Patents

Literature

38results about How to "Lighten bands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-copper and nickel acid resistant pipeline steel X52MS and production method of hot-rolled plate coil thereof

The invention relates to non-copper and nickel acid resistant pipeline steel X52MS. The non-copper and nickel acid resistant pipeline steel X52MS comprises the following components in percentage by weight: 0.02-0.06 wt% of C, 0.05-0.35 wt% of Si, 1.0-1.4 wt% of Mn, P not greater than 0.018 wt%, S not greater than 0.003 wt%, 0.10-0.50 wt% of Cr, 0.05-0.10 wt% of Ti, 0.005-0.10 wt% of Nb, 0-0.05 wt% of V, and the balance of Fe and inevitable trace impurities. The invention further provides a preparation method of a hot-rolled plate coil of the non-copper and nickel acid resistant pipeline steel X52MS. Part of all Cr is used for replacing original Ni / Cu elements, so that the material cost is largely reduced under the precondition of guaranteeing the material HIC resistance.

Owner:SHOUGANG CORPORATION

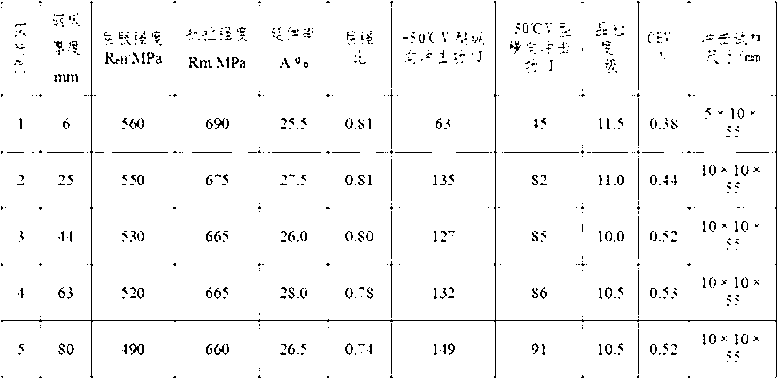

Preparation of normalizing weldable fine grain steel plate with a yield strength of 420MPa

ActiveCN101413049AElimination of internal stress and bainite structureReduces segregation bands and bandingTemperature control deviceMetal rolling arrangementsCooling temperatureImpact energy

