Production process for effectively preventing marine anchor chain round steel from generating cracks

A production process and round steel technology, which is applied in the field of production process to effectively avoid cracks in marine anchor chain round steel, can solve the heavy economic burden of anchor chain manufacturers, reduce enterprise production efficiency, chain link cracks and other problems, and achieve the goal of avoiding hydrogen Embrittlement and stress cracks, avoiding continuous casting slab cracks, and reducing the effect of carbon equivalent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 (stove number 616030121)

[0036] (1) Electric furnace smelting process

[0037] The electric furnace smelting adopts high-quality molten iron and clean scrap steel, and blows argon at the bottom of the whole process. Among them, the mass content of the components in the molten iron is: Si: 0.49%, P: 0.093%, S: 0.021%, and the temperature of the molten iron in the furnace is T = 1308 ℃; The content of residual element Cu≤0.15%, the content of Nb≤0.05%

[0038] Reasonable design composition: [C]: 0.28~0.32%, [Mn]: 1.45~1.60%, [Cr]: 0.15~0.25%, [Al]: 0.025~0.055%, [Ti]: 0.010~0.025%; control Carbon equivalent Ceq≤0.65; electric furnace smelting control tapping end point tapping [C]: 0.11%, tapping [P]: 0.010%, tapping temperature: 1635°C, slag blocking operation is adopted during tapping, slag tapping is strictly prohibited , the amount of deoxidizer added is: silicon carbide 100kg, aluminum block 120kg;

[0039] (2) LF refining process

[0040] The LF re...

Embodiment 2

[0048] Embodiment 2 (stove number 616030122)

[0049] Electric furnace smelting controls the end point of tapping [P] = 0.009%, the end point of steel [C] = 0.14%, adding 90kg of aluminum to tapping, and the rest

[0050] Operation is the same as in Example 1.

Embodiment 3

[0051] Embodiment 3 (stove number 616030123)

[0052] Ensure that the white slag time is 28 minutes; ensure the fluidity of the refining slag, control the basicity of the refining slag R=4.3, and the rest of the operations are the same as in Example 1.

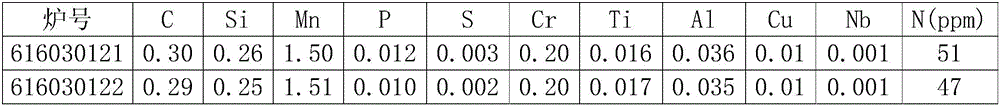

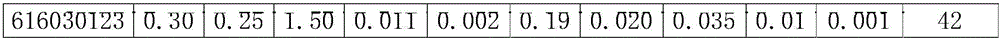

[0053] The chemical composition, mechanical properties and surface quality of the steel obtained in Examples 1-3 are shown in Table 1, Table 2 and Table 3 respectively:

[0054] The chemical composition (wt / %) of the prepared steel of table 1 example 1-3

[0055]

[0056]

[0057] Table 2 mechanical properties (tests carried out for the prepared steel of example 1-3)

[0058] furnace number

Yield strength Re

Tensile strength Rm

Elongation A(%)

Reduction of area Z(%)

Impact energy AKV(J)

616030121

608

779

23.5

69

151

616030122

610

778

23.0

70

153

616030123

605

772

23.5

68

149

[0059] Table 3 Anchor chain steel surface quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com