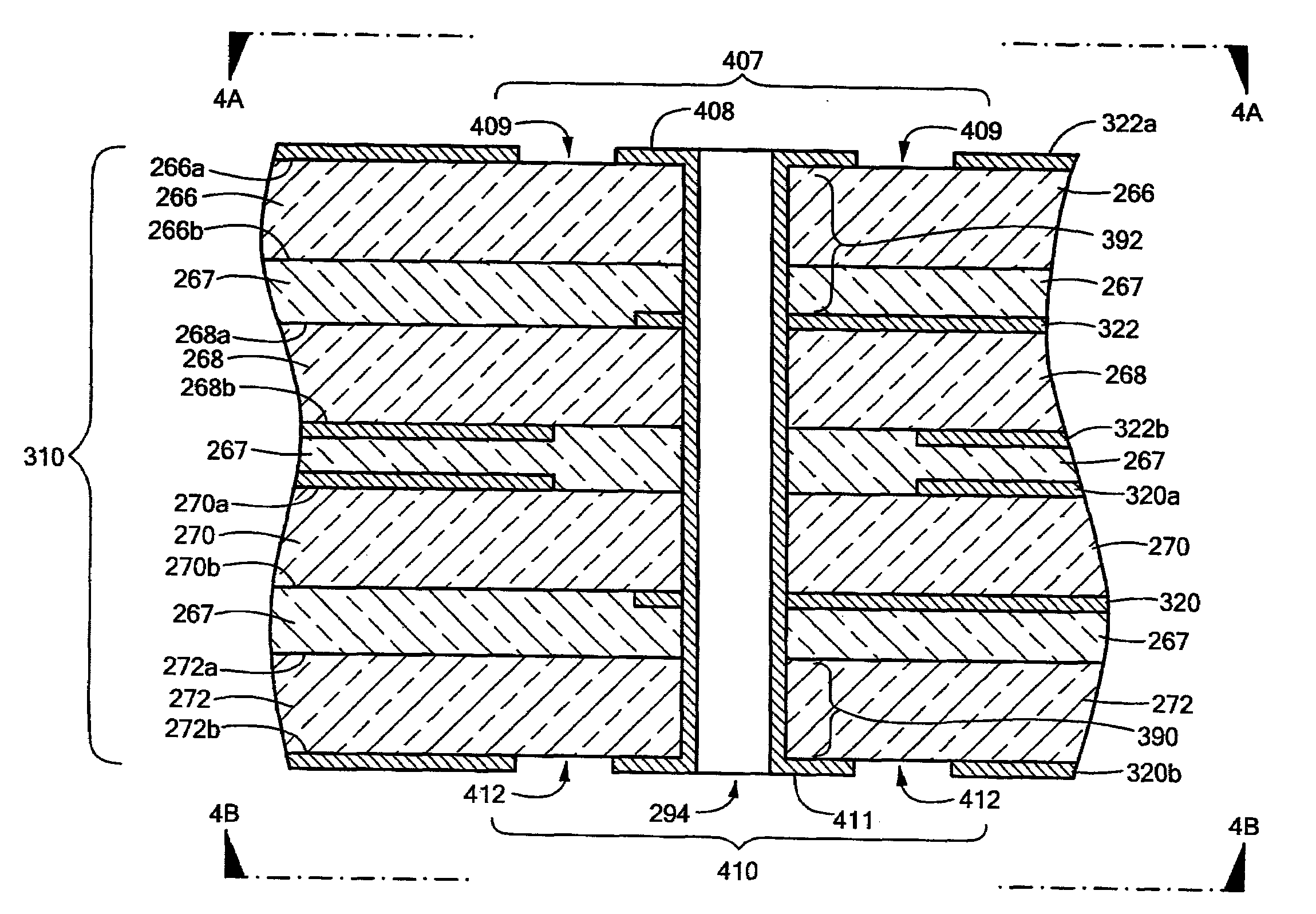

Radio frequency interconnect circuits and techniques

ActiveUS7671696B1Lower acquisition and life cycle costs of phased arraysLow costMultiple-port networksPrinted circuit aspectsEngineeringRadio frequency

A multilayer circuit board assembly includes one or more radio frequency (RF) interconnects between different circuit layers on different circuit boards which make up the circuit board assembly. The RF interconnects can include one or more RF matching pads which provide a mechanism for matching impedance characteristics of RF stubs to provide the RF interconnects having desired insertion loss and impedance characteristics over a desired RF operating frequency band. The RF matching pads allow the manufacture of circuit boards having RF interconnects without the need to perform any back drill and back fill operation to remove stub portions of the RF interconnects in the multilayer circuit board assembly.

Owner:RAYTHEON CO

Method for address translation in virtual machines

InactiveUS8151085B2Improve performanceAddress performance requirementsSoftware simulation/interpretation/emulationMemory systemsNetwork address translationTranslation lookaside buffer

The invention relates to a method for address translation in a system running multiple levels of virtual machines containing a hierarchically organized translation lookaside buffer comprising at least two linked hierarchical sub-units, a first sub-unit comprising a lookaside buffer for some higher level address translation levels, and the second sub-unit comprising a lookaside buffer for some lower level address translation levels, and said second sub-unit being arranged to store TLB index address information of the upper level sub-unit as tag information in its lower level TLB structure, comprising the steps of collecting intermediate address translation results on different virtual machine levels; and buffering the intermediate translation results in the translation lookaside buffer.

Owner:IBM CORP

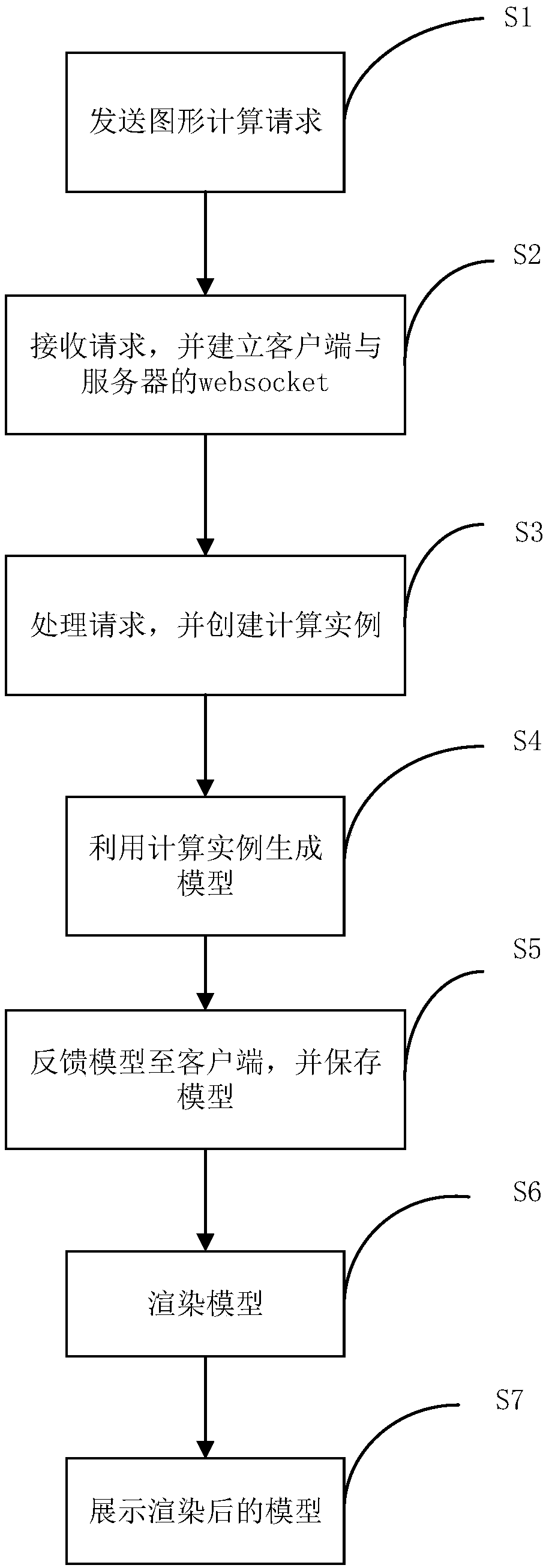

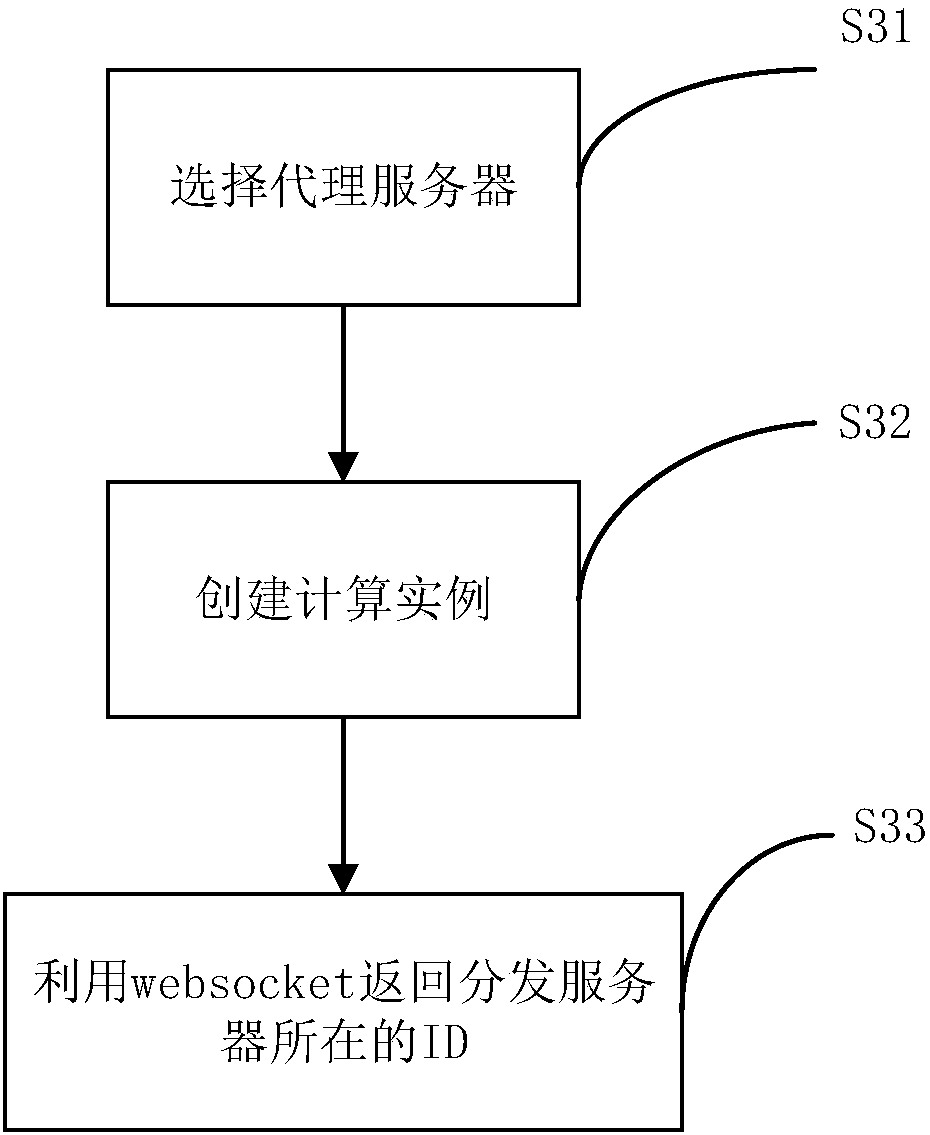

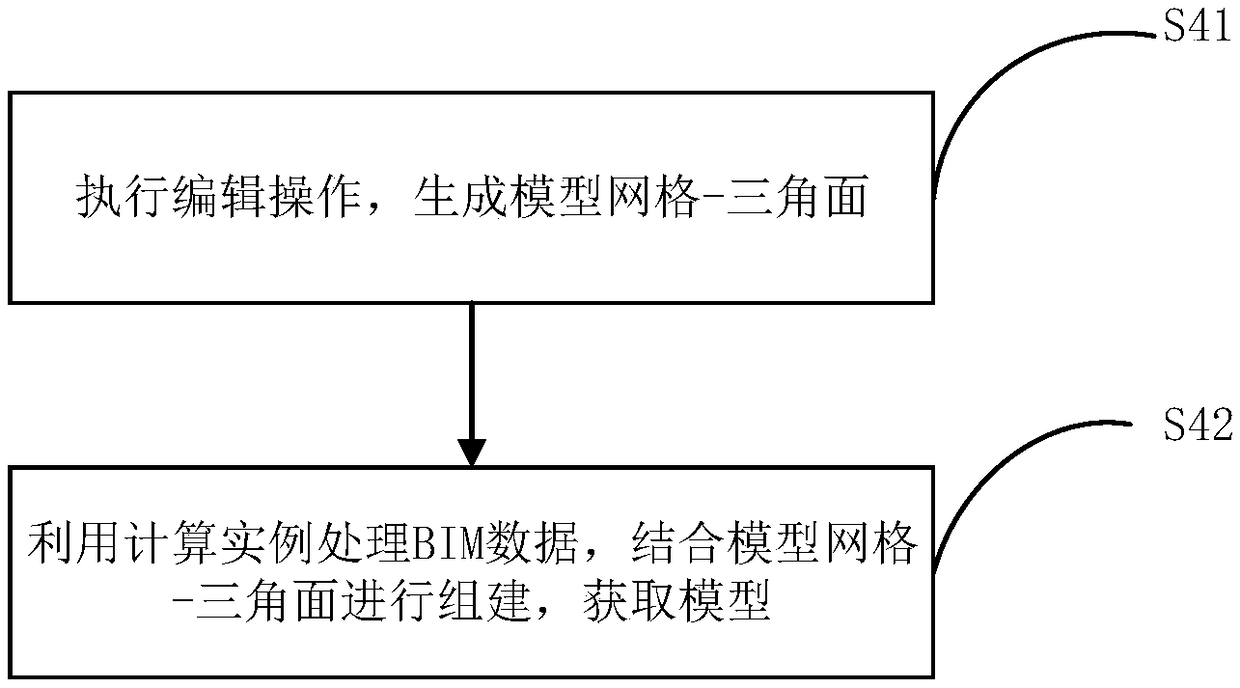

Real-time BIM model rendering method and device based on browser

InactiveCN108074274AAddress performance requirementsSolve problems with high performance requirementsImage generation3D-image renderingClient-sideReal-time rendering

The invention discloses a real-time BIM model rendering method and device based on a browser. The method includes the following steps of sending a graph calculation request; receiving the request andestablishing a websocket between a client side and a server; processing the request and creating a calculation instance; using the calculation instance to generate a model; feeding back the model to the client side and saving the model; rendering the model; displaying the rendered model. According to the scheme, a BIM model is processed on the server side and rendered and displayed on the browser,the problems of slow rendering speed and high computer performance requirements of current online rendering software are solved, storage and calculation of all BIM models are completed on the cloud server, and the client side can conduct rendering only through the browser to meet the rendering needs of different users in different areas and different time; in addition, users can check geometric information, physical information and other required parameters of components in real time while seeing the realistic rendering effect.

Owner:深圳拎得清软件有限公司

Radio frequency interconnect circuits and techniques

ActiveUS20100033262A1High bandwidthImproving polarization diversityMultiple-port networksHigh frequency circuit adaptationsFrequency bandRadio frequency

A multilayer circuit board assembly includes one or more radio frequency (RF) interconnects between different circuit layers on different circuit boards which make up the circuit board assembly. The RF interconnects can include one or more RF matching pads which provide a mechanism for matching impedance characteristics of RF stubs to provide the RF interconnects having desired insertion loss and impedance characteristics over a desired RF operating frequency band. The RF matching pads allow the manufacture of circuit boards having RF interconnects without the need to perform any back drill and back fill operation to remove stub portions of the RF interconnects in the multilayer circuit board assembly.

