Patents

Literature

112results about How to "Reduce inclusion content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

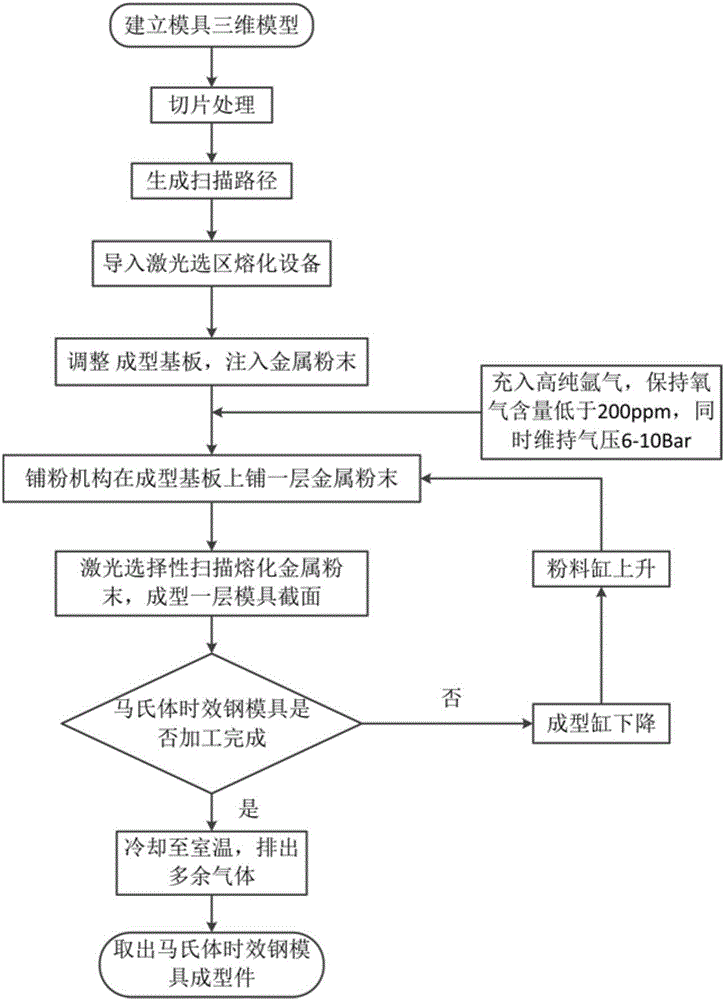

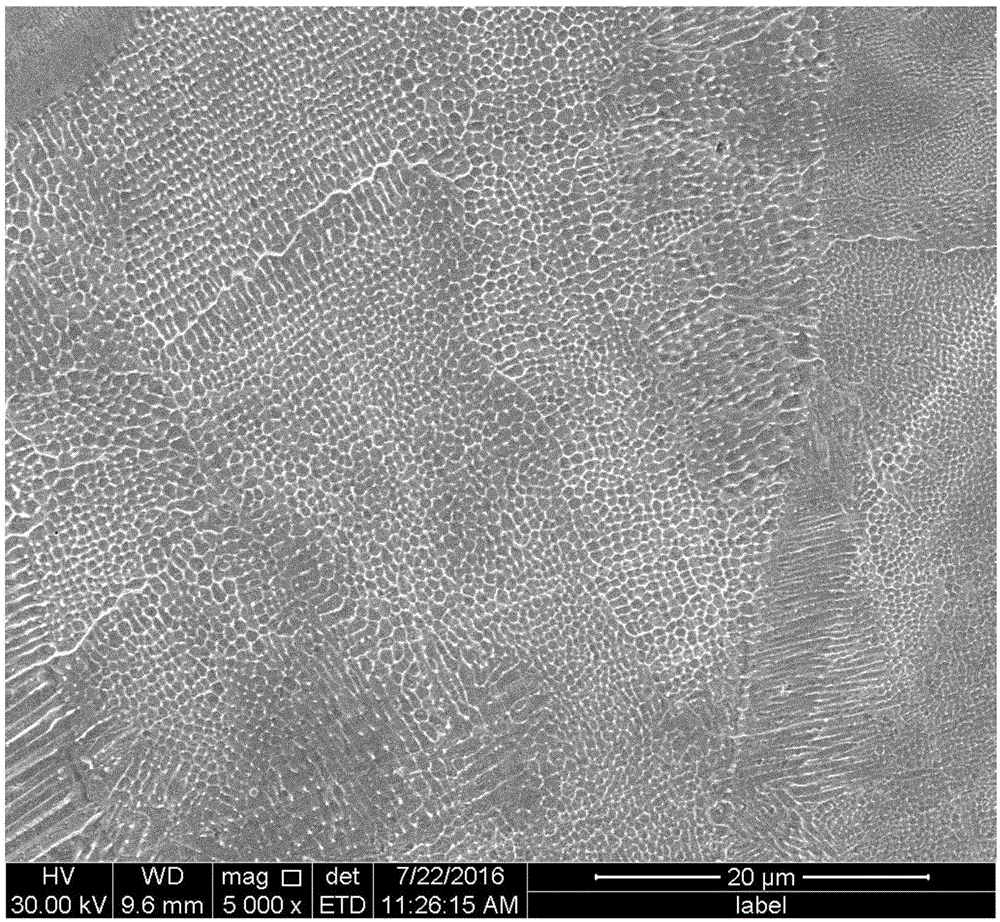

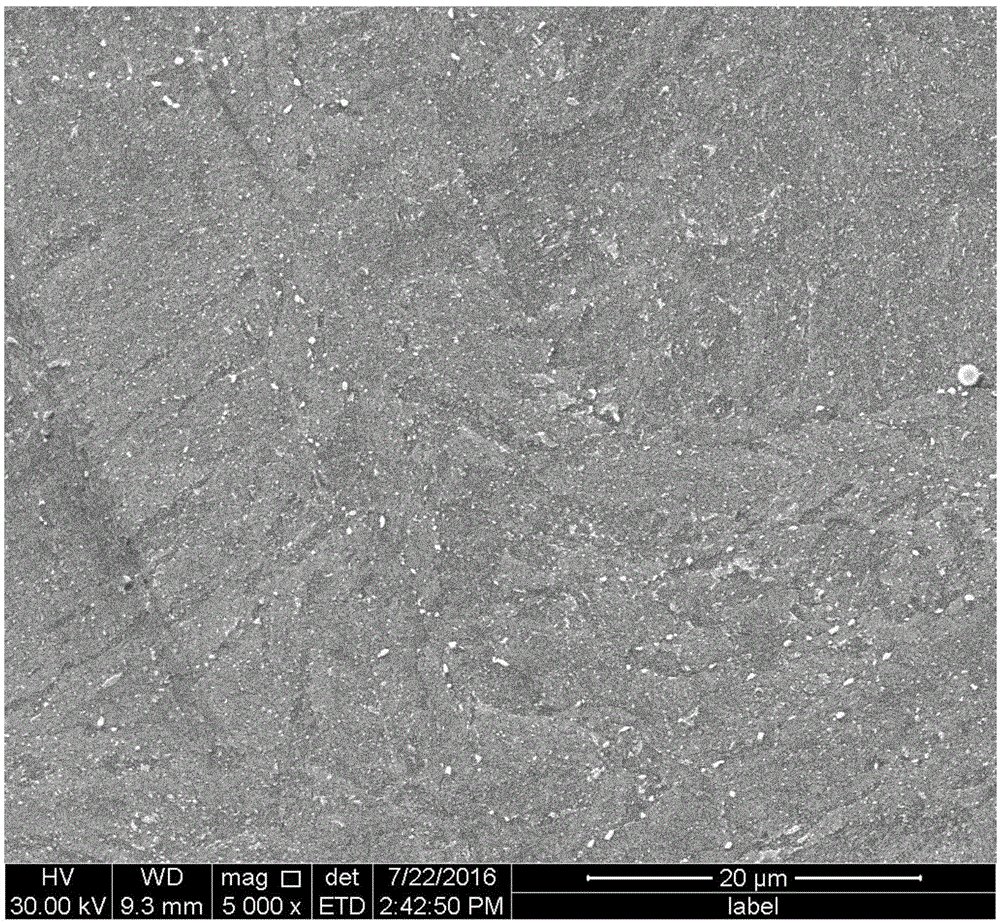

Forming method of maraging steel mold adopting selective laser melting

InactiveCN106825566AEasy to manufactureReduce pollutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingManufacturing cost reduction

The invention discloses a forming method of a maraging steel mold adopting selective laser melting. A three-dimensional structure of the mold is designed firstly by using three-dimensional design software such as Solidworks, ProE and Ug; and then the three-dimensional mold is subjected to slicing layering and route planning treatment, data are guided into a selective laser melting device, reasonable technical parameters are set, and the mold with a complex cooling channel is formed at a time. The mold formed by the method has the advantages of being high in compactness, few in internal defect, high in forming efficiency and high in free degree on the follow-up forming cooling channel. According to the forming method of the maraging steel mold adopting selective laser melting, the production period of the mold is effectively shortened, forming efficiency is high, external disturbance is small, the compressive property and production efficiency of the mold are remarkably improved, and meanwhile manufacturing cost is greatly reduced. After the directly-formed mold is subjected to solution and aging treatment, hardness and strength of the mold are remarkably improved, and the using requirements of the mold are met.

