Novel-structure crucible for high-temperature alloy smelting and vacuum induction smelting process thereof

A technology of high-temperature alloy and new structure, applied in the direction of crucible furnace, process efficiency improvement, furnace type, etc., can solve the problems of scum entering the ingot, alloy liquid entering the ingot mold, and the reduction of filtering effect, so as to improve the purity, Effect of improving metallurgical quality and reducing inclusion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

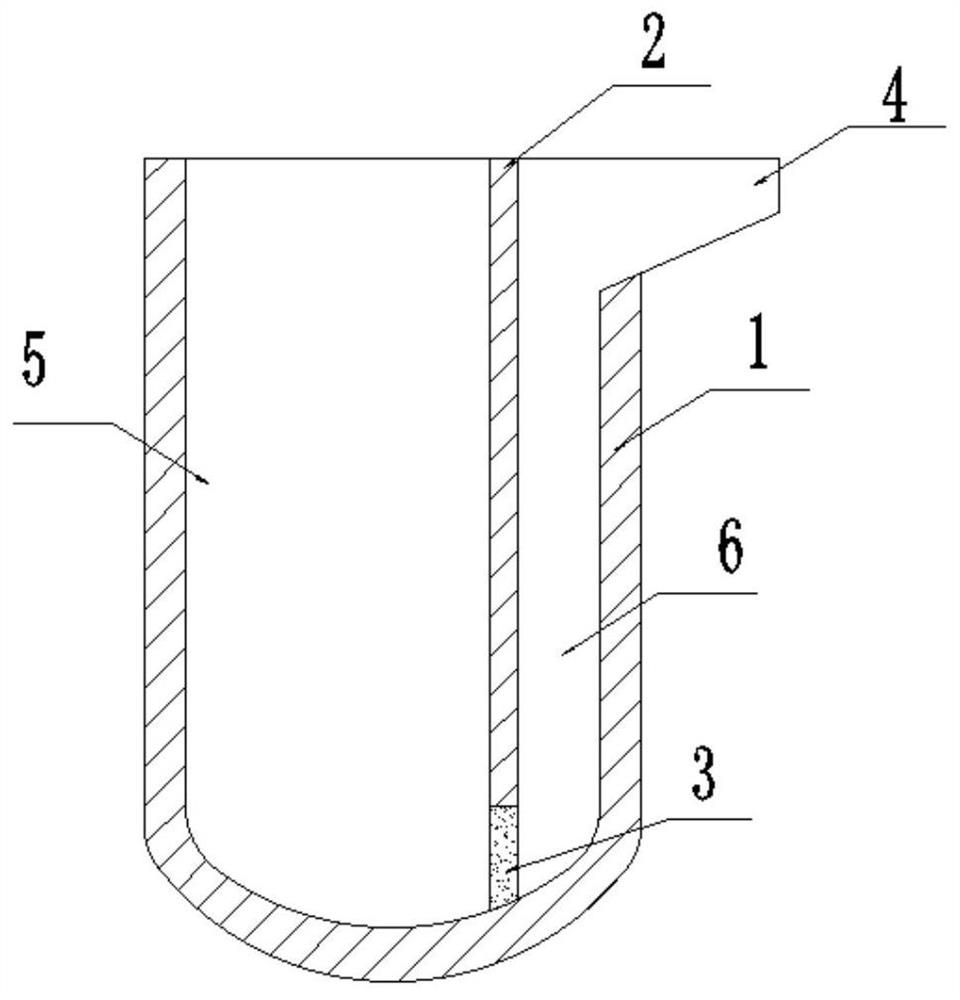

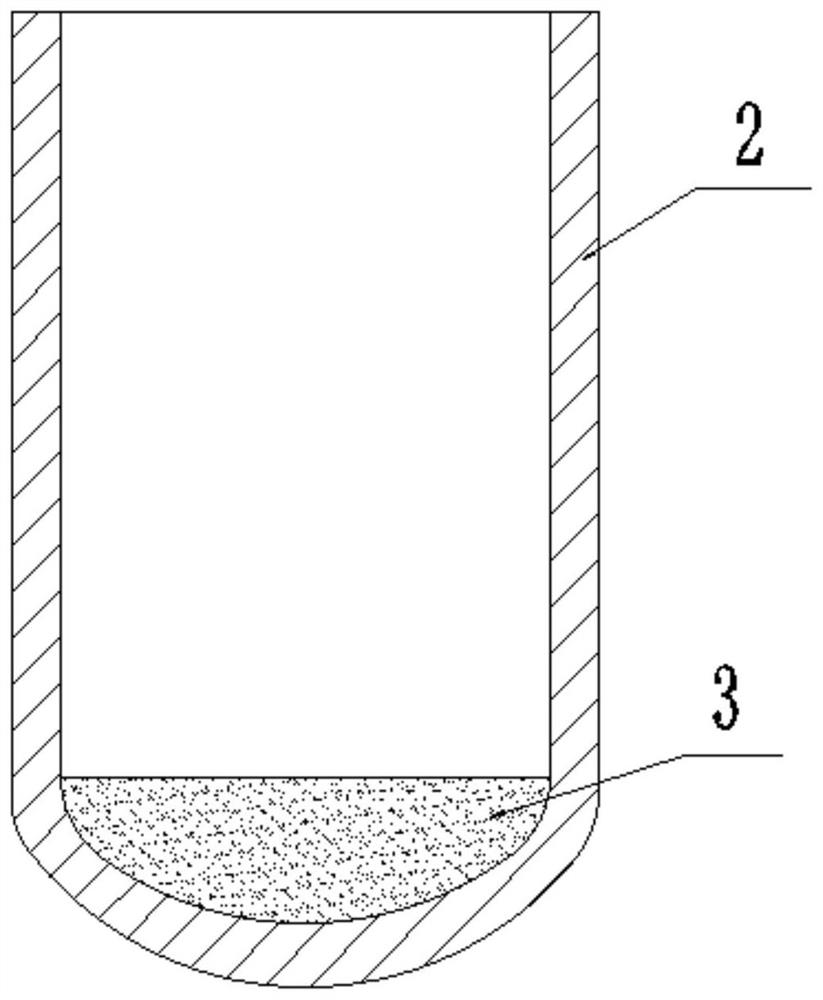

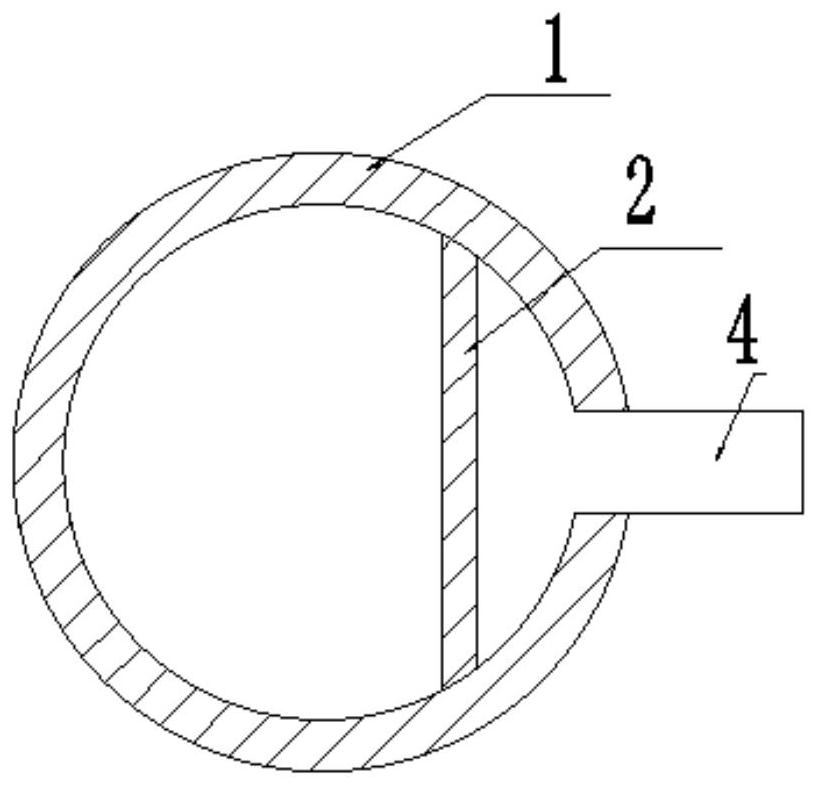

[0025] Such as Figure 1~3 As shown, the present embodiment provides a new structure crucible for smelting superalloys, including a crucible body 1, wherein: a baffle 2 is vertically arranged in the crucible body 1, and the upper end of the baffle 2 is connected to the upper end of the crucible body 1. flush, there is a gap between the lower end of the baffle plate 2 and the bottom of the crucible body 1 , a filter screen 3 is set in the gap, and a gate 4 is set on the top of the crucible body 1 .

[0026] Wherein: the left and right ends of the baffle plate 2 are connected to the inner wall of the crucible body 1, the lower end of the baffle plate 2 is connected to the upper end of the filter screen 3, and the lower end of the filter screen 3 is connected to the bottom of the crucible body 1.

[0027] Wherein: the top of the right side of the crucible body 1 is provided with a gate 4 .

[0028] Wherein: the material of the baffle plate 2 is the same as that of the crucible b...

Embodiment 2

[0033] This embodiment provides a vacuum induction smelting process. The grade of the smelted alloy is K417. In terms of mass fraction, the chemical composition of the alloy is: 0.18%C, 9.0%Cr, 5.4%Al, 4.9%Ti, 3.0% Mo, 15% Co, 0.8% V, 0.017% B, 0.07% Zr, the balance is Ni, 13Kg alloy is smelted in a single furnace.

