A processing method for scrap superalloy return material

A technology of superalloy and treatment method, applied in chemical instruments and methods, improvement of process efficiency, transportation and packaging, etc., can solve problems such as waste of metal materials and resources, and achieve the effect of improving utilization rate and reducing scum content

Active Publication Date: 2022-05-31

JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The high-temperature alloy shavings return material is mainly the turning material produced during the machining process of high-temperature alloy parts. Manufacturers use downgrading or waste treatment, resulting in a lot of waste of metal materials and resources

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] Step S1, sorting: sorting the scrap-like return material, sorting and removing foreign matters such as magnetic metals and non-metals;

Embodiment 2

[0061] Step S1, sorting: sorting the scrap-like return material, sorting and removing foreign matters such as magnetic metals and non-metals;

Embodiment 3

[0071] Step S1, sorting: sorting the scrap-like return material, sorting and removing foreign matters such as magnetic metals and non-metals;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Login to View More

Abstract

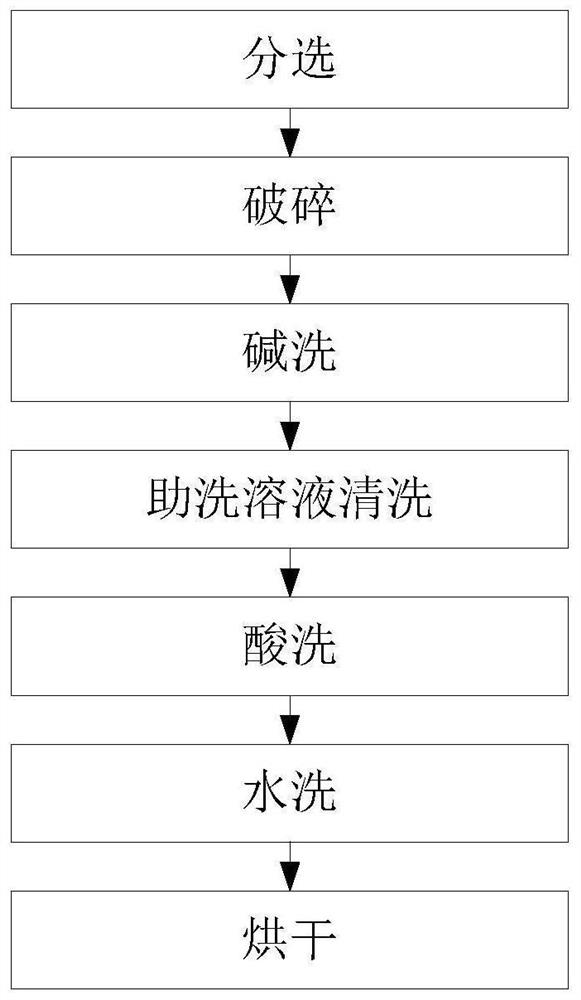

The present invention provides a method for processing returned materials of chip-like superalloys. The method is carried out in accordance with the following steps: step S1, sorting; step S2, crushing; step S3, alkali cleaning; step S4, cleaning with a booster solution; step S5, pickling; step S6, water washing; step S7, drying. The embodiment of the present invention can effectively remove the non-metallic inclusions on the surface of the chip-like superalloy return material, reduce the scum content of the superalloy return material, and melt the treated superalloy return material. The master alloy inclusion content after smelting is 0.5 , the scum content is within 2%; and it can effectively remove the oil stain on the surface of the scrap superalloy return material, and the residual carbon content range is within 100ppm. After the superalloy return material treated by this treatment method is smelted, its master alloy basically reaches The new material level greatly improves the utilization rate of returned materials.

Description

A kind of crumb superalloy return material processing method technical field The invention belongs to the crumb-shaped return material processing technical field, relate in particular to a kind of crumb-shaped superalloy return material processing method Law. Background technique [0002] Superalloys are those that can withstand a certain stress and have anti-oxidation or anti-corrosion properties at a high temperature of 600-1200 °C. Alloy is the material of hot end components such as aviation and aerospace engines and ground gas turbines in my country, especially turbine blades and guide vanes. The material used for parts such as blades and turbine disks. In recent years, with the rapid development of aero-engine and gas turbine industries, high temperature The use of alloys has been greatly increased, and raw materials such as nickel (Ni), chromium (Cr), cobalt (Co), tungsten (W), molybdenum (Mo), and rhenium (Re) have been largely eliminated. consumption. There...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B09B3/35B09B3/40B09B1/00C23G1/02C23G1/10C23G1/14C23G1/20

CPCB09B3/00B09B5/00C23G1/14C23G1/02C23G1/20C23G1/10Y02P10/20

Inventor 董鸿志浦益龙王博李亚峰李华兵李淑苹徐进涛熊兰兰马列东

Owner JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com