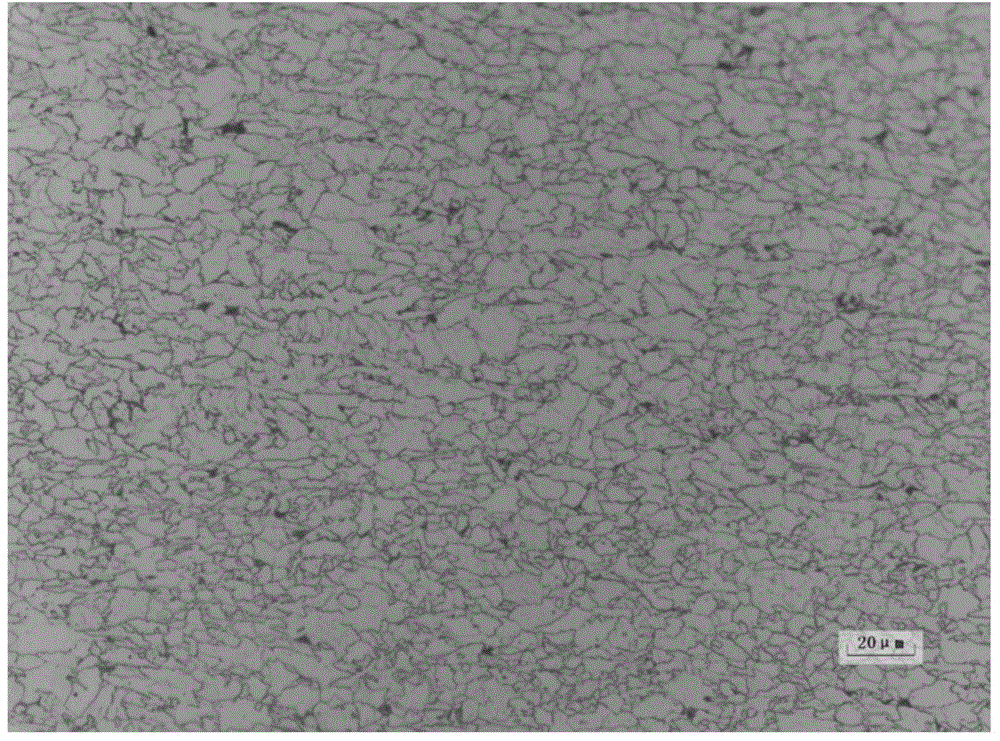

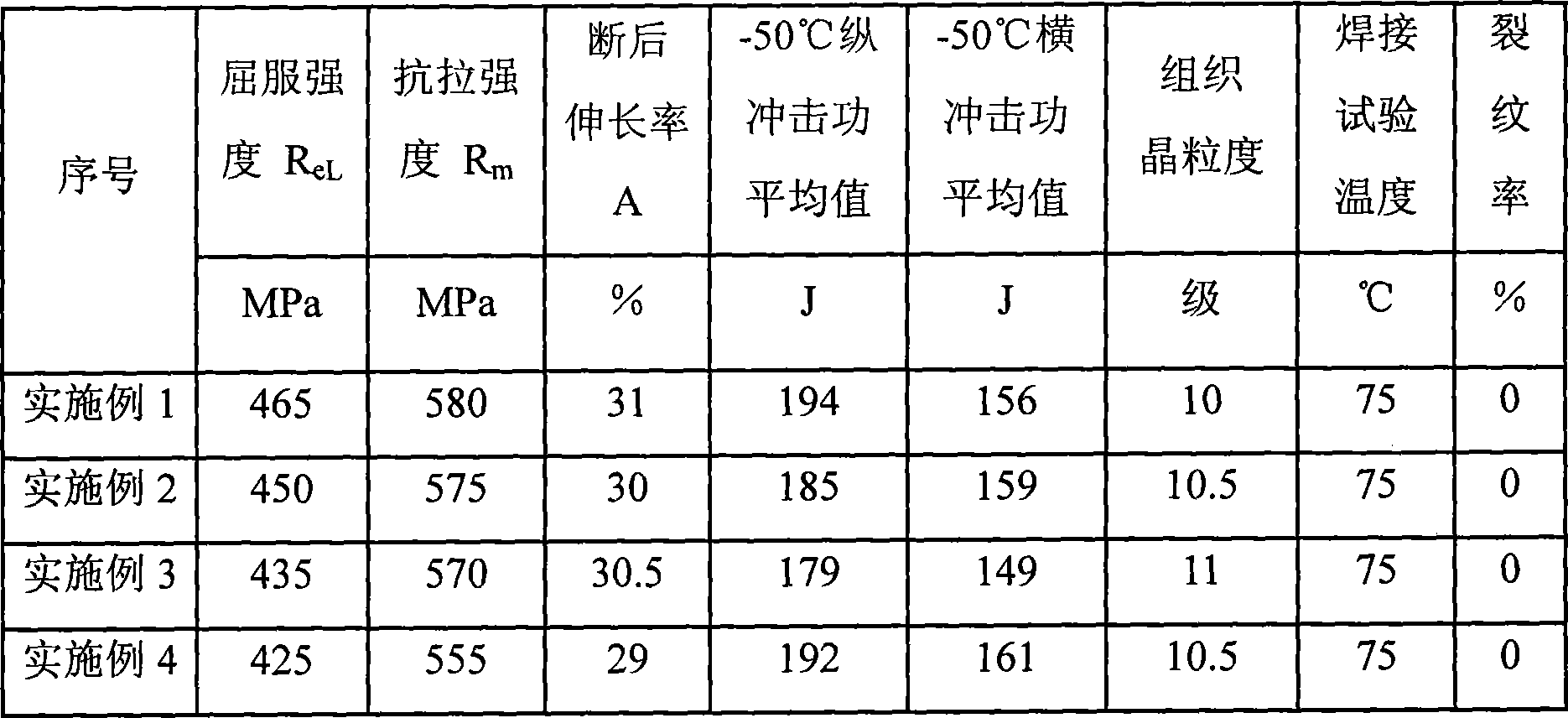

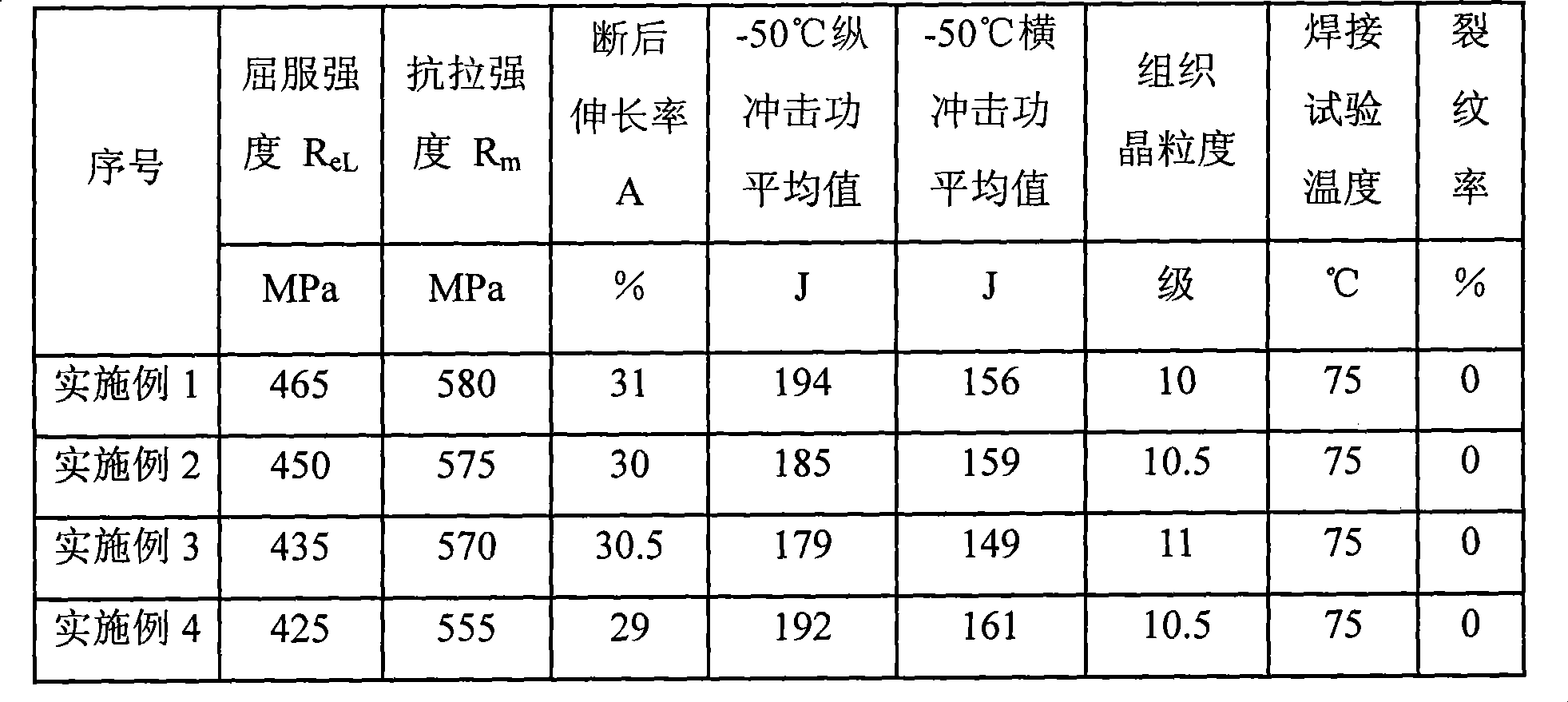

The invention provides a method for preparing normalized weldable fine-grain steel plates with the yield strength of 420 MPa, which belongs to the technical field of manufacturing medium thick steel plates. A production process comprises the following steps: a continuous casting billet is heated to be between 1,200 and 1,250 DEG C, and the heat is preserved for 4 to 5 hours; hot rolling is performed after heat preservation; rolling is divided into two stages, namely recrystallization zone rolling and non-recrystallization zone rolling; intermediate temperature waiting thickness is controlled to be between 2.5 and 4.0 times the thickness of a finished product; the initial rolling temperature of a non-recrystallization zone is controlled between 850 and 880 DEG C; the final rolling temperature is controlled between 810 and 830 DEG C; water cooling is performed after hot rolling; the final cooling temperature is controlled between 650 and 740 DEG C, and cooling rate is controlled between 5 and 8 DEG C per second; and the steel plates are normalized at a temperature between 880 and 910 DEG C and then are thermally insulated for 5 to 20 minutes. The method has the advantages that the steel plates are excellent in mechanical properties; the mechanical property of the steel plate can stably reach over 420 MPa; the tensile strength of the steel plates can stably reach over 550 MPa; and the V-type notched impact energy of the steel plates at 50 DEG C below zero can stably reach over 140 J.

Owner:SHOUGANG CORPORATION

Pressure container steel plate resistant to hydrogen induced cracking and manufacturing method thereof

ActiveCN105886909AHigh strengthImprove low temperature impact toughnessFurnace typesHeat treatment furnacesNon-metallic inclusionsHardness

The invention relates to a pressure container steel plate resistant to hydrogen induced cracking. The steel plate comprises, by weight, 0.16%-0.20% of C, 0.15%-0.40% of Si, 1.05%-1.20% of Mn, less than or equal to 0.008% of P, less than or equal to 0.002% of S, less than or equal to 0.01% of Nb, less than or equal to 0.01% of V, less than or equal to 0.01% of Ti, less than or equal to 0.0005% of B, and the balance Fe and inevitable impurity elements. The carbon equivalent Ceq is less than or equal to 0.42%, and a calculation formula for the carbon equivalent Ceq is Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The steel plate is high in strength and low-temperature impact toughness, low in hardness and good in HIC resistance. The steel plate has fine grains and low nonmetal inclusion content, and obvious banded structures do not exist. After long-time simulation of postweld heat treatment at a high temperature, the strength and the low-temperature impact toughness of the steel plate are not obviously weakened.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

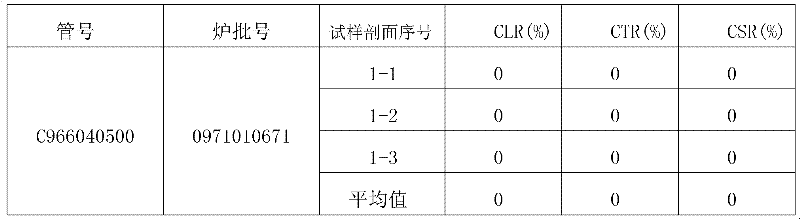

Method for manufacturing delivery steel pipe serving acid environment

InactiveCN102121081AGuaranteed corrosion resistanceFulfil requirementsHigh frequency current welding apparatusWelding/soldering/cutting articlesCrack resistanceIntermediate frequency

The invention discloses a method for manufacturing a delivery steel pipe serving an acid environment. The steel pipe comprises the following chemical components of raw materials in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 1.6 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.002 percent of S, less than or equal to 0.15 percent of Nb, V and Ti, less than or equal to 0.22 percent of Pcm, more than or equal to 1.5 percent of Ca / S and the balance of Fe. High frequency induction welding is adopted in welding of the steel pipe; the welding quality is improved in the welding process by increasing the welding extrusion quantity, controlling the open angle of seams and increasing welding protective gas; and on-line quenching and on-line tempering are performed in heat treatment of the seams by adopting six intermediate frequency heat treatment machines. By selection of raw material components and metallographic structures, completeness of a welding mechanism and improvement of the heat treatment process, the steel pipe has hydrogen induced cracking resistance and sulfide stress corrosion resistance and has high strength and high pressure resistance, the cost can be reduced, and the use of the steel pipe under the acid serving condition can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High-toughness normalizing steel plate with 460MPa yield strength and manufacturing method thereof

ActiveCN102719737BFine grainSpread evenlyHeat treatment process controlSheet steelChemical composition

The invention relates to the technical field of manufacture of medium steel plates, and discloses a high-toughness normalizing steel plate with 460MPa yield strength and a manufacturing method thereof. The high-toughness normalizing steel plate comprises the following chemical components by weight percent: 0.14%-0.20% of C, 0.20%-0.60% of Si, 1.20%-1.70% of Mn, 0.12%-0.20% of V, 0.15%-0.40% of Ni, 0.005%-0.020% of N, 0.005%-0.040% of Alt, less than or equal to 0.015% of P, less than or equal to 0.005% of S, and the balance of Fe and inevitable impurity. The manufacturing method disclosed by the invention comprises the steps of: heating a continuous casting blank to be at 1210-1240 DEG C by using a controlled rolling process and a normalizing process; controlling the total heating time according to 1.0-1.2min / mm; adopting a two-stage rolling mode, and controlling the initial rolling temperature of a non-recrystallization zone to be at 850-920 DEG C, and controlling the finishing temperature to be at 780-840 DEG C; carrying out air cooling after rolling; and controlling the normalizing temperature of the steel plate to be at 880-920 DEG C, and controlling the heat preservation time for 15-40 minutes. According to the high-toughness steel plate manufactured by using the method, the quality is stable, the performance is good and the production cost is low.

Owner:XINYU IRON & STEEL CO LTD

Cold-rolled steel sheet with tensile strength larger than 900 MPa and manufacturing method thereof

