Treatment method for scrap-shaped high-temperature alloy return scraps

A technology of high-temperature alloy and processing method, which is applied in the field of shavings return material processing, can solve the problems of waste of metal materials and resources, and achieve the effect of improving utilization rate and reducing scum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

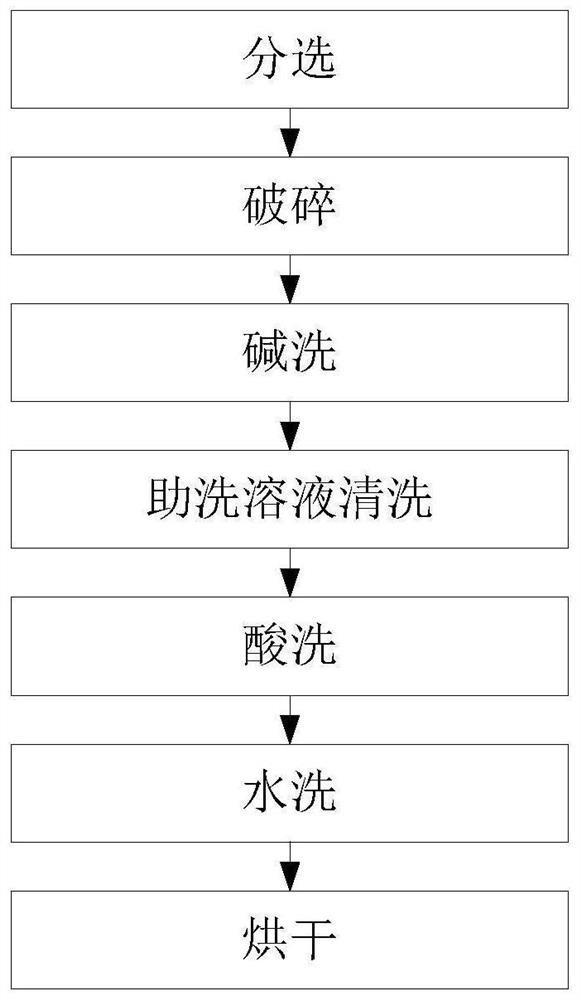

[0050] A method for processing the return material of a chip-like superalloy, the steps are as follows:

[0051] Step S1, sorting: sorting the crumb-like return materials, sorting and removing sundries such as magnetic metals and non-metals;

[0052] Step S2, crushing: using a crusher with a sieve with an aperture of 20 mm to crush the sorted crumb-like return material to obtain fish scale-like crumb material;

[0053] Step S3, alkali washing: put the fish scale-like debris in step S2 into a cleaning tank containing sodium hydroxide solution for ultrasonic vibration cleaning, the mass fraction of sodium hydroxide solution is 20%, set the cleaning time to 20min, and clean The temperature is 90°C, and the stirring rate is 40r / min;

[0054] Step S4, cleaning with builder solution: put the scale-like debris cleaned in step S3 into a cleaning tank containing builder solution for ultrasonic vibration cleaning, set the cleaning time to 10 minutes, the cleaning temperature to 50°C, a...

Embodiment 2

[0060] A method for processing the return material of a chip-like superalloy, the steps are as follows:

[0061] Step S1, sorting: sorting the crumb-like return materials, sorting and removing sundries such as magnetic metals and non-metals;

[0062] Step S2, crushing: using a crusher with a sieve with an aperture of 10 mm to crush the sorted crumb-like return material to obtain fish scale-like crumb material;

[0063] Step S3, alkali washing: put the fish scale-like debris in step S2 into a cleaning tank containing sodium hydroxide solution for ultrasonic vibration cleaning, the mass fraction of sodium hydroxide solution is 30%, and the cleaning time is set to 18 minutes. The temperature is 80°C, and the stirring rate is 40r / min;

[0064] Step S4, cleaning with builder solution: put the scale-like debris cleaned in step S3 into a cleaning tank containing builder solution for ultrasonic vibration cleaning, set the cleaning time to 8 minutes, the cleaning temperature to 45°C, ...

Embodiment 3

[0070] A method for processing the return material of a chip-like superalloy, the steps are as follows:

[0071] Step S1, sorting: sorting the crumb-like return materials, sorting and removing sundries such as magnetic metals and non-metals;

[0072] Step S2, crushing: selecting a crusher with a sieve aperture of 15 mm to crush the sorted chip-like return material to obtain fish scale-like chip material;

[0073] Step S3, alkali washing: put the fish scale-like debris in step S2 into a cleaning tank containing sodium hydroxide solution for ultrasonic vibration cleaning, the mass fraction of sodium hydroxide solution is 40%, set the cleaning time to 15 minutes, and clean The temperature is 70°C, and the stirring rate is 40r / min;

[0074] Step S4, cleaning with builder solution: put the scale-like debris cleaned in step S3 into a cleaning tank containing builder solution for ultrasonic vibration cleaning, set the cleaning time to 5min, the cleaning temperature to 50°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com