Owner:SOUTH CHINA UNIV OF TECH

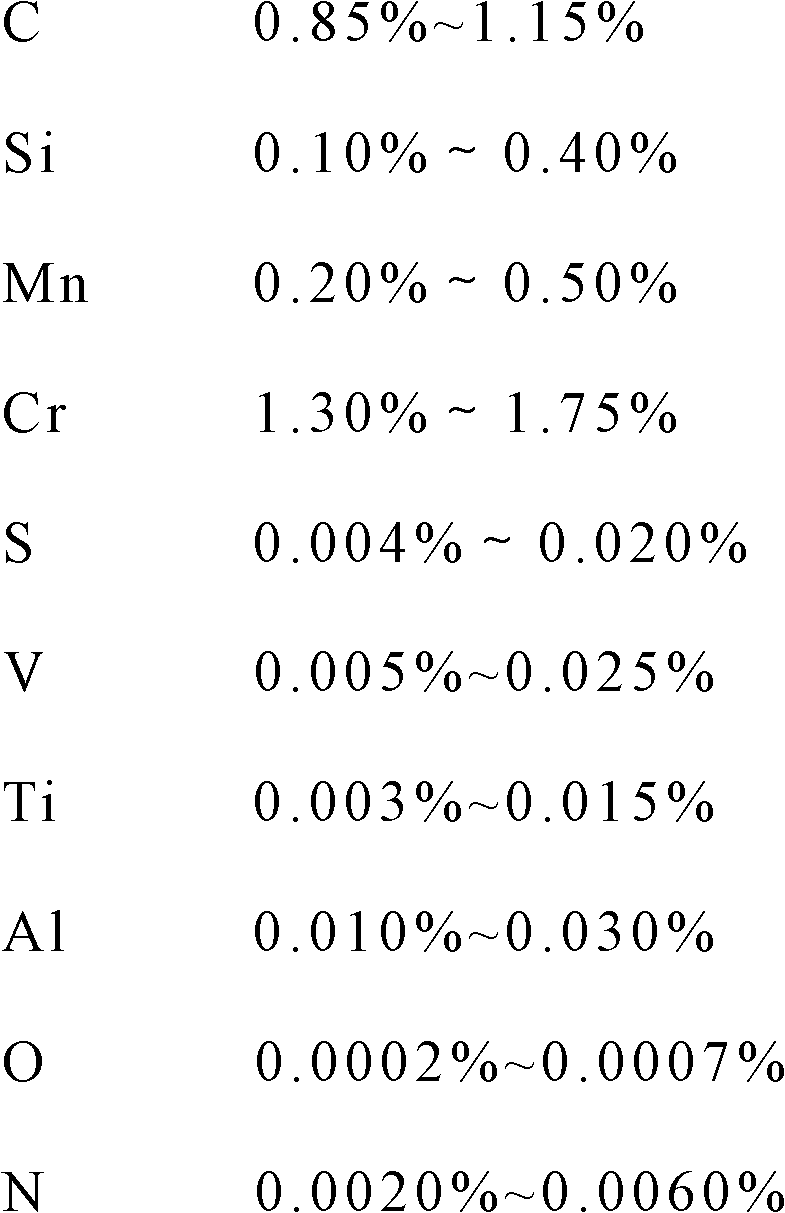

High-carbon chromium bearing steel GCr15 and production method thereof

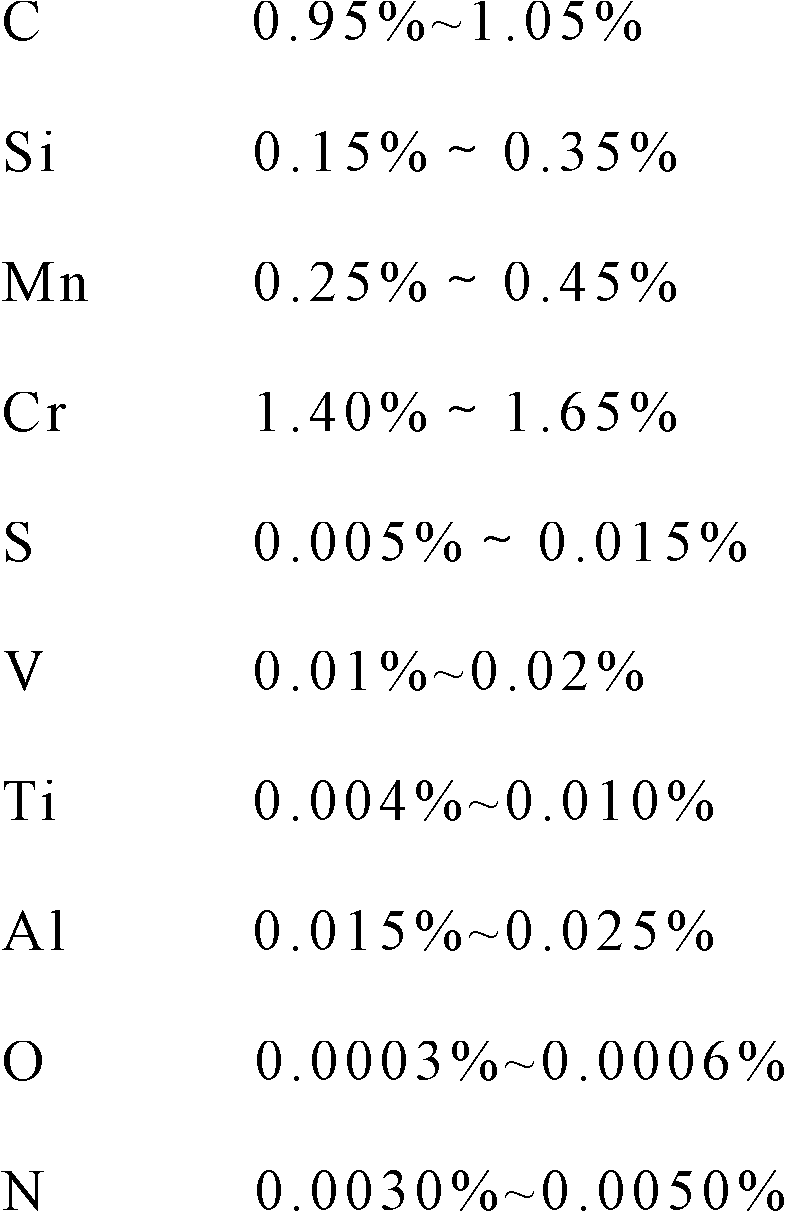

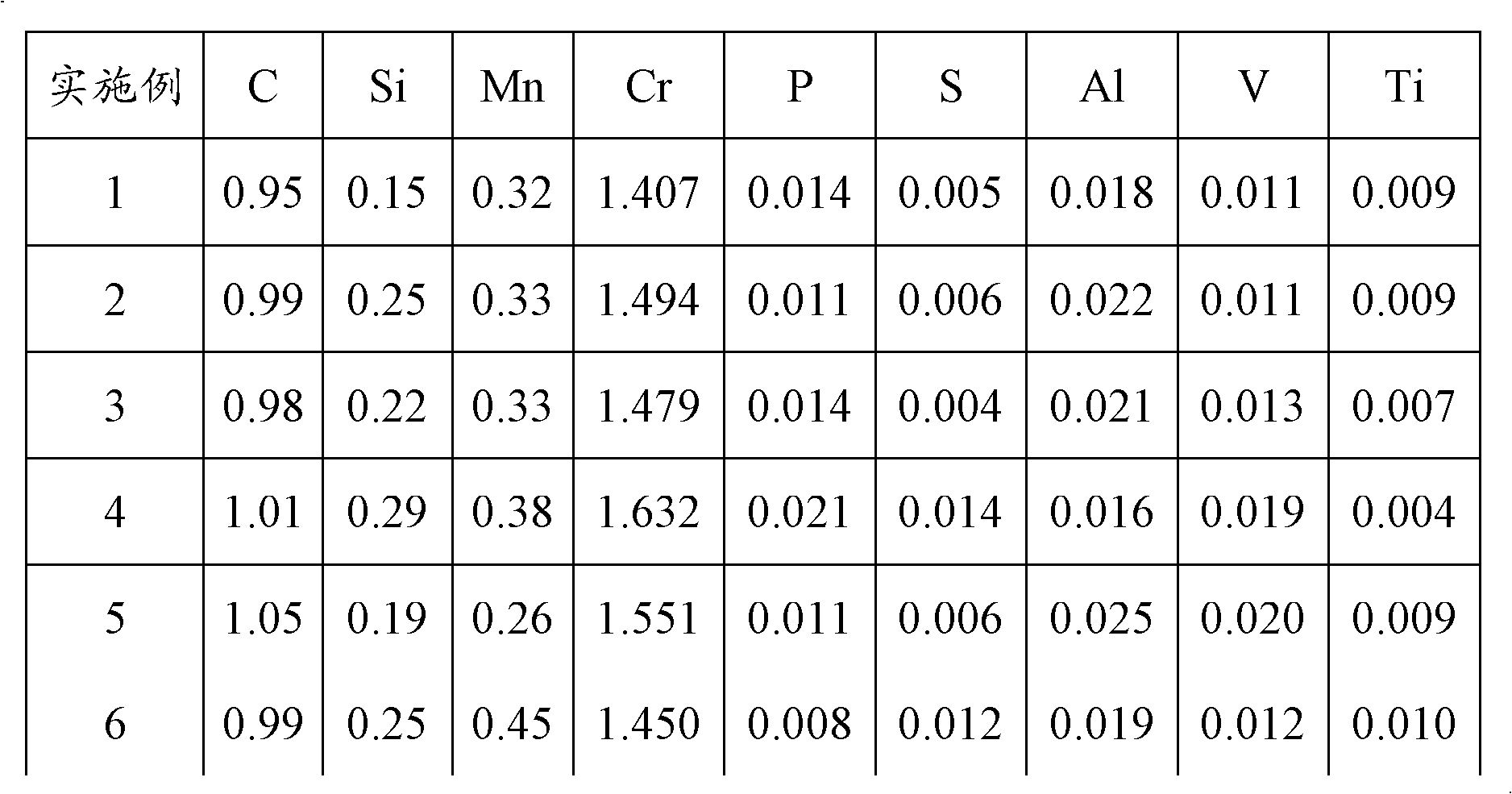

The invention relates to high-carbon chromium bearing steel GCr15 and a production method thereof. The bearing steel comprises the following components by weight percent: 0.85%-1.15% of C, 0.10%-0.40% of Si, 0.20%-0.50% of Mn, 1.30%-1.75% of Cr, 0.004%-0.020% of S, 0.005%-0.025% of V, 0.003%-0.015% of Ti, 0.010%-0.030% of Al, 0.0002%-0.0007% of O, 0.0020%-0.0060% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps of: performing primary smelting, refining, performing vacuum degassing, feeding silicon-barium wires, performing continuous pouring, rolling and performing post-treatment. Compared with the prior art, the production method can be used to realize low cost and ensure the comprehensive mechanical property of the product; and theobtained product is characterized by low oxygen content, low nitrogen content and low inclusion content.

Owner:CHENGDE JIANLONG SPECIAL STEEL

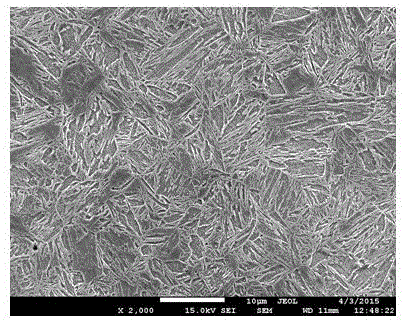

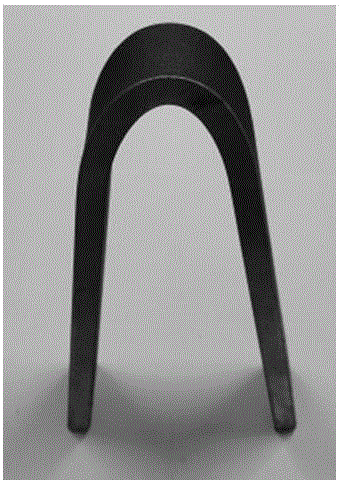

Excellent-cold-bending-performance steel plate with yield strength larger than 1100 MPa and manufacturing method thereof

The invention relates to a quenched type ultra-high-strength steel plate with yield strength larger than 1100 MPa. The production technology of the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa comprises the steps of smelting, external refining, vacuum degassing, Ca treatment, continuous casting, dehydrogenation treatment on a casting blank, heating, rolling, cooling, warm straightening, quenching and powerful straightening. According to the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa, the ingredients are economical, the technology is simple, the comprehensive mechanical performance of the steel plate is excellent, the yield strength is over 1100 MPa, the tensile strength is over 1200 MPa, and the Charpy impact energy at the minus 40 DEG C is larger than or equal to 30 J; meanwhile, the performances of the steel plate are uniform, the steel plate is flat, and the waviness of the steel plate is smaller than or equal to 5 mm / m; the cold bending forming performance of the whole steel plate is good, d is equal to 3a, and the result of the 180-degree laboratory GB / T232 cold bending test of the steel plate is qualified; b is larger than or equal to 500 mm, r is equal to 3a, and no crack is generated during 90-degree industrial cold bending forming; and therefore, the machining and use requirements on the ultra-high-strength steel plate of the domestic and overseas large machinery industry are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

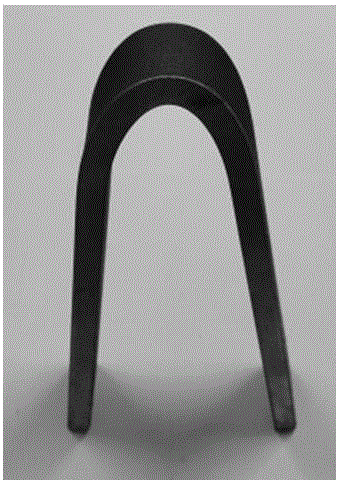

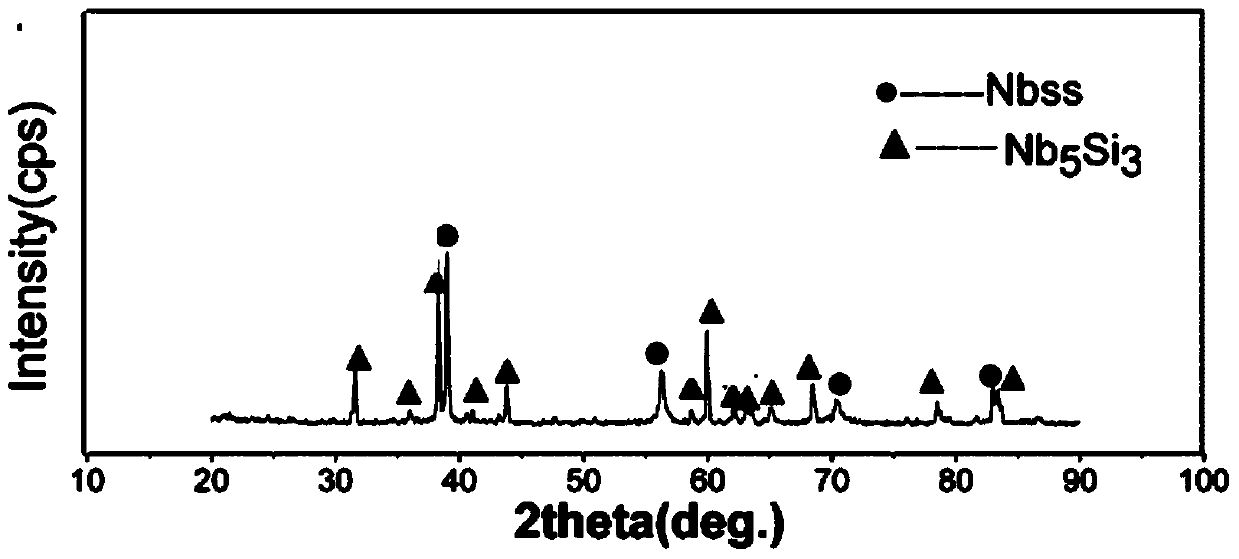

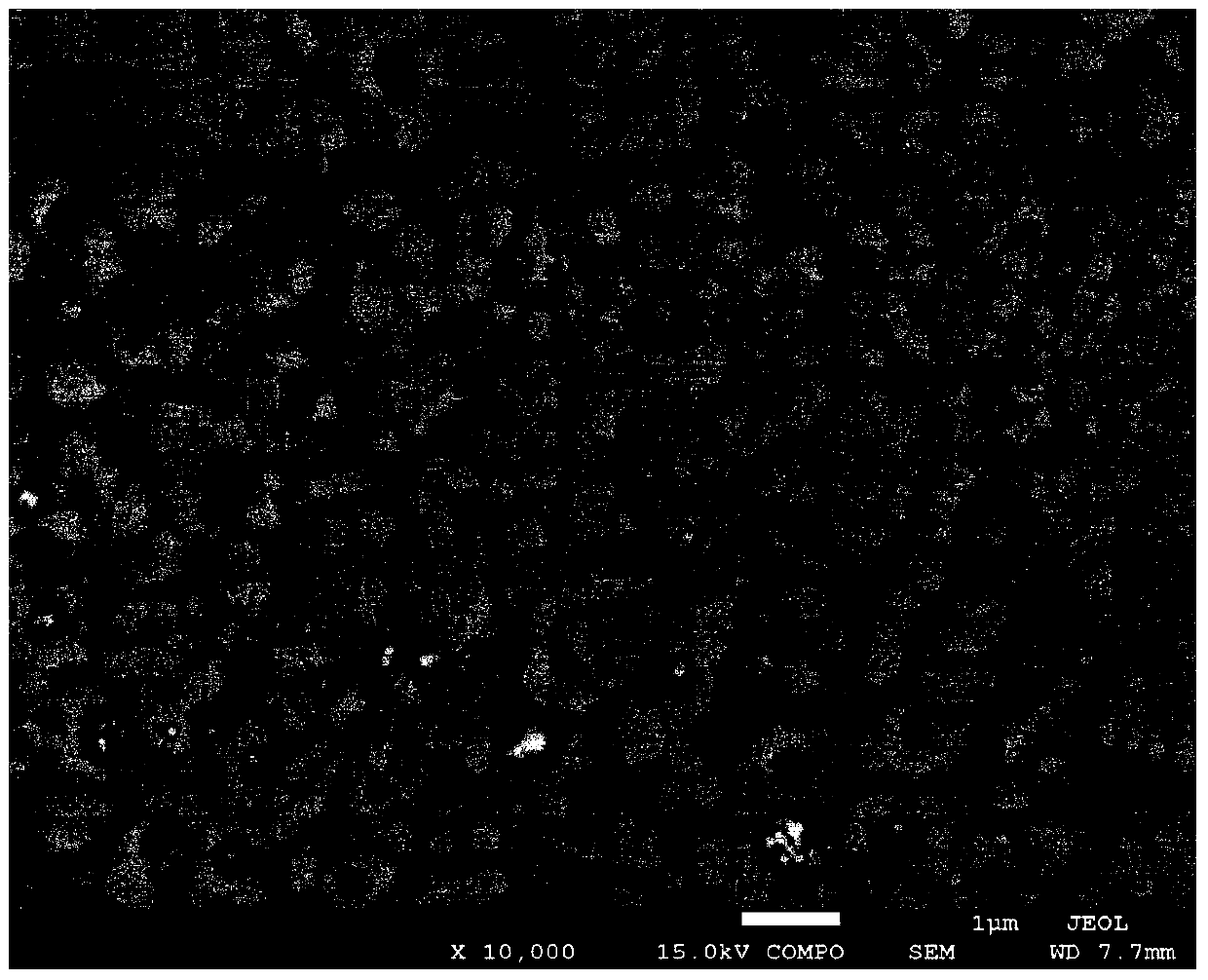

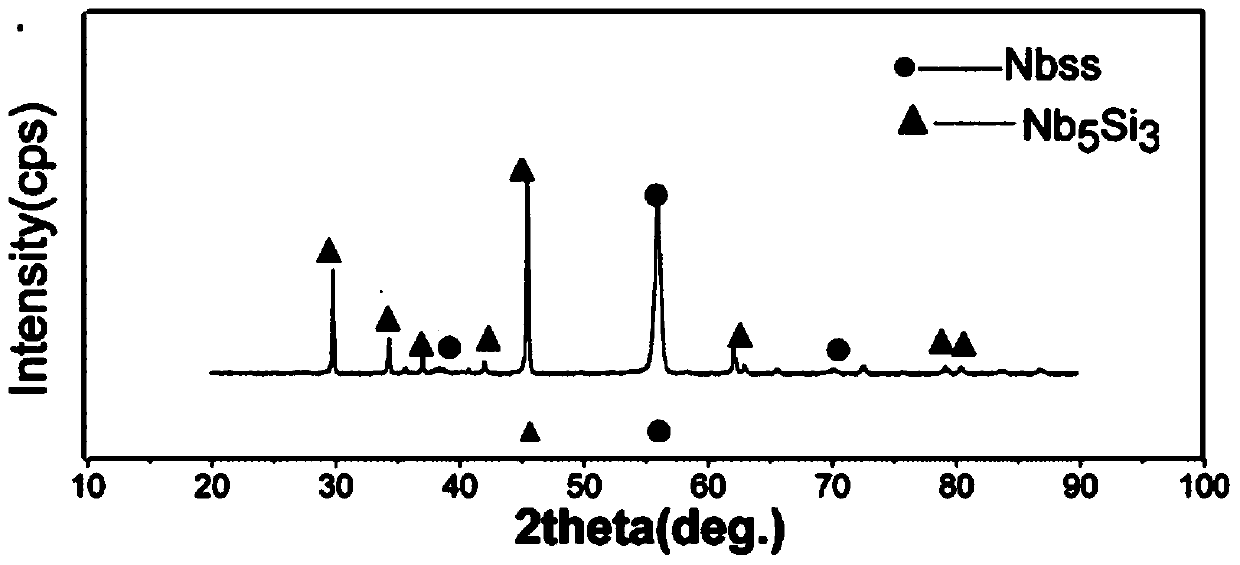

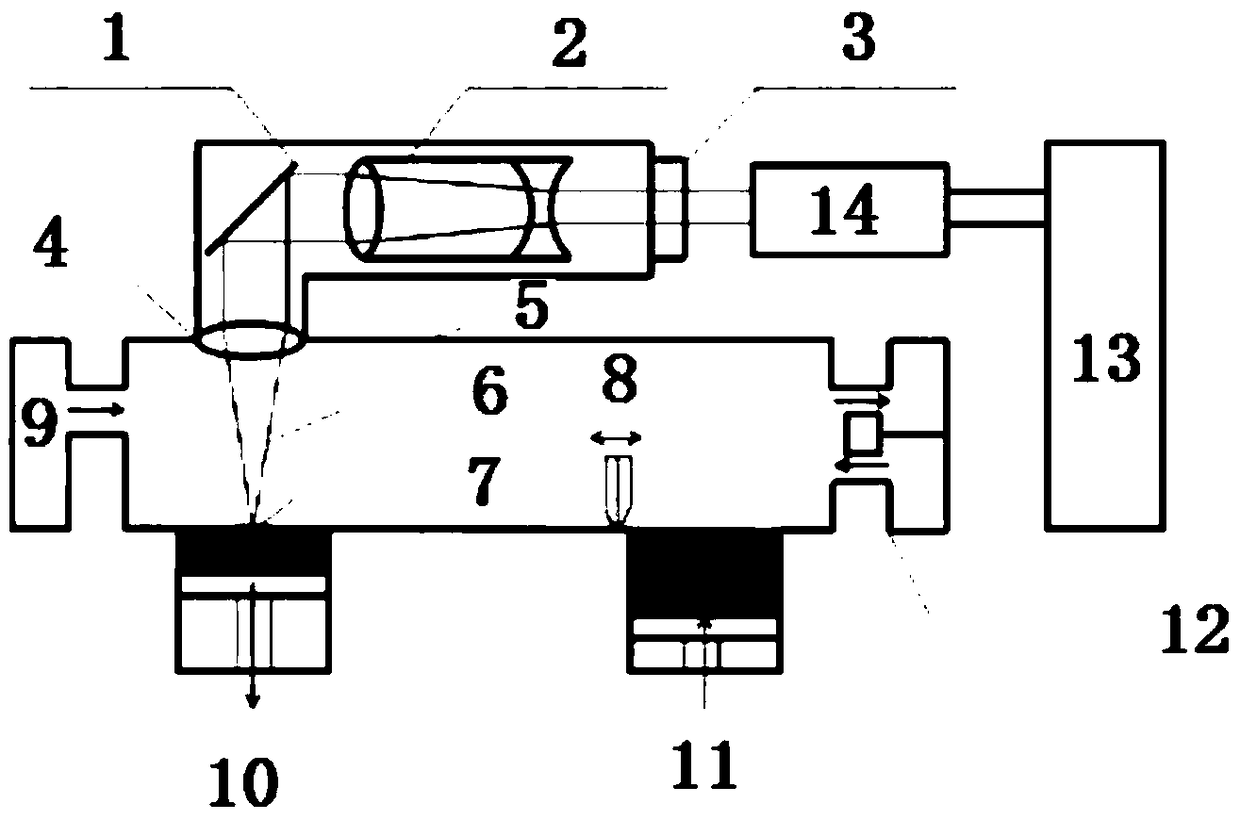

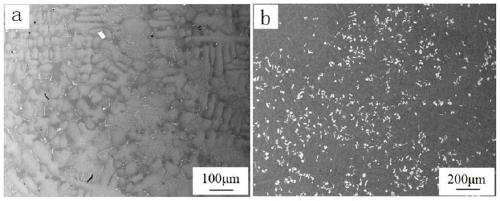

Method for preparing NbSi-base ultrahigh-temperature alloy through EBM (Electron Beam Melting)

