Method for producing anti-acid anti-corrosion pipeline steel plate billet through chamfering crystallizer continuous casting machine

A technology of chamfering mold and continuous casting machine, applied in the field of metallurgy, can solve the problems of low pass rate of anti-HIC performance, unstable acid and corrosion resistance of pipeline steel, etc., to eliminate hydrogen diffusion channels, improve product quality, Eliminate or lighten the effect of band tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

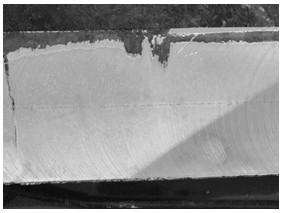

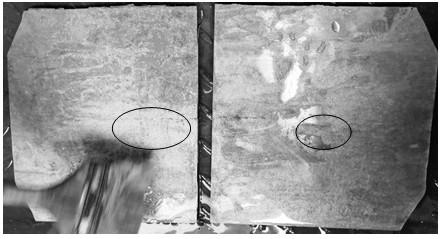

Image

Examples

Embodiment 1

[0027] The thickness specification of the acid-resistant and corrosion-resistant pipeline steel slab in this example is 236mm, and its chemical composition and mass percentage are: C: 0.034%, Si: 0.18%, Mn: 1.18%, P: 0.007%, S: 0.0008% , Nb: 0.0320%, Ti: 0.015%, Ca: 0.0020%, Al: 0.035%, Mo: 0.11%, and the balance is Fe and unavoidable impurities.

[0028] In this embodiment, a method for producing an acid-resistant and corrosion-resistant pipeline steel slab by a chamfering crystallizer continuous casting machine includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, and continuous casting. The specific process steps are as follows:

[0029] (1) Hot metal pretreatment process: hot metal P: 0.043%, S: 0.029%, lime and magnesium powder are used for composite desulfurization, the injection ratio of powder lime and magnesium powder is 2.5, the slag is cleaned after desulfurization, and the sulfur after the converter is 47ppm;

[0030] (2) Converte...

Embodiment 2

[0038] The thickness specification of the acid-resistant and corrosion-resistant pipeline steel slab in this embodiment is 235mm, and its chemical composition and mass percentage are: C: 0.025%, Si: 0.28%, Mn: 0.95%, P: 0.005%, S: 0.0007% , Nb: 0.045%, Ti: 0.010%, Ca: 0.0010%, Al: 0.025%, Mo: 0.09%, and the balance is Fe and unavoidable impurities.

[0039] In this embodiment, a method for producing an acid-resistant and corrosion-resistant pipeline steel slab by a chamfering crystallizer continuous casting machine includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, and continuous casting. The specific process steps are as follows:

[0040] (1) Hot metal pretreatment process: hot metal P: 0.055%, S: 0.035%, lime and magnesium powder are used for composite desulfurization, the injection ratio of powder lime and magnesium powder is 2.7, the slag is cleaned after desulfurization, and the sulfur after the converter is 53ppm;

[0041] (2) Conver...

Embodiment 3

[0047] The thickness specification of the acid-resistant and corrosion-resistant pipeline steel slab in this embodiment is 245mm, and its chemical composition and mass percentage are: C: 0.042%, Si: 0.16%, Mn: 0.84%, P: 0.004%, S: 0.0005% , Nb: 0.054%, Ti: 0.016%, Ca: 0.0042%, Al: 0.038%, Mo: 0.12%, and the balance is Fe and unavoidable impurities.

[0048] In this embodiment, a method for producing an acid-resistant and corrosion-resistant pipeline steel slab by a chamfering crystallizer continuous casting machine includes molten iron pretreatment, converter smelting, LF refining, RH vacuum treatment, and continuous casting. The specific process steps are as follows:

[0049] (1) Hot metal pretreatment process: hot metal P: 0.059%, S: 0.033%, lime and magnesium powder are used for composite desulfurization, the injection ratio of powder lime and magnesium powder is 2.8, the slag is cleaned after desulfurization, and the sulfur after the converter is 42ppm;

[0050] (2) Conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness specification | aaaaa | aaaaa |

| Thickness specification | aaaaa | aaaaa |

| Thickness specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com