Owner:RAYTHEON CO

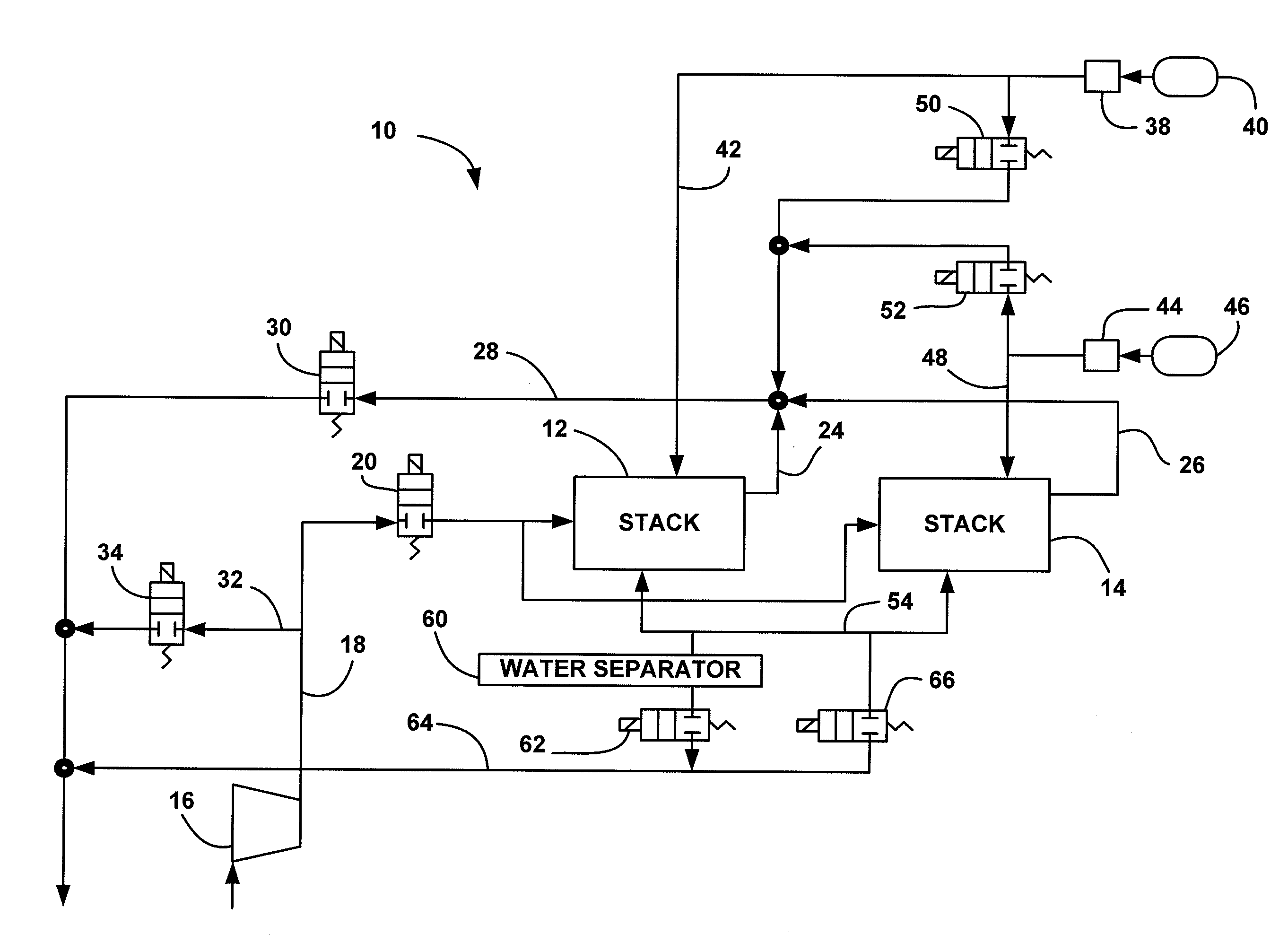

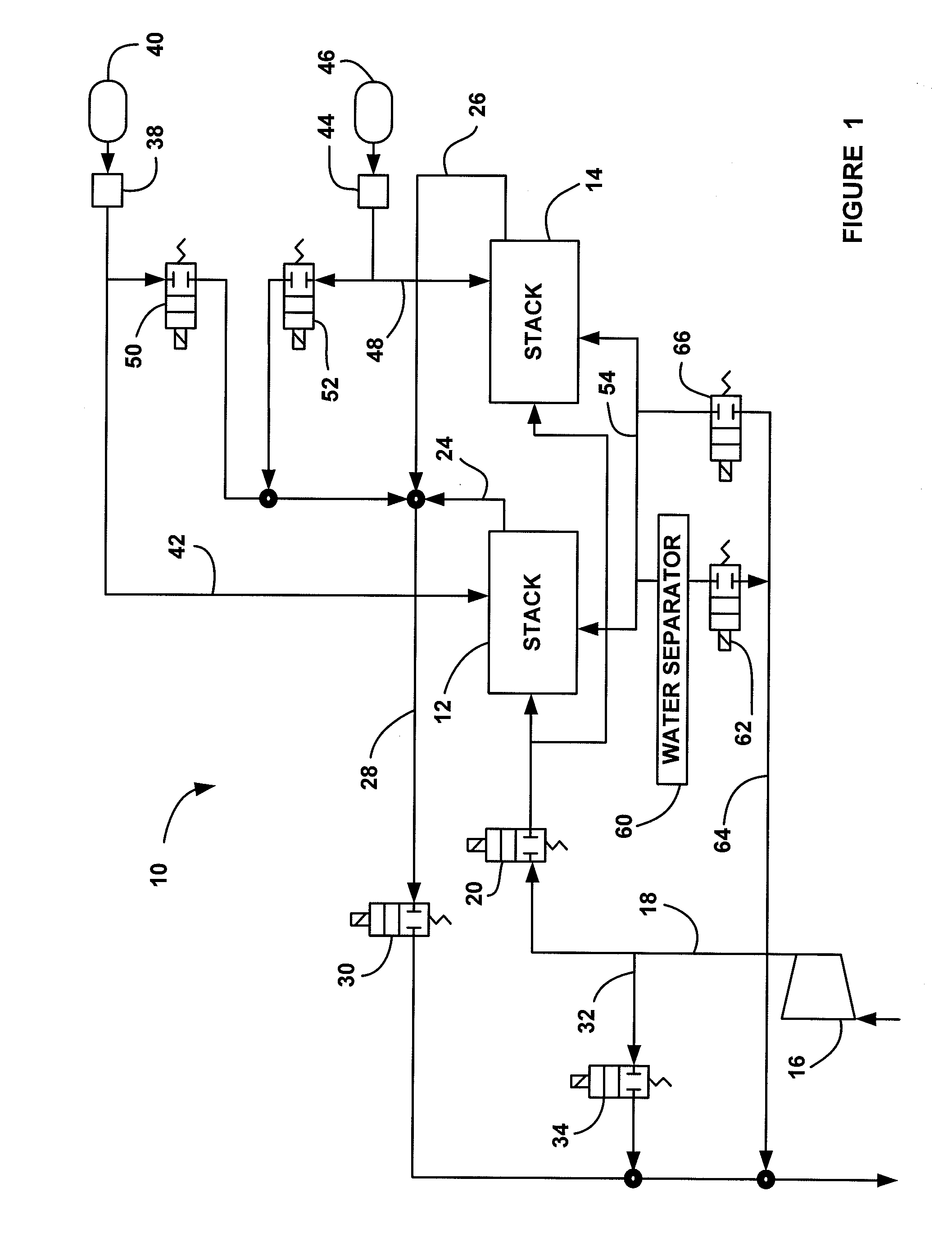

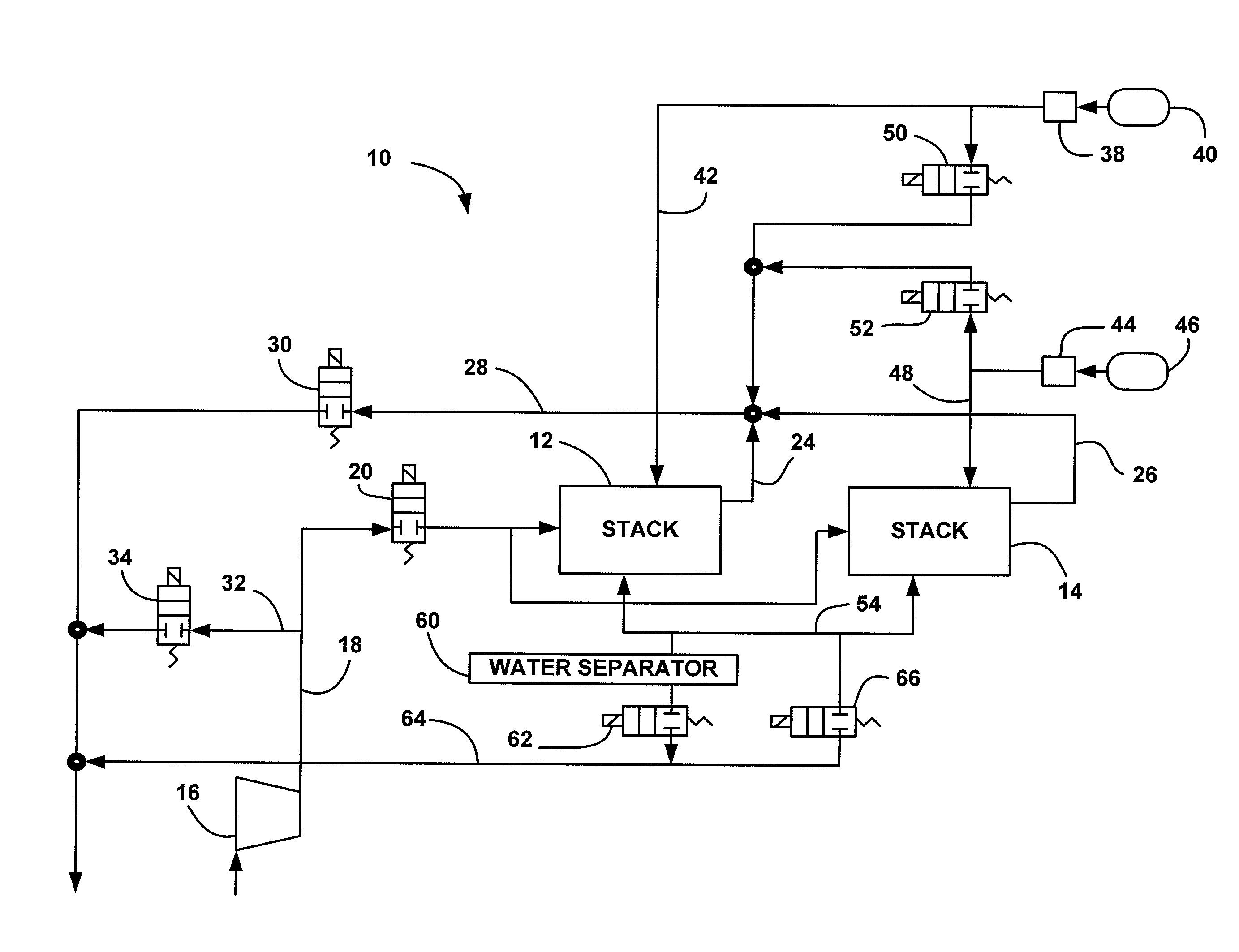

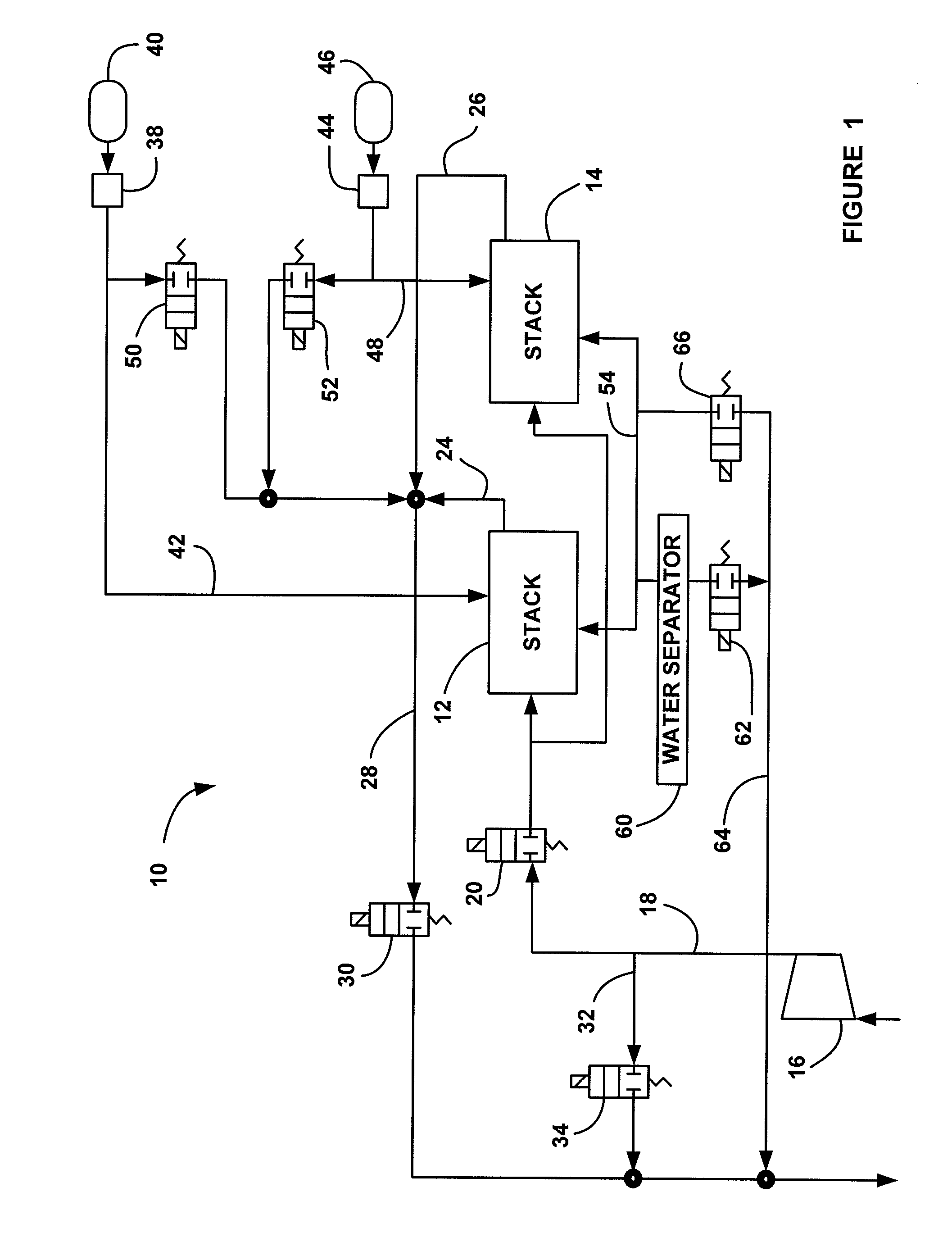

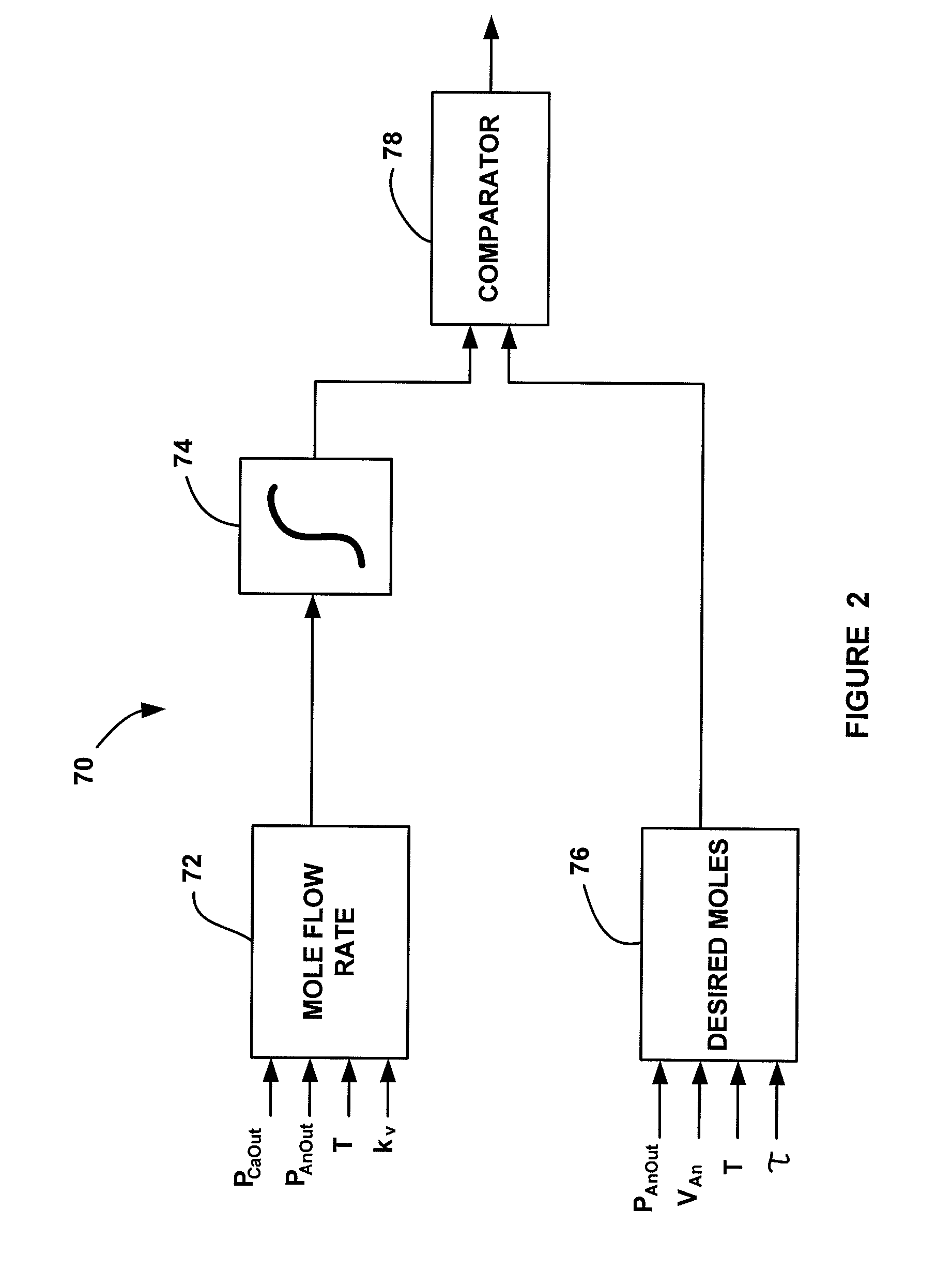

Anode Bleed Control Strategy for Improved Water Management and Hydrogen Utilization

ActiveUS20080312849A1Improve water managementSolve the durability problemVolume flow measuring devicesVolume/mass flow by differential pressureHydrogenFuel cells

A control strategy for bleeding an anode side of fuel cell stack in a fuel cell system that improves water management and addresses durability and performance concerns. The method includes determining when to begin the anode bleed, typically by estimating or measuring the amount of nitrogen in the anode side of the stack. The method also includes determining when to end the anode bleed based on the volume of gas that has been bled. The method determines the mole flow rate of the anode gas flowing through a bleed valve, integrates the mole flow rate to get the number of moles of the gas that have passed through the bleed valve, determines a desired amount of moles to be bled, and ends the bleed when the actual number of moles of the gas equals the desired number of moles of the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

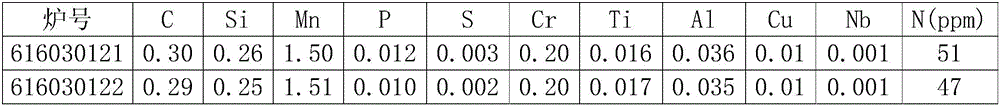

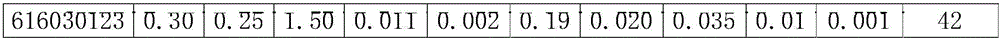

Production process for effectively preventing marine anchor chain round steel from generating cracks

InactiveCN106086595ASolve the problem of nozzle nodulationReduce inclusion contentProcess efficiency improvementElectric furnaceChemical compositionSlag

The invention relates to a production process for effectively preventing marine anchor chain round steel from generating cracks. A preparation method includes the steps of an electric furnace smelting procedure, a refining procedure outside an LF, a square billet continuous casting procedure and a rolling procedure. Chemical components are reasonably designed, the carbon equivalent is controlled, Ti microalloy reinforcement is added, the content of P and S is controlled to be smaller than or equal to 0.015%, the content of N is controlled to be smaller than or equal to 70 ppm, the content of residual elements of Cu, Nb and the like is reasonably controlled, the LF is well sealed, the soft blowing flow of argon is reasonably controlled, molten steel is prevented from absorbing nitrogen, aluminum deoxidation is enhanced, the soft blowing time of the argon is properly prolonged, whole-process protective casting is adopted for the continuous casting, the pulling speed and the superheat degree are low, proper protective slag is selected, the straightening temperature is raised, continuously cast billet enters a pit to be slowly cooled, the tapping interval is well controlled in a rolling manner, the compression ratio is increased, and a reasonable heat treatment process is selected. The marine anchor chain round steel produced through the method is simple in procedure and low in cost, vacuum treatment is not needed, and the technical problems that marine anchor chain round steel produced at present is bad in surface quality, high in crack occurrence ratio, not stable in quality and the like are solved.

Owner:ZENITH STEEL GROUP CORP

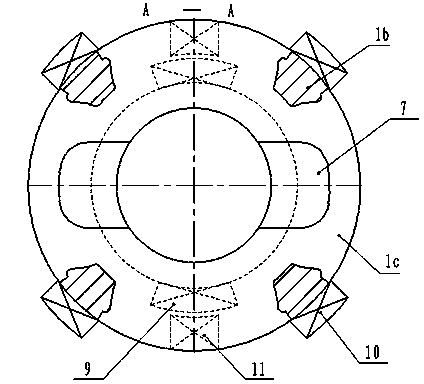

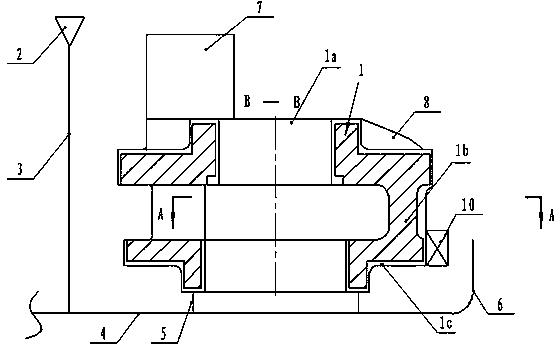

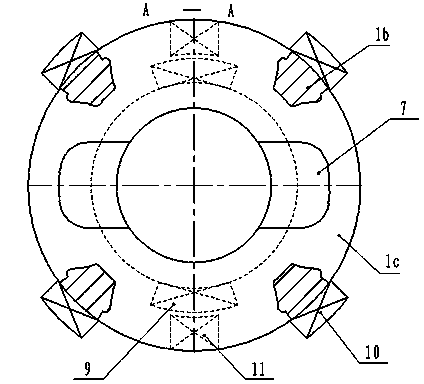

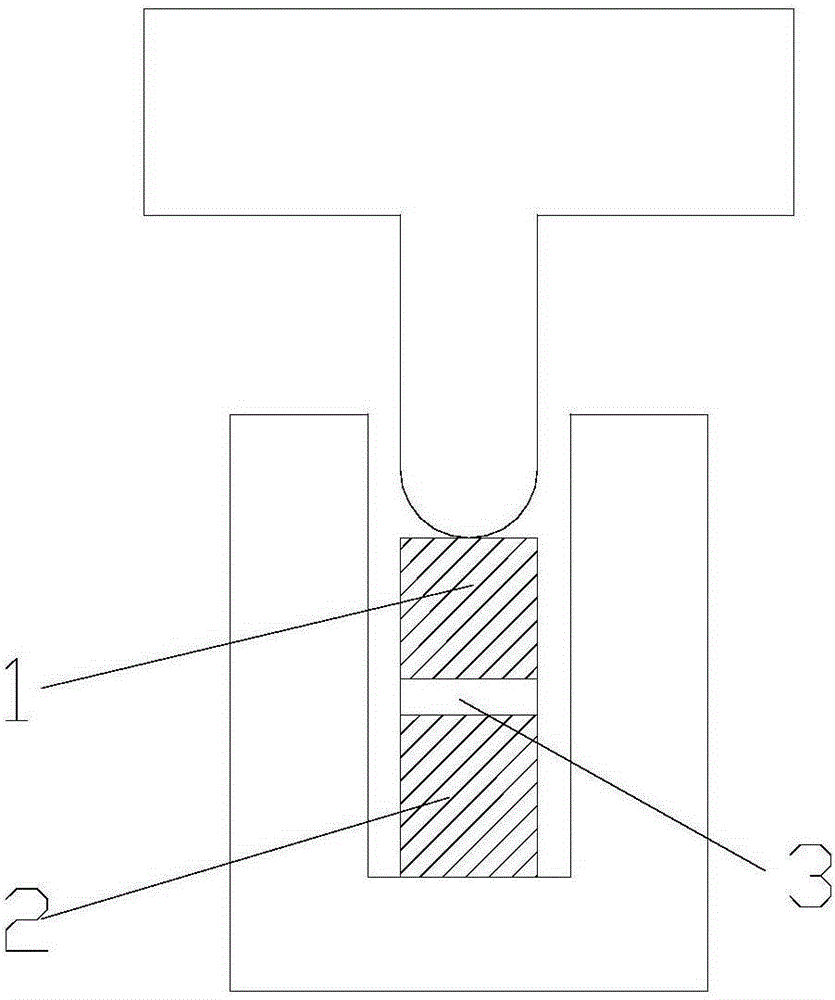

Casting technology for three-stage planetary frame of ocean platform climbing machine

ActiveCN104174819AMeet performance requirementsAddress performance requirementsFoundry mouldsFurnace typesThree stagePre treatment

The invention discloses a casting technology for a three-stage planetary frame of an ocean platform climbing machine. A three-stage planetary frame casting of the ocean platform climbing machine is obtained by performing an integrated casting forming technology and thermal treatment on a ZG35Gr1Mo material. The casting technology comprises the following processing steps: (a) molten liquid smelting; (b) casting process: forming two deadheads and four attaches, placing chill blocks, wherein the attaches are connected with the roots of the deadheads and are arranged at the top ends of vertical columns of the casting; the chill blocks comprise four #2 molded chill blocks, two #1 molded chill blocks and two #3 outer chill blocks which are respectively arranged at the thickest parts at the lower parts of the vertical columns and the thickest parts on the end faces of the bottoms; (c) normalization and tempering pretreatment; (d) tempering thermal treatment. Due to the mode, by reasonable arrangement of the deadheads, the attaches and the chill blocks, the internal quality, the size precision and the mechanical performance of the casting can be improved; meanwhile, the use amount of molten steel can be reduced, and the production cost is lowered.