InactiveCN103949640AReduce pollutionInhibit interface reactionIncreasing energy efficiencyComputer Aided DesignVolumetric Mass Density

The invention belongs to the technical field of high-temperature alloy preparation and particularly relates to a method for preparing NbSi-base ultrahigh-temperature alloy through EBM (Electron Beam Melting). By using electron beam selective melting equipment and arranging reasonable process parameters, the preparation of an NbSi-base alloy three-dimensional formed part can be completed in one step directly through a CAD (Computer-Aided Design) model. The density of the obtained NbSi-base alloy is high, the NbSi-base alloy mainly comprises NbSS (Nb Solid Solution) and an Nb5Si3 strengthening phase, the phase size is very fine (smaller than 1[mu]m) and the distribution is uniform. The method has the advantages that a mold is not needed during the preparation of the NbSi-base alloy, the alloy pollution is reduced, the impurity content is decreased, the material utilization ratio is high, and the mechanical property and the production efficiency of the NbSi-base ultrahigh-temperature alloy can be improved.

Owner:BEIHANG UNIV

Clean steel and manufacturing method

InactiveCN101096736AReduce heat lossQuality assuranceTemperature control deviceMetal rolling arrangementsMetallurgyImpurity

The invention discloses clean steel and its manufacturing method, which comprises the following parts: C<=0.0030%, Si<=0.0030%, 0.10%-0.30%Mn, P<=0.0030%, S<=0.0030, 0.01%-0.06%Al, Ti<=0.09%, Nb<=0.05%, N<=0.0030%, O<=0.0030%, H<=0.0002%, Fe and unavoidable impurity. The method comprises the following steps: desulfurizing hot iron; bessemerizing; refining outside the furnace; casting the middle sheet plate blank continuously; loading hotly and directly; heating the furnace; roughing down; planishing; cooling lamellar flow; batching; cleaning with acid ; rolling coldly; annealing ( flattening; shearing ). The invention reduces the inclusion content in the steel by controlling the proper content of C, Mn, P, S, N, O, and H, which makes the inclusion shape fine and dispersing, the composition homogeneous and the structure homogeneous, and guarantees the integrated property.

Owner:ANGANG STEEL CO LTD

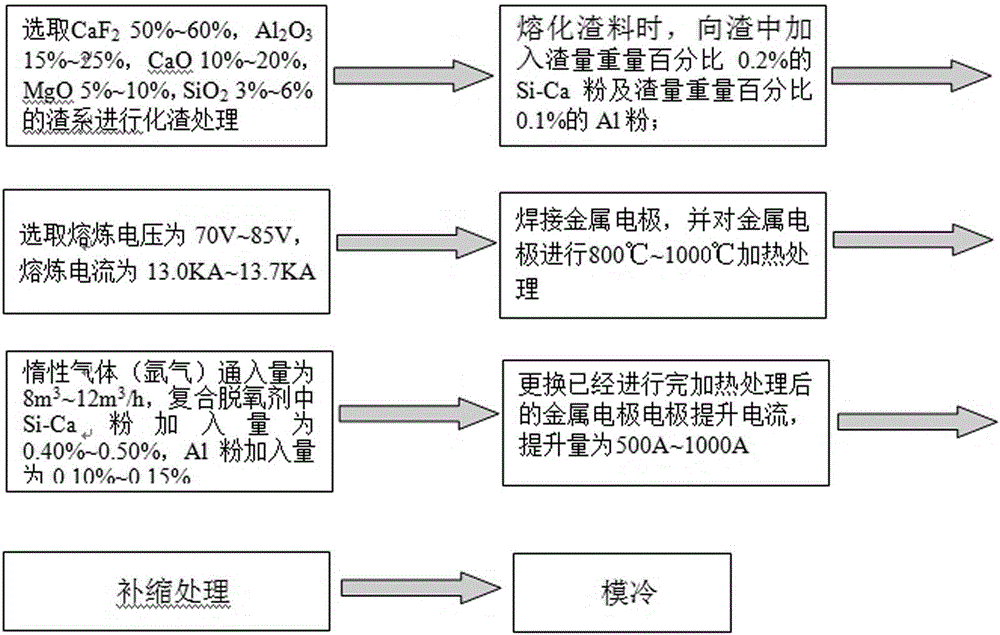

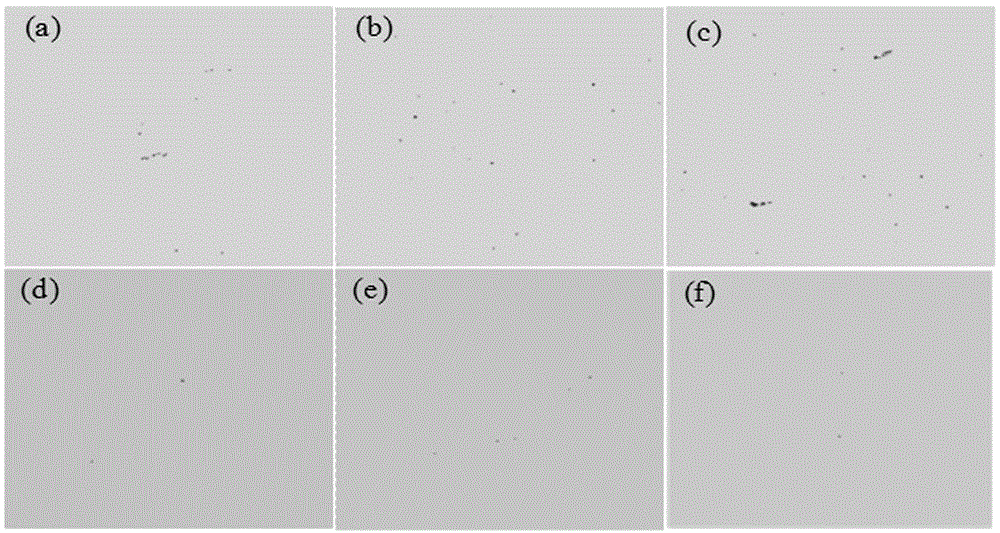

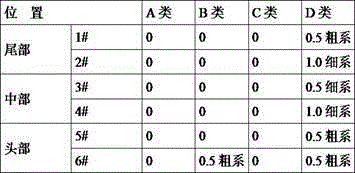

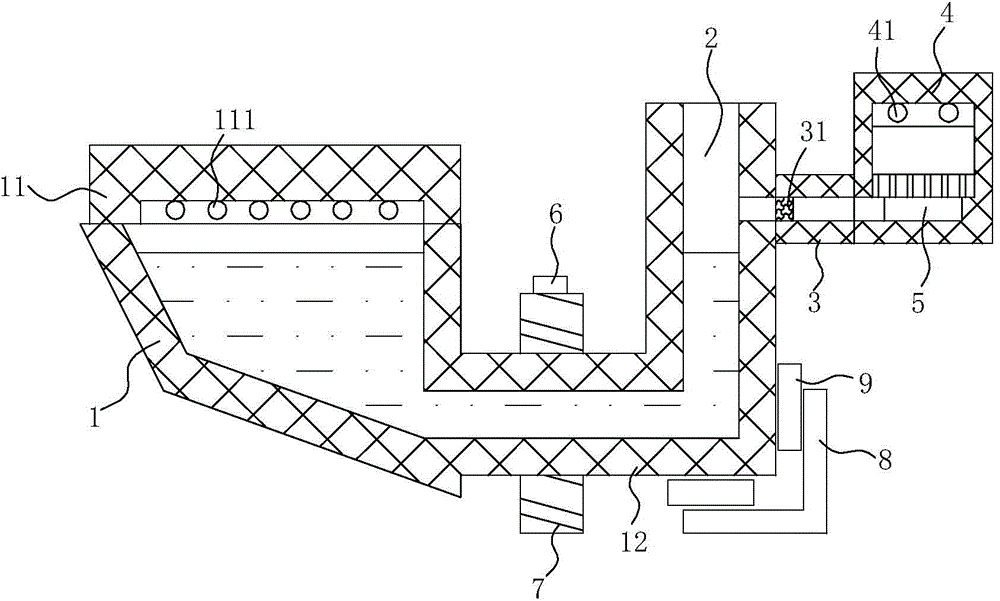

Electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power

The invention discloses an electroslag remelting method for high-purity austenite nitrogenous stainless steel for nuclear power. The method comprises the following steps: (1) selecting a cylindrical metal electrode for electroslag; (2) treating the metal electrode by adopting a machining method; (3) carrying out welding treatment and heating treatment on the metal electrode and a stainless-steel false electrode for the electroslag; (4) carrying out slag melting treatment by selecting a slag system which contains 50%-60% (by weight) of CaF2, 15%-25% (by weight) of Al2O3, 10%-20% (by weight) of CaO, 5%-10% (by weight) of MgO and 3%-6% (by weight) of SiO2; (6) carrying out feeding treatment; (7) carrying out die cooling. According to the austenite nitrogenous stainless steel prepared by the method, the forming of a steel ingot surface is good, and the inclusion content is low and can reach that the inclusion content of a coarse series of a class A is not higher than 0.5, the inclusion content of a fine series of the class A is not higher than 0.5, the inclusion content of a coarse series of a class B is not higher than 0.5, the inclusion content of a fine series of the class B is not higher than 0.5, the inclusion content of a coarse series of a class C is not higher than 0.5, the inclusion content of a fine series of the class C is not higher than 0.5, the inclusion content of a coarse series of a class D is not higher than 0.5, and the inclusion content of a fine series of the class D is not higher than 1.0.

Owner:沈阳科金特种材料有限公司

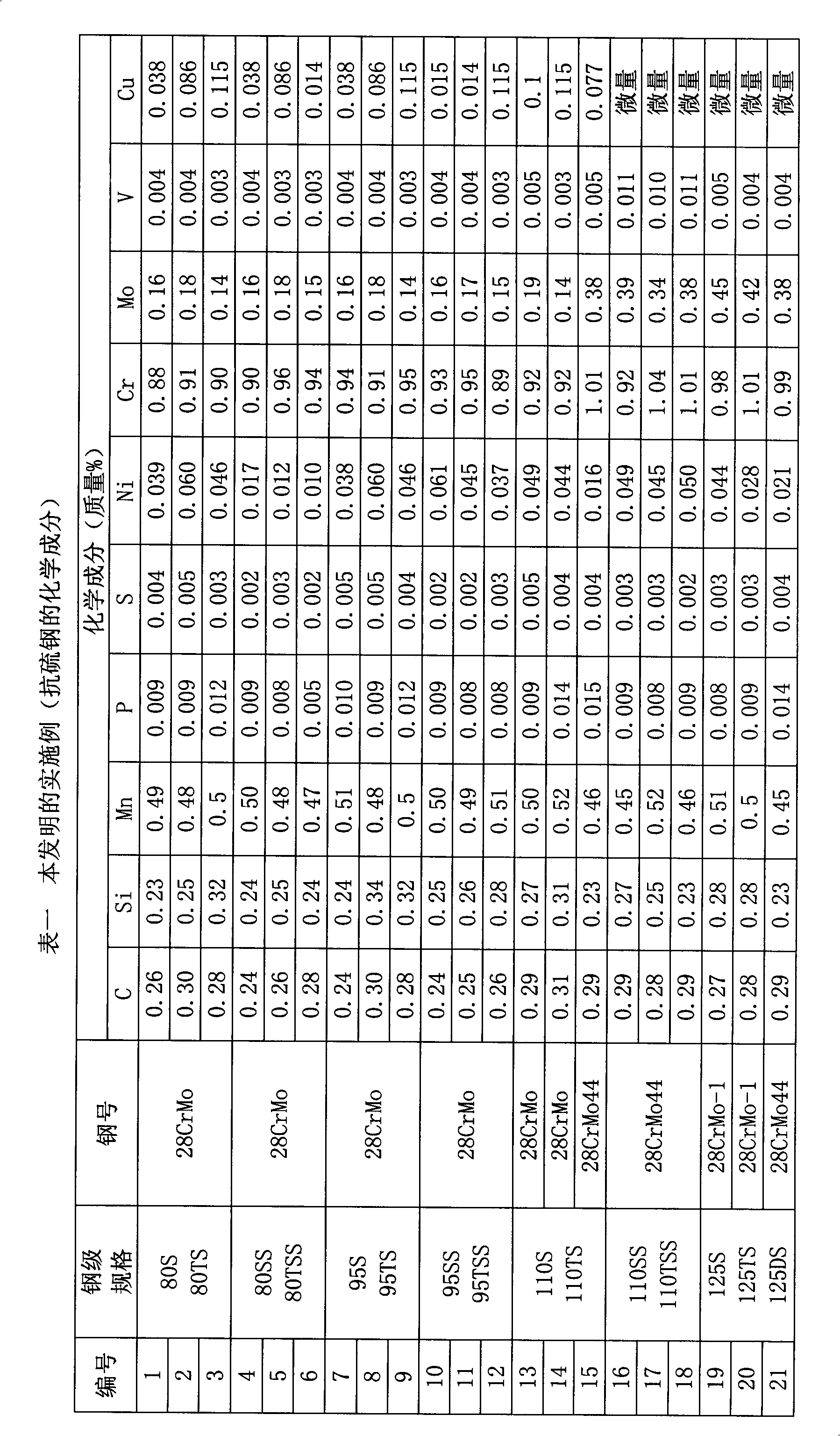

Clean steel smelting method of anti-S steel oil well pipe

InactiveCN101643882AQuality assuranceGuaranteed performanceElectric furnaceProcess efficiency improvementElectric arc furnaceChemical composition

