Production method of steel for tire bead wires

A technology of bead steel wire and production method, which is applied in the field of iron and steel metallurgy, and can solve problems such as increased production costs, increased billet rolling, continuous casting billet flaw detection, continuous casting billet peeling/grinding costs, and molten steel pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

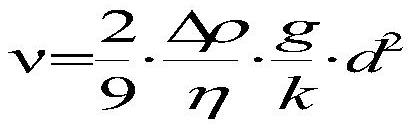

Method used

Image

Examples

Embodiment 1

[0042] A production method of steel for bead wires provided in this embodiment includes steelmaking, continuous casting and steel rolling processes. The continuous casting slab section size produced by continuous casting is: 150mm×150mm, and the original wire rod size of the obtained product is

[0043] The specific production process is: top-bottom compound blown converter → LF ladle refining furnace → R8 m arc 6-machine 6-strand billet continuous casting machine → 150mm×150mm cross-section continuous casting billet → high-speed wire rod rolling mill controlled rolling → Stelmore wind Cold wire controlled cooling→ Specifications of bead wire for hot-rolled wire rod.

[0044] The key control parameters are: (1) blast furnace molten iron + self-produced returned scrap steel, molten iron temperature 1320°C, molten iron composition content: P = 0.075wt%, S = 0.045wt%, Ti = 0.0032wt%; Carbon" operation, the end-point C content is 0.53wt%, the end-point temperature is 1583°C, c...

Embodiment 2

[0046] A production method of steel for bead wires provided in this embodiment includes steelmaking, continuous casting and steel rolling processes. The continuous casting slab section size produced by continuous casting is: 150mm×150mm, and the original wire rod size of the obtained product is

[0047]The specific production process is: top-bottom compound blown converter → LF ladle refining furnace → R8 m arc 6-machine 6-strand billet continuous casting machine → 150mm×150mm cross-section continuous casting billet → high-speed wire rod rolling mill controlled rolling → Stelmore wind Cold wire controlled cooling → Specifications of bead wire for hot-rolled wire rod.

[0048] The key control parameters are: (1) blast furnace molten iron + self-produced returned scrap steel, molten iron temperature 1345°C, molten iron composition content: P = 0.060wt%, S = 0.050wt%, Ti = 0.0040wt%; Carbon" operation, the end-point C content is 0.58wt%, the end-point temperature is 1579°C, c...

Embodiment 3

[0050] A production method of steel for bead wires provided in this embodiment includes steelmaking, continuous casting and steel rolling processes. The continuous casting slab section size produced by continuous casting is: 150mm×150mm, and the original wire rod size of the obtained product is

[0051] The specific production process is: top-bottom compound blown converter → LF ladle refining furnace → R8 m arc 6-machine 6-strand billet continuous casting machine → 150mm×150mm cross-section continuous casting billet → high-speed wire rod rolling mill controlled rolling → Stelmore wind Cold wire controlled cooling → Specifications of bead wire for hot-rolled wire rod.

[0052] The key control parameters are: (1) blast furnace molten iron + self-produced returned scrap steel, molten iron temperature 1370°C, molten iron composition content: P = 0.080wt%; S = 0.040wt%; Ti = 0.0022wt%; Carbon" operation, the end-point C content is 0.61wt%, the end-point temperature is 1571°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com