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

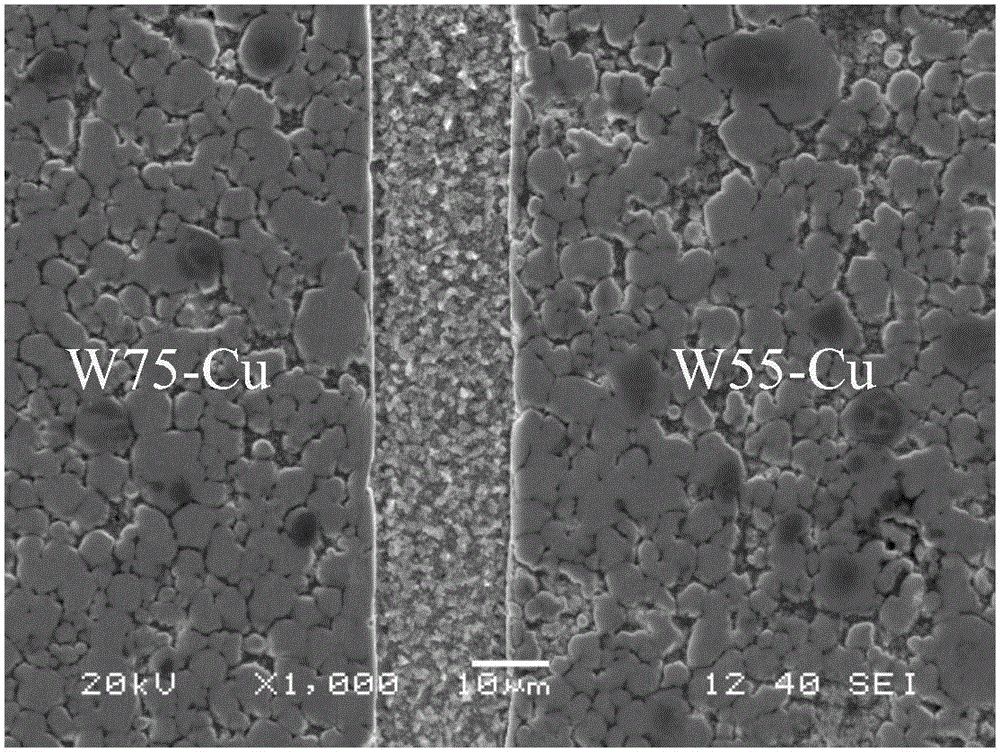

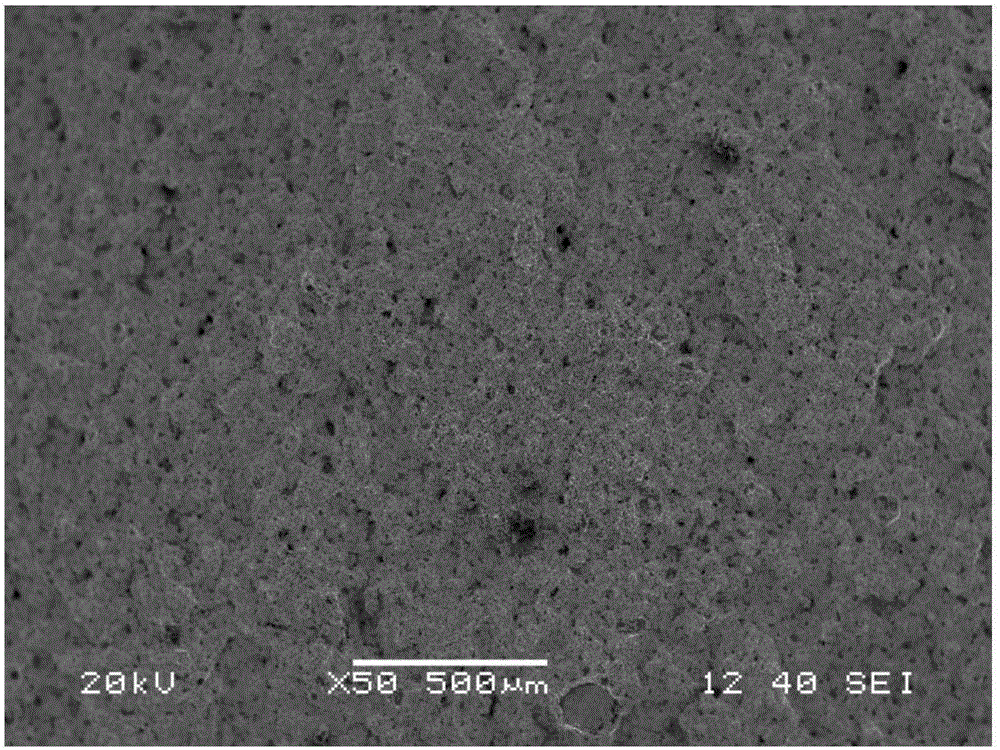

Solder for soldering different-component W-Cu alloy, preparing method and soldering method thereof

ActiveCN105171270AAccelerated corrosionEasy to processWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingCopper

The invention discloses a solder for soldering a different-component W-Cu alloy, a preparing method and a soldering method thereof. The mass percents of the components of the solder are described as follows: 10.0-16.0% of Mn, 0.5-3.5% of Co, 1.0-5.0% of Ni, 1.0-4.0% of Ti, 0.2-0.6% of Si, 0.1-.03% of B, and the balance of Cu. The soldering temperature of the copper-based solder is 1000-1050 DEG C. Moderate fusing temperature of the solder and high fusion uniformity of the solder are realized. Through adding related beneficial elements, good wetability and high metallurgical miscibility of the solder to the W-Cu alloy are realized. An obtained solder joint has high strength and high corrosion resistance and can be totally applied in a complicated environment. The solder is an economical solder with high comprehensive performance. A prepared copper-based solder foil has functions of facilitating diffusion and interface reaction between alloy elements in a soldering connecting process, improving wetting and spreading capabilities of the solder on the surface of the W-Cu alloy, and facilitating forming of a compact solder joint.

Owner:无锡腾达海川新材料有限公司

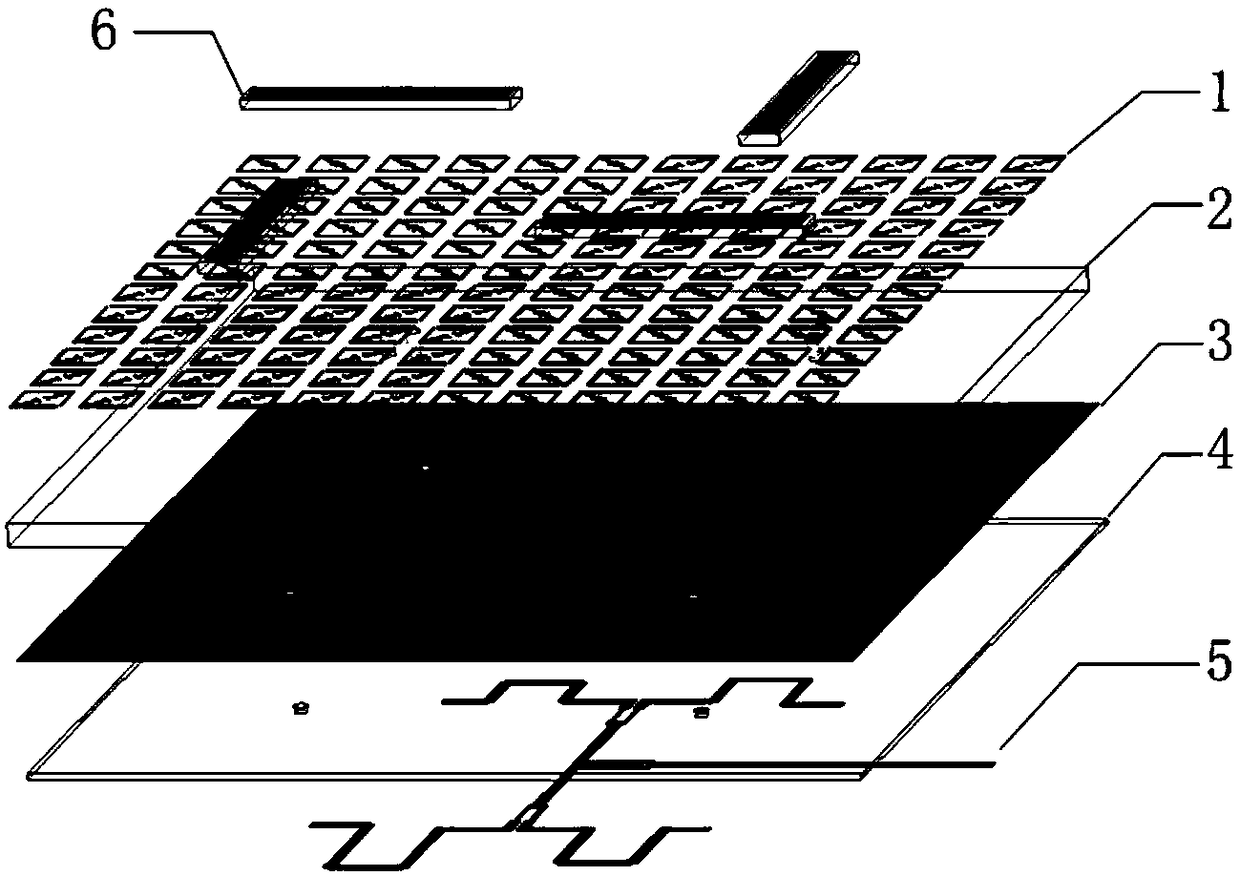

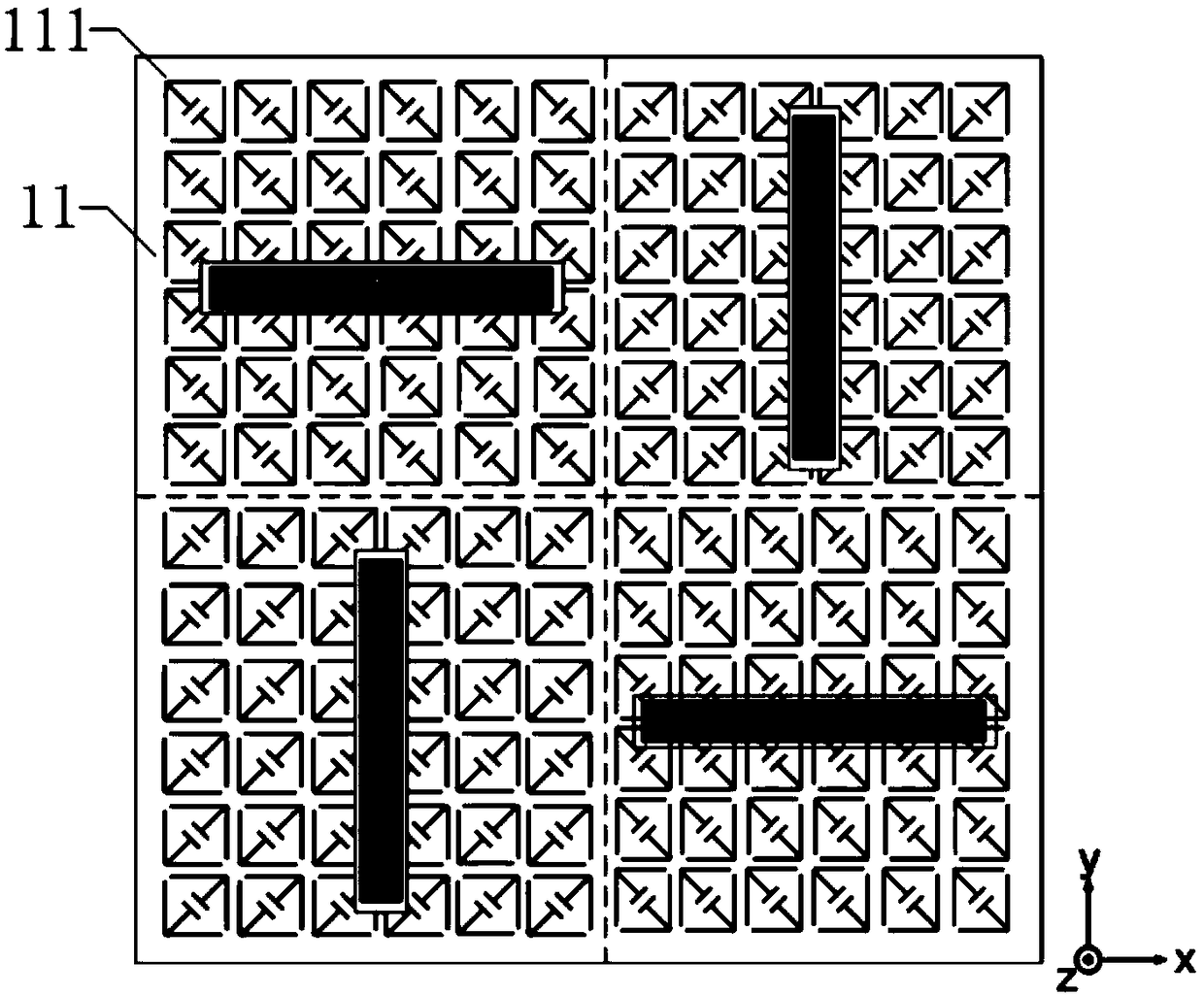

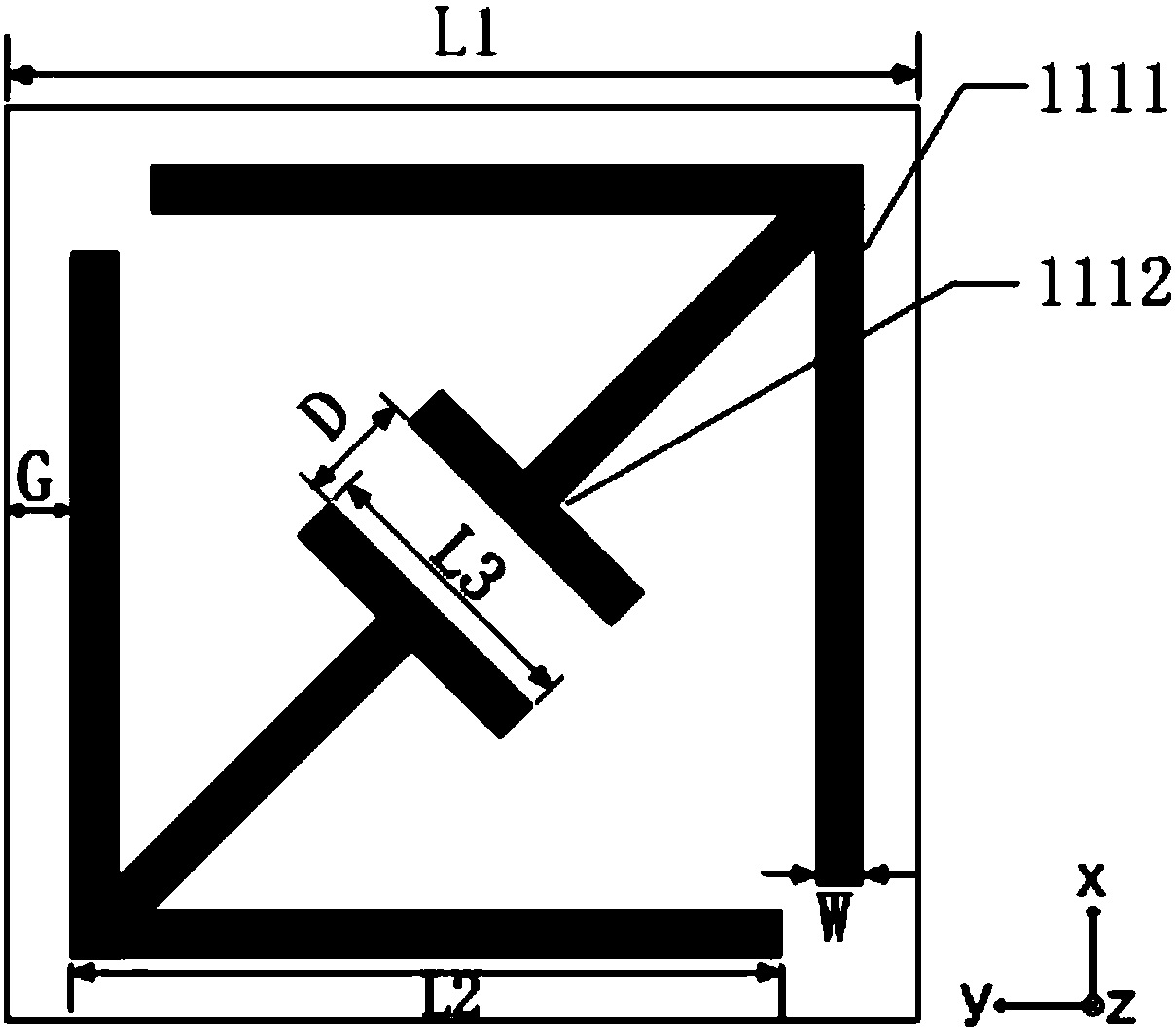

Low radar cross section array antenna based on polarization conversion

InactiveCN108963438ATo overcome the low polarization conversion rateAchieving Low Profile PropertiesAntenna arraysRadiating elements structural formsPhysicsBroadband

The invention provides a low radar cross section array antenna based on polarization conversion. The antenna comprises a polarization conversion supersurface, a first dielectric plate printed on a lower surface of the polarization conversion supersurface, and a metal floor printed on a lower surface of the first dielectric plate. A second dielectric plate and a feed network on the low surface of the second dielectric plate are arranged on the low surface of the metal floor. The polarization conversion supersurface is composed of four square polarization conversion unit groups and N polarization conversion units arranged periodically. Each polarization conversion supersurface unit is composed of a pair of L-shaped metal patches located at the edge of the polarization conversion unit and T-shaped metal patches located in the center of the polarization conversion unit, the patches being of the same structure. The facing ends of the T-shaped metal patches are parallel to each other, and opposite ends of the T-shaped metal patches are connected to the right angles of the two respective L-shaped metal patches. The low radar cross section array antenna is high in polarization conversion rate within the broadband and solves the technical problems of the reduced radar cross section and the narrow bandwidth in the prior art.