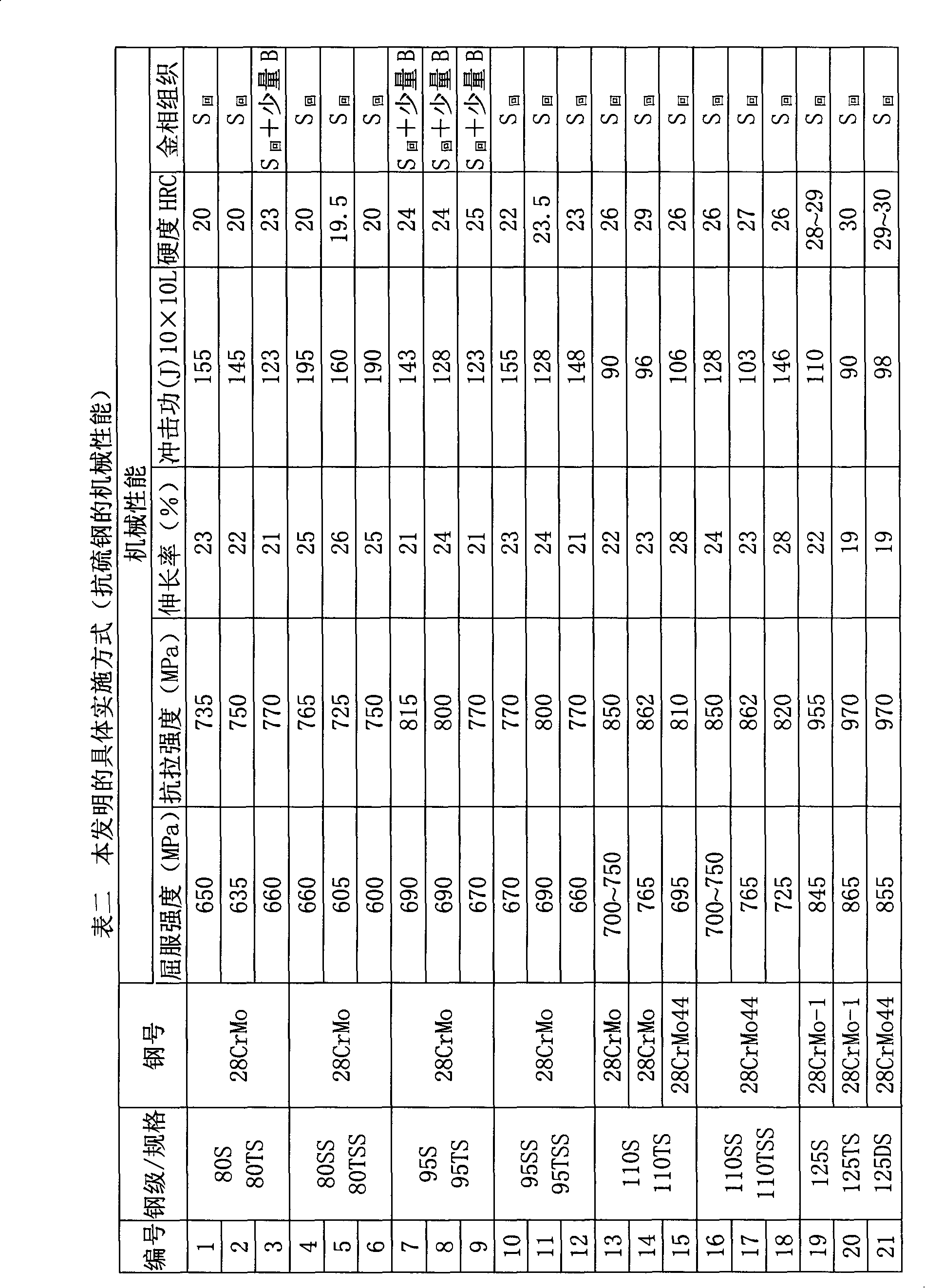

The invention provides a clean steel smelting method of an anti-S steel oil well pipe, which relates to a smelting and preparing technology of an oil well pipe blank used in a corrosive oil-gas fieldenvironment. Clean steel comprises suitable chemical compositions by weight percent: 0.20-0.35 percent of C, not more than 1.00 percent of Si, not more than 0.60 percent of Mn, not more than 0.015 percent of P, not more than 0.010 percent of S, not more than 1.50 percent of Cr, 0.15-1.0 percent of Mo, 0.01-0.06 percent of Als, not more than 0.09 percent of Ti, not more than 0.05 percent of Nb, notmore than 0.0030 percent of N, not more than 0.0030 percent of O, not more than 0.0002 percent of H and Fe and the balance of unavoidable impurities. The clean steel smelting method adopts the following production technical lines by aiming at the clean steel with the compositions: choosing matching materials; smelting in an arc furnace; refining in an LF furnace; refining in a VD furnace; continuously casting in an arc shape; controlling hydraulic pressure and casting in full protection. The clean steel smelting method reduces the impurity content in the steel by controlling the proper content of C, Mn, P, S, Cr, Mo, N, O, H, and the like, the impurities are smaller and dispersive by the control of a subsequent technology, the component distribution is more uniform, tissues are evenly thinned, and the combination property of the anti-sulfur oil well pipe is ensured.

Owner:朝阳西姆莱斯石油铸钢管件有限公司 +1

Soft tinning raw steel plate and manufacture method thereof

The invention provides a soft tinning raw steel plate and a manufacture method of the soft tinning raw steel plate. The steel plate is prepared from the following chemical components in percentage by weight: 0.0001 to 0.010% of C, not greater than 0.02% of Si, 0.10 to 060% of Mn, not greater than 0.02% of P, not greater than 0.02% of S, not greater than 0.02% of Al, not greater than 0.002% of N, not greater than 0.005% of O, 0.005 to 0.05% of Nb, and / or 0.005 to 0.07% of Ti, and the balance of Fe. The manufacture method comprises the technical processes as follows: preprocessing molten iron-melting through a converter-refining outside the converter-protectively casting-performing hot rolling-pickling and performing cold rolling-annealing- inspecting-packaging; activity of end-point oxygen of a molten iron is controlled to reach a value of 0.02 to 0.06% during melting by the converter; the molten iron is processed in vacuum during being refined outside the furnace; contents of alloy elements such as C and Mn are precisely controlled; and the contents of gases such as oxygen and nitrogen in the molten iron can be reduced. By adopting the manufacture method provided by the invention, a problem that the soft tinning raw steel plate is relatively hardly produced by a continuous annealing method can be solved, content of inclusion in steel can be decreased, and a forming performance of the steel plate can be improved.

Owner:ANGANG STEEL CO LTD

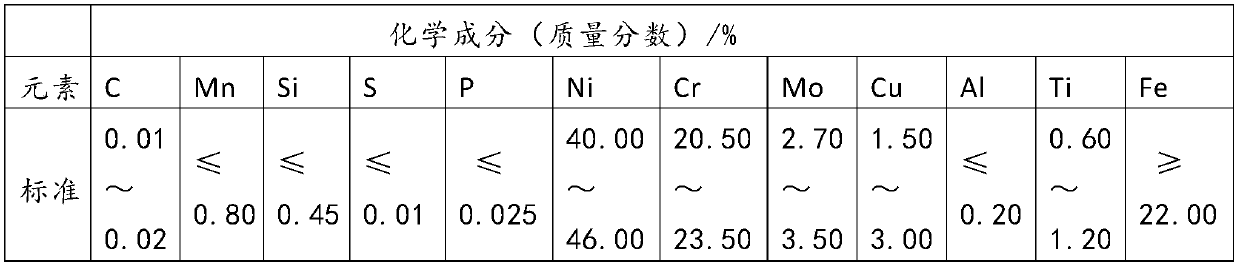

Electroslag remelting process of nickel-based superalloy

InactiveCN110724826ASmooth surface qualityHigh yieldIncreasing energy efficiencyFurnace typesSlagSuperalloy

Owner:JINGYE STEEL CO LTD

Preparation method of spherical titanium and nickel shape memory alloy for 3D (three-dimensional) printing

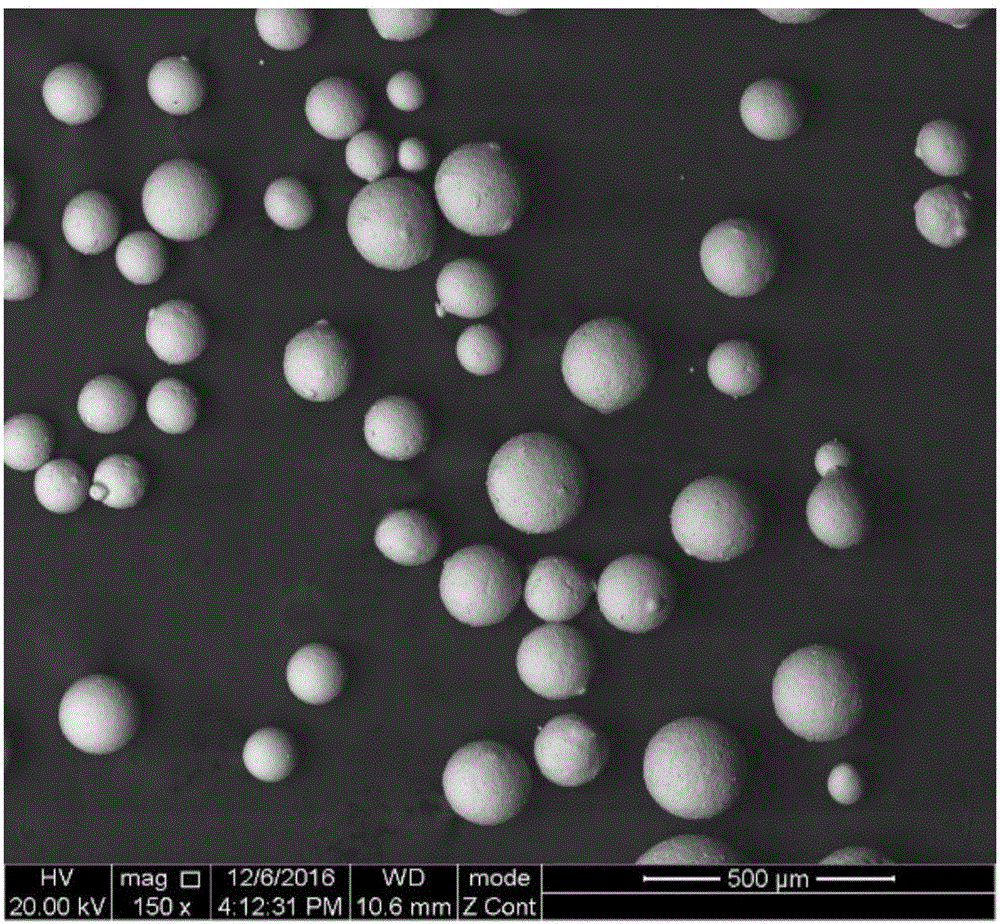

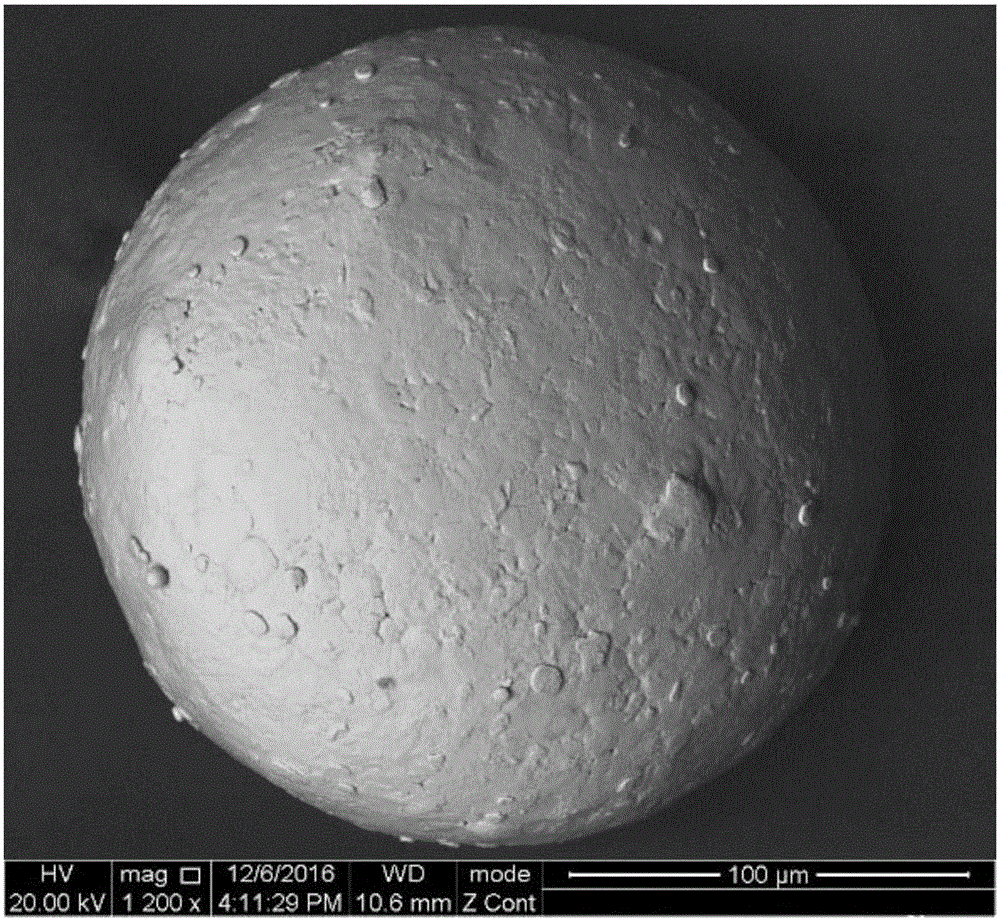

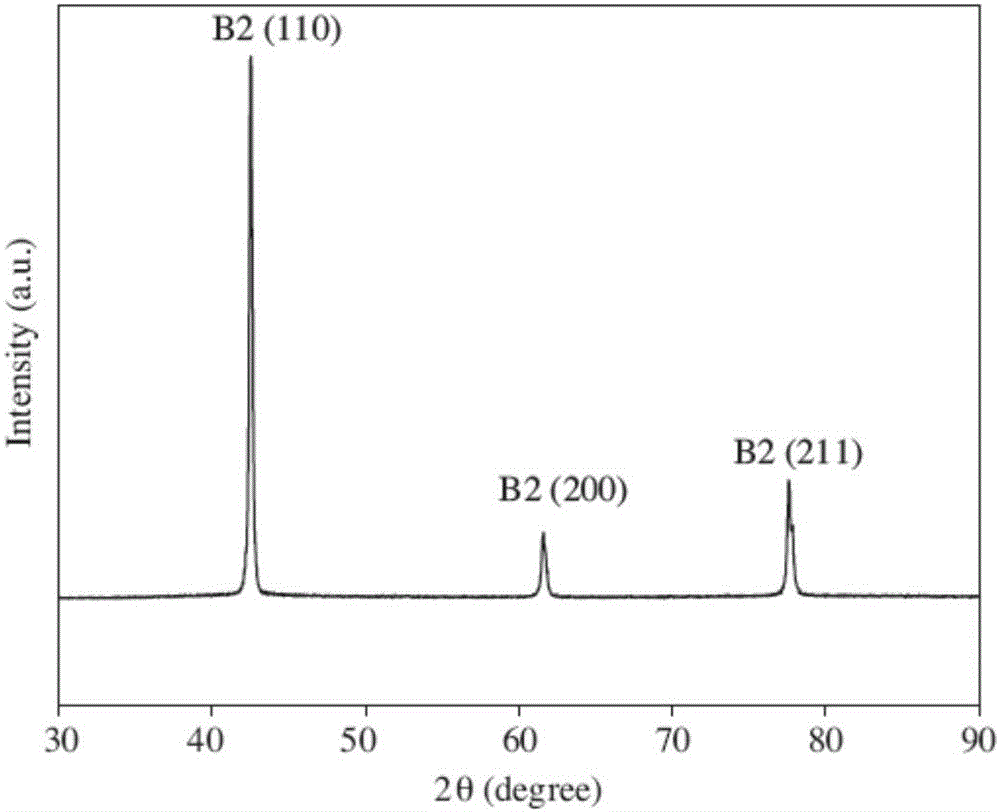

ActiveCN106825594APowder sphericity guaranteeEnsure consistencyTransportation and packagingMetal-working apparatusSmall dropletShape-memory alloy

The invention discloses a preparation method of spherical titanium and nickel shape memory alloy for 3D (three-dimensional) printing, and belongs to the technical field of 3D printing. The method includes the steps: taking titanium and nickel alloy bars as induction electrodes under the vacuum states or the protection states of inert gas, and rotating downwards electrode bars to enter conical coils; gradually melting top ends of the bars in the conical coils under the action of induction heating in the moving process to form molten drop or molten fluid flow, enabling the molten drop or the molten fluid flow to directly flow into an atomizer below the conical coils under the action of gravity; crushing the molten drop or the molten fluid flow into small droplets under the action of high-pressure gas, and balling and coagulating the small droplets into metal powder through surface tension of the small droplets in the flight process of the small droplets. The preparation method has the advantages that power is high in sphericity degree, components are uniform and nonmetal inclusion is low in content.