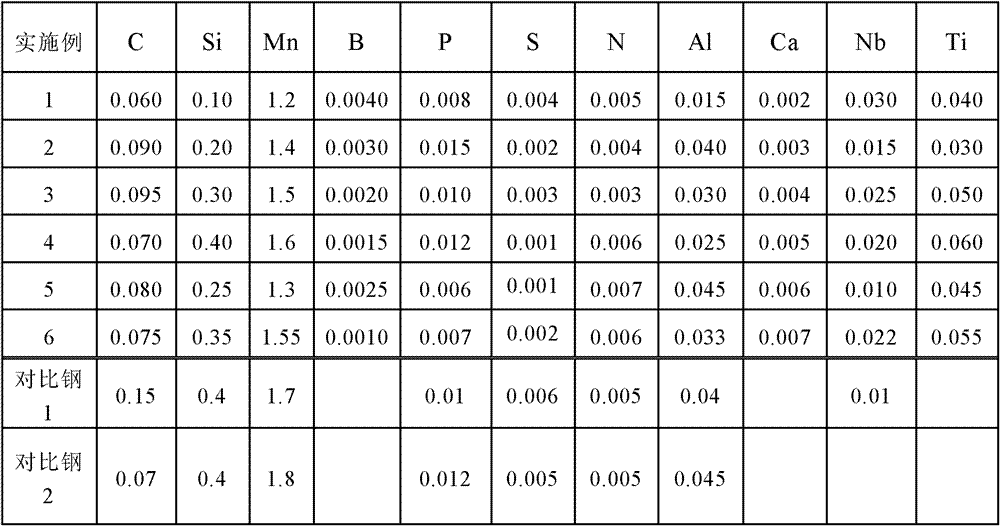

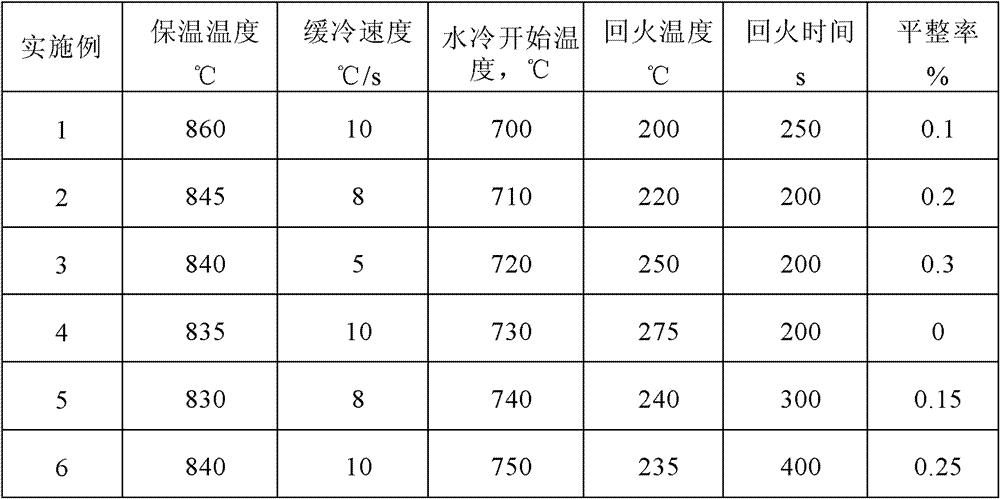

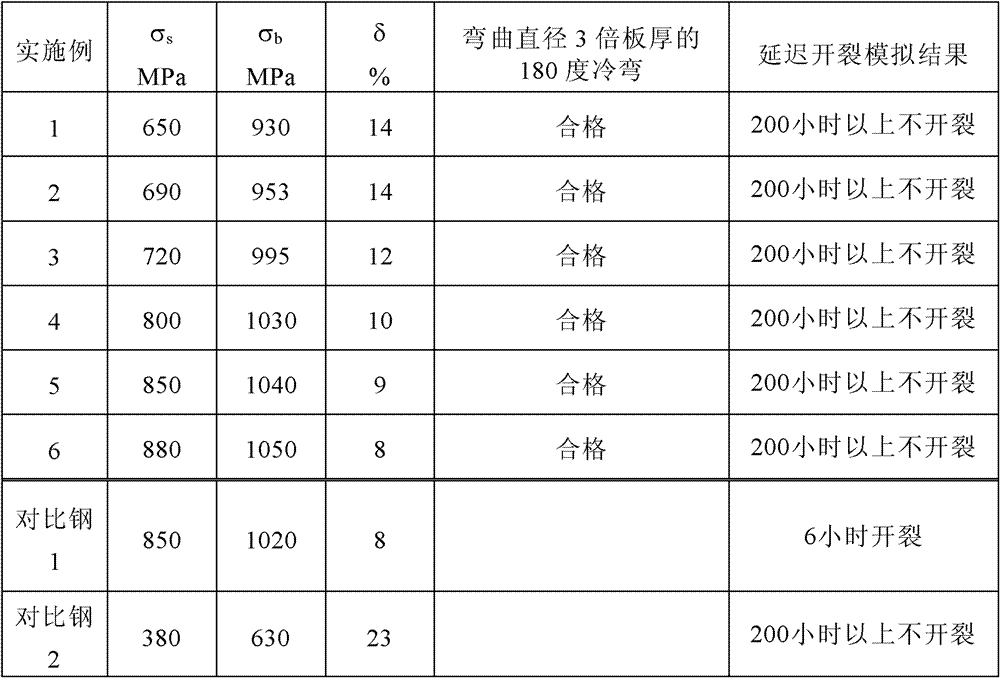

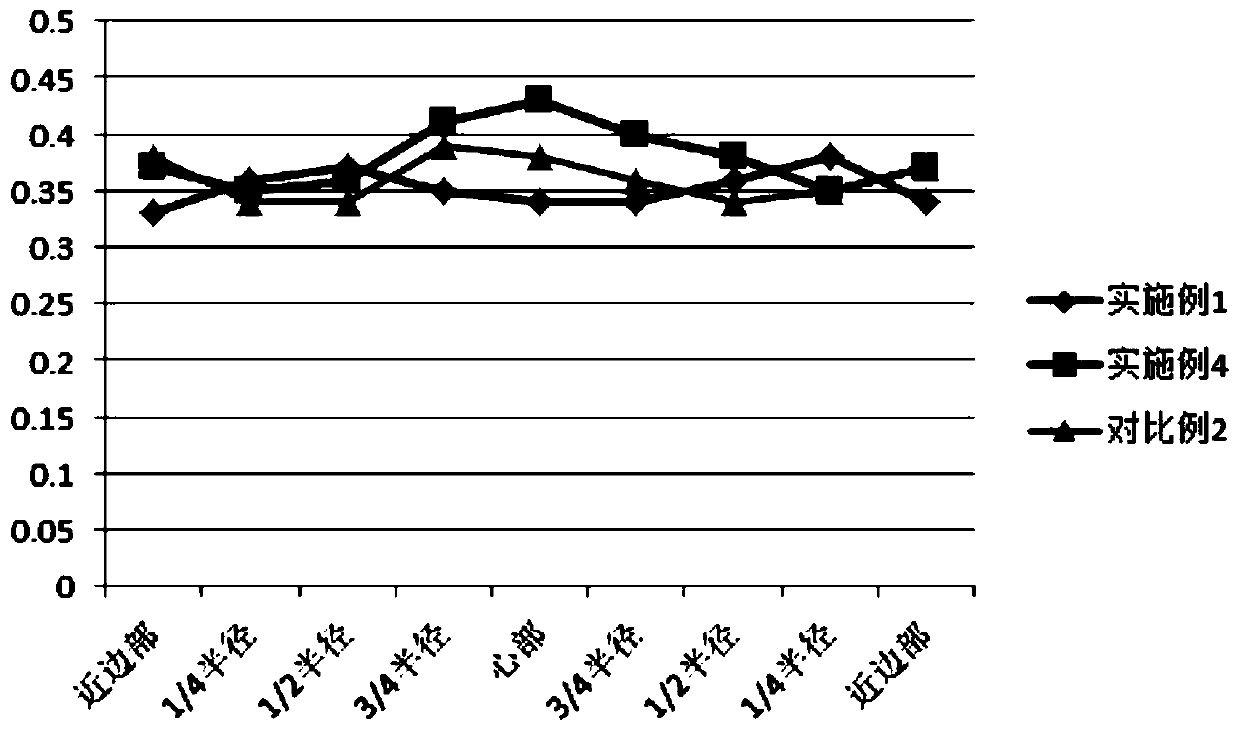

ActiveCN102953001AReduce segregation tendencyReduce overgrowthTemperature control deviceSheet steelCrack resistance

The invention discloses a cold-rolled steel sheet with tensile strength larger than 900 MPa and a manufacturing method of the cold-rolled steel sheet. The cold-rolled steel sheet is composed of the following ingredients in percentage by weight: 0.06-0.095wt% of C, 0.1-0.4wt% of Si, 1.2-1.6wt% of Mn, 0.001-0.004% of B, not larger than 0.015wt% of P, not larger than 0.004wt% of S, 0.003-0.007wt% of N, 0.01-0.03wt% of Nb, 0.03-0.06% of Ti, 0.015-0.045wt% of Al, 0.002-0.007wt% of Ca and the rest balance of Fe and inevitable impurities. Cold-rolled high strength steel with tensile strength larger than 900 MPa and excellent cold bending property and delayed cracking resistance is obtained by reasonable ingredient design and technique design in the invention, and the steel has the characteristics of small and uniform tissues and excellent cold bending property. Meanwhile, the delayed cracking resistance of the steel is excellent, so that the steel meets the manufacturing demands of safety elements and structural members of automobiles.

Owner:BAOSHAN IRON & STEEL CO LTD

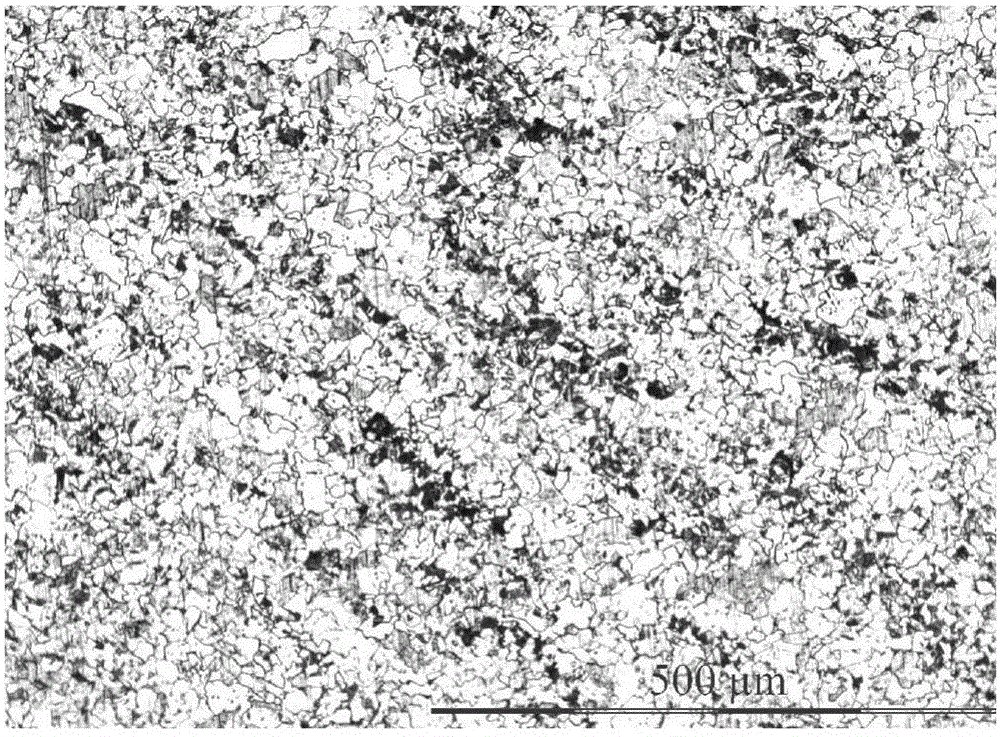

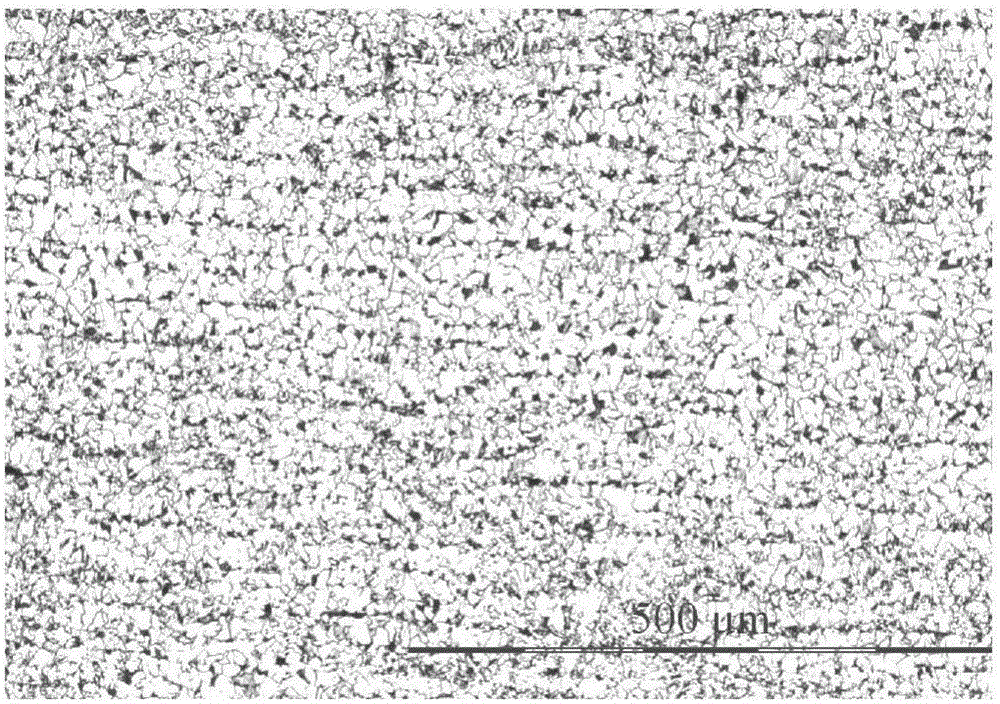

Non-quenched and tempered steel for crankshaft, crankshaft forging and preparation process thereof

The invention provides a non-quenched and tempered steel for a crankshaft, a crankshaft forging and a preparation process thereof, and belongs to the technical field of the non-quenched and tempered steel. The non-quenched and tempered steel comprises the following components in percentage by weight: 0.36-0.39% of C, 0.50-0.65% of Si, 1.35-1.50% of Mn, 0-0.030% of P, 0.040-0.055% of S, 0-0.25% ofCr, 0-0.20% of Mo, 0-0.03% of Al and 0.010-0.020% of N; and the carbon equivalent Ceq is 0.75-0.81%. The hardenability of the non-quenched and tempered steel is J5mm of 47-52 HRC, J9mm of 35-42 HRC and J13mm of 30-36 HRC; the tensile strength is not lower than 760 MPa; the elongation A is not lower than 14%; the belt structure is not higher than 2.0 grade; the Brinell hardness is 220-250 HBW; andthe non-quenched and tempered steel is suitable for preparing crankshaft forgings.