Owner:XIDIAN UNIV +1

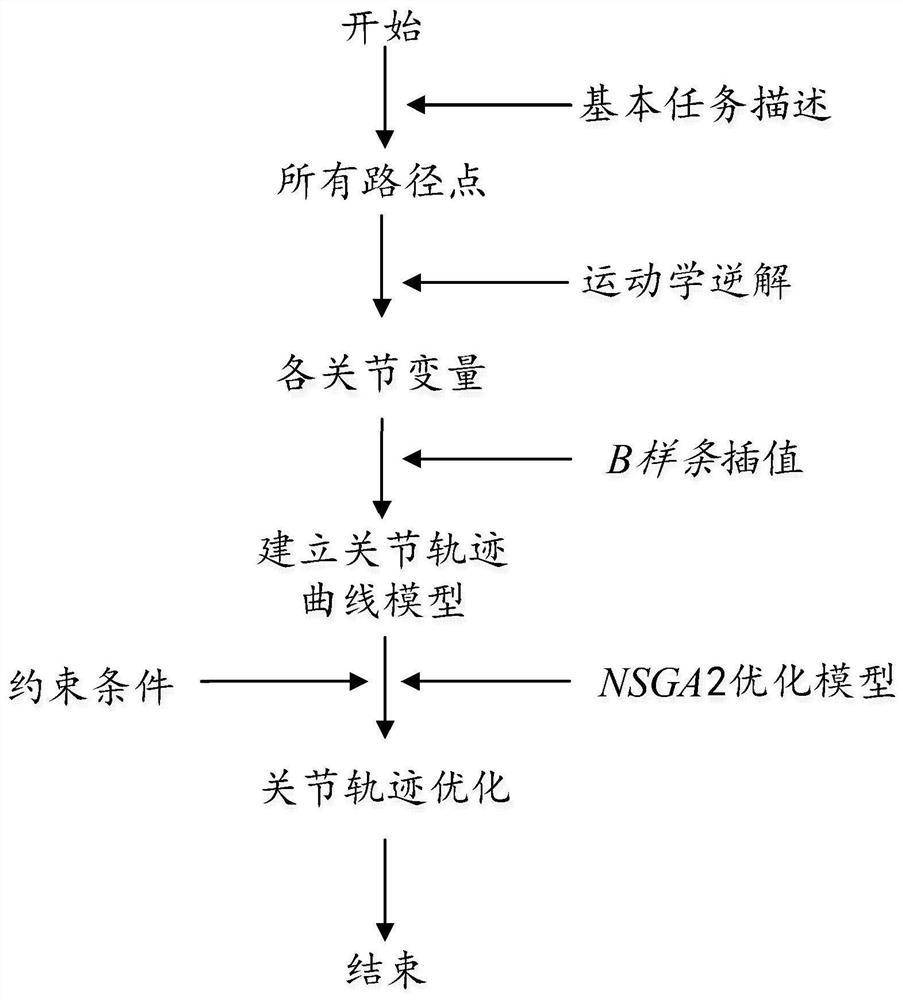

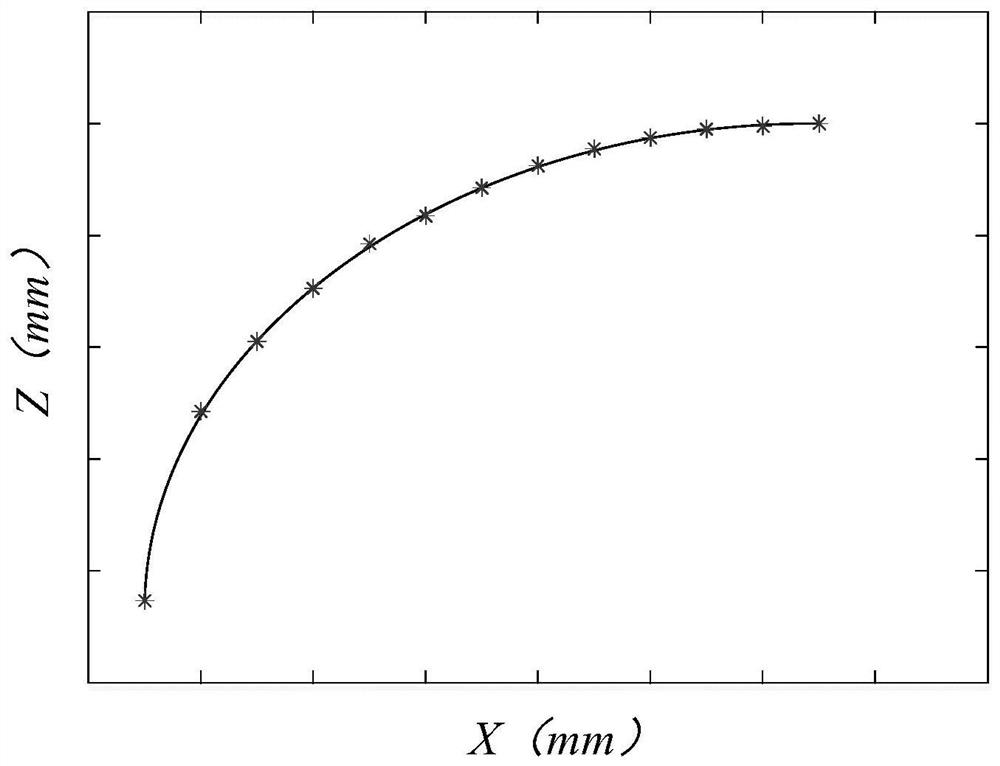

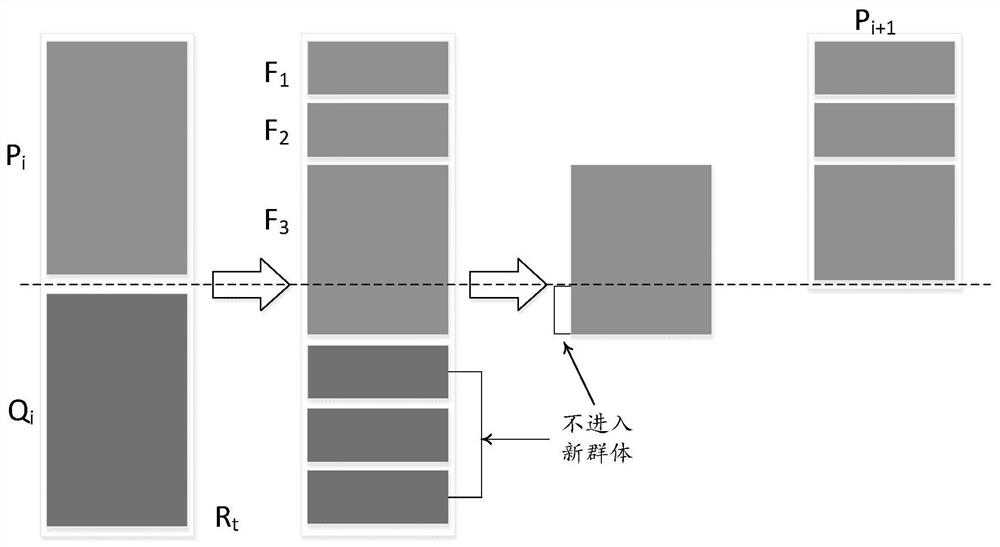

Multi-machine cooperative trajectory optimization method based on quintic non-uniform rational B-spline

InactiveCN113296407AAddress performance requirementsOvercoming the Runge phenomenonAdaptive controlAlgorithmMathematical model

The invention discloses a multi-machine cooperative trajectory optimization method based on a quintic non-uniform rational B-spline, and the method comprises the steps of firstly, carrying out discretization on a machining path of each robot after the respective motion trajectory of each robot is determined, carrying out inverse solution on the discrete points through the robots, and obtaining a series of joint position sequences in a joint space, interpolating the joint sequence by using a quintic non-uniform rational B spline mathematical model, and constructing a high-order continuous joint trajectory with designable end point motion parameters; adopting a non-dominated sorting genetic algorithm (NSGA2) with an elitist strategy, taking operation time and trajectory smoothnessas targets, taking time intervals serve as decision variables to optimize the motion trajectory of a mechanical arm, and obtaining a high-order continuous optimized trajectory. According to the method, a Runge phenomenon of polynomial interpolation caused by increase of the number of times is overcome, and the problem that a single-target optimization technology cannot meet the requirement of actual engineering on the comprehensive performance of the robot under the advanced manufacturing background is solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