Owner:中航迈特增材科技(北京)有限公司 +1

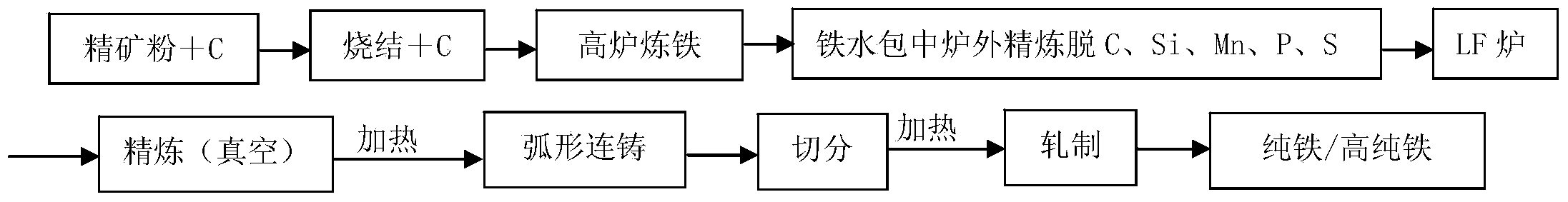

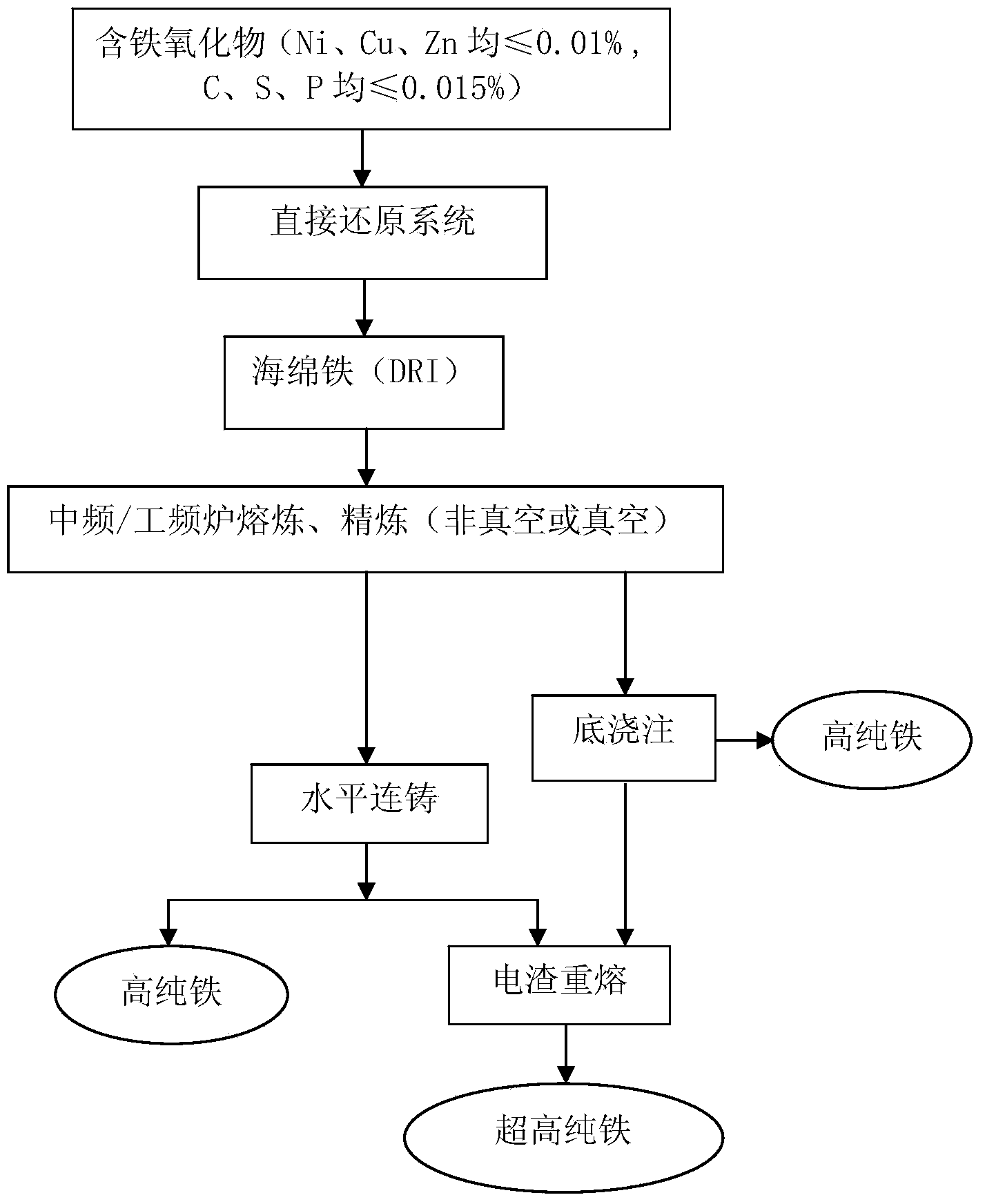

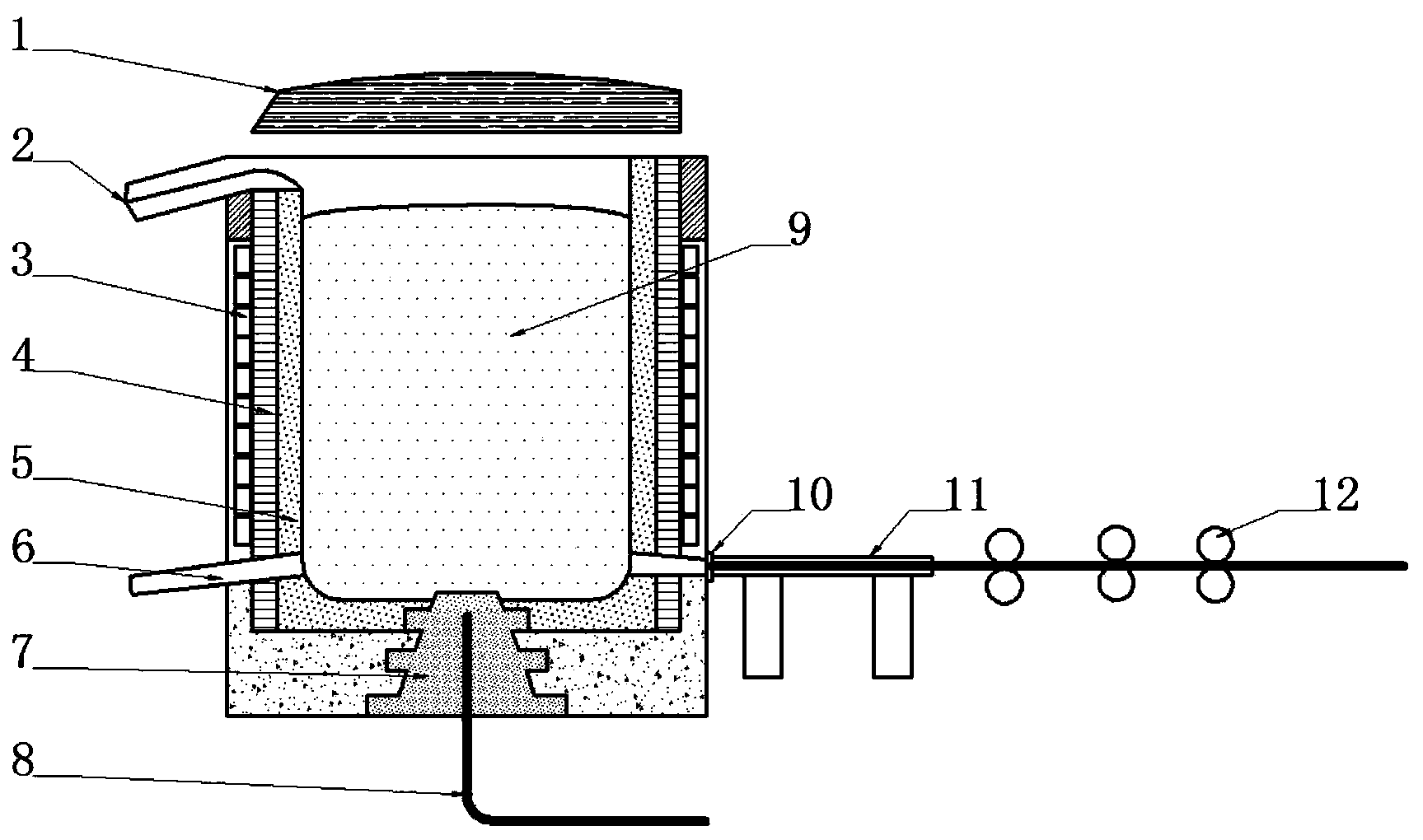

Method for producing high-purity pure iron

ActiveCN104141024AExtend your lifeUniform temperatureIncreasing energy efficiencyBrown iron oxideControl mode

The invention relates to a method for producing high-purity pure iron. The method includes the following steps: iron oxide is reduced in a layered-control mode through a direct-reduction system to manufacture sponge iron; the sponge iron is added into a medium-frequency or power-frequency induction furnace for smelting, and composite slag forming constituents are added in batches; after smelting and slagging-off are conducted, composite slag forming constituents are added, argon-oxygen mixed gas bottom blowing is carried out on the medium-frequency or power-frequency induction furnace through porous bricks at the bottom, blowing of the mixed gas is stopped when the temperature of molten steel reaches 1620 DEG C to 1650 DEG C, standing is carried out on the molten steel for 25 minutes to 35 minutes, then slagging-off is conducted, a proper amount of aluminum is added into the molten steel for 1 minute to 2 minutes, argon bottom blowing is carried out through the air bricks at the bottom of the induction furnace at the moment, and stopped when the temperature is continuously raised to range from 1640 DEG C to 1680 DEG C, horizontal continuous casting or bottom casting is conducted after standing is conducted on the molten steel for 15 minutes, and the low-impurity pure iron with the iron content larger than 99.9% is obtained, wherein the contents of more than twenty elements are all smaller than 0.01%. Meanwhile, the pure iron with the higher purity can be produced through vacuum refining or electroslag remelting. By means of the method, the flow path is short, devices are simple, and investment is saved.

Owner:武汉桂坤科技有限公司

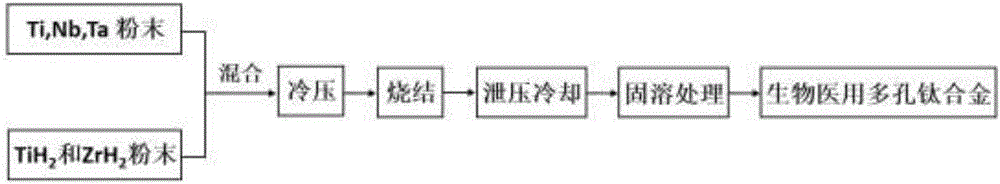

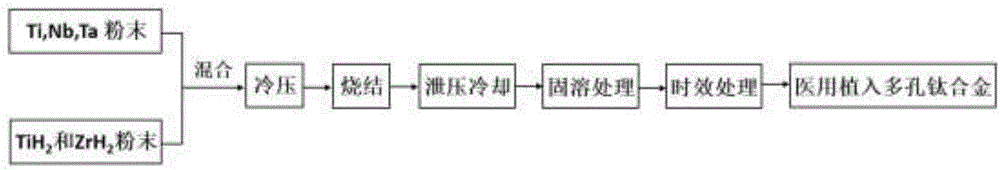

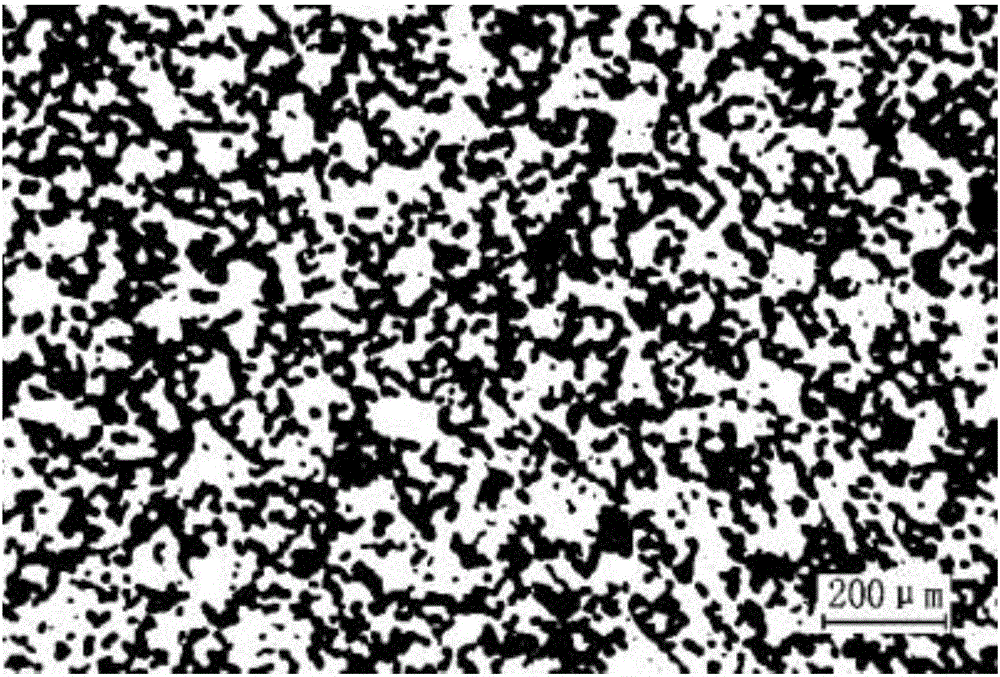

Biomedical porous Ti alloy and preparation method

The invention relates to a biomedical porous Ti alloy and a preparation method. The biomedical porous Ti alloy comprises the following components in percentage by weight: 20-22wt% of Nb, 6-8wt% of Zr, 4-6wt% of Mo, and the balance of Ti; the porosity and mechanical property adjustment range of the biomedical porous Ti alloy is wide; when the porosity is relatively low, the low modulus of elasticity and the high strength property can be achieved; and accordingly, the biomedical porous Ti alloy is suitable for preparation of a medical implant. The preparation method comprises the following specific steps: uniformly mixing Ti powder, Nb powder, Zr powder, Mo powder, TiH2 powder, and ZrH2 powder at the ratio; carrying out cold pressing to obtain a green body; sintering the green body in a sintering furnace filled with argon gas; after the sintering is finished, opening a gas bleed valve to quickly reduce the pressure in the sintering furnace to 0.15-0.30 MPa, and then powering off the sintering furnace; meanwhile, filling the sintering furnace with argon gas, so as to cool the obtained sinter; and finally, carrying out solution treatment on the cooled sinter. The preparation method is low in preparation cost, and the TiH2 powder and the ZrH2 powder are adopted as not only foaming materials but also alloy materials.

Owner:SOUTHEAST UNIV

Smelting technique and production method of bearing steel and bearing steel

The invention relates to a smelting technique and production method of bearing steel and the bearing steel. Impurities in the bearing steel are controlled through the smelting technique. Low-titanium ferrochromium with the Cr content being equal to or higher than 75% serves as raw materials, and Al is added at one time for deoxidation before smelting and tapping of an electric furnace. High-purity silicon carbide with the purity being larger than 95% is adopted for deoxidation. After degassing of a vacuum furnace is conducted, the standing time of molten steel is not shorter than 10 minutes. By the adoption of a tundish current regulator, a covering agent with the calcium oxide content being not smaller than 50% serving as a tundish covering agent, and casting powder with the calcium oxide content being not smaller than 34% serving as tundish casting powder, the bearing steel is obtained, wherein the A type coarse impurity content of the beating steel is smaller than or equal to 1.0%, the A type fine impurity content of the beating steel is smaller than or equal to 1.0%, the B type coarse impurity content of the beating steel is smaller than or equal to 0.5%, the B type fine impurity content of the beating steel is smaller than or equal to 0.5%, the D type coarse impurity content of the beating steel is smaller than or equal to 0.5%, the D type fine impurity content of the beating steel is smaller than or equal to 0.5%, the C type coarse impurity content of the beating steel is 0, the C type fine impurity content of the beating steel is 0, and the DS type impurity content of the bearing steel is smaller than or equal to 1.0%. By the adoption of the smelting technique, the content of all the impurities is greatly reduced.

Owner:SUZHOU SUXIN SPECIAL STEEL +2

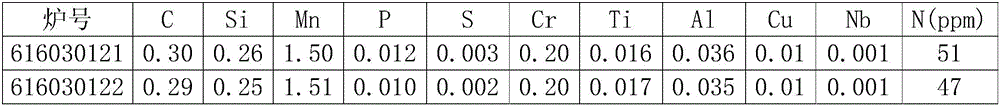

Production process for effectively preventing marine anchor chain round steel from generating cracks

InactiveCN106086595ASolve the problem of nozzle nodulationReduce inclusion contentProcess efficiency improvementElectric furnaceChemical compositionSlag

The invention relates to a production process for effectively preventing marine anchor chain round steel from generating cracks. A preparation method includes the steps of an electric furnace smelting procedure, a refining procedure outside an LF, a square billet continuous casting procedure and a rolling procedure. Chemical components are reasonably designed, the carbon equivalent is controlled, Ti microalloy reinforcement is added, the content of P and S is controlled to be smaller than or equal to 0.015%, the content of N is controlled to be smaller than or equal to 70 ppm, the content of residual elements of Cu, Nb and the like is reasonably controlled, the LF is well sealed, the soft blowing flow of argon is reasonably controlled, molten steel is prevented from absorbing nitrogen, aluminum deoxidation is enhanced, the soft blowing time of the argon is properly prolonged, whole-process protective casting is adopted for the continuous casting, the pulling speed and the superheat degree are low, proper protective slag is selected, the straightening temperature is raised, continuously cast billet enters a pit to be slowly cooled, the tapping interval is well controlled in a rolling manner, the compression ratio is increased, and a reasonable heat treatment process is selected. The marine anchor chain round steel produced through the method is simple in procedure and low in cost, vacuum treatment is not needed, and the technical problems that marine anchor chain round steel produced at present is bad in surface quality, high in crack occurrence ratio, not stable in quality and the like are solved.