Owner:SGIS SONGSHAN CO LTD

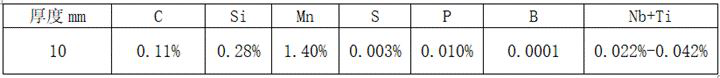

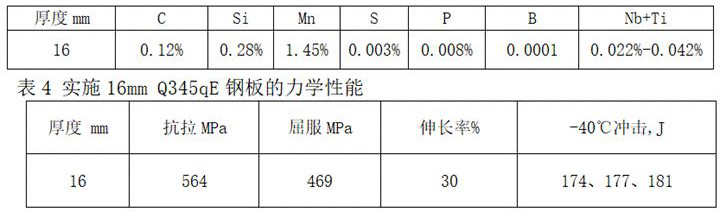

Production method of low-cost Q345q series bridge steel plate

PendingCN114540580ALow costIncrease nucleation rateFurnace typesProcess efficiency improvementAlloyPearlite

The invention discloses a production method of a low-cost Q345q series bridge steel plate. The steel plate comprises the following chemical components in percentage by mass: 0.10-0.13% of C; 1.4 to 1.5 percent of Mn; the steel plate comprises the following components in percentage by weight: 0.25 to 0.35 percent of Si, less than or equal to 0.004 percent of S, less than or equal to 0.015 percent of P, 0.020 to 0.040 percent of Als, 0.02 to 0.03 percent of Nb, 0.002 to 0.012 percent of Ti and less than or equal to 0.0005 percent of B. The thickness of the produced steel plate is 8 to 40mm; the adopted production method comprises the steps of molten iron pre-desulfurization treatment, 120 t converter treatment, LF refining and RH vacuum degassing, continuous casting, slab heating, controlled rolling, stack cooling, (flaw detection), finishing, sampling inspection, identification and warehousing. By adopting a low-temperature high-pressure technology and a TMCP controlled rolling and controlled cooling technology, the nucleation rate of ferrite is increased, so that ferrite grains are refined, and controlled cooling after controlled rolling can improve banded structures, refine pearlite pellets and reduce the interlayer spacing of pearlite, so that the effects of refined grain strengthening and precipitation strengthening are fully exerted, and the mechanical property index of a product is increased; and the alloy cost is greatly reduced while various properties of the bridge steel reach the national standard.

Owner:XINJIANG BAYI IRON & STEEL

Low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for kitchen cutter

The invention discloses a low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for a kitchen cutter. The low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is characterized in that the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt comprises the specific components by weight percentage: 0.50-0.60% of C, 0.3-0.7% of Mn, 2.5-3.5% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 9.00-10.00% of Cr, less than or equal to 0.6% of Ni, 0.16-0.32% of V, 0.04-0.08% of N, 0.0008-0.002% of B and the balance of Fe. According to the low-chromium and high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt for the kitchen cutter, the matrix strength is high; a cutting edge of the cutter has good sharpness, wear resistance and corrosion resistance; and the production cost is low. The low-chromium high-silicon wear-resistant vanadium-nitrogen-boron reinforced steel belt is mainly used for the kitchen cutter and can also be used for the production of shears.

Owner:SHANDONG TAISHAN STEEL GROUP

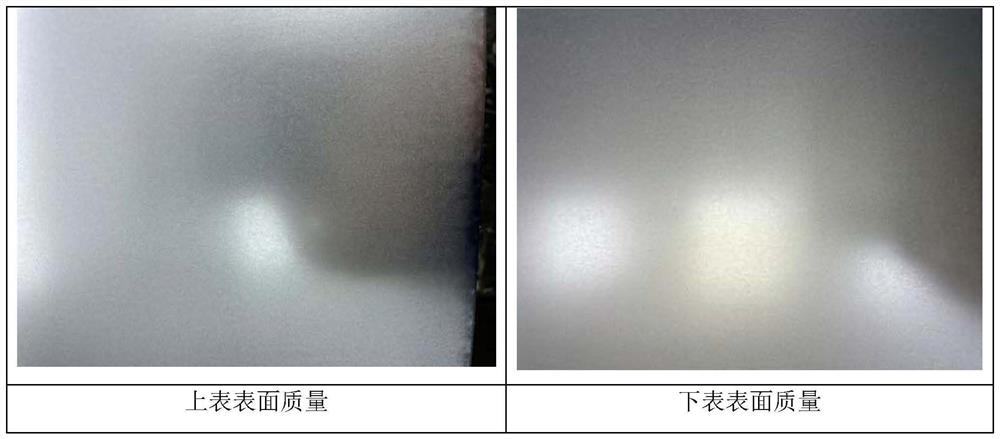

450MPa-grade hot-dip galvanized dual-phase steel with high work hardening rate and surface quality and production method of 450MPa-grade hot-dip galvanized dual-phase steel

PendingCN114107806AExcellent surface coating qualityImprove strong plasticityHot-dipping/immersion processesManganeseSlow cooling

The invention discloses 450MPa-grade hot-dip galvanized dual-phase steel and a production method thereof, and belongs to the field of galvanized automobile steel manufacturing, the 450MPa-grade hot-dip galvanized dual-phase steel adopts a low-carbon-low-manganese component design of trace Si, low Mo and high Cr, processes of coiling at a low temperature of 520-560 DEG C, slow cooling at a temperature of 640-660 DEG C and rapid cooling at a temperature of more than or equal to 10 DEG C are carried out, and the 450MPa-grade hot-dip galvanized dual-phase steel is prepared by matching a dew point in a furnace at a temperature of less than or equal to-40 DEG C and an oxygen content of less than or equal to 5ppm. And obtaining the 450MPa-grade hot-dip galvanized dual-phase steel under the atmosphere that the dew point of a furnace nose is not more than-20 DEG C. According to the produced hot-dip galvanized dual-phase steel with the tensile strength of 450 MPa, the uniform elongation is 18%-23%, the work hardening rate n value is not lower than 0.19, the after-fracture elongation A80 reaches up to 28%-33%, and the hot-dip galvanized dual-phase steel is suitable for being used as a high-drawing and high-flanging complex forming automobile part.