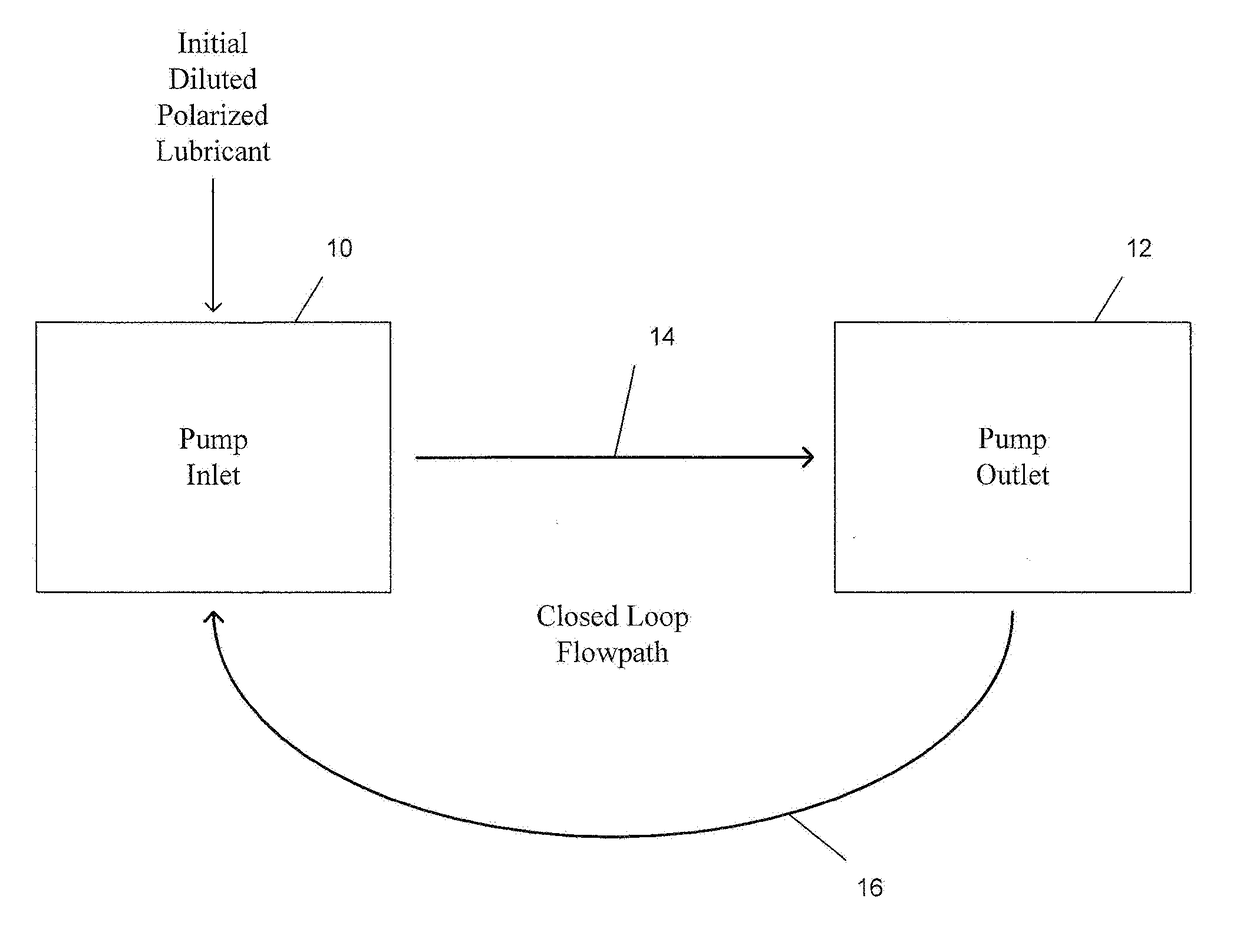

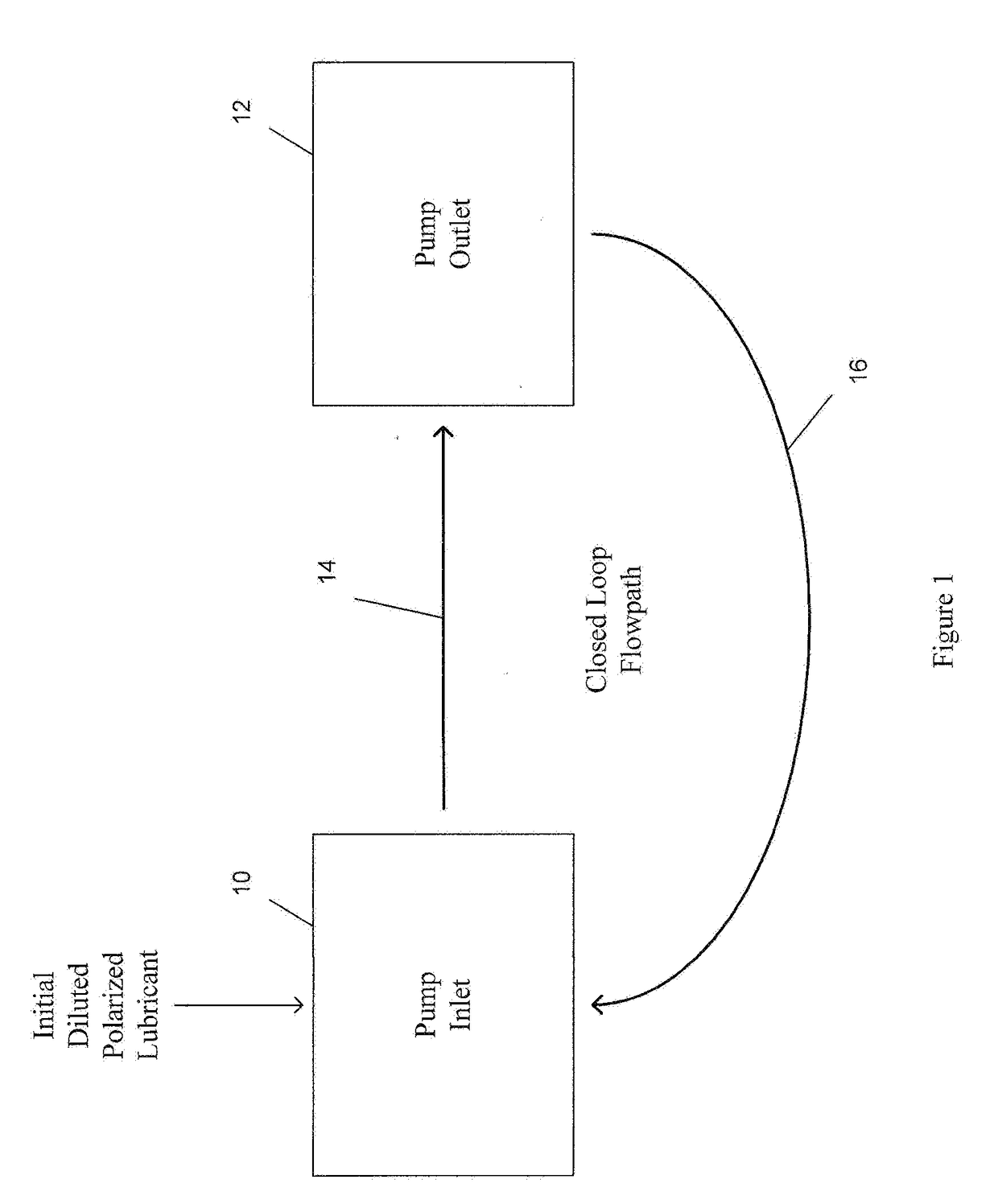

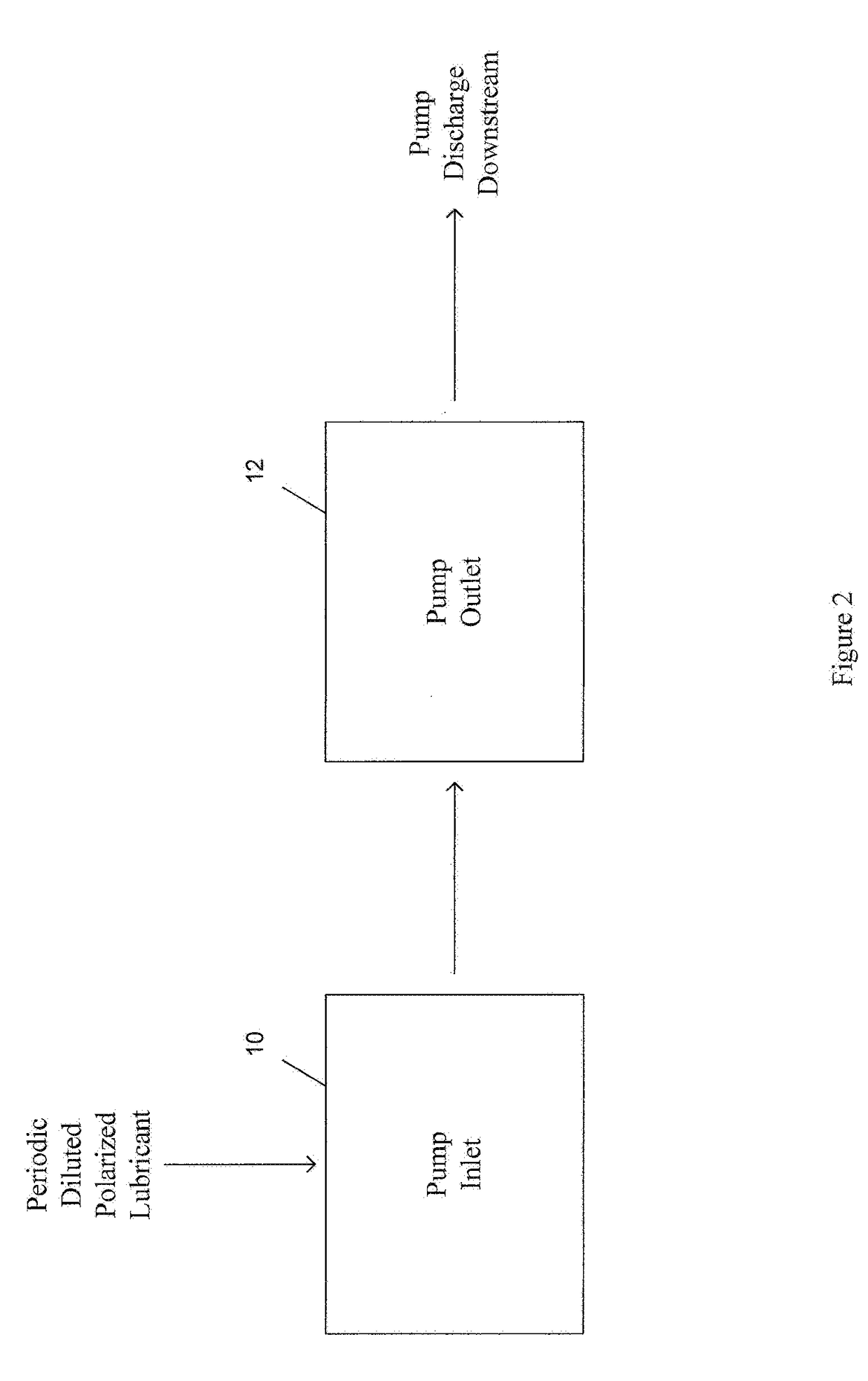

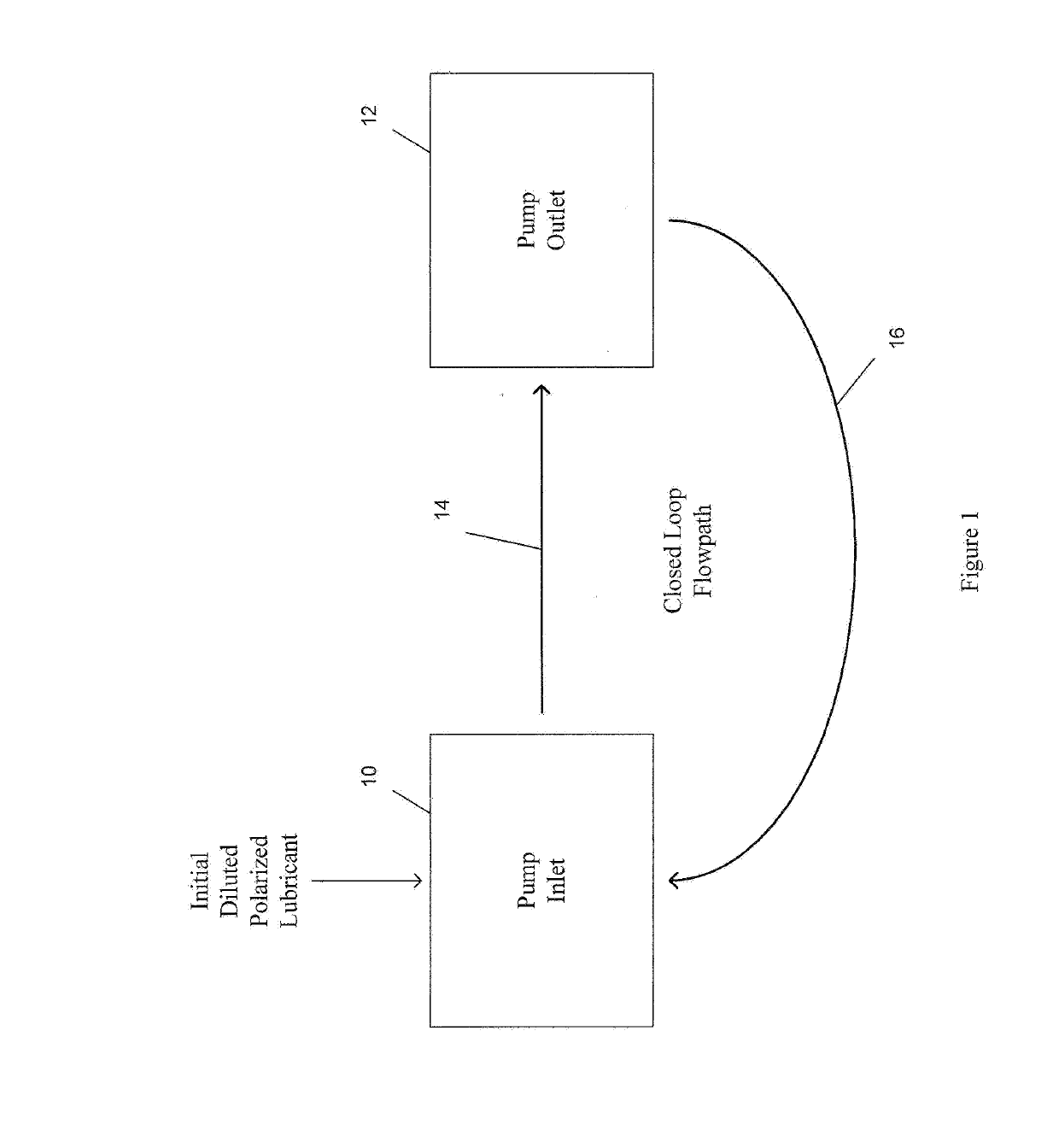

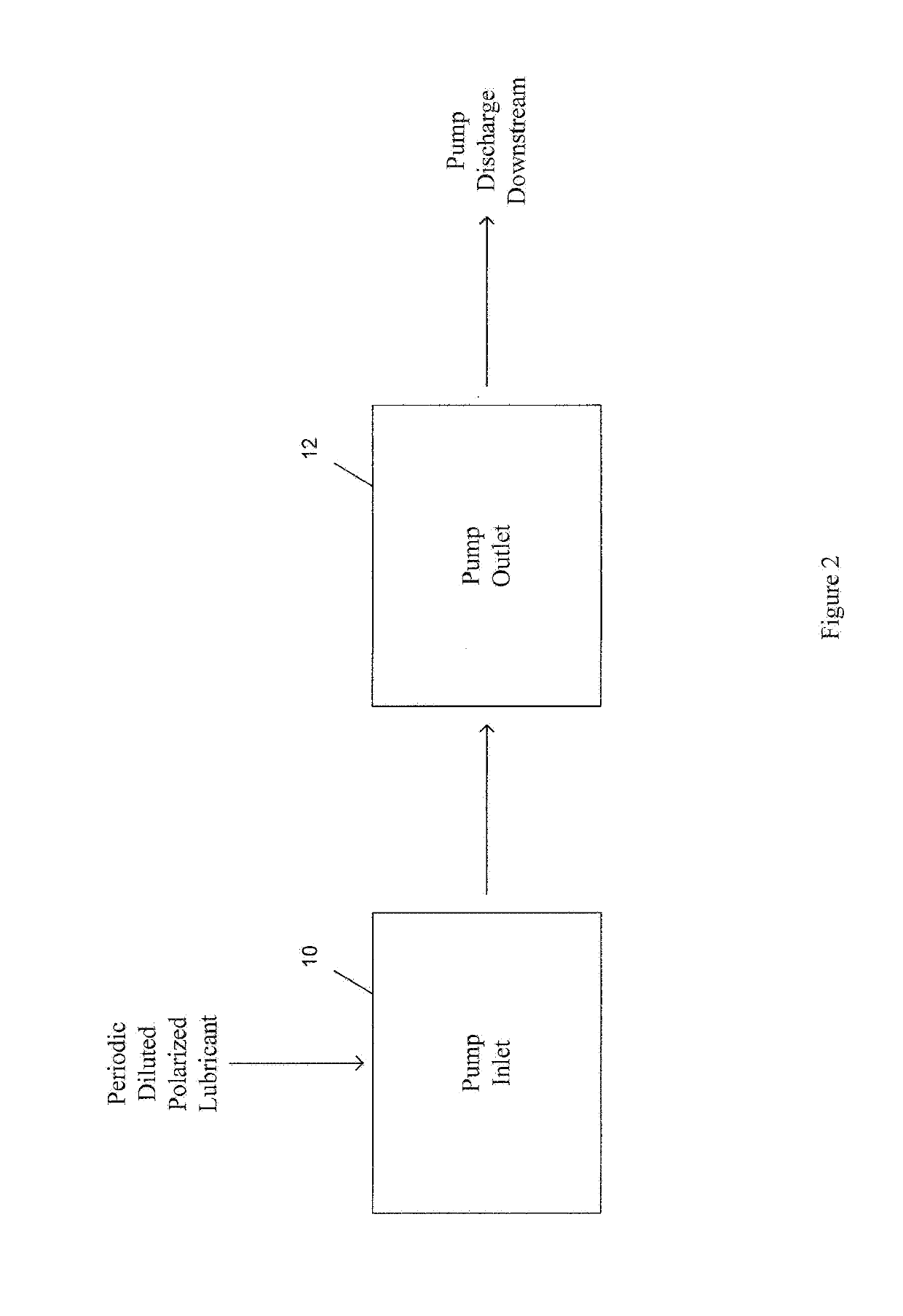

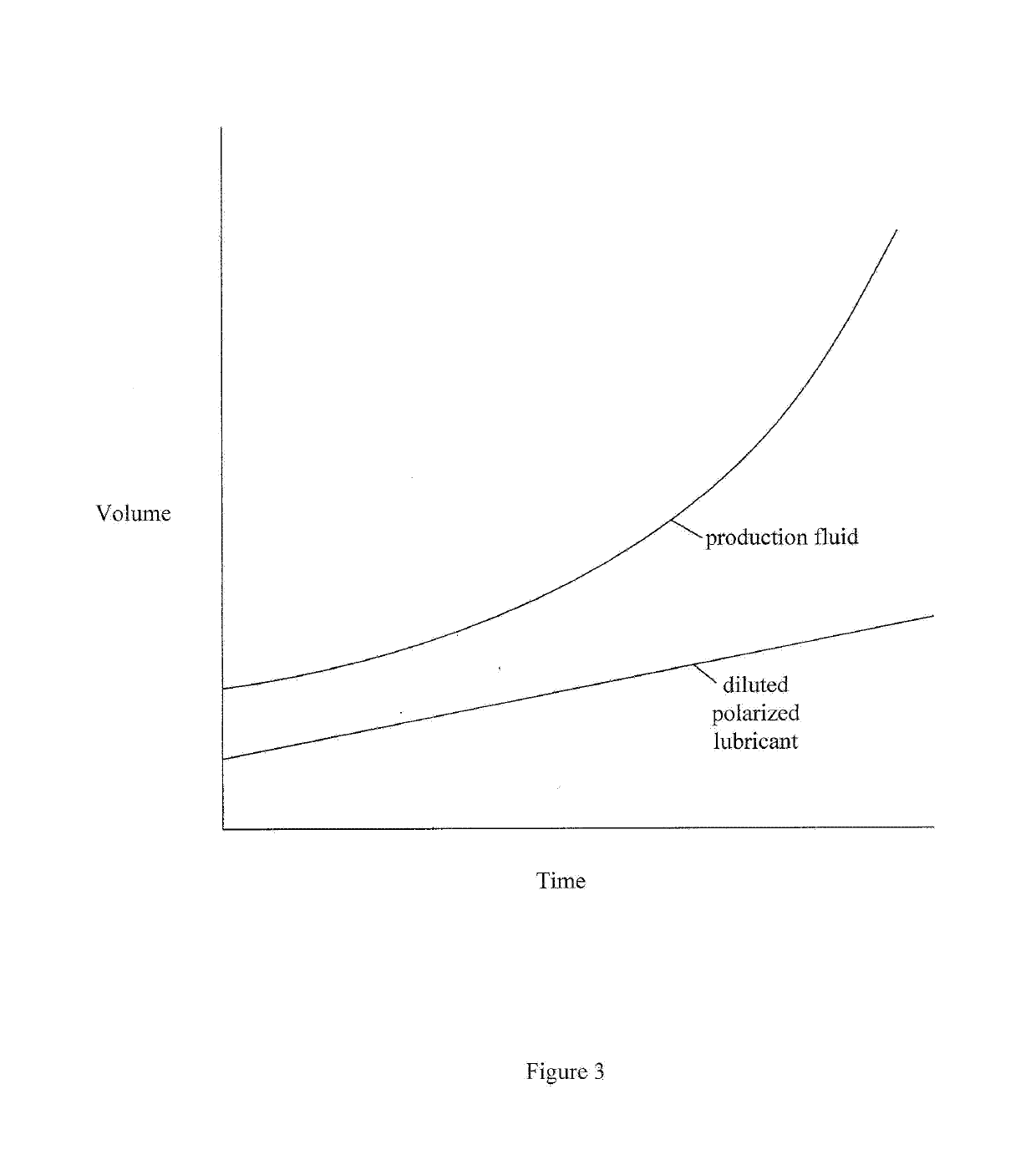

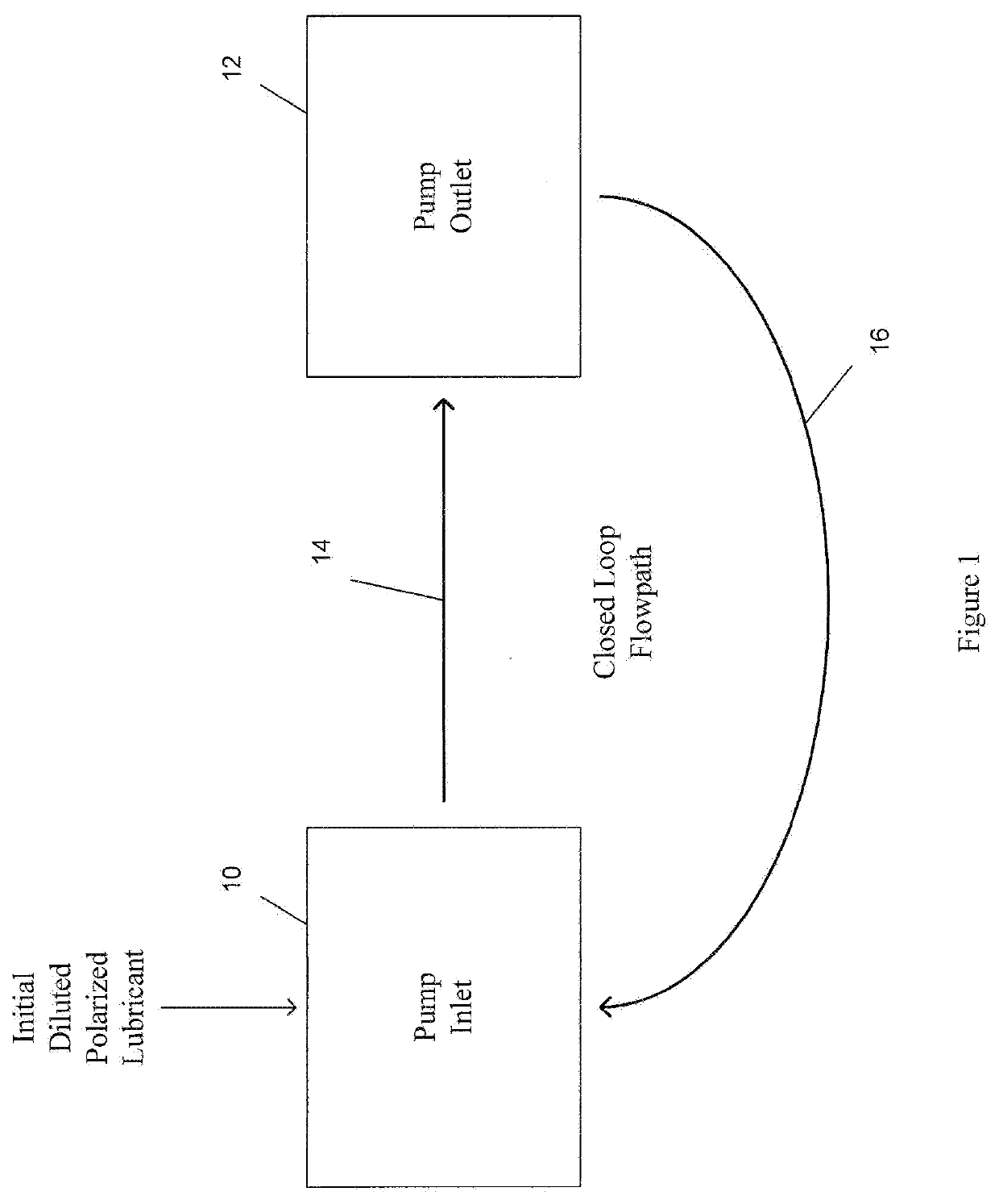

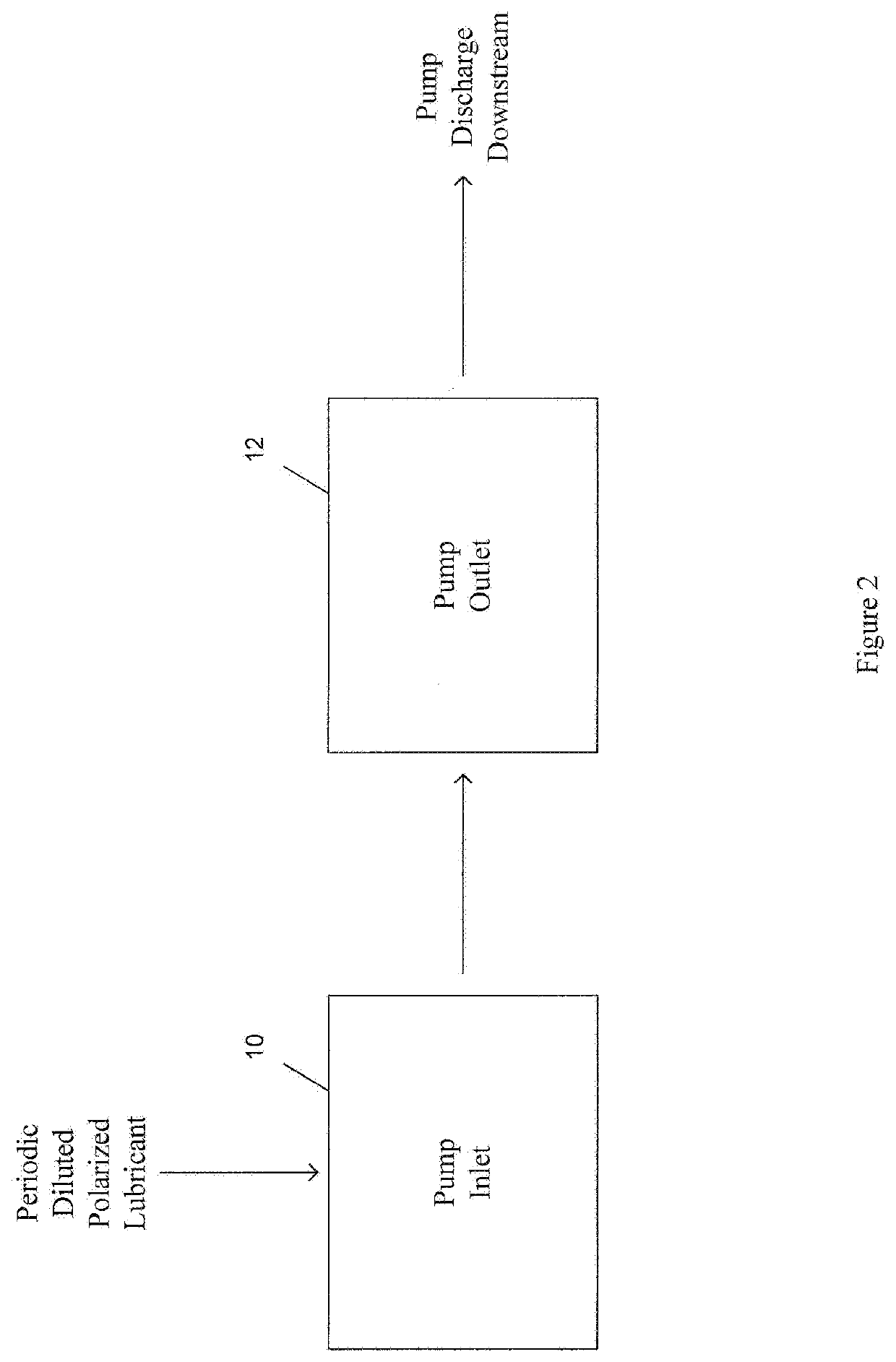

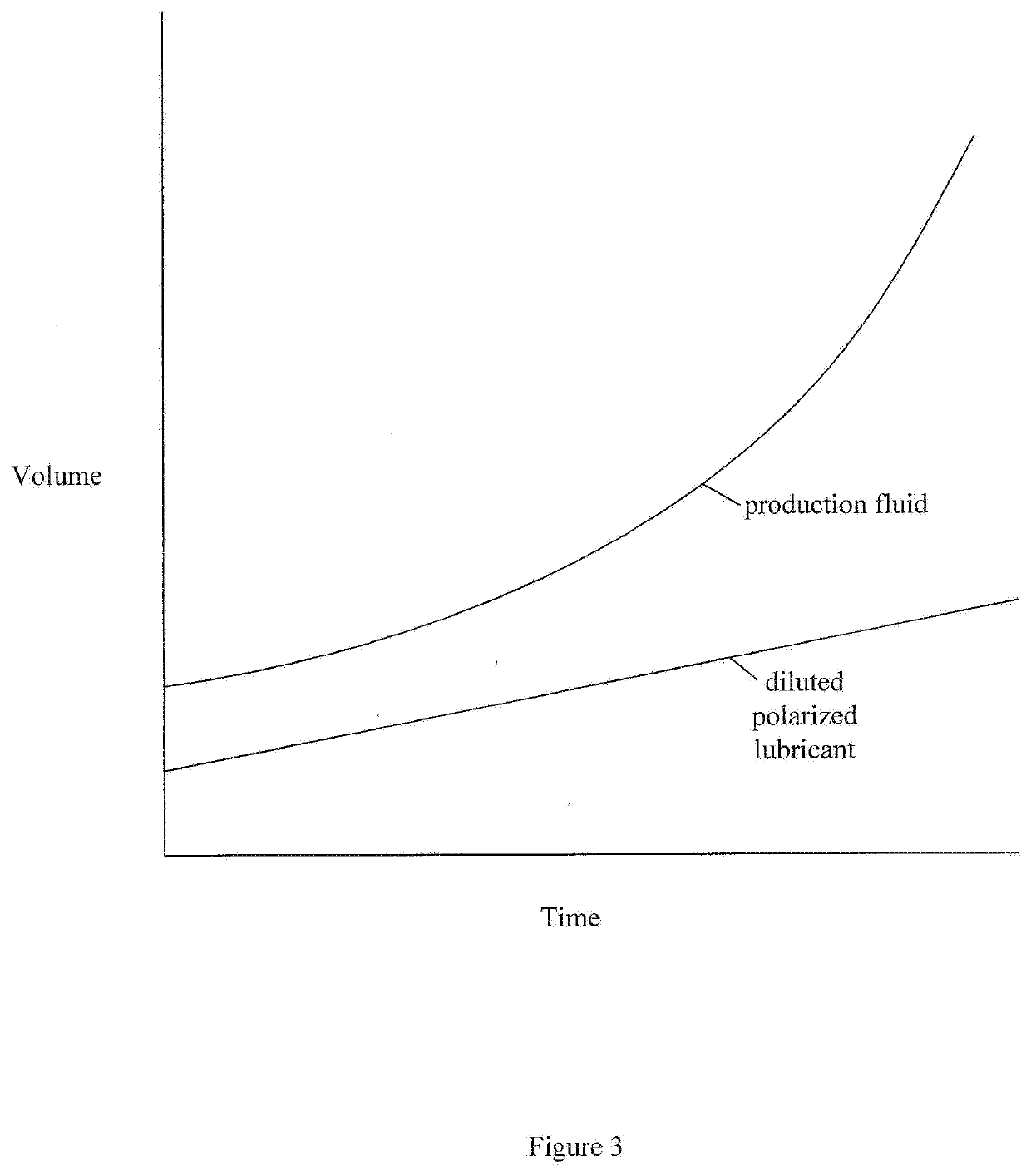

System and method for reducing friction, torque and drag in artificial lift systems used in oil and gas production wells

InactiveUS20180216022A1Expand coverageReduce frictionPositive displacement pump componentsAdditivesEngineeringPetroleum

A method of lubricating a fluid production pump may include mixing a polarized lubricant with water to produce a diluted lubricant. The method may additionally include creating a flowpath within the fluid production pump. An initial volume of the diluted lubricant may be circulated within the flowpath to allow the diluted lubricant to react with components of the fluid production pump and form a protective barrier on the components of the fluid production pump. The method may further comprise repeatedly introducing a periodic volume of diluted lubricant into the fluid production pump according to a predefined lubrication schedule.