Owner:ZENITH STEEL GROUP CORP

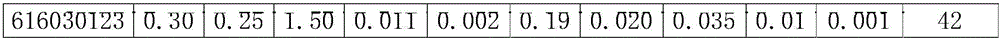

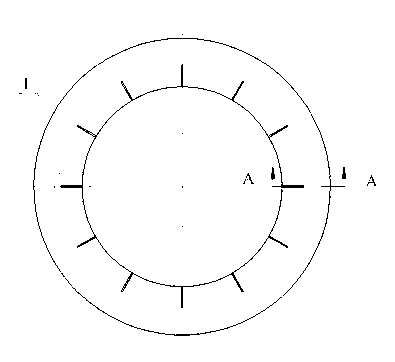

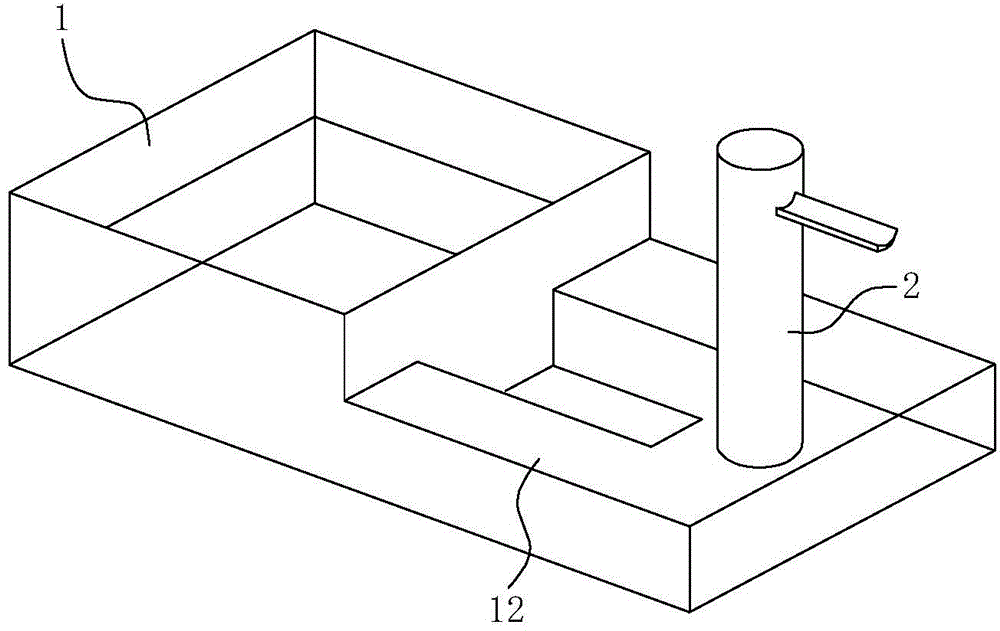

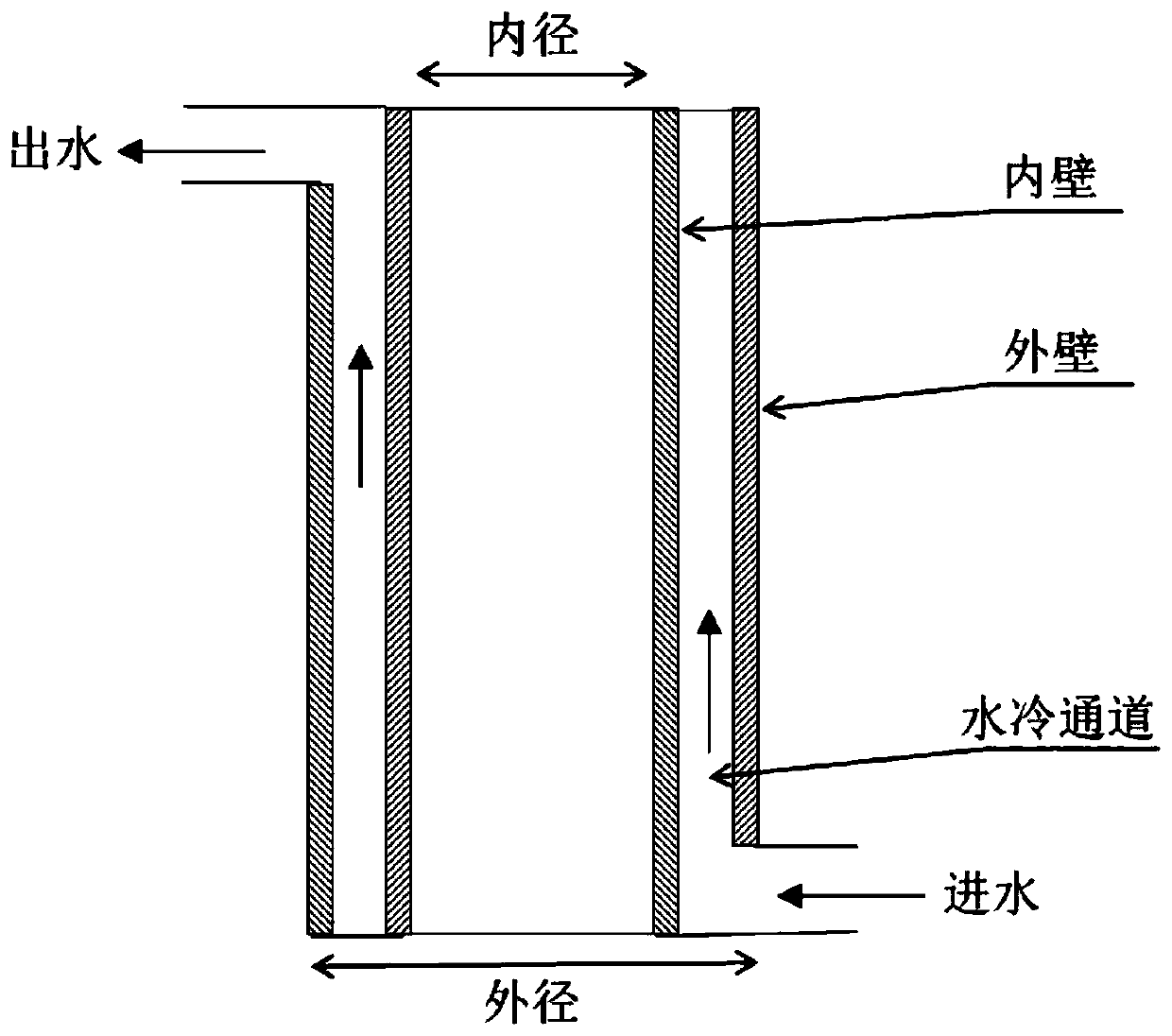

Aluminum alloy hollow ingot semi-continuous casting crystallizer and application thereof

The invention relates to an aluminum alloy hollow ingot semi-continuous casting crystallizer and application thereof. A water diversion ring is arranged in a cooling water cavity of a water jacket; a water spraying hole communicated with the cooling water cavity is toward a cooling wall of an outer crystallizer; an outer lubricant channel is arranged in the outer crystallizer body; one end of the outer lubricant channel is formed on the outer oil storage groove; an outer oil injection ring on the outer oil storage groove is toward a cooling wall of the outer crystallizer body; an outer heat preservation cap is fixed on the outer crystallizer body; a core body is placed in the center of the outer crystallizer body; the inner side of the core body is of a hollow structure; a water inlet pipe is arranged on the core body; a water outlet pipe coaxial to the water inlet pipe is sleeved on the outer side of the water inlet pipe; an inner lubricant channel is arranged in the core body; one end of the inner lubricant channel is formed in the inner oil storage groove; an inner oil injection oil ring on the inner oil storage groove is toward the core cooling wall; and an inner heat preservation cap is fixed on the core body. The hollow ingot is cooled by circulating water during casting; and the cooling walls of the outer crystallizer body and the core are subjected to pulse-type oil injection lubrication, so that the fineness of the inner surface and the outer surface of the hollow ingot can be obviously improved, and the peeling amount before subsequent plastic processing is reduced.

Owner:苏州有色金属研究院有限公司

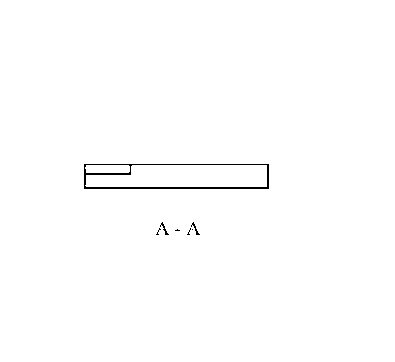

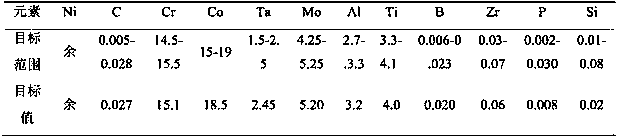

Novel powder high-temperature alloy and preparing method thereof

The invention relates to novel powder high-temperature alloy and preparing method thereof. The novel powder high-temperature alloy comprises, by weight percent, 14.00 to 15.00% of Cr, 14.50 to 19.50%of Co, 4.5 to 5.5% of Mo, 3.25 to 4.10% of Ti, 2.50 to 3.10% of Al, 1.45 to 2.50% of Ta, 0.55 to 1.55% of Hf, 0.045 to 0.068% of Zr, 0.005 to 0.030% of C, 0.006 to 0.023% of B, 0.002 to 0.030% of P, 0.01 to 2.0% of Re, 0.1 to 2.0% of W, 0.1 to 1.0% of Nb, smaller than 0.5% of Y, smaller than 0.3% of V, smaller than 0.5% of Fe, smaller than 0.15% of Si, smaller than 0.12% of Mn, and the balance Ni.The gamma' phase content in the l powder high-temperature alloy is about 40 to 50%. The novel powder high-temperature alloy prepared through the preparing method has the good room temperature strength, high temperature strength and high temperature creep properties, and the use temperature is up to 750 DEG C.

Owner:西部超导材料科技股份有限公司

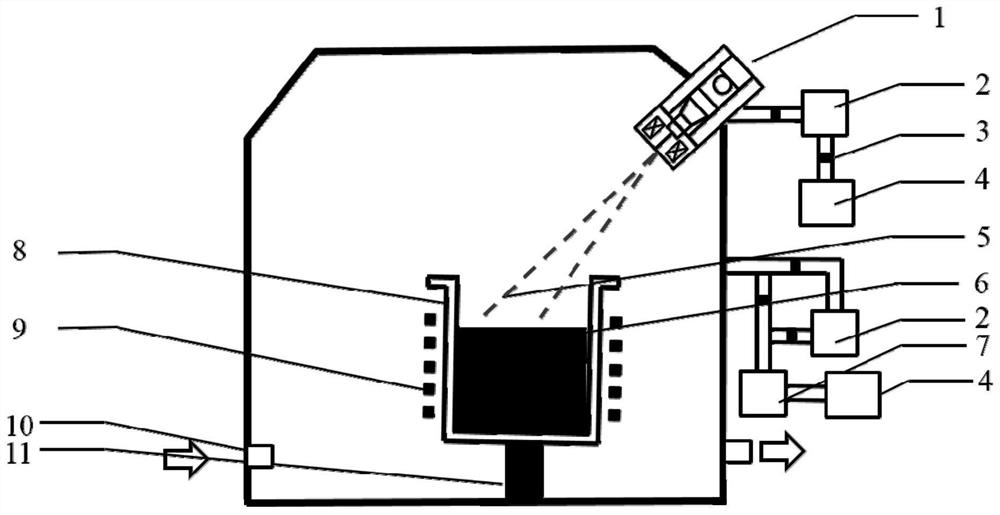

Method for preparing high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining

The invention provides a method for preparing a high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining. The method comprises the following stepsof S1, pretreatment of raw materials; S2, charging into a furnace; S3, vacuum induction melting; and S4, electron beam refining, so that the refined alloy is obtained. By coupling vacuum induction melting and electron beam refining, a superalloy mother alloy is melted through a vacuum induction method, then the superalloy is further purified through electron beam refining, the segregation degreeis reduced, the metallurgical quality of a superalloy cast ingot is improved by fully utilizing the advantages of induction melting and electron beam refining, and finally, high-purity preparation ofthe alloy is realized.

Owner:DALIAN UNIV OF TECH

Heat treatment technology for increasing strength of aluminum alloy profile

The invention discloses a heat treatment technology for increasing strength of an aluminum alloy profile, and belongs to the technical field of aluminum profile processing. According to the heat treatment technology disclosed by the invention, secondary solid-solution treatment and tertiary aging treatment are combined; the secondary solid-solution treatment is in favor of uniform combination of vacancies and a solid solution, and thus, a foundation is laid for solute to diffuse, cluster and form precipitated phase precipitation through a vacancy mechanism during ageing treatment, and thereby,uniformity of heat treatment is increased, and material property deficiencies brought by single-stage solid-solution treatment and ageing treatment in the prior art are overcome.

Owner:ANHUI CHUANGHONG PRECISION MACHINERY

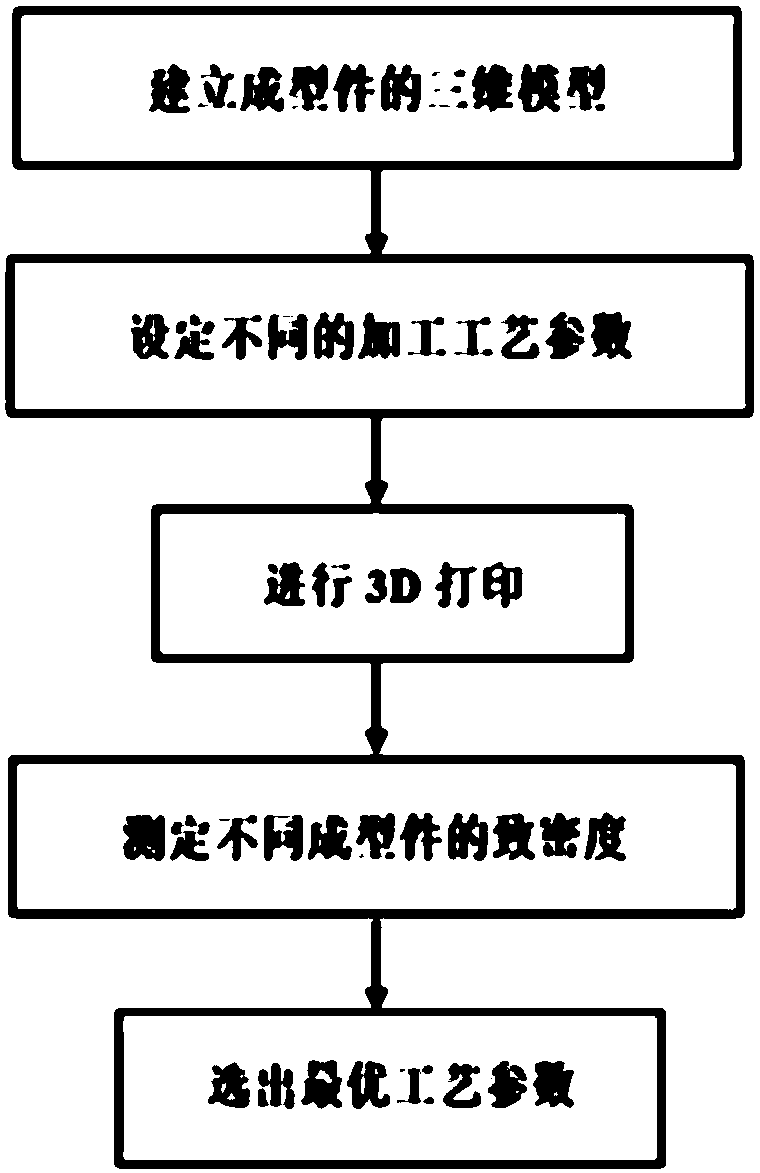

High-density pure molybdenum selective laser melting producing method

InactiveCN109317675APrevent oxidationImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh density

The invention provides a high-density pure molybdenum selective laser melting producing method. The high-density pure molybdenum selective laser melting producing method comprises the following stepsof establishing a molybdenum plate three-dimensional solid numerical model on a computer; setting the power, scanning speed, scanning spacing and scanning mode of a laser beam; performing 3D printing;determining the density of different formed parts; and selecting the optimal process parameters. By optimizing the process parameters of SLM technology, the pure molybdenum formed parts with high density and high surface quality can be obtained, traditional machining and post-processing are avoided, manpower and material resources are saved, and the machining period is shortened. Pure molybdenumworkpieces produced according to the machining process have good mechanical properties at room temperature and technically have certain theoretical research value and practical application value.