Owner:MAANSHAN IRON & STEEL CO LTD

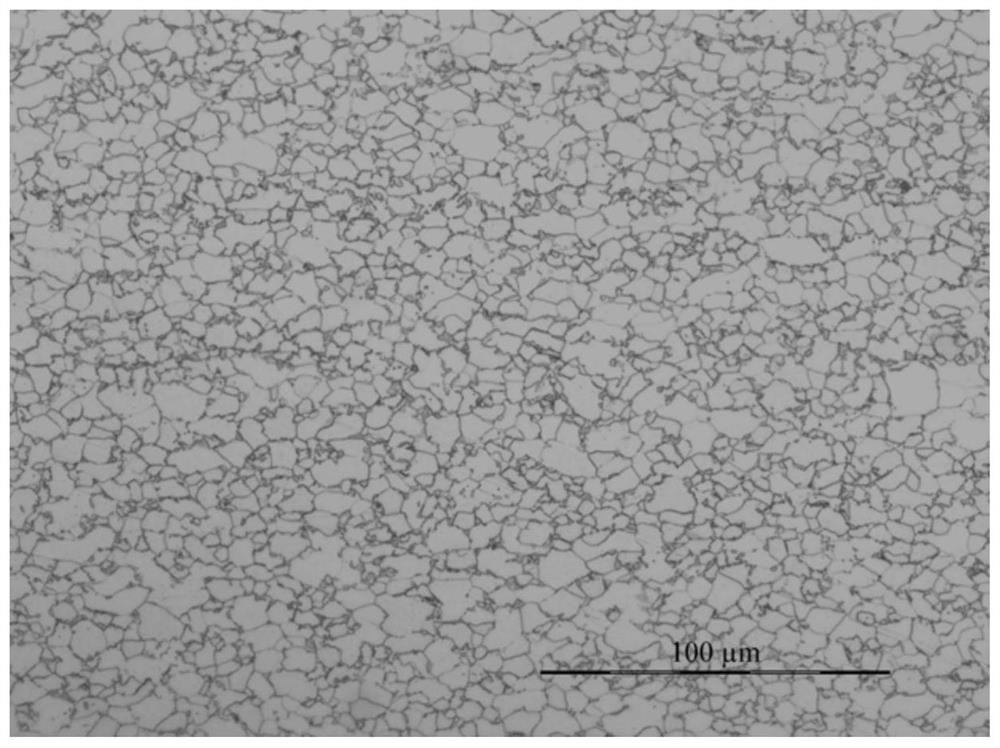

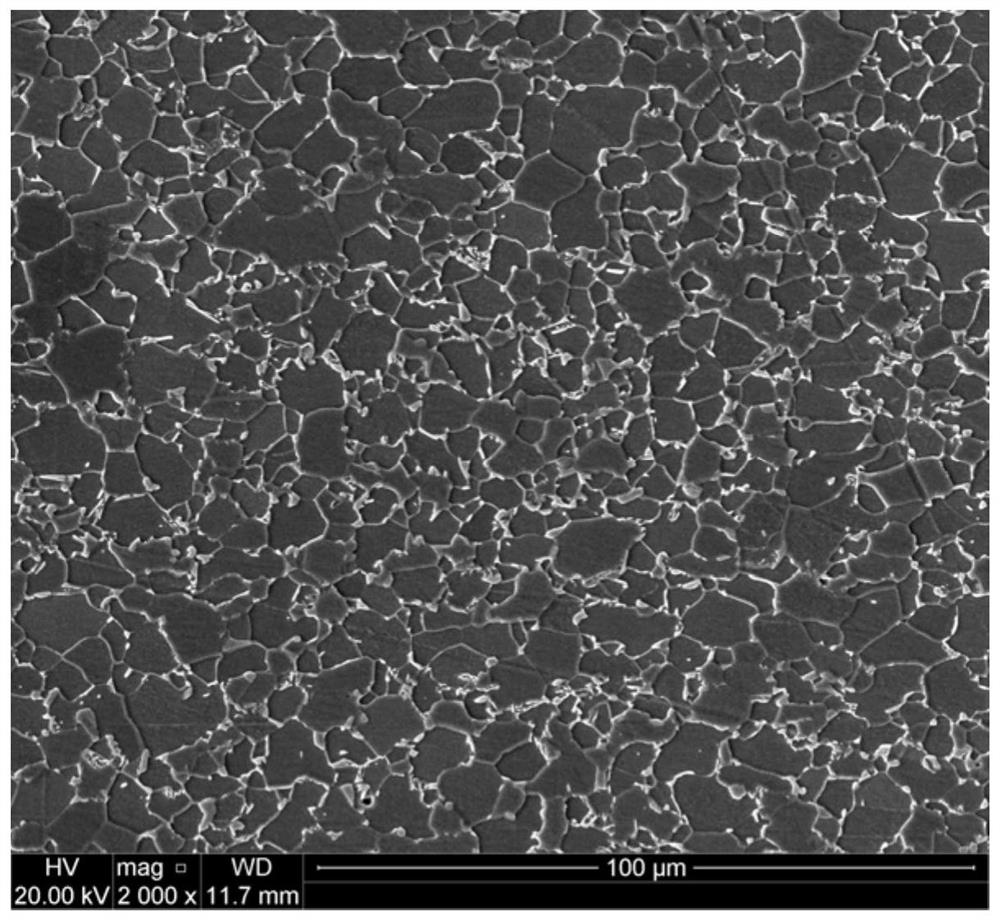

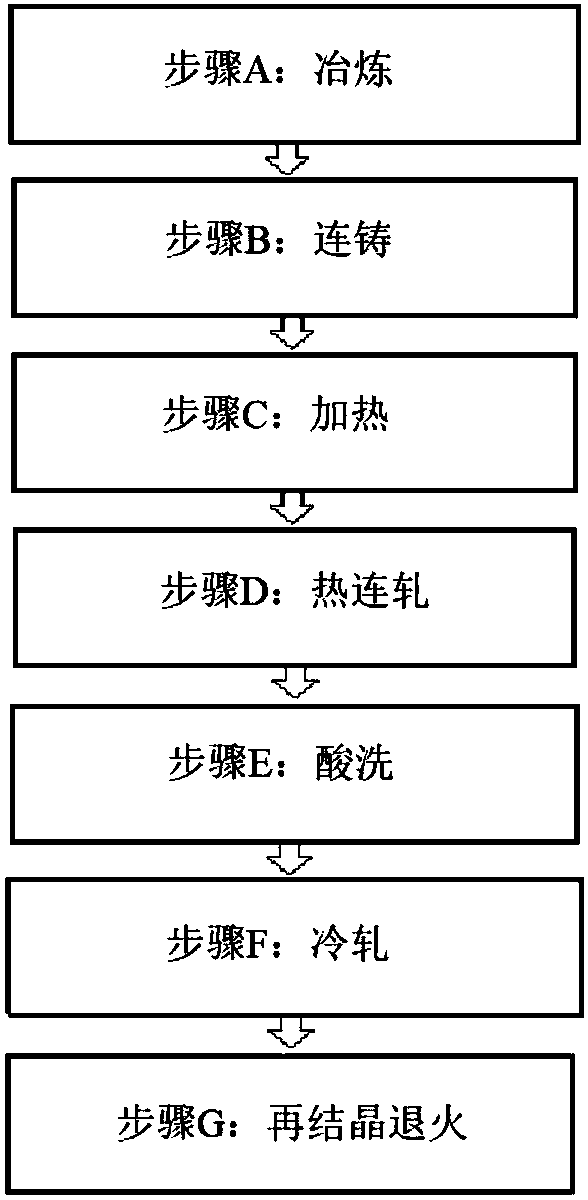

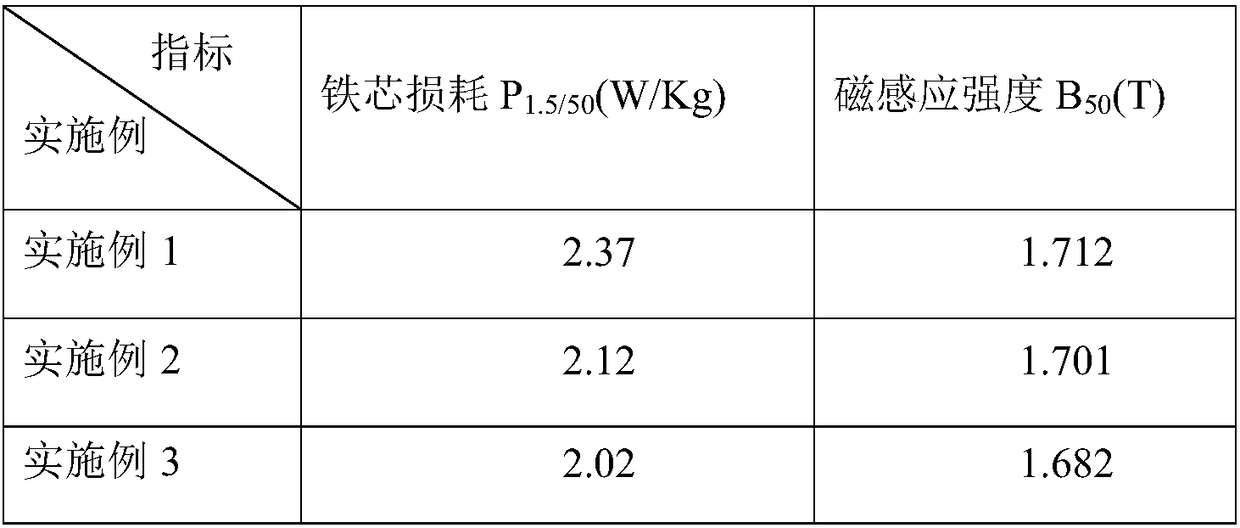

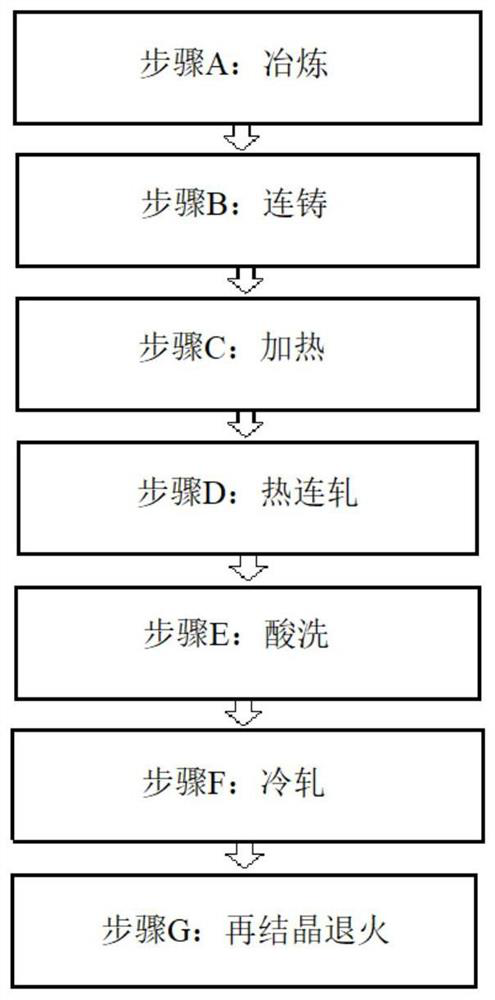

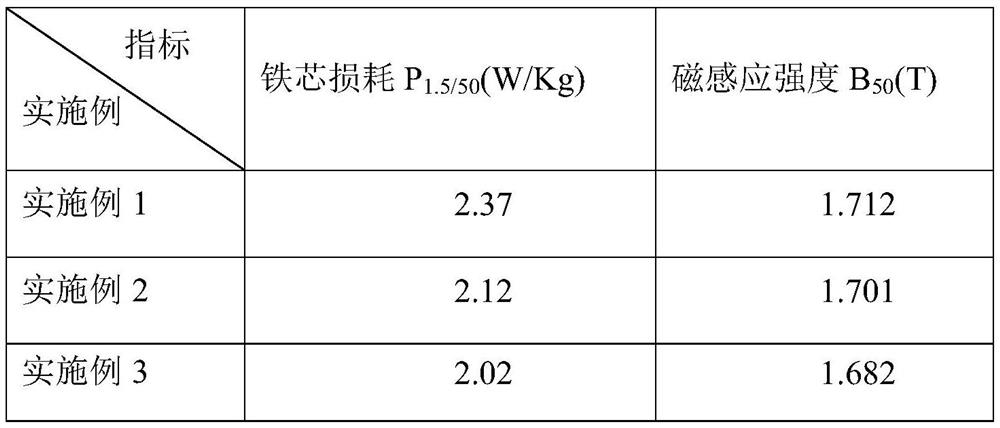

Method for producing non-oriented silicon steel by virtue of continuous casting and rolling flow of non-oriented silicon steel and thin slabs

ActiveCN108374130AHigh magnetic inductionReduce iron lossMetal rolling arrangementsThin slabContinuous rolling

The invention discloses a method for producing non-oriented silicon steel by virtue of a continuous casting and rolling flow of non-oriented silicon steel and thin slabs, and relates to non-oriented silicon steel and a production method thereof. The method comprises the following steps: (A) smelting, (B) continuous casting, (C) heating, (D) hot continuous rolling, (E) acid pickling, (F) cold rolling and (G) recrystallization annealing. According to the method, qualified high-grade non-oriented silicon steel is prepared by virtue of the thin slab casting and rolling flow.