Owner:RETTBERG SCOTT

Corrosion-resistant insulated cable material and preparation method thereof

InactiveCN107141765AExtended service lifeImprove wear resistanceRubber insulatorsYarnHigh resistance

The invention discloses a corrosion-resistant insulated cable material and a preparation method thereof. The corrosion-resistant insulated cable material comprises the following raw materials in parts by weight: 70-90 parts of polyurethane rubber, 1-20 parts of a mica powder, 6-12 parts of nylon, 10-15 parts of alkali-free glass fiber yarn, 5-10 parts of dipropylene glycol dibenzoate, 5-10 parts of HRB-6 resin, 7-13 parts of magnesium hydroxide, 4-8 parts of aluminum hydroxide, 2-3 parts of tert-butyl peroxybenzoate, 1.5-2 parts of zinc oxide, 2-3 parts of stearic acid, 3-6 parts of chlorinated paraffin, 15-20 parts of fumed silica, 10-15 parts of nano attapulgite, 10-15 parts of precipitated barium sulfate, 1.5-2.5 parts of an antioxidant, 2-3 parts of an anti-aging agent TPPD, 3-6 parts of composite fillers, 1-2 parts of an accelerator ZDMC and 1-2 parts of an accelerator CZ. The cable material provided and prepared in the invention has high wear resistance, also has high heat resistance, high flame retardancy, high aging resistance, high oil resistance, high flexure resistance, high impact resistance and high tear resistance, is durable in use, and can fully meet performance requirements of modern wires and cables.

Owner:山东励仙电力工程有限公司

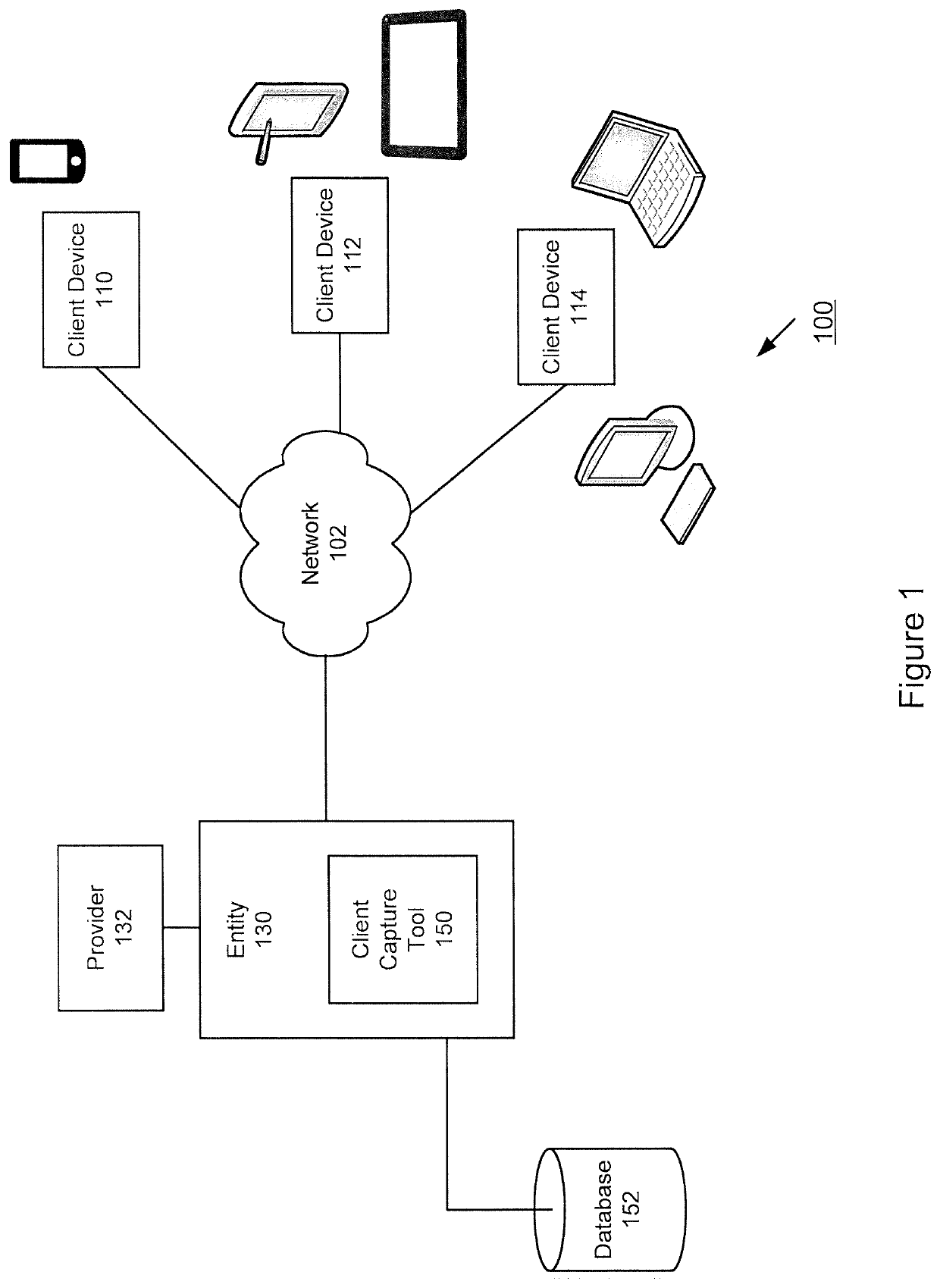

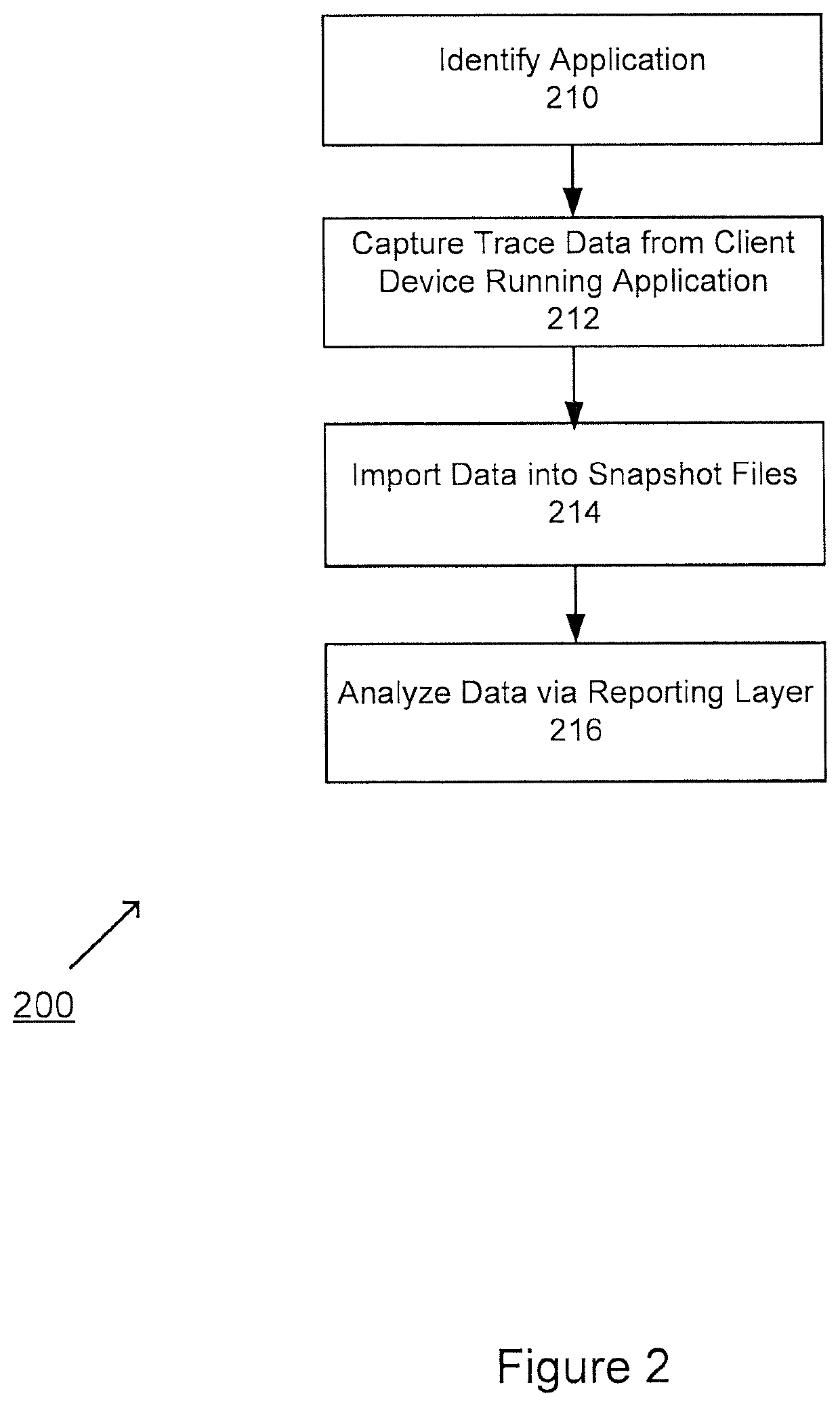

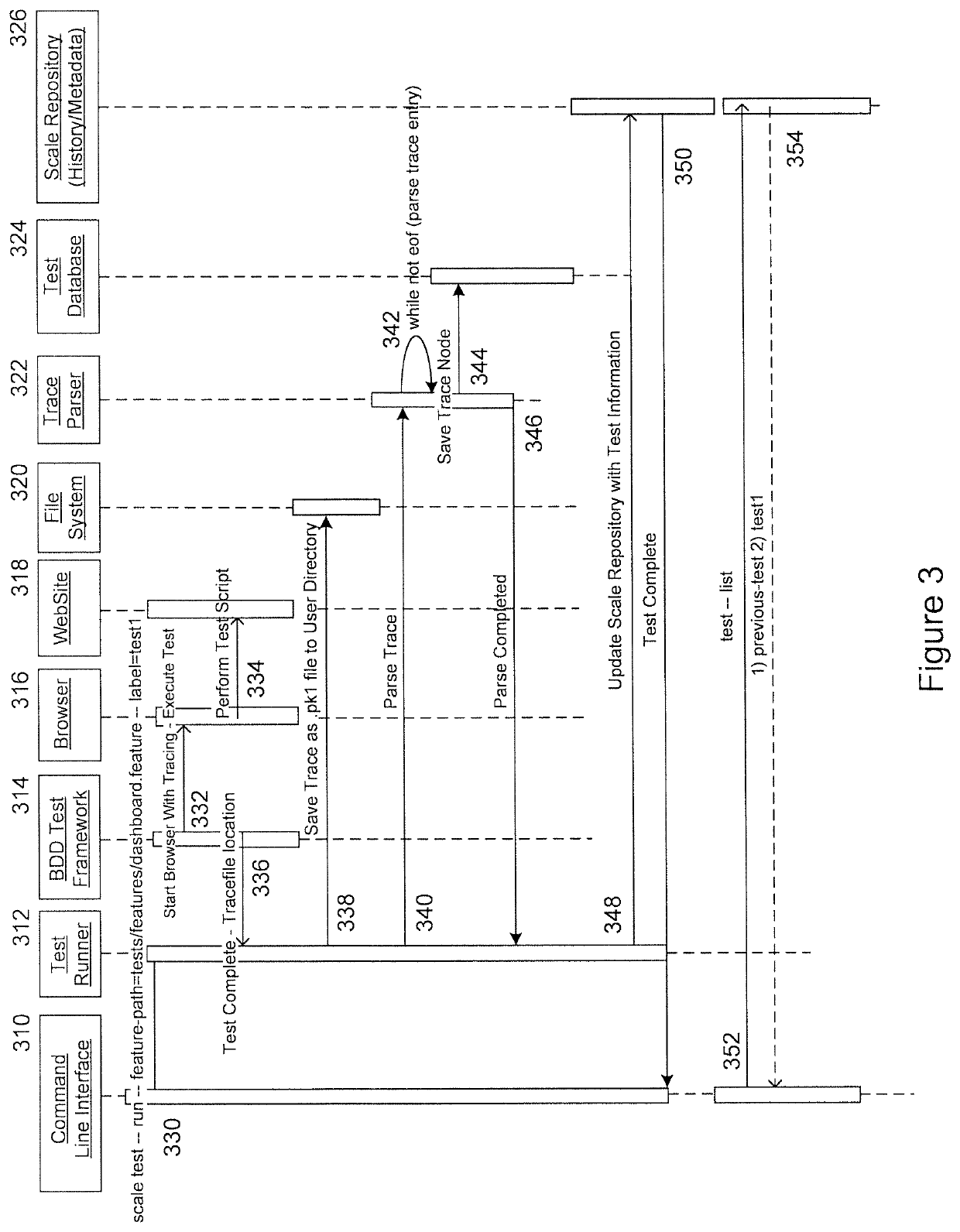

System and method for implementing a client performance capture tool

ActiveUS10498616B1Improve abilitiesEfficiently collecting dataData switching networksSpecific program execution arrangementsCommand-line interfaceTest script

The invention relates to a capture tool that remotely captures client-side performance data comprising: an interactive interface that receives user input; a computer processor, coupled to a memory component and the interactive interface, programmed to: receive, via a command line interface, a test command that comprises a path to a test script; launch, via a test runner component, a browser, at a remote client device, to execute a test in response to the test command; capture trace data from the browser launching at the remote client device; save the trace data at a local storage as snapshot files; and generate, via the interactive interface, performance data based on the trace data.

Owner:JPMORGAN CHASE BANK NA

Address translation method and apparatus

ActiveUS8239657B2Address performance requirementsMultiple address translationMemory architecture accessing/allocationEnergy efficient ICTBoundary crossingOperating system

Address translation performance within a processor is improved by identifying an address that causes a boundary crossing between different pages in memory and linking address translation information associated with both memory pages. According to one embodiment of a processor, the processor comprises circuitry configured to recognize an access to a memory region crossing a page boundary between first and second memory pages. The circuitry is also configured to link address translation information associated with the first and second memory pages. Thus, responsive to a subsequent access the same memory region, the address translation information associated with the first and second memory pages is retrievable based on a single address translation.

Owner:QUALCOMM INC

System and method for reducing friction, torque and drag in artificial lift systems used in oil and gas production wells

InactiveUS20190137035A1Expand coverageReduce frictionFluid removalLubrication elementsLubricationProtective barrier

A method of lubricating a fluid production pump may include mixing a polarized lubricant with water to produce a diluted lubricant. The method may additionally include creating a flowpath within the fluid production pump. An initial volume of the diluted lubricant may be circulated within the flowpath to allow the diluted lubricant to react with components of the fluid production pump and form a protective barrier on the components of the fluid production pump. The method may further comprise repeatedly introducing a periodic volume of diluted lubricant into the fluid production pump according to a predefined lubrication schedule.