Owner:HARBIN ENG UNIV

Preparation method of 5356 aluminum alloy ingot

ActiveCN104894443AImprove uniformityEasy to control temperatureIncreasing energy efficiencyMagnetic currentTemperature control

The invention relates to a preparation method of a 5356 aluminum alloy ingot. The method uses an electromagnetic effect for heating and for preserving the temperature of an alloy melt, so that the temperature control is convenient; at the same time of heating, as alternating current supplied in an induction coil can form variable magnetic current, and the variable magnetic current can form induction current in an annular pipe communicated with a crucible, the melt circularly flows by surrounding the annular pipe to achieve a stirring effect, and the component and structure uniformity of the aluminum alloy ingot is effectively improved; under the stirring effect generated by the induction coil, the vacuum purification treatment is supplemented to effectively improve the dispersion speed of hydrogen atoms in the melt, so that the high-speed degassing is facilitated, the degassing effect is enhanced, and the hydrogen content in the 5356 aluminum alloy ingot is reduced; and through detections, the hydrogen content of the 5356 aluminum alloy ingot prepared by the method is lower than 0.15 mL / 100 gAl.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Medical implant porous Ti alloy and preparation method

The invention relates to a medical implant porous Ti alloy and a preparation method. The medical implant porous Ti alloy comprises the following components in percentage by weight: 37-38wt% of Nb, 2-4wt% of Zr, 1-2wt% of Ta, and the balance of Ti. The preparation method comprises the following specific steps: uniformly mixing Ti powder, Nb powder, Ta powder, TiH2 powder, and ZrH2 powder at the ratio; carrying out cold pressing to obtain a green body; sintering the green body in a sintering furnace filled with argon gas; after the sintering is finished, opening a gas bleed valve to quickly reduce the pressure in the sintering furnace to 0.15-0.30 MPa, and then powering off the sintering furnace; meanwhile, filling the sintering furnace with argon gas, so as to cool the obtained sinter; and finally, carrying out solution and aging treatment on the cooled sinter, so as to obtain the medical implant porous Ti alloy. According to the medical implant porous Ti alloy and the preparation method provided by the invention, TiH2 and ZrH2 particles are adopted as not only foaming materials but also alloy materials; the porous Ti purity is high; the porosity and mechanical property adjustment range is wide; when the porosity is relatively low, the low modulus of elasticity and the high strength property can be achieved; accordingly, the medical implant porous Ti alloy is suitable for preparation of a medical implant; and the preparation cost is low.

Owner:SOUTHEAST UNIV

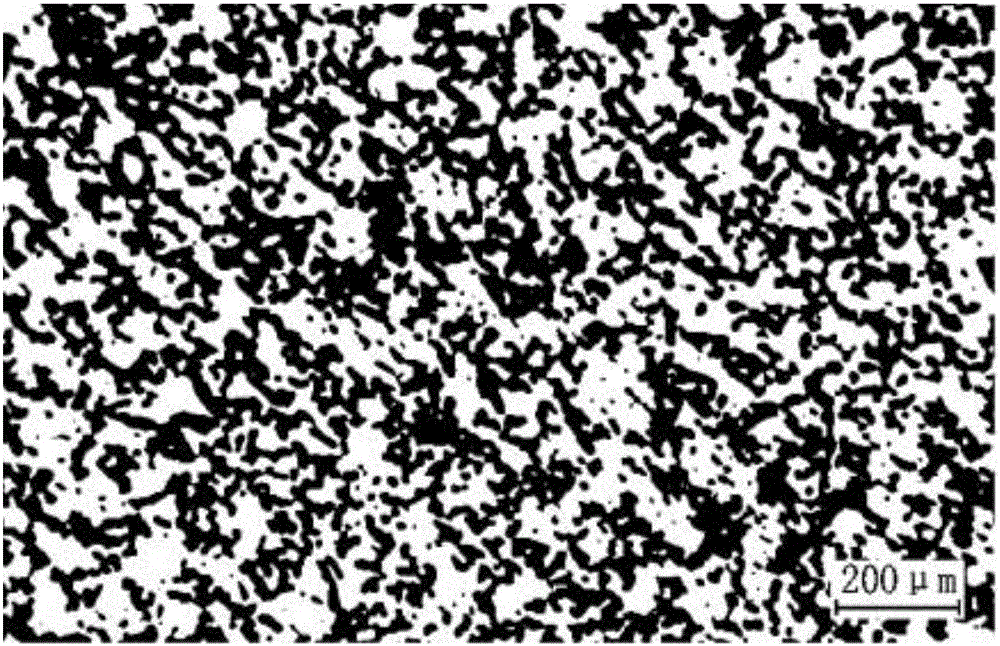

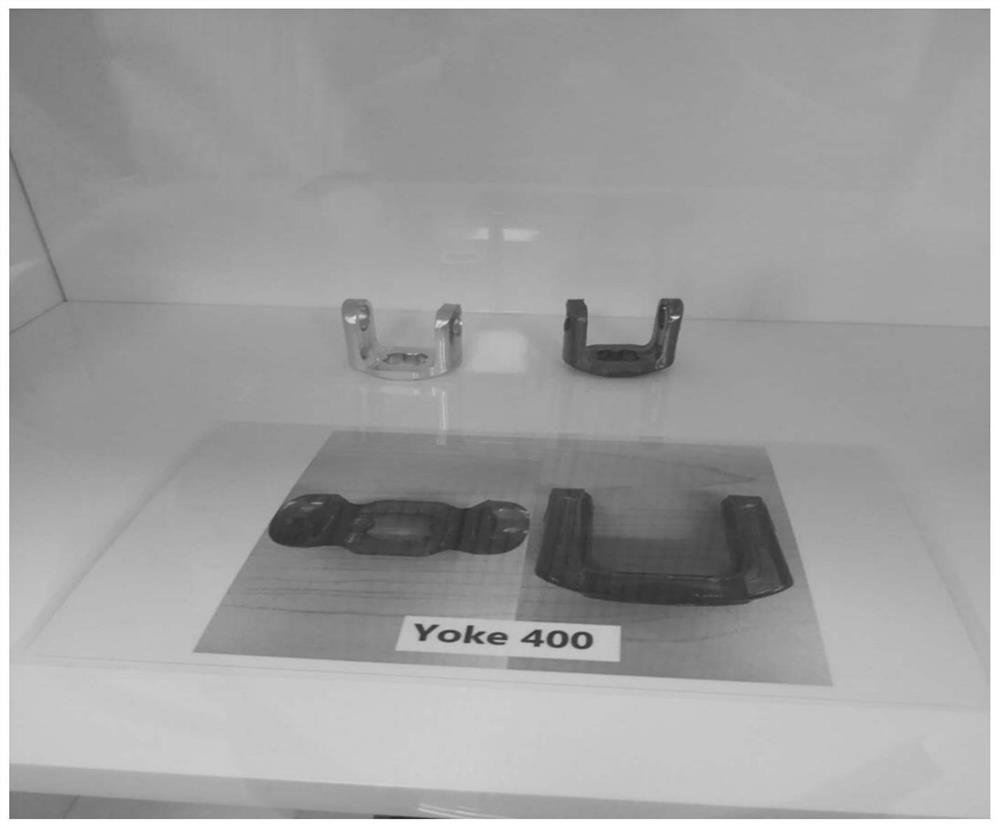

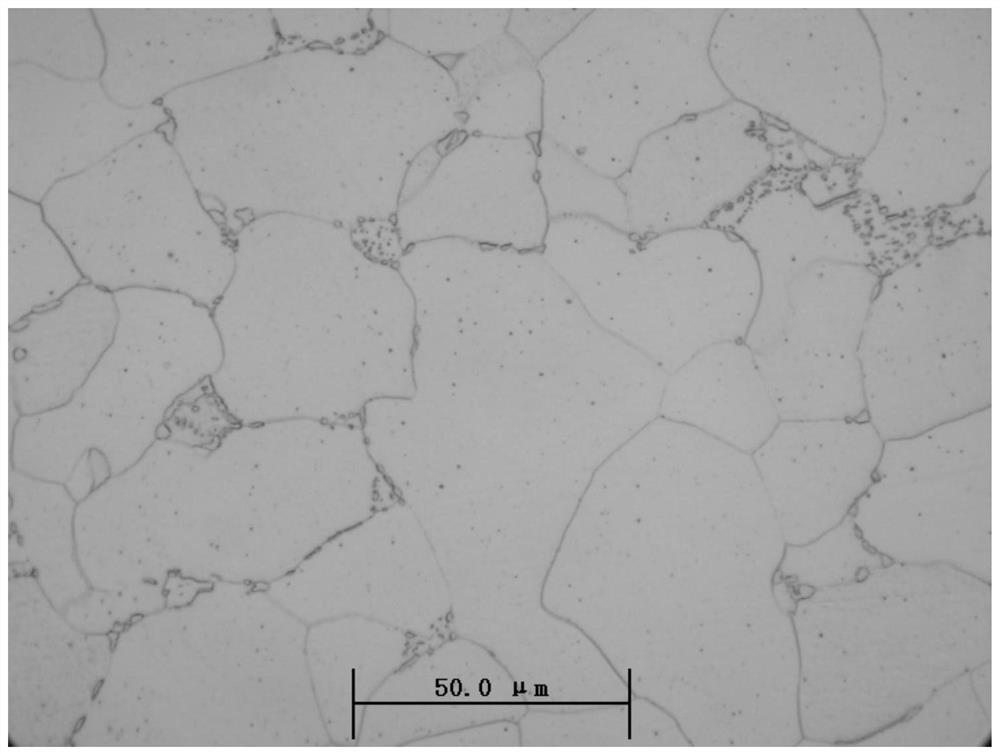

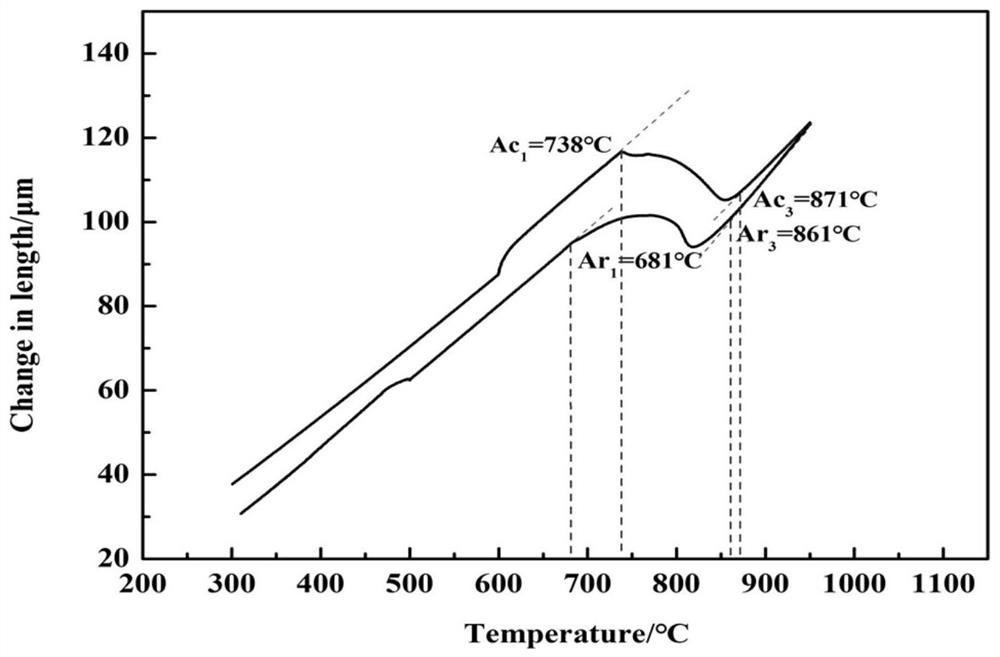

Steel for cold forging of universal joint fork of passenger car and manufacturing method of steel

The invention relates to steel for cold forging of a universal joint fork of a passenger car and a manufacturing method of the steel. The steel comprises the following chemical components in percentage by mass: 0.04 to 0.10 percent of C, 0.01 to 0.12 percent of Si, 0.40 to 0.60 percent of Mn, less than or equal to 0.015 percent of P, 0.020 to 0.035 percent of S, less than or equal to 0.10 percent of Cr, less than or equal to 0.10 percent of Ni, less than or equal to 0.10 percent of Cu, less than or equal to 0.02 percent of Mo, 0.020 to 0.050 percent of Al, 0.007 to 0.009 percent of N and the balance of Fe and inevitable impurity elements. The texture of the steel is ferrite and pearlite, and the spheroidization rate of the pearlite is larger than or equal to 85%. The production process route comprises the steps of molten iron pretreatment, primary smelting in a converter, refining, continuous casting, continuous casting billet cooling, continuous casting billet heating, rolling, cooling, spheroidizing annealing and lathing. Taking a bar with the diameter phi of 20-40 mm as an example, the surface hardness is smaller than or equal to 110 HV30; Rp0.2 is smaller than or equal to 280 MPa, Rm is smaller than or equal to 360 MPa, the ductility A5 is larger than or equal to 40%, the percentage reduction of area Z is larger than or equal to 75%, and a product has excellent plasticity and low deformation resistance and is steel for cold forging with ideal performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

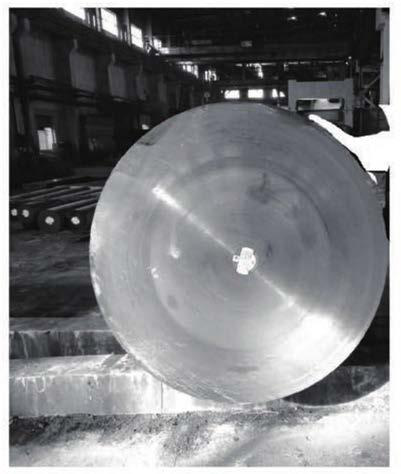

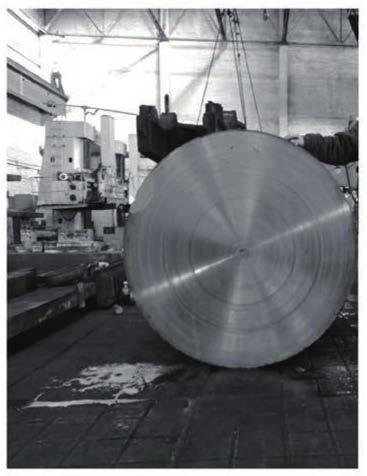

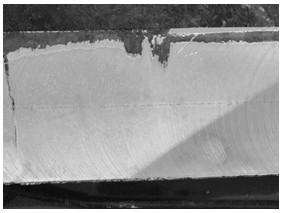

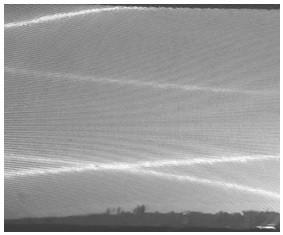

Manufacturing method of 825 anti-corrosion alloy bar material with super-large diameter

The invention discloses a manufacturing method of 825 anti-corrosion alloy bar material with a diameter phi of 1300 mm. The purpose is to solve the technical problem that the risks that chemical compositions and homogeneity do not meet a standard stipulation can be caused, and segregation and porosity existing in a macroscopic examination structure can be caused when the diameter of a steel ingotis increased. According to an electric furnace and electroslag smelting novel technology and forging technology, 1, the technical route comprises the steps of smelting through a non-vacuum induction furnace, processing through an LF furnace, processing through a VOD furnace, conducting electroslag remelting, processing through an 8000 t high-speed forging machine, smoothing on a lathe and conducting packaging; 2, according to the specific solving measures and beneficial effects, (1) a superior raw material is selected to avoid drag-in of a harmful element; (2) the slag whitening time of the LFfurnace is prolonged to effectively reduce the content of D-type inclusion; (3) the vacuum degree of VOD is reduced, the degassing time is shortened, and the content of gas elements is reduced; (4) in the pouring process, ultra-low carbon protecting slag is used for optimizing the surfaces of electrodes, and the deficiency of double skin of the surfaces of the electrodes is overcome; and (5) increasing of the ingot case of steel ingot electroslag meets the requirement for the size of the finished products of phi 1300 mm, and meanwhile, the annealing requirements are increased to avoid the risk of cracking of the steel ingot.