[0034] A 25Kg-capacity magnesia crucible with a middle baffle and a bottom filter is used for melting. The width of the gap between the lower end of the crucible baffle and the bottom of the crucible is about 20mm, and the filter is a zirconia-based filter with a porosity of 20PPI.

[0035] A vacuum induction melting process, wherein: comprising the following steps:

[0036] (1) Add Ni, C, Mo, Co, and Cr for smelting high-temperature alloy master alloy into the first space in the crucible for charging, and perform the first smelting after the charging is completed; after the first refining, add Nb, Ti , Al elements for the second refining and stirring; finally ad...

Embodiment 3

[0040] This example provides a new structure crucible for high-temperature alloy smelting and its vacuum induction smelting process. The grade of the smelted alloy is K417, and the chemical composition (mass fraction) of the alloy is: 0.18%C, 9.0%Cr, 5.4 %Al, 4.9%Ti, 3.0%Mo, 15%Co, 0.8%V, 0.017%B, 0.07%Zr, the balance is Ni, smelting 13Kg alloy in a single furnace.

[0041] A 25Kg-capacity magnesia crucible with a middle baffle and a bottom filter is used for melting. The width of the gap between the lower end of the crucible baffle and the bottom of the crucible is about 20mm, and the filter is a zirconia-based filter with a porosity of 20PPI.

[0042] A vacuum induction melting process, wherein: comprising the following steps:

[0043] (1) Add Ni, C, Mo, Co, and Cr for smelting high-temperature alloy master alloy into the first space in the crucible for charging, and carry out the first smelting after the charging is completed; after the first refining, add Ti, Al , V eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com