Owner:INNER MONGOLIA UNIV OF TECH

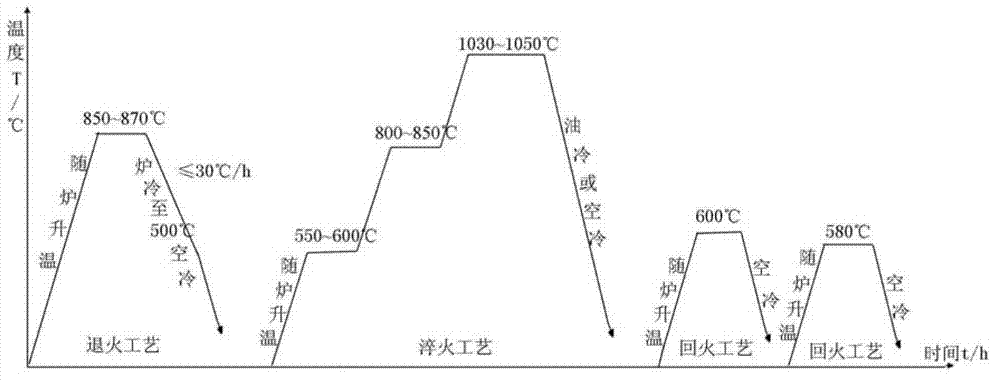

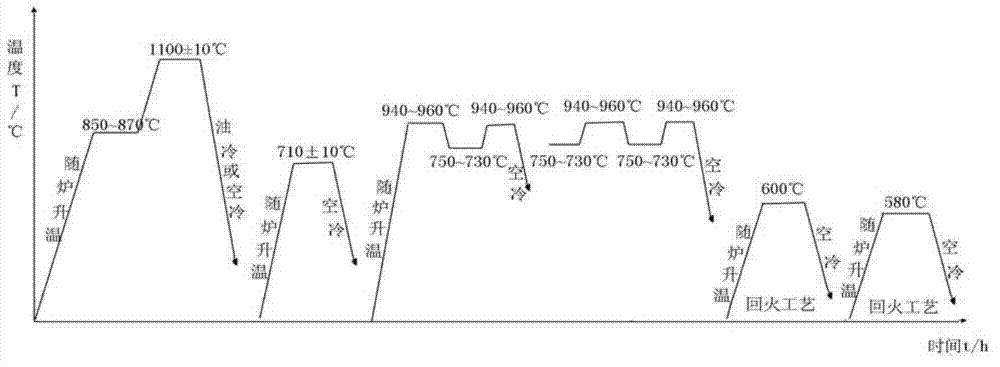

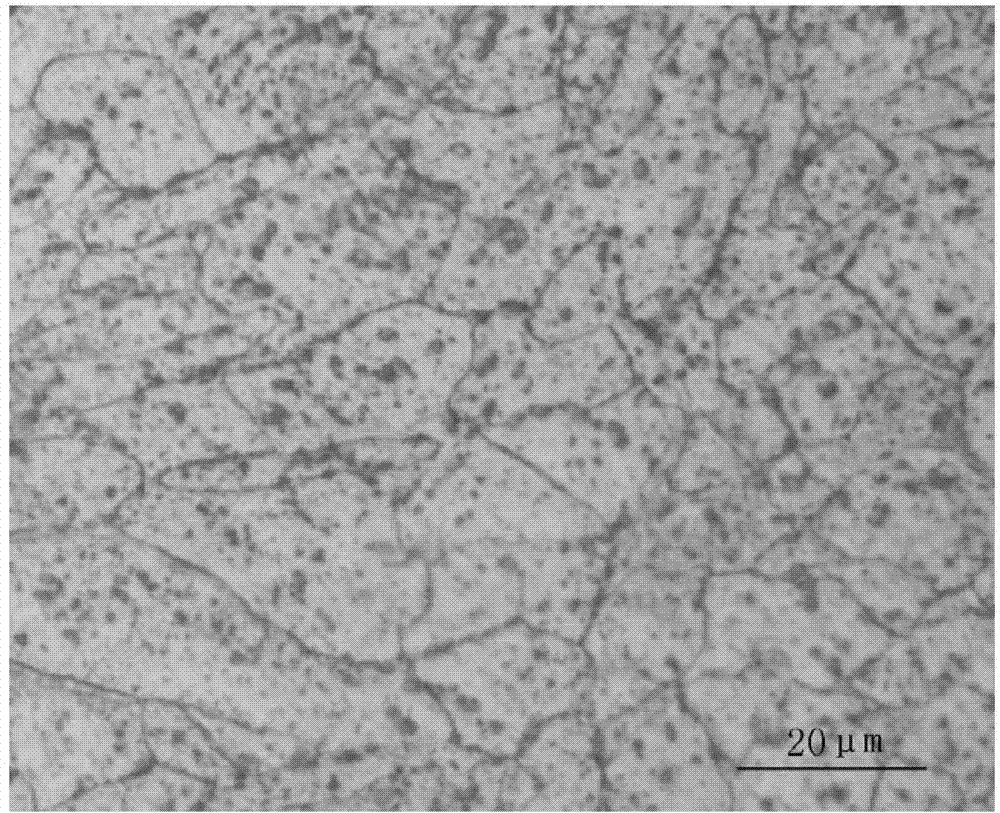

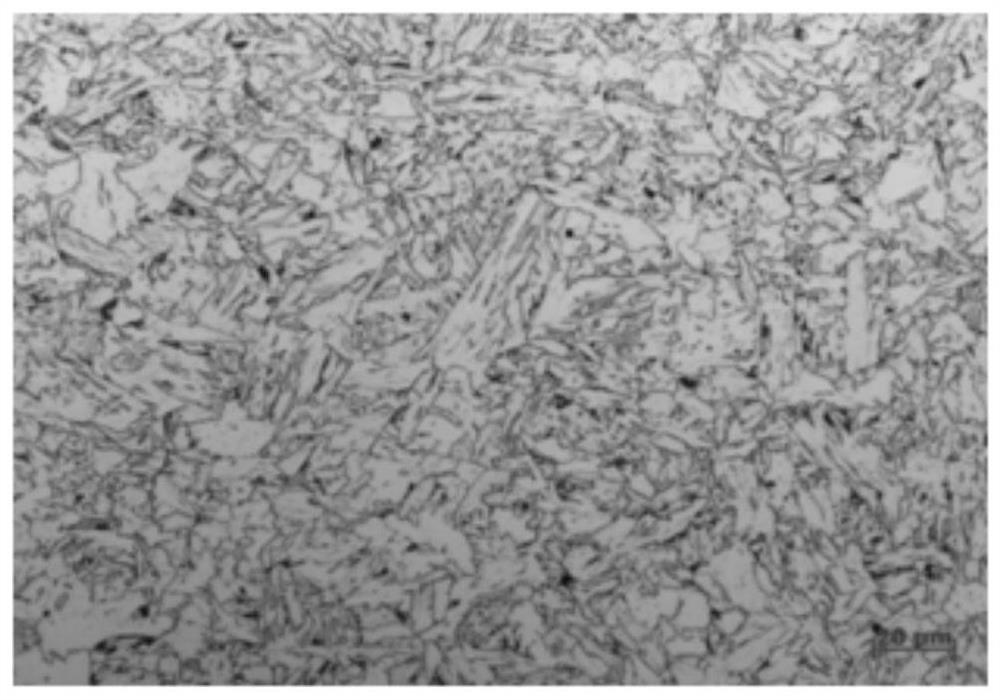

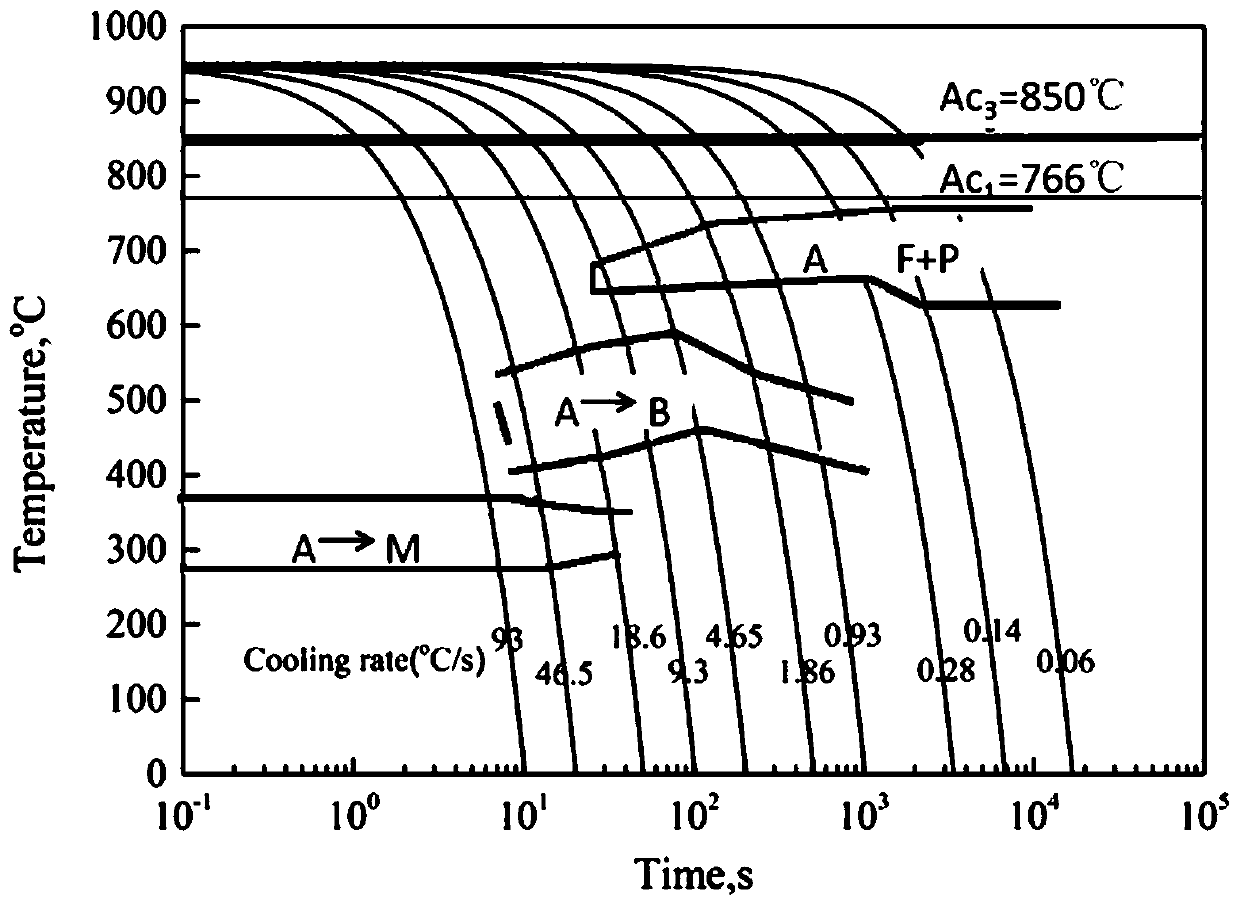

Strengthening and toughening heat treatment method of hot work die steel 4Cr5MoSiV1