Owner:FUSHUN SPECIAL STEEL SHARES

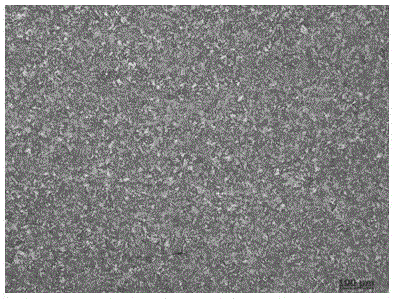

7, 000-series alloy material for automobile bumpers, and production method thereof

The invention discloses a 7, 000-series alloy material for automobile bumpers. The 7, 000-series alloy material for the automobile bumpers is characterized in that the aluminum alloy comprises the alloy ingredients of Zn, Mg, Cu, Zr, Ti, Sn, Mn, Ag, Co, Sc, Yb, B, Cr4 and the balance aluminum and unavoidable impurities, wherein the ratio of Mg to Zn ranges from 0.17 to 0.19, the ratio of Cu to Mgranges from 0.43 to 0.53, the ratio of Cu to Ti ranges from 1.5 to 1.8, the content of one single impurity is smaller than or equal to 0.005%, the total content of the impurities is smaller than or equal to 0.1%, the average grain diameter of aluminum alloy grains ranges from 20 microns to 40 microns. When the alloy is observed through SEM and TEM, the area percentage of the strengthening phase MgZn2 ranges from 1% to 1.6% while the average size of the MgZn2 ranges from 50 nanometers to 60 nanometers, the area percentage of the strengthening phase Mg2Sn ranges from 0.3% to 0.6% while the average size of the Mg2Sn ranges from 30 nanometers to 50 nanometers, the area percentage of the strengthening phase Al6Mn ranges from 0.3% to 0.4% while the average size of the Al6Mn ranges from 20 nanometers to 30 nanometers, the area percentage of the strengthening phase Al3Ti ranges from 0.5% to 0.8% while the average size of the Al3Ti ranges from 20 nanometers to 30 nanometers, the yield strengthranges from 580 MPa to 650 Mpa, the tensile strength ranges from 670 MPa to 720 MPa, and the elongation ranges from 18% to 23%.

Owner:温州市赢创新材料技术有限公司

Method for producing anti-acid anti-corrosion pipeline steel plate billet through chamfering crystallizer continuous casting machine

InactiveCN109158557AEliminate or Lighten Band TissueReduce inclusion contentProcess efficiency improvementCopperMetal

The invention discloses a method for producing an anti-acid anti-corrosion pipeline steel plate billet through a chamfering crystallizer continuous casting machine. The method comprises the working procedures of hot metal pretreatment, converter smelting, LF refining, RH vacuum treatment and continuous casting. The chamfering angle of a crystallizer is 44.95-45.05 degrees, the chamfering width is39.90-40.10mm, the flow speed of cooling water in a chamfering crystallizer copper plate water groove is 6.5-7.0m / s, the water yield of the narrow face of the chamfering crystallizer is 560-570L / min,and the water yield of the wide face is 4300-4400L / min. The design of low carbon, ultralow phosphorus and sulfur and low manganese content is adopted, the dual technology and argon blowing after calcium treatment are adopted, and occluded foreign substance is controlled; and crystallizer cooling parameters and the sector section tightly-pressing-down amount and pressing-down mode are designed, therefore, casting blank center segregation is reduced, MnS inclusion forming is reduced, banded structures are eliminated or relieved, and therefore anti-acid anti-corrosion performance of products is improved.

Owner:HANDAN IRON & STEEL GROUP +1

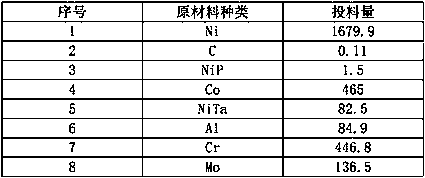

Preparation process of nickel-based high temperature alloy with high-content refractory elements

ActiveCN109913702AImprove melting efficiencyImproves ingredient uniformityIncreasing energy efficiencyRefractoryLow density

The invention discloses a preparation process of a nickel-based high temperature alloy with high-content refractory elements, and belongs to the technical field of alloy preparation. According to theprocess, a vacuum induction melting (VIM) and electroslag remelting (ESR) process is adopted for preparing the alloy containing the high-content refractory elements. During the vacuum induction melting stage, by controlling the feeding mode, increasing the refining temperature, prolonging the refining time, accelerating the solidification rate and the like, the segregation phenomena of refractorymetal and low-density alloy elements are effectively suppressed, and the composition uniformity of upper and lower parts of a parent alloy ingot is improved. Through electroslag remelting, secondary shrinkage in the alloy ingot is eliminated, the impurity content is reduced, and the metallurgical quality is improved. The preparation process can significantly reduce the microsegregation and macrosegregation phenomena of the high-content refractory elements and can effectively reduce the content of harmful gas elements such as O and N in the high-temperature alloy, the purity of the alloy is improved, the degree of segregation of the high-specific gravity elements is reduced, the heredity of alloy anomalous tissues is improved, and the overall mechanical properties of the alloy are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method of steel for tire bead wires

ActiveCN112760552AEasy to handleReduce processManufacturing convertersProcess efficiency improvementTire beadWire rod

The invention discloses a production method of steel for tire bead wires, and relates to the technical field of ferrous metallurgy. The production method comprises the steps of converter smelting, ladle furnace refining, small square billet continuous casting and high-speed wire rolling, and specifically comprises the following steps: 1, adding scrap steel and blast furnace molten iron into a converter, and providing quality applicable conditions for the scrap steel and the molten iron; 2, controlling the endpoint carbon content of the converter to be 0.50 wt%-0.70 wt%; 3, controlling converter tapping; 4, conducting ladle furnace refining; 5, conducting small square billet continuous casting, conducting electromagnetic stirring through a crystallizer, and adopting aerial fog cooling for secondary cooling, wherein the continuous casting pulling speed is 2.0-2.3 m / min; and 6, conducting high-speed wire rod rolling, wherein a hot-rolled wire rod for the tire bead steel wires with the diameter phi being 5.5 mm is rolled through a high-speed wire rod rolling mill. According to the method, the technological processes of molten iron pretreatment and molten steel secondary vacuum treatment are reduced, electromagnetic stirring in a casting flow area and electromagnetic stirring at the tail end in continuous casting production are reduced, cogging of a casting blank, flaw detection of the casting blank, scaling of the casting blank or coping of the casting blank is reduced, the yield is increased, the equipment investment and the production cost are reduced, and the energy consumption is saved.

Owner:ANYANG IRON & STEEL

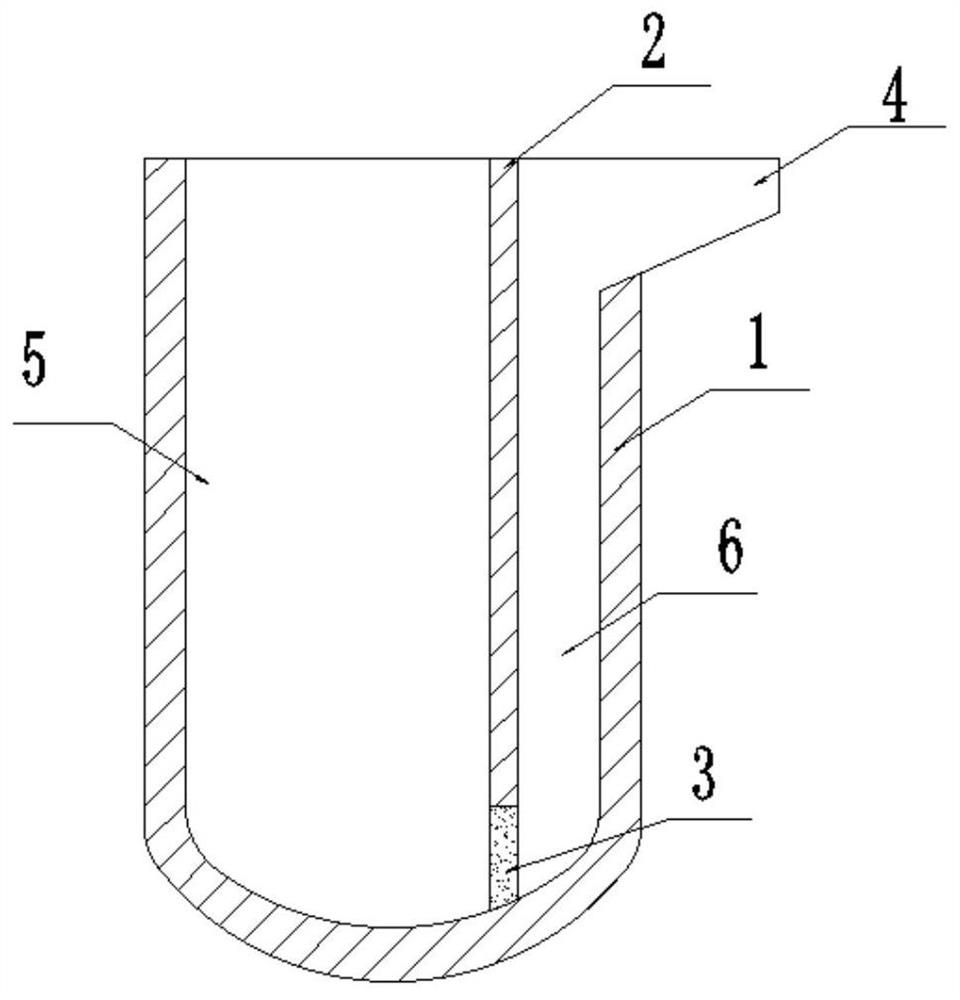

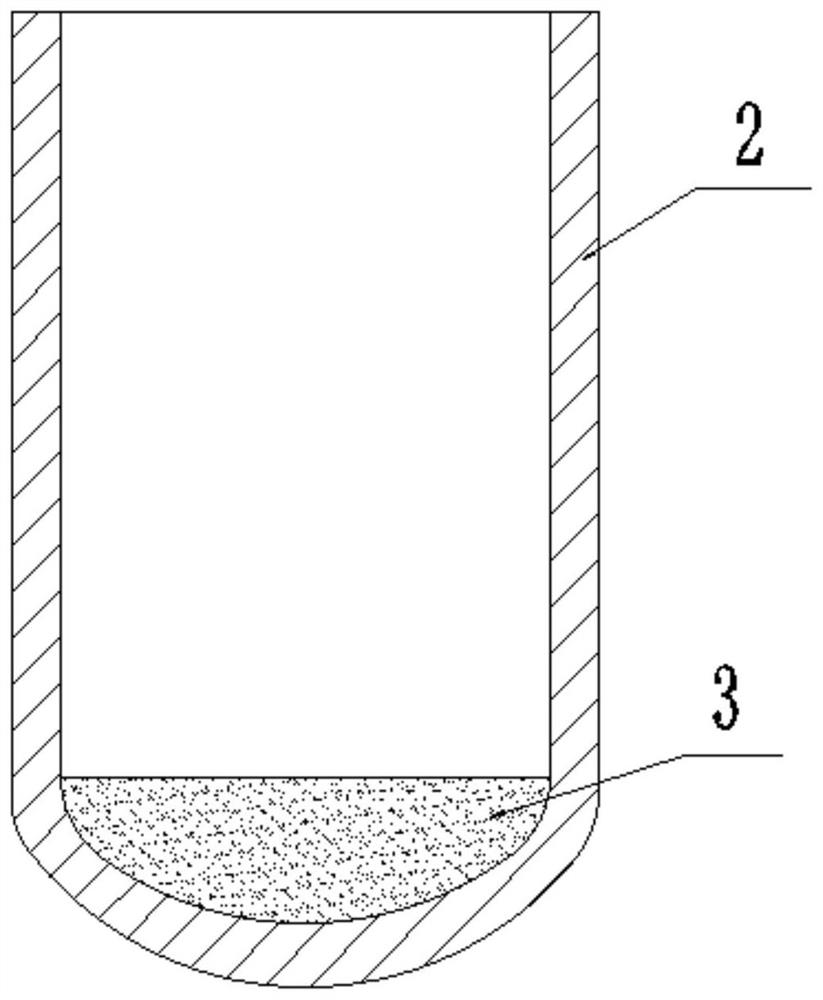

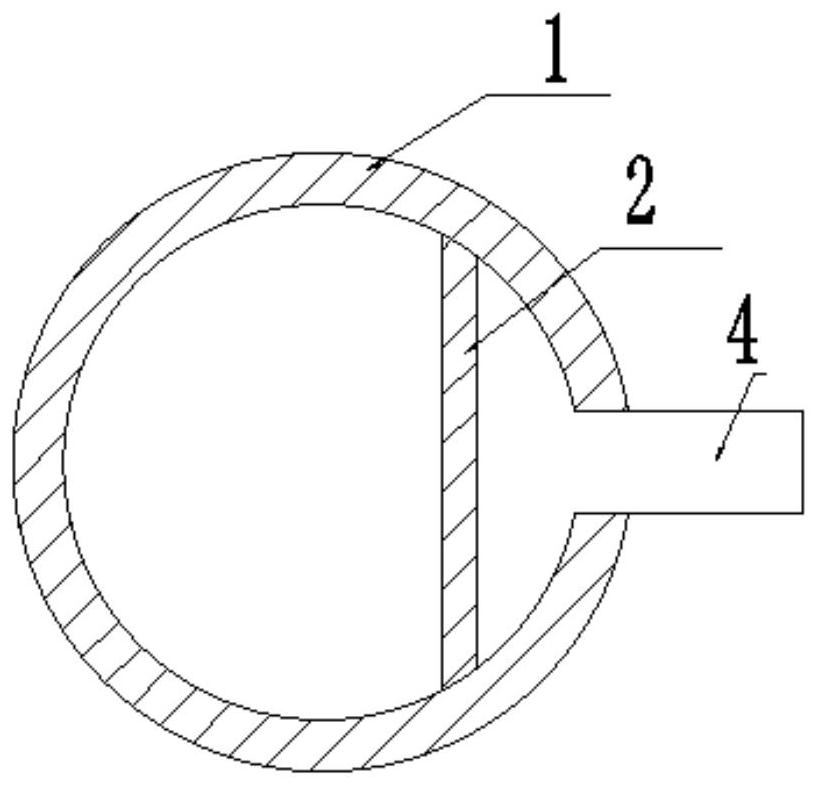

Novel-structure crucible for high-temperature alloy smelting and vacuum induction smelting process thereof

PendingCN112066725AReduce scum contentWith adsorptionIncreasing energy efficiencyCrucible furnacesSmelting processCrucible

The invention provides a novel-structure crucible for high-temperature alloy smelting. The novel-structure crucible comprises a crucible body; a baffle is vertically arranged in the crucible body; theupper end of the baffle is flush with the upper end of the crucible body; a gap is reserved between the lower end of the baffle and the bottom of the crucible body; a filter screen is arranged in thegap; and a sprue is formed in the top of the crucible body. The baffle inside the crucible has an adsorption effect on dross, the dross floating on the surface of alloy liquid can be adsorbed on thebaffle by slightly shaking in the furnace shaking process, the filter screen at the bottom can filter inclusions in alloy melt, and the contents of the inclusions and the dross in the poured alloy melt are effectively reduced.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

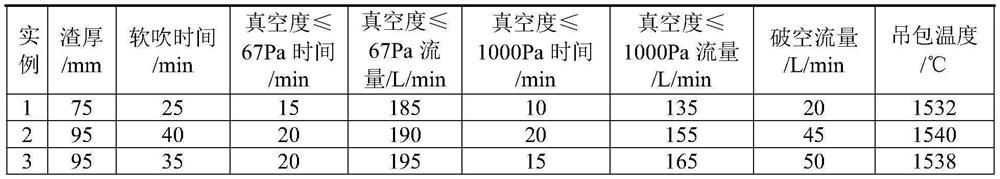

Smelting method for electrode bar base material for electroslag remelting of H13 steel at protective atmosphere

ActiveCN112981249AReduce inclusion contentImprove cleanlinessMelt-holding vesselsSteelmakingRefining (metallurgy)

The present invention discloses a smelting method for an electrode bar base material for electroslag remelting of H13 steel at a protective atmosphere, and belongs to the field of ferrous metallurgy. The smelting method for the electrode bar base material for electroslag remelting of the H13 steel at the protective atmosphere includes steps of: electric furnace steelmaking, LF furnace refining, VD vacuum degassing, protective pouring and the like. According to the method disclosed by the present invention, the content of inclusions in the molten steel can be effectively reduced by adjusting the composition of LF slag, a proper VD argon soft blowing system, protecting pouring and the like, and thus, the cleanliness of the electrode bar base material is improved. The electrode bar base material prepared by using the method provided by the present invention is low in oxygen content and inclusion content and high in cleanliness, and the problem that an existing electrode bar base material for electroslag remelting of the H13 steel at the protective atmosphere is low in cleanliness can be effectively solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

A steel plate with excellent cold bending performance and yield strength greater than 1100mpa and its preparation method

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com