Oil-containing water-enriched scum dehydration treatment method

A treatment method, water scum technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of low automation, poor fluidity of scum, and small amount of water released and other problems, to achieve the effect of high degree of automation, good flocculation effect, and less addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

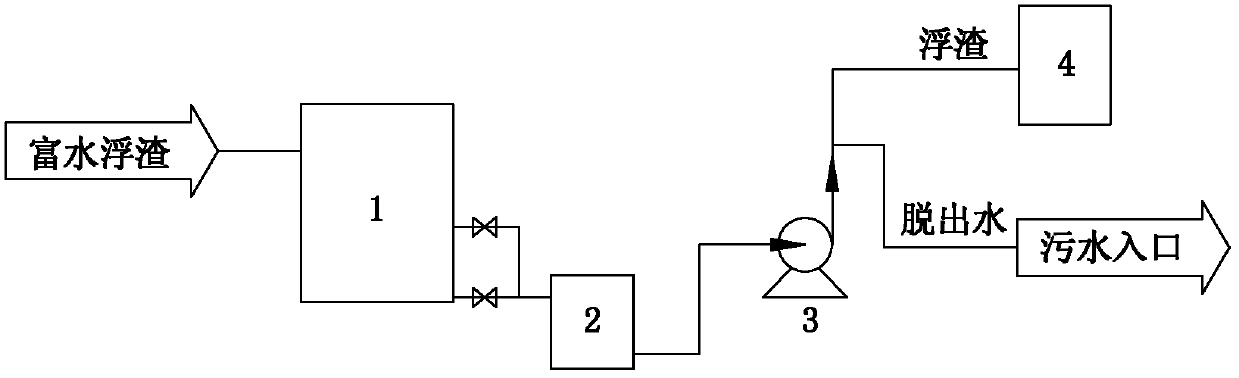

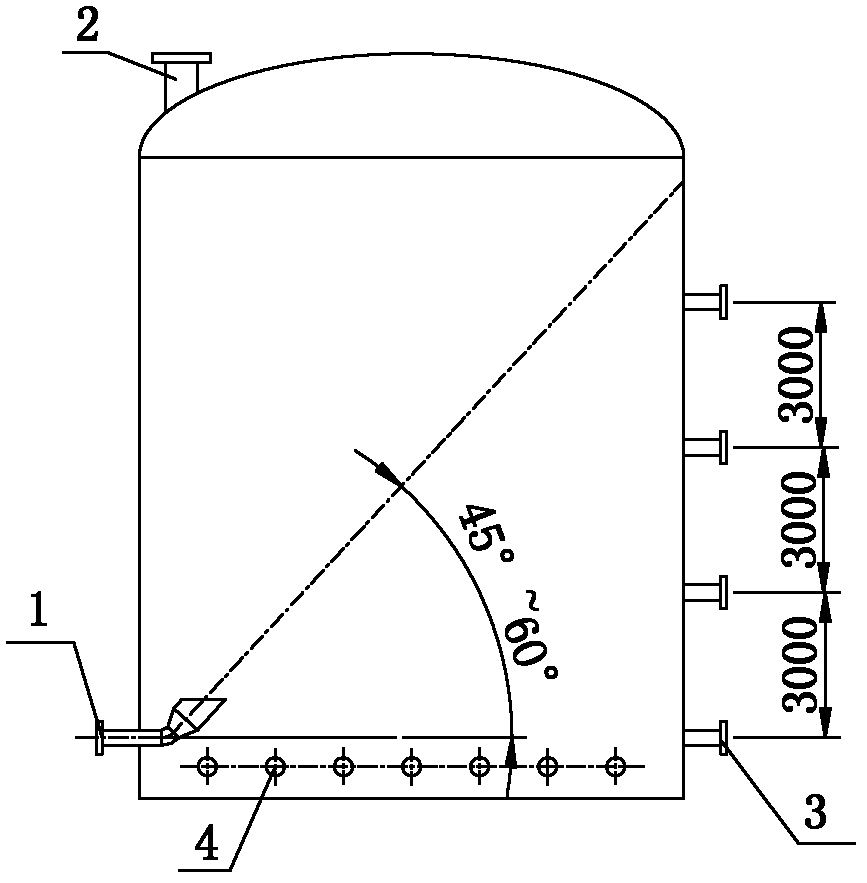

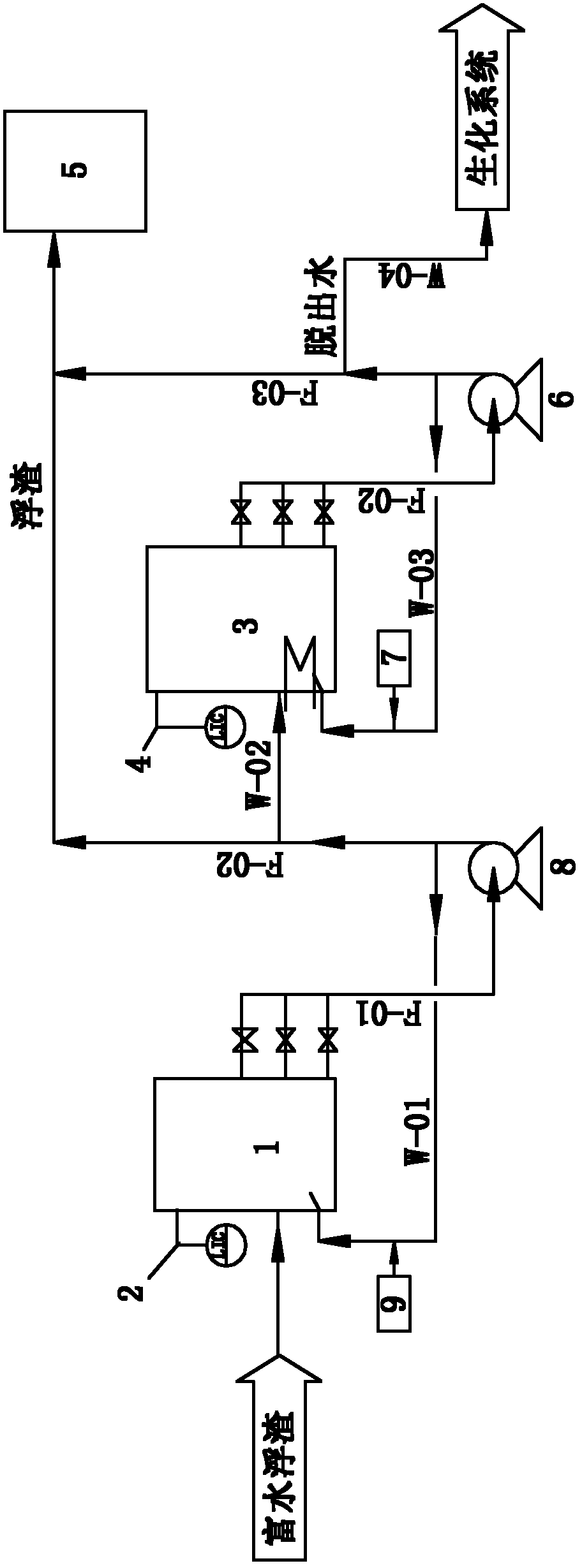

Method used

Image

Examples

example 1

[0046] Take 1 OL of scum from a sewage treatment plant in an oil refinery, the scum has a water content of 97%, put it into the first scum settling tank, add 20 mg / L flocculant polymerized ferric sulfate, stir and mix for 5 minutes, and settle for 72 hours. It will be divided into upper, middle and lower layers of liquid, of which the upper and lower layers are scum, and the middle part is water. After removing the scum at the bottom, cut 4L of water in the middle into the second scum settling tank, put 20mg / L flocculant polyferric sulfate into the second scum settling tank, heat to 60°C, stir and mix for 10min, settle for 72h, and drain There is a small amount of scum at the bottom, and 2.7L of clear water is obtained. The COD is 489mg / L after testing, fully meeting the requirements of biochemical treatment, and the dehydration rate is 27%.

example 2

[0048] In a refinery with a processing capacity of 3.5 million t / a, the sewage treatment plant produces 10,000 tons of scum with a water content of 96% every year. The factory has a delayed coking unit of 500,000 t / a, which consumes about 7,500 t / a of scum. There are four 500m3 scum tanks in the sewage treatment plant, which are divided into two groups of 2 tanks, which are called the first group of scum settling tanks and the second group of scum settling tanks according to their uses. One of the first group of scum settling tanks is filled with scum and then settled, and the other is used to collect scum from the scum tank, and recycling does not affect the normal operation of the device. The first group of settling tanks filled with scum, add 20mg / L flocculant polyferric sulfate, start the circulation pump, the material circulates internally for 30 minutes, after settling for 72 hours, open the middle and lower valves through the radar level gauge, and settle the middle laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com