High-yield strength (450MPa), high-strength and weather-resistant steel plate and production method thereof

A yield strength and high-strength technology, applied in the field of steel material manufacturing, can solve the problems of Ti-containing steel with large performance fluctuations, high strength, strict process control requirements, etc. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Process flow: molten iron pretreatment, converter smelting, LF furnace refining, CSP continuous casting, CSP continuous rolling, laminar cooling, coiling;

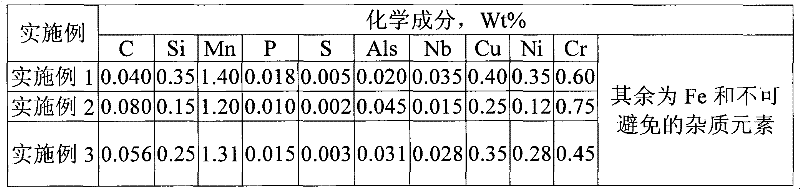

[0033] (2) Chemical composition: the main chemical composition of molten steel after LF furnace refining is shown in Table 1;

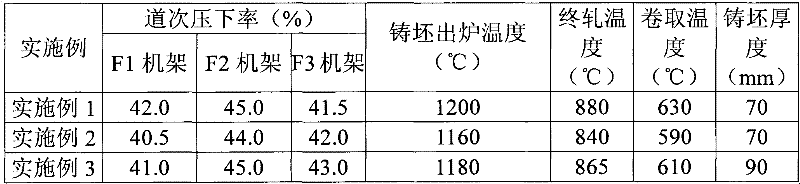

[0034] (3) Rolling process: the hot rolling process parameters are shown in Table 1;

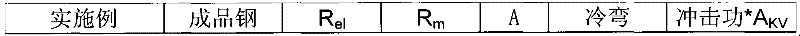

[0035] The mechanical properties of the finished steel plate are shown in Table 1.

Embodiment 2

[0037] (1) Process flow: molten iron pretreatment, converter smelting, LF furnace refining, CSP continuous casting, CSP continuous rolling, laminar cooling, coiling;

[0038](2) Chemical composition: the main chemical composition of molten steel after LF furnace refining is shown in Table 1;

[0039] (3) Rolling process: the hot rolling process parameters are shown in Table 1;

[0040] The mechanical properties of the finished steel plate are shown in Table 1.

Embodiment 3

[0042] (1) Process flow: molten iron pretreatment, converter smelting, LF furnace refining, CSP continuous casting, CSP continuous rolling, laminar cooling, coiling;

[0043] (2) Chemical composition: the main chemical composition of molten steel after LF furnace refining is shown in Table 1;

[0044] (3) Rolling process: the hot rolling process parameters are shown in Table 1;

[0045] The mechanical properties of the finished steel plate are shown in Table 1.

[0046] The chemical composition of table 1 embodiment

[0047]

[0048] The continuous rolling process parameter of table 2 embodiment

[0049]

[0050] The mechanical property of table 3 embodiment

[0051]

[0052]

[0053] It can be seen from the above implementation cases that the yield strength of the steel plates developed by the present invention is greater than 480MPa, the tensile strength is greater than 580MPa, and the elongation reaches more than 26%. The work is greater than 100J, indicatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com