Owner:RETTBERG SCOTT

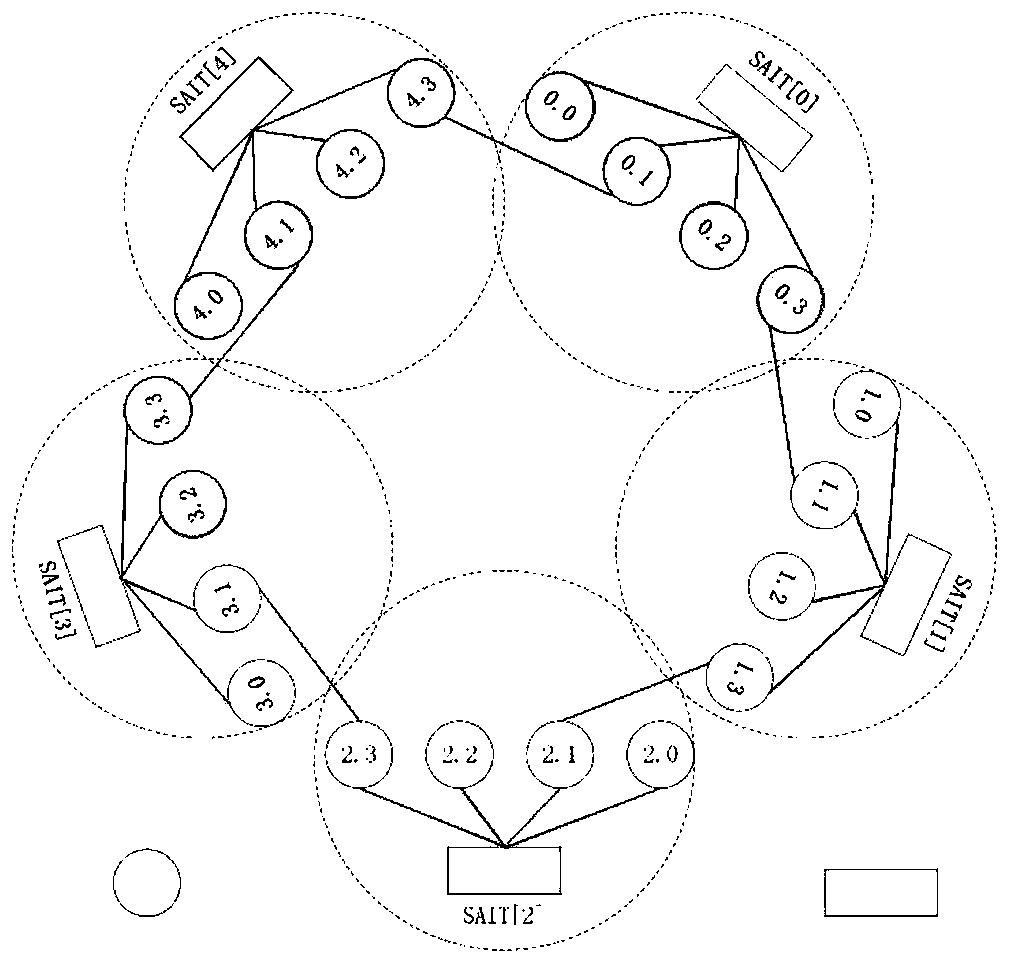

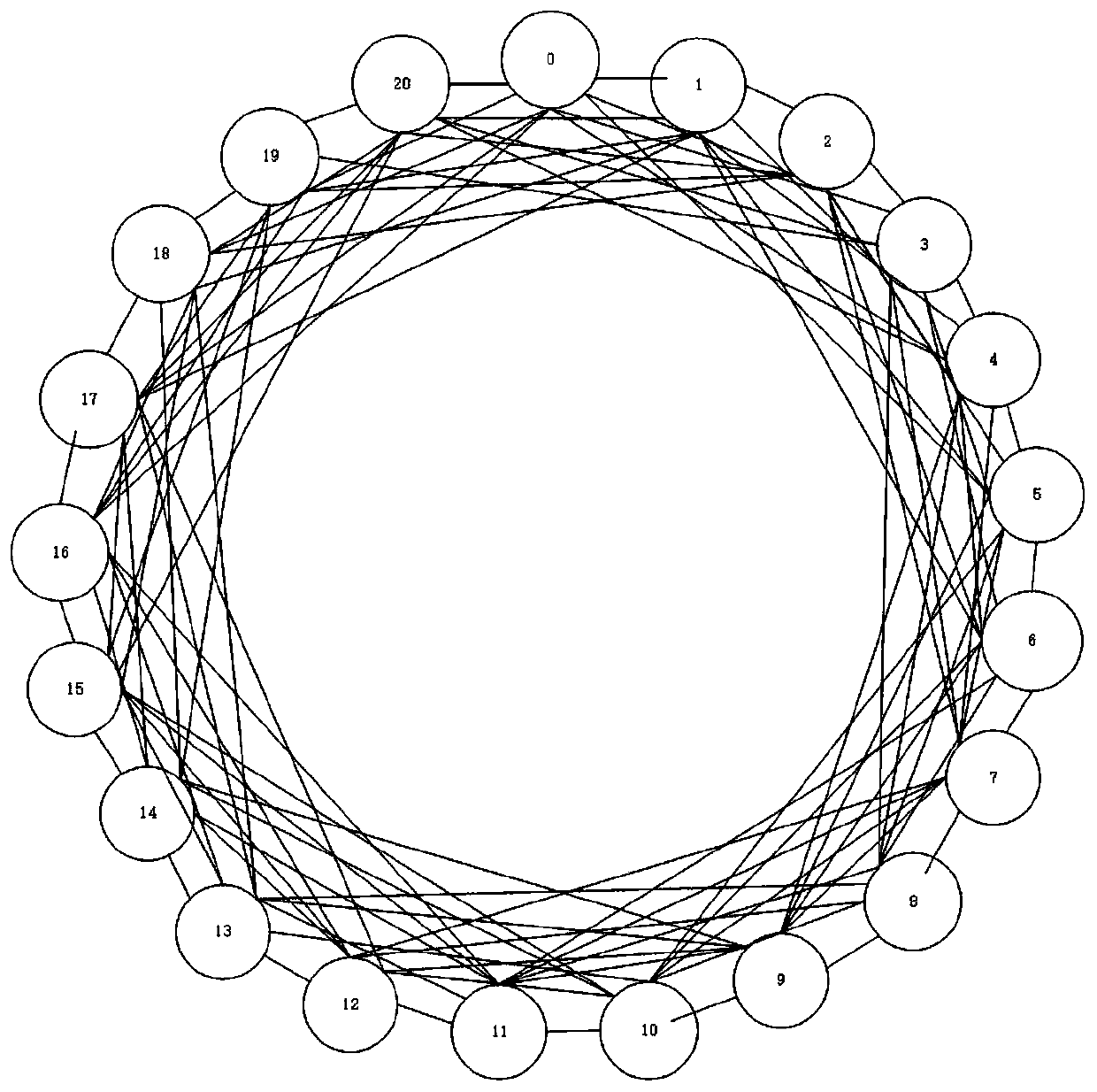

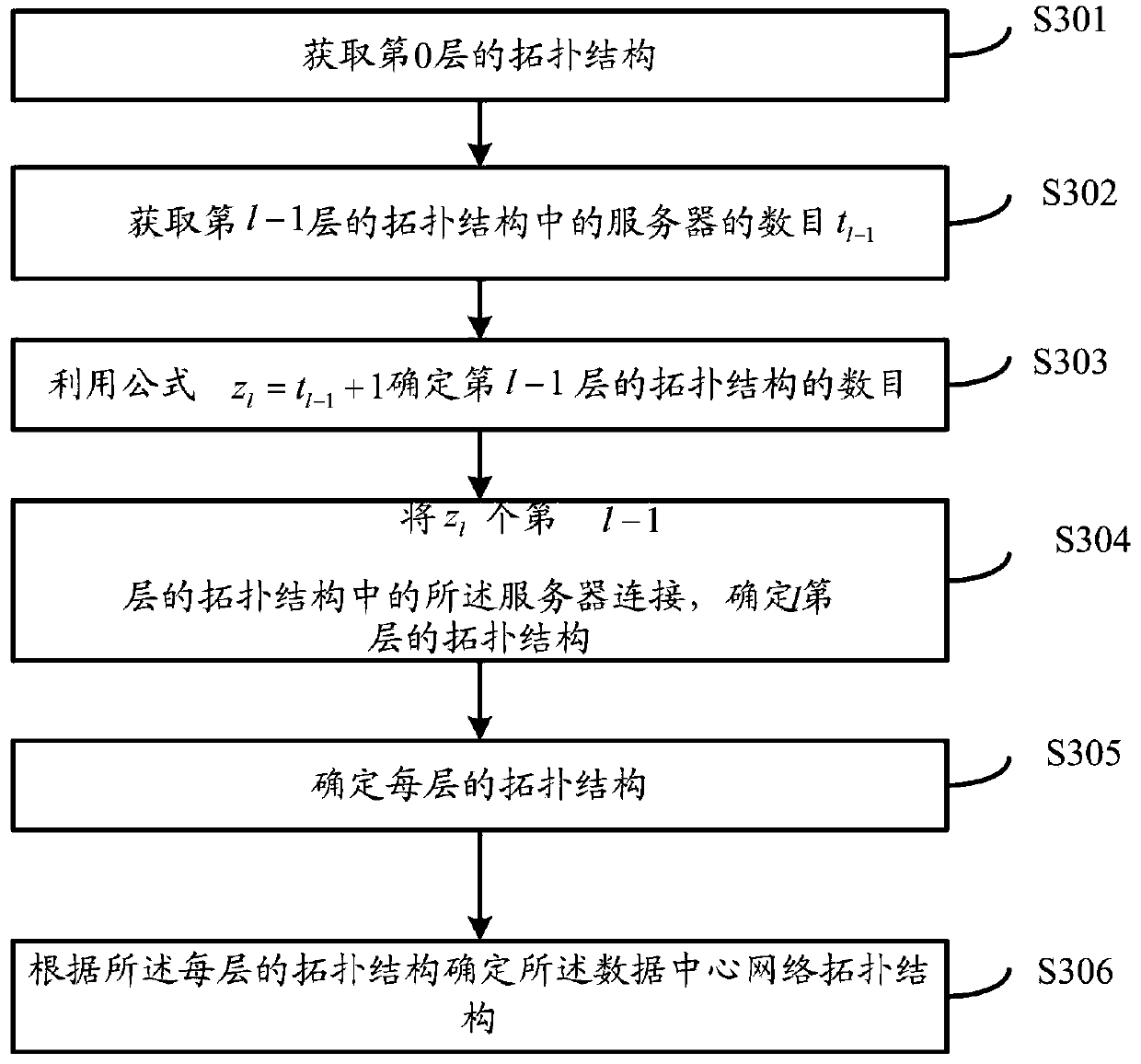

Data center network topology structure, and determination method and system

ActiveCN111262913AAddress performance requirementsSolve the problem that is difficult to expandTransmissionHigh level techniquesSoftware engineeringData transmission

The invention relates to a data center network topology structure, a determination method and a system. A server comprises a plurality of connection ports, and a switch comprises n ports; a topological structure of the 0th layer of an inline network topological structure comprises one switch and n servers; one switch is directly connected with the n servers; the topological structure of the 0th layer is the topological structure of the bottommost layer; the topological structure of the lth layer comprises the topological structure of the t<l-1>+1 layer; the t<l-1> / 2 servers in the topological structure of the ith (l-1)th layer are connected with the servers in the topological structure of the (l-1)th layer at different positions respectively; t<l-1> is the number of the servers in thetopological structure of the (l-1)th layer. The data center network topology structure provided by the invention solves the problems of low data transmission efficiency and low reliability in the prior art.

Owner:CHANGCHUN UNIV OF SCI & TECH

High-performance long-service-life aluminum alloy stamping tool and die profile and preparation method thereof

ActiveCN114045429AImprove wear resistanceHigh strengthProcess efficiency improvementGraphiteAluminium alloy

The invention discloses a high-performance long-service-life aluminum alloy stamping tool and die profile and a preparation method thereof. The high-performance long-service-life aluminum alloy stamping tool and die profile comprises, by mass, 3-4% of Ni, 3.6-3.9% of C, 2.0-2.8% of Si, 0.6-1.0% of Mn, smaller than or equal to 0.1% of P, smaller than or equal to 0.04% of S, 0.03-0.05% of Mg, 0.03-0.05% of Re and the balance Fe and inevitable impurities. Through component control, adding of an inoculant and a spheroidizing agent in the solidification process of the profile, heat treatment and the like, the profile with a structure comprising lower bainite, 30-40% of carbon-rich austenite, fine and uniformly-distributed spherical graphite and a small amount of martensite is obtained. Therefore, the profile has the characteristics of high hardness, high wear resistance, high strength, high toughness, low friction coefficient, good self-lubricating performance, low adhesion to aluminum and the like, and meets the performance requirements on the preparation material of the aluminum alloy stamping die when the aluminum alloy stamping die is in service.

Owner:XIAN UNIV OF TECH

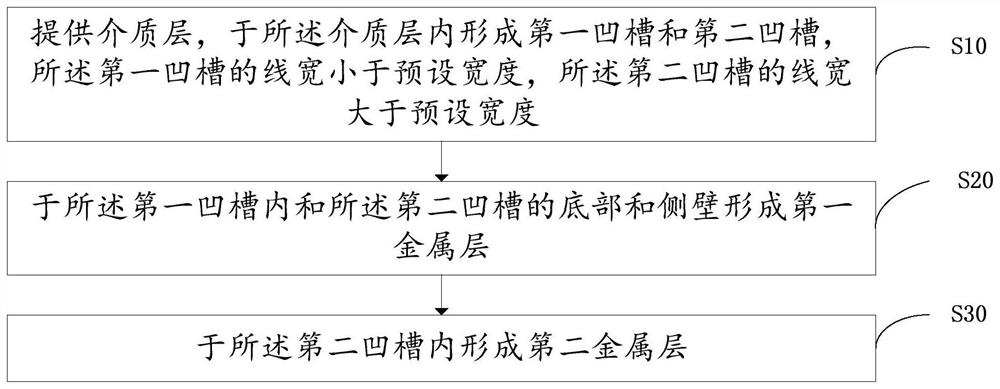

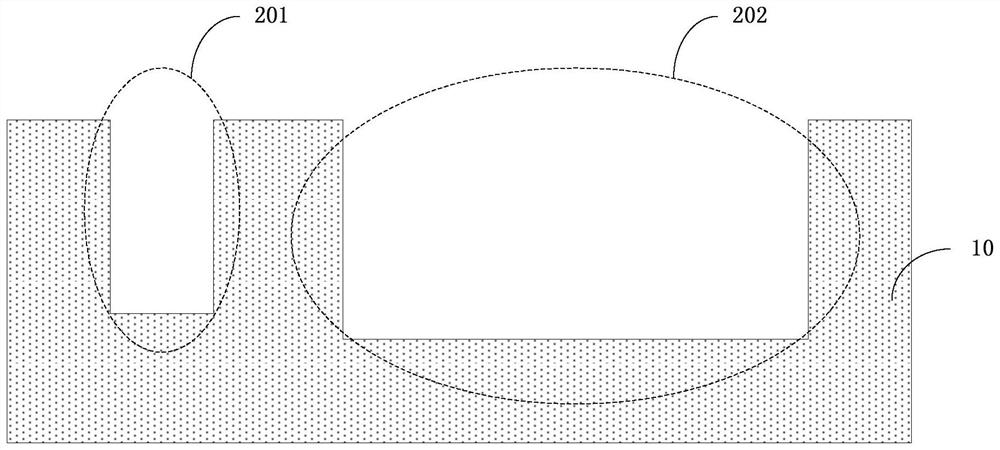

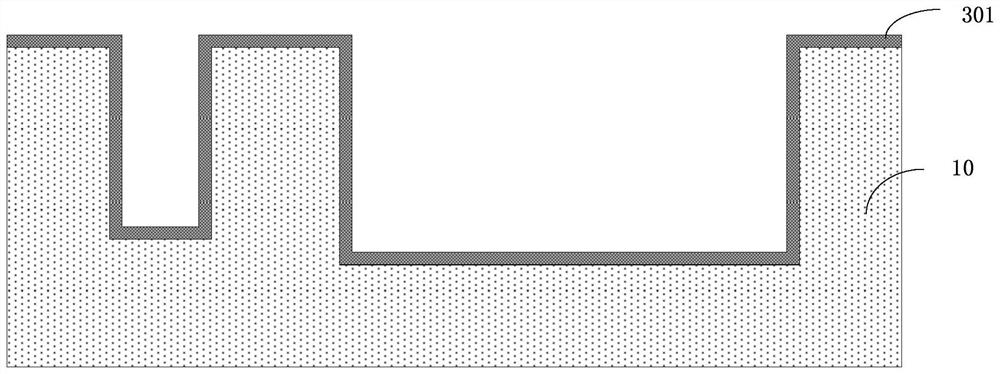

Semiconductor device and preparation method thereof

PendingCN113380761AAddress performance requirementsSolve technical problems that cannot be balanced with performance requirementsSemiconductor/solid-state device detailsSolid-state devicesDevice materialDielectric layer

The invention discloses a semiconductor device and a preparation method thereof. The semiconductor device comprises a dielectric layer; a first groove located in the dielectric layer; a second groove located in the dielectric layer, wherein the line width of the first groove is smaller than the preset width, and the line width of the second groove is larger than the preset width; a first metal layer located in the first groove and at the bottom and the side wall of the second groove; and a second metal layer positioned in the second groove. The technical effect that the performance requirement of a large-size interconnection structure and the performance requirement of a small-size interconnection structure are met is achieved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

System and method for reducing friction, torque and drag in artificial lift systems used in oil and gas production wells

ActiveUS20200056112A1Reduce dragReduce frictionPositive displacement pump componentsAdditivesThermodynamicsFriction torque

A method of lubricating a fluid production pump may include mixing a polarized lubricant with water to produce a diluted lubricant. The method may additionally include creating a flowpath within the fluid production pump. An initial volume of the diluted lubricant may be circulated within the flowpath to allow the diluted lubricant to react with components of the fluid production pump and form a protective barrier on the components of the fluid production pump. The method may further comprise repeatedly introducing a periodic volume of diluted lubricant into the fluid production pump according to a predefined lubrication schedule.

Owner:RETTBERG SCOTT

Anode bleed control strategy for improved water management and hydrogen utilization

ActiveUS8855942B2Improve water managementSolve the durability problemVolume/mass flow measurementFuel cell auxillariesHydrogenFuel cells

A control strategy for bleeding an anode side of fuel cell stack in a fuel cell system that improves water management and addresses durability and performance concerns. The method includes determining when to begin the anode bleed, typically by estimating or measuring the amount of nitrogen in the anode side of the stack. The method also includes determining when to end the anode bleed based on the volume of gas that has been bled. The method determines the mole flow rate of the anode gas flowing through a bleed valve, integrates the mole flow rate to get the number of moles of the gas that have passed through the bleed valve, determines a desired amount of moles to be bled, and ends the bleed when the actual number of moles of the gas equals the desired number of moles of the gas.

Owner:GM GLOBAL TECH OPERATIONS LLC

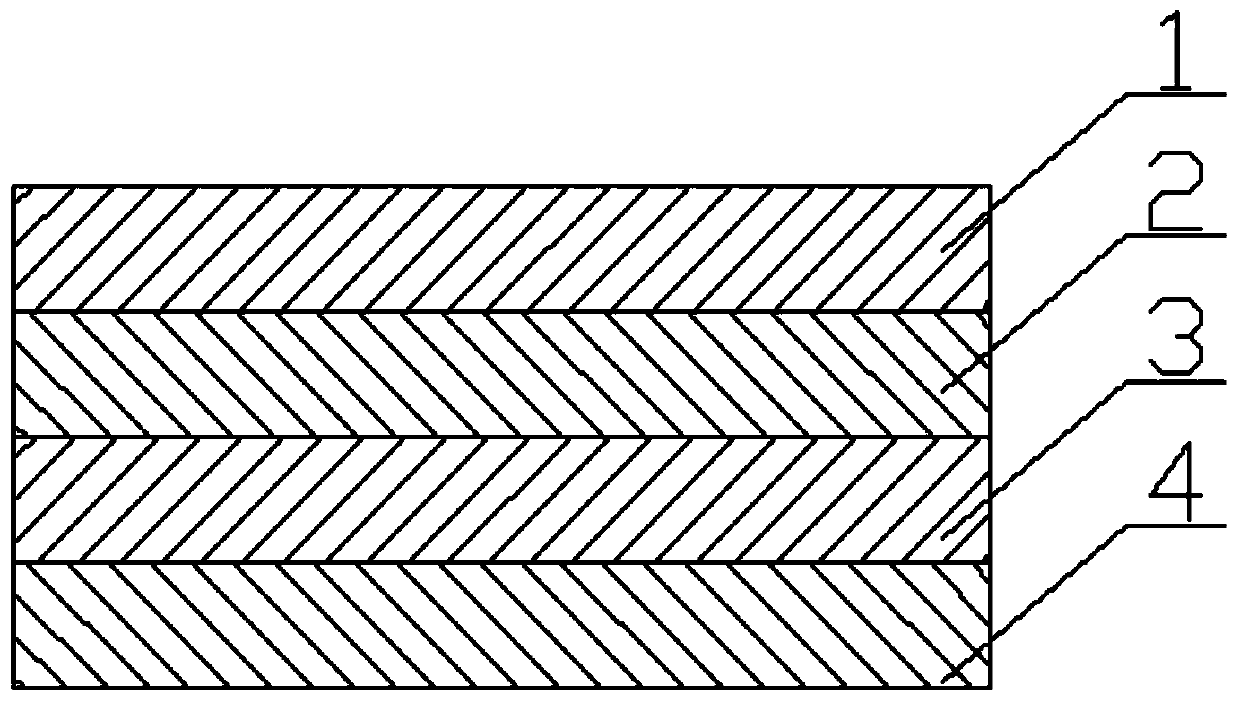

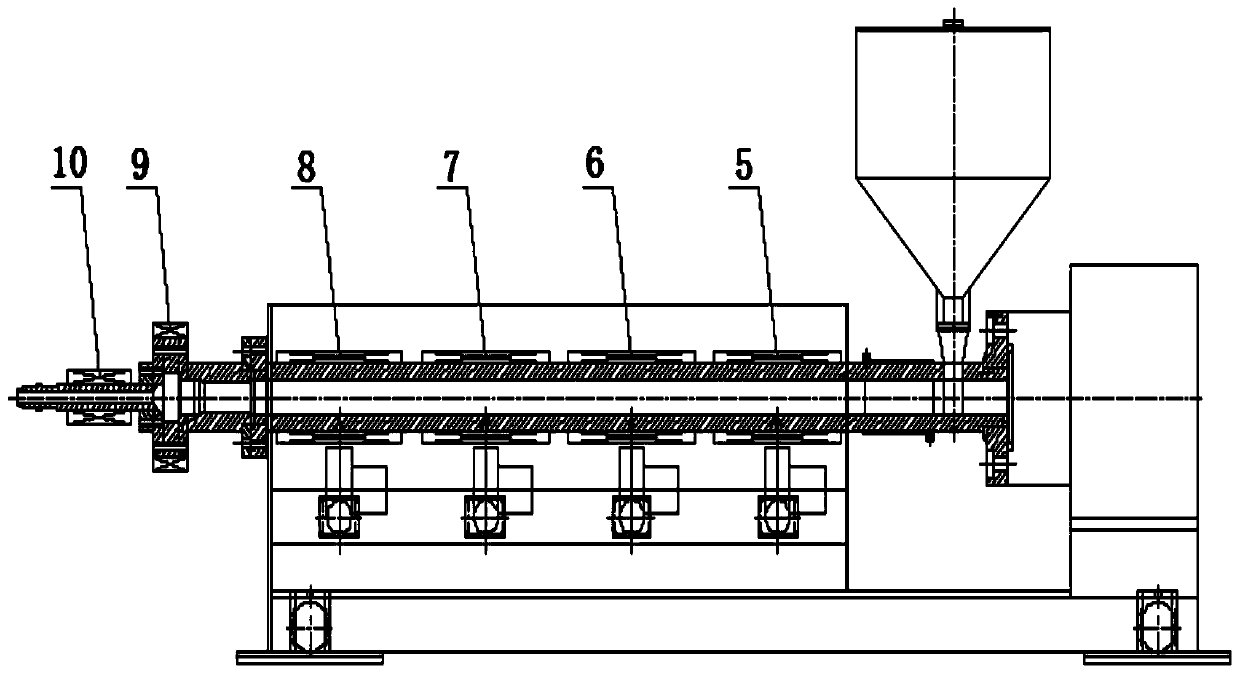

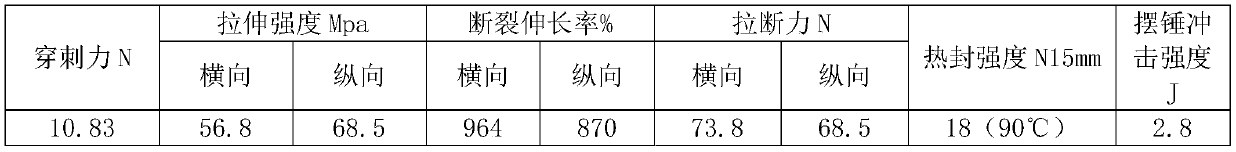

Preparation method of anti-puncture high-barrier co-extrusion film

PendingCN111421934ASolve the tensile resistanceAddress performance requirementsSynthetic resin layered productsFlat articlesBlow moldingTear resistance

The invention provides a preparation method of a puncture-resistant high-barrier co-extrusion film, relates to the technical field of packaging materials, and solves the technical problems that a PE film and a PP film in the prior art are low in puncture resistance, poor in tensile resistance and low-temperature resistance and prone to bag breaking and poor sealing. The co-extrusion film comprisesa composite layer, a first core layer, a second core layer and a heat sealing layer, and the co-extrusion film is formed by blow molding and co-extrusion of the composite layer, the first core layer,the second core layer and the heat sealing layer which are sequentially arranged. The co-extrusion film provided by the invention integrates a series of mechanical properties such as puncture resistance, stretching resistance, impact resistance, tear resistance and the like, and in addition, on the premise of ensuring the mechanical properties, the processability of a product and the use performance of a client need to be met at the same time.