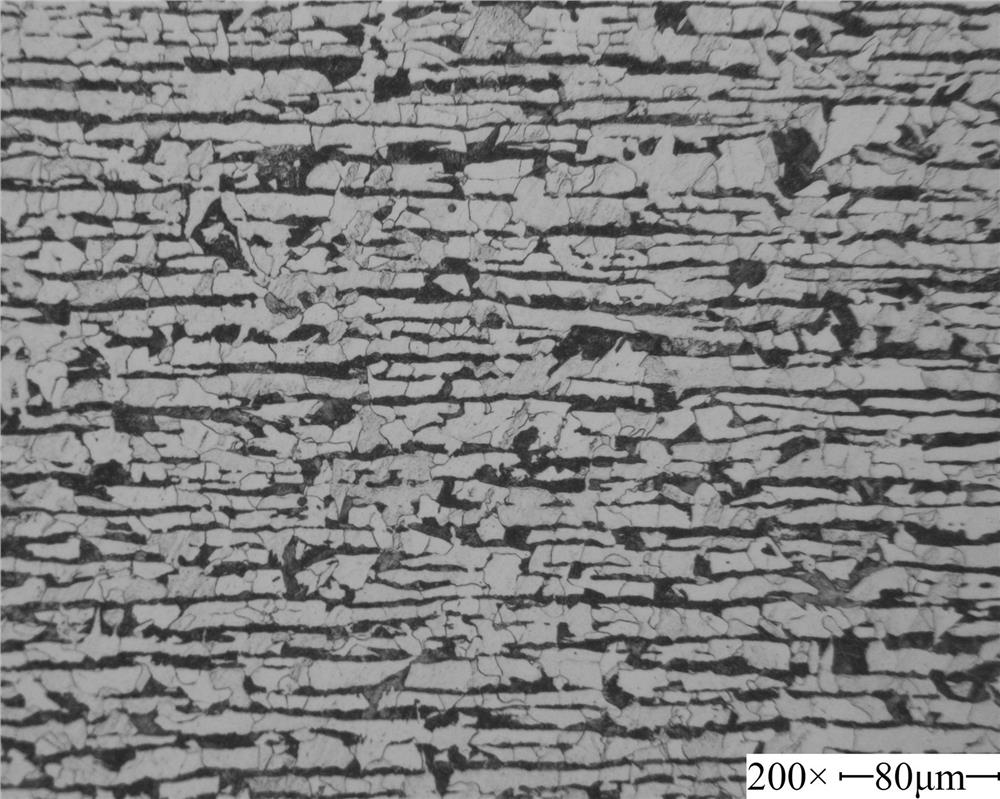

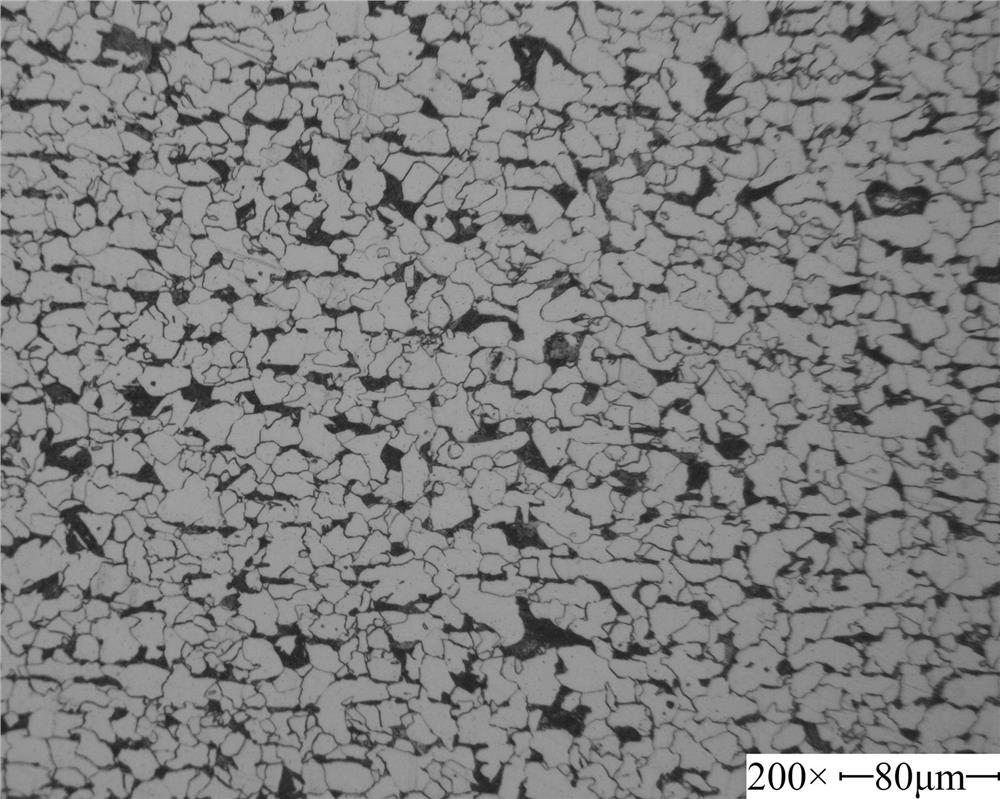

The invention discloses a strengthening and toughening heat treatment method of hot work die steel 4Cr5MoSiV1, which is characterized by comprising the following steps of: 1, placing a steel material in a resistance furnace, setting the temperature to 850-870 DEG C, preserving the temperature for 60-90s per millimeter of steel material; 2, raising the temperature to 1090-1110 DEG C, preserving the temperature for 70-90s per millimeter of steel material, oil cooling or air cooling to room temperature; 3, then re-placing the steel material in the resistance furnace, raising the temperature to 700-720 DEG C, preserving the temperature for 90min, air cooling to room temperature; 4, placing the steel material in a salt bath furnace, raising the temperature to 940-960 DEG C, preserving the temperature for 60-90s per millimeter of steel material; 5, taking the steel material out and then rapidly placing in a salt bath furnace with a temperature of 730-750 DEG C, preserving the temperature for 60-90s per millimeter of steel material, then taking the steel material out and then rapidly placing in a salt bath furnace with a temperature of 940-960 DEG C, preserving the temperature for 60-90s per millimeter of steel material; 6, repeating the step 5 for 3-5 times, air cooling to room temperature; 7, placing the steel material in a tempering furnace, reducing the temperature to 600 DEG C, preserving the temperature for 90 min, air cooling to room temperature; and 8, placing the steel material in the tempering furnace again, reducing the temperature to 580 DEG C, preserving the temperature for 90min, and air cooling to room temperature to obtain the hot work die steel. The hot work die steel 4Cr5MoSiV1 has the advantages of remarkable refined grains, uniform microstructure, reduced large-size carbide and lightened banded structure.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

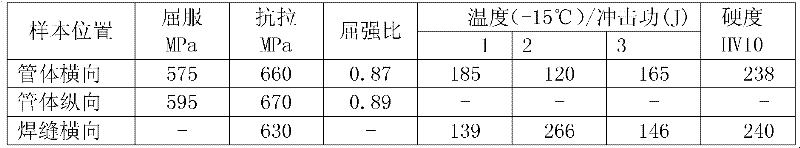

Seamless steel tube for nuclear power and preparation method for seamless steel tube

The invention relates to a seamless steel tube and a preparation method for the seamless steel tube, in particular to a thick-wall seamless steel tube for nuclear power and a preparation method for the tube. A steel blank of the seamless steel tube is composed of, by weight percent, 0.13%-0.15% of C, 0.15%-0.38% of Si, 0.80%-1.20% of Mn, not larger than 0.015% of P, not larger than 0.001% of S, not larger than 0.25% of Cr, not larger than 0.50% of Ni, not larger than 0.10% of Mo, not larger than 0.18% of Cu, 0.020%-0.050% of Al, not larger than 0.03% of Sn and the balance Fe. Composition segregation and a banded structure of the prepared P280GH thick-wall steel tube can be obviously relieved, and original austenite grains and ferrite crystal grains are refined, so that the transverse impact toughness and other mechanical properties of the tube are obviously improved, and a metallographic structure of the seamless steel tube also can meet the requirement of the RCC-M standard.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