Owner:DALIAN JUTONG PLASTIC PRODS

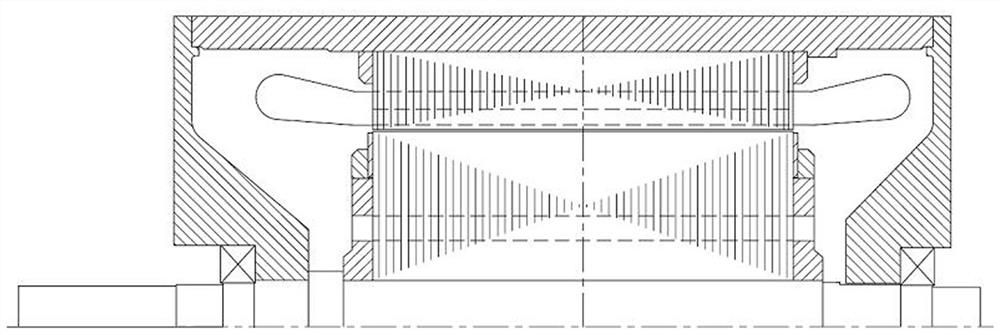

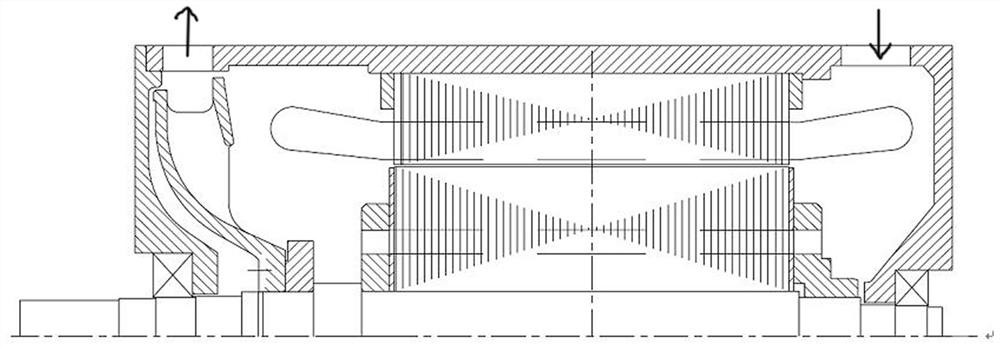

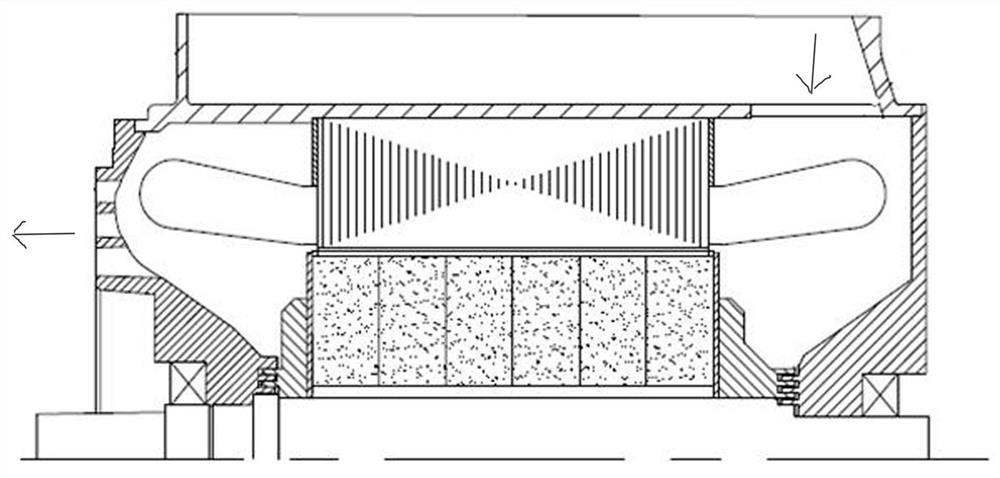

A closed motor and motor base with internal and external cooling air passages

ActiveCN112713716BImprove cooling effectSolve the disadvantages of poor protection performanceCooling/ventillation arrangementSupports/enclosures/casingsElectric machineryEngineering

The invention relates to a motor and its machine base, in particular to a closed motor with internal and external cooling air passages and its machine base. In order to solve the problem of many defects in the existing open motors and closed motors, the present invention provides a closed motor with internal and external cooling air passages and its frame. The motor in the present invention includes a double The layered cylindrical machine base and the heat dissipation plate in it, the heat dissipation plate divides the hollow area into an outer cooling air duct and an inner cooling air duct, and the transmission end plate of the machine base is provided with an outer cooling air duct that communicates with the outer cooling air duct and is suitable for the machine base. The inlet of the cooling air duct, the outer cooling air duct outlets communicated with the outer cooling air duct are respectively provided on the peripheral surface of the non-transmission end of the outer frame, and the outer cooling air duct outlets are respectively provided on the peripheral surfaces of the transmission end and the non-transmission end of the inner layer frame. The inner cooling air duct communicates with the inner air circulation port of the transmission end and the inner air circulation port of the non-transmission end. The structure of the motor in the present invention enables the motor to have good protection performance and excellent cooling and heat dissipation.

Owner:CRRC YONGJI ELECTRIC CO LTD

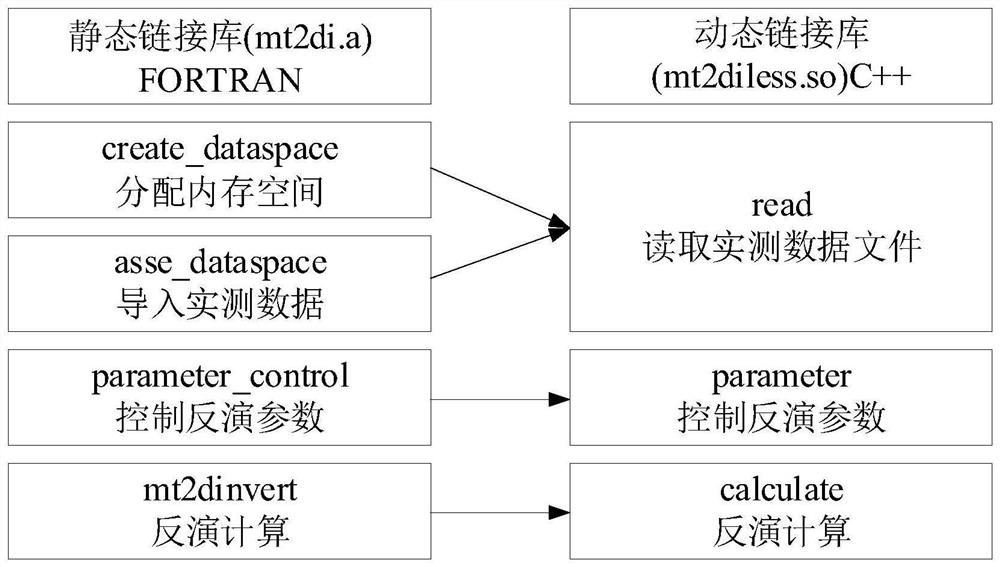

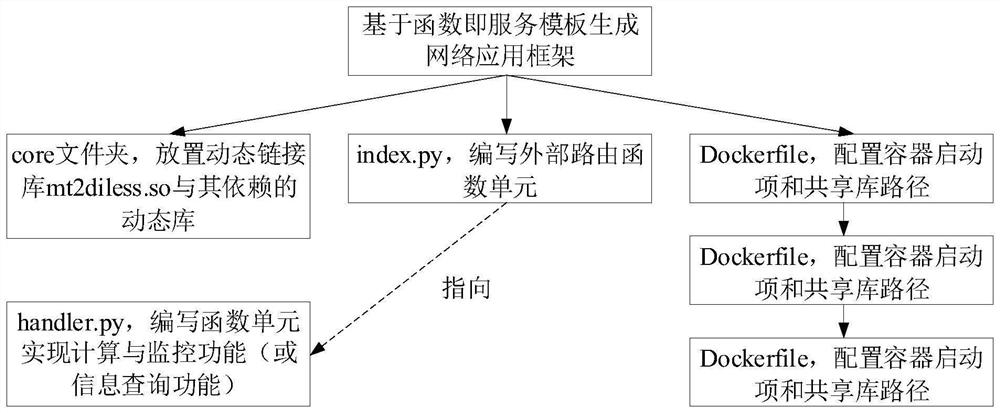

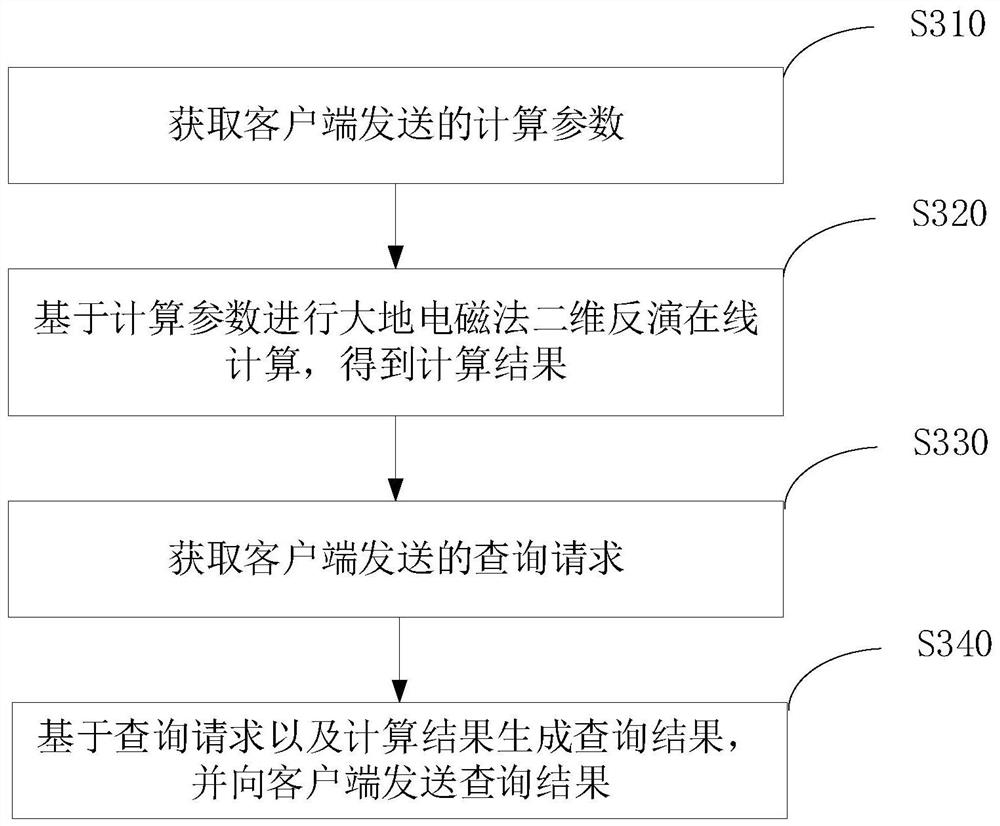

Processing method of online inversion data

PendingCN114880128ACollaborative workEasy to operateDigital data information retrievalResource allocationTheoretical computer scienceEngineering

The invention provides an online inversion data processing method, relates to the technical field of two-dimensional inversion of a magnetotelluric method, and solves the problems of online calculation and practical application of two-dimensional inversion calculation of the magnetotelluric method. The method comprises the following steps: acquiring calculation parameters sent by a client; carrying out two-dimensional inversion online calculation of the magnetotelluric method based on the calculation parameters to obtain a calculation result; obtaining a query request sent by a client; and generating a query result based on the query request and the calculation result, and sending the query result to the client.

Owner:中国地质科学院地球物理地球化学勘查研究所

Nitrocellulose varnish and preparation method thereof

ActiveCN102020916BAddress performance requirementsSame hardnessPolyester coatingsPolymer scienceNitrocellulose

The invention discloses a nitrocellulose varnish and a preparation method thereof. The raw material formula of the nitrocellulose varnish contains two components, namely main agent and electrostatic thinner; by reasonably selecting materials and adjusting the proportions of the materials, the nitrocellulose varnish has the same performance requirement on hardness, luster, hand feeling, adhesive force and the like as the conventional product; and by adjusting the formulas of the main agent and the electrostatic thinner, the nitrocellulose varnish disclosed by the invention has good conductivity, volatile speed, anti-sagging property, elevation levelling property and other performances. The nitrocellulose varnish disclosed by the invention is suitable for the electrostatic spraying process;compared with the air spraying nitrocellulose varnish, the utilization rate of the paint can be greatly increased; the nitrocellulose varnish is suitable for special-shaped pieces such as guitars andornaments; and the cost of the paint is greatly reduced, the loss is reduced and the pollution to the environment is lowered.

Owner:HUIZHOU CHANGRUNFA PAINT

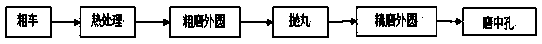

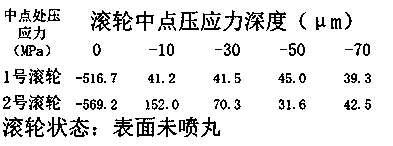

Machining technology capable of increasing compressive stress depth of surface of rolling wheel

ActiveCN111411202AIncrease stressAdd depthSolid state diffusion coatingFurnace typesEngineeringMachine

The invention relates to a processing technology capable of increasing compressive stress depth of the surface of a rolling wheel. The machining technology comprises the following steps of rough turning, heat treatment, excircle rough grinding, shot blasting, and two-end-face grinding, wherein fine grinding on an excircle and a middle hole is conducted by using a double-disc grinder to machine theexcircle and the middle hole into the size of a finished product in the two-end-face grinding step. Compared with a conventional machining technology of the rolling wheel, a shot-throwing process isadded after rough grinding on the excircle is conducted, steel shots with a diameter of 0.5mm are used to continuously impacts the surface of the rolling wheel in a shot blasting machine to greatly enhance the surface compressive stress of the rolling wheel, a compressive stress hardened layer with sufficient depth is obtained, meanwhile, too many hardened layers cannot be consumed in subsequent machining, and the abrasion resistance of the rolling wheel is greatly enhanced.

Owner:NANJING WEIFU JINNING

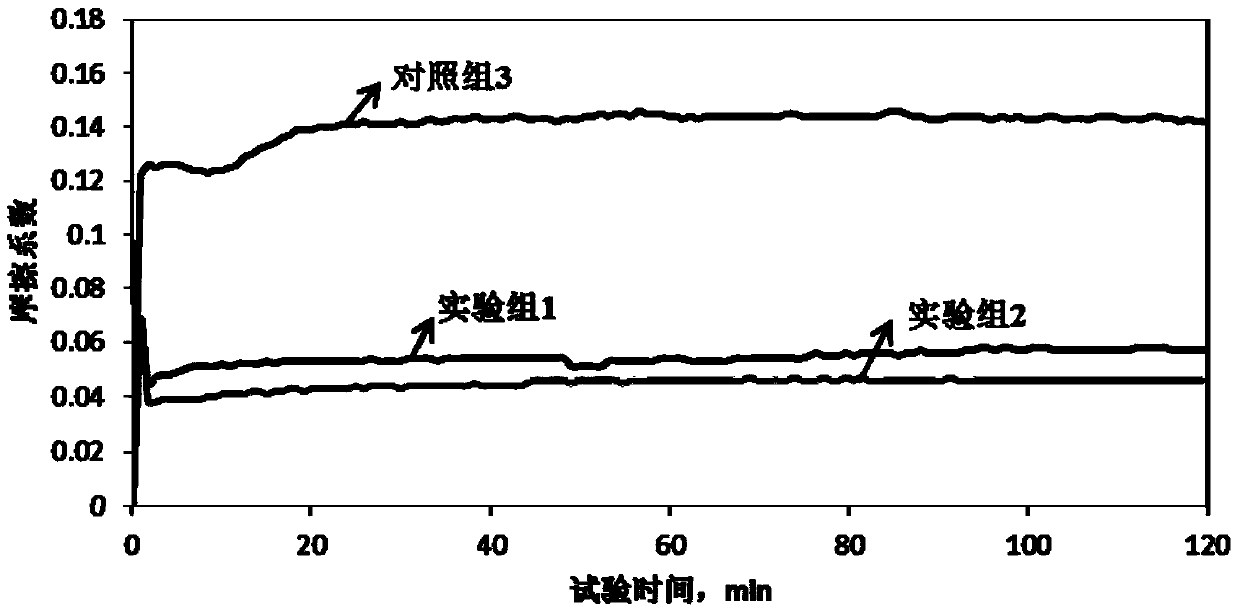

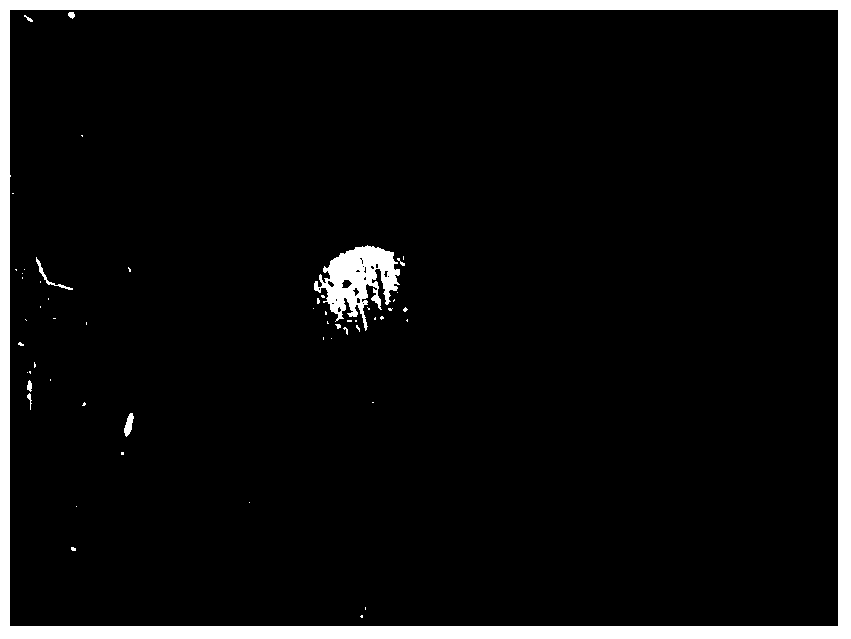

A kind of low-viscosity high-efficiency energy-saving engine oil and its preparation process

ActiveCN105524689BAddress performance requirementsSolve the requestLubricant compositionOil canProcess engineering

The invention discloses low-viscosity high-efficiency energy-efficient engine oil. The low-viscosity high-efficiency energy-efficient engine oil comprises the following components in parts by weight: 8.0-10.0 parts of an engine oil complexing agent, 10.0-15.0 parts of a viscosity index improver, 70.0-80.0 parts of a base oil, and 0.2-0.5 parts of a pour-point depressant. According to the invention, MoDTC is added in the internal combustion engine oil, by metering molybdenum component, 0.05 wt%-0.10wt% of MoDTC is added in the lubricating oil through external addition. The low-viscosity high-efficiency energy-efficient engine oil can satisfy API / ILSAC SN / GF-50W-20 specification requirement, and the technical problems of oil product viscosity-temperature performance and energy saving requirement of an OEM manufacturer can be solved by using a PMA-type viscosity index improver and a MoDTC strengthening agent through external addition. The low-viscosity high-efficiency energy-efficient engine oil can effectively reduce the lubricating oil friction coefficient, increases the fuel economy of an engine, has excellent low temperature performance, can effectively improve the antioxidation performance of an oil product, and reduces generation of a lubricating oil high temperature deposit.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com