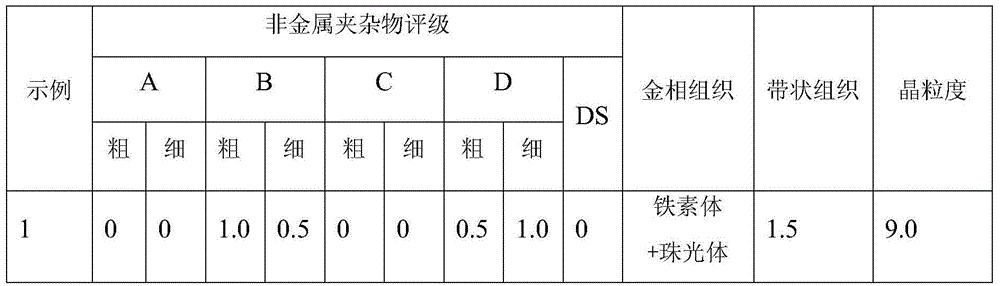

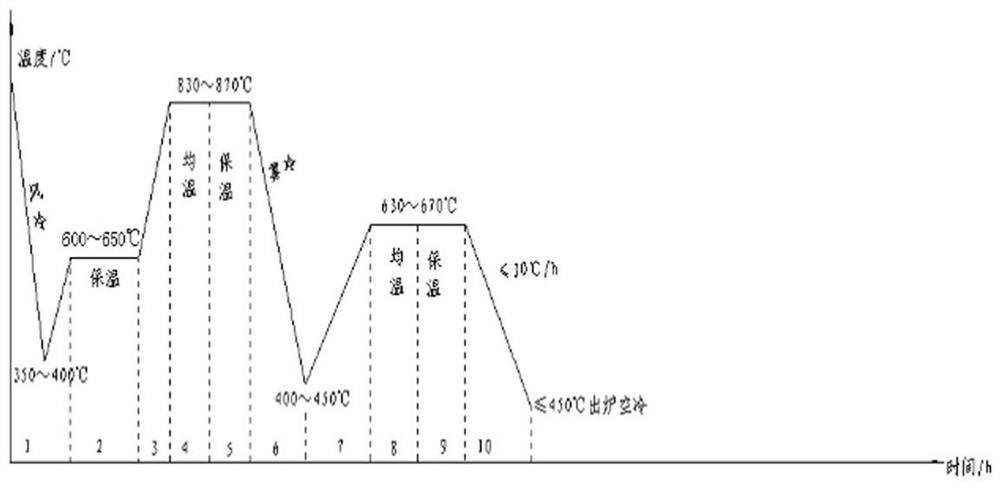

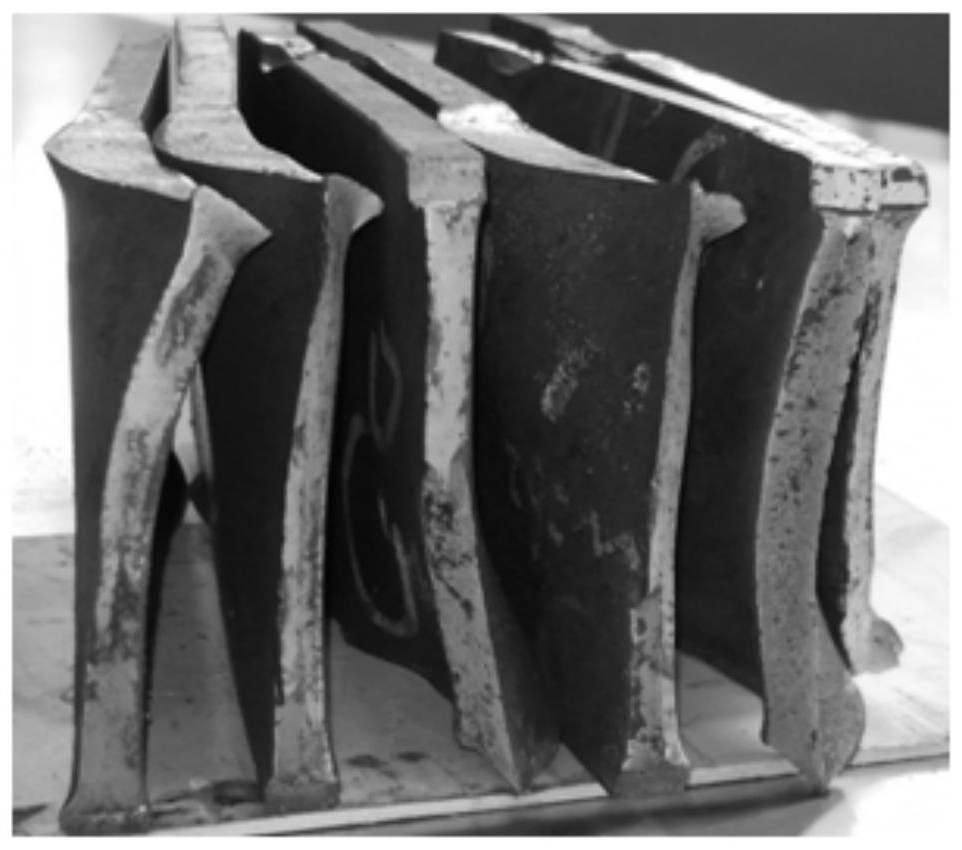

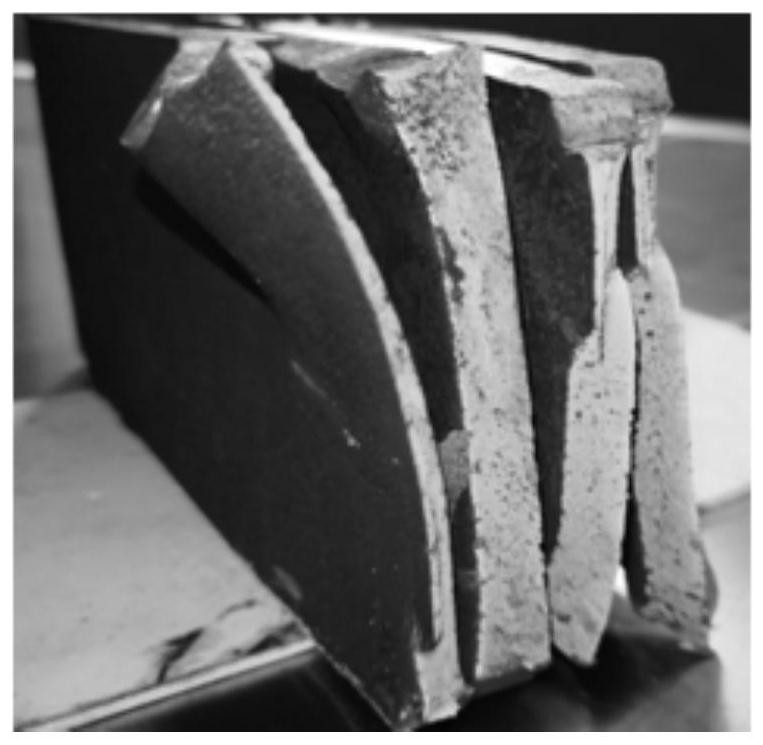

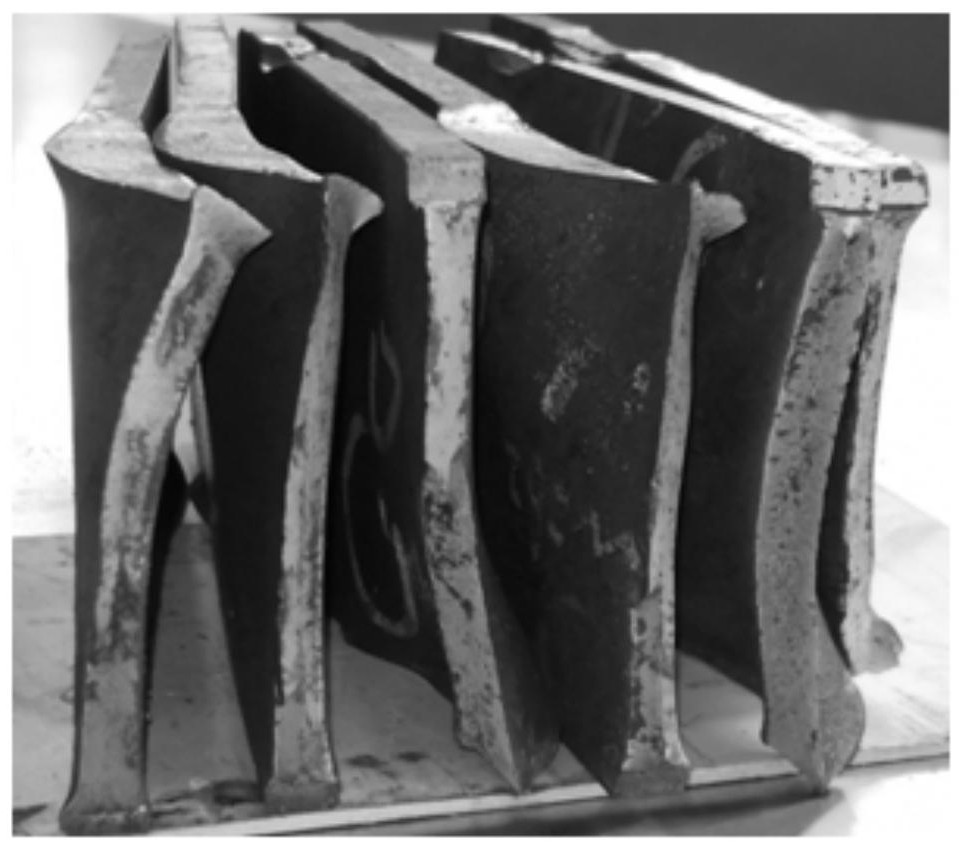

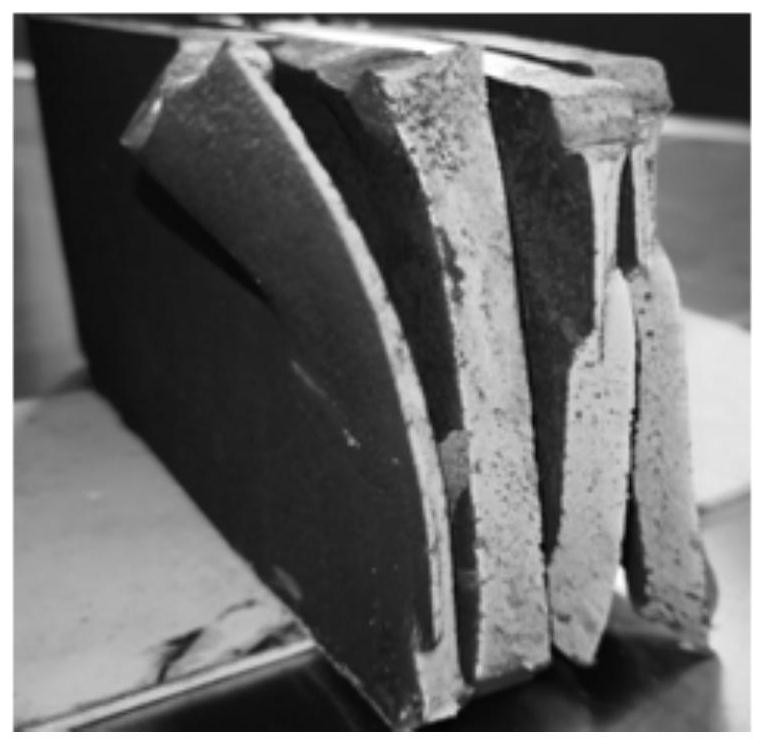

Method for improving banded structure of 42CrMoA crankshaft

PendingCN114657363AReduce or eliminate component segregationLighten bandsMetal-working apparatusFurnace typesFurnace temperatureIngot

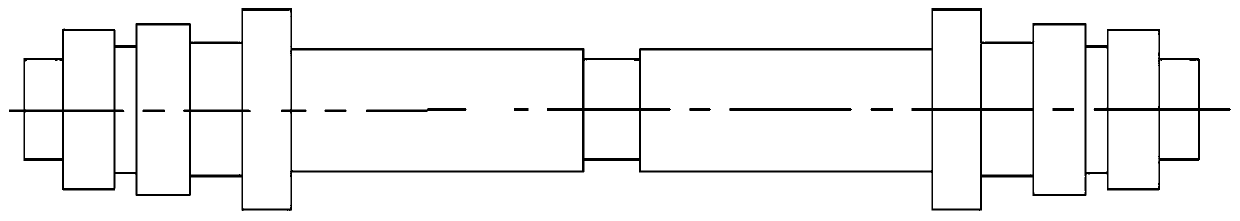

The invention relates to a method for improving the banded structure of a 42CrMoA crankshaft, which comprises the following steps of: cogging and forging a hot-fed steel ingot into an intermediate billet through an oil press, returning to a furnace, heating to 1230-1270 DEG C, preserving heat for 10-20 hours, pulling out a trolley, airing the material to 600-650 DEG C, reducing the furnace temperature to 930-970 DEG C, returning to the furnace, preserving heat for 2 hours, discharging, airing the material to 750-800 DEG C, forging and forming by a precision forging machine, quickly cooling the forged piece to 350-400 DEG C after forging, heating to 600-650 DEG C at full power, preserving heat for 1 hour / 100mm, and cooling to the room temperature to obtain the 42CrMoA crankshaft banded structure. The temperature is increased to 840-880 DEG C with full power, heat preservation is conducted for 1-2 h / 100 mm, the temperature is rapidly cooled to 400-450 DEG C after heat preservation is finished, the temperature is increased to 630-670 DEG C with full power, heat preservation is conducted for 4 h / 100 mm, furnace cooling is conducted to the temperature smaller than or equal to 450 DEG C at the speed smaller than or equal to 30 DEG C / h after heat preservation is finished, and the 42CrMoA crankshaft is taken out of a furnace and subjected to air cooling. The problem of the banded structure of a forged 42CrMoA crankshaft is well solved, and the banded structure requirement of the 42CrMoA crankshaft material is met.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Round steel with low magnetic mark rate, crankshaft forging and manufacturing method thereof

The application provides a round steel with low magnetic mark rate, a crankshaft forging and a manufacturing method thereof, and belongs to the technical field of crankshafts. The round steel comprises 0.46-0.50% of C, 0.20-0.30% of Si, 1.05-1.15% of Mn, not greater than 0.020%of P, not greater than 0.035%of S, not greater than 0.25% of Cr, not greater than 0.05%of Mo, not greater than 0.030% of Al, 0.06-0.10% of V, and 0.010-0.018% of N, wherein the carbon equivalent Ceq=C+Si / 6+Mn / 5+Cr / 4+1.5V; Ceq ranges from 0.87-0.92%; the tensile strength of the round steel is not less than 850MPa; the elongation A is not less than 12%; the band-shaped tissue is less than or equal to grade 2.0; and the C segregation values of the R / 2 part of the cross section and the core part of the round steel are less than or equal to 10%. The round steel is used for preparing the crankshaft forging, and the magnetic mark rate of the crankshaft forging can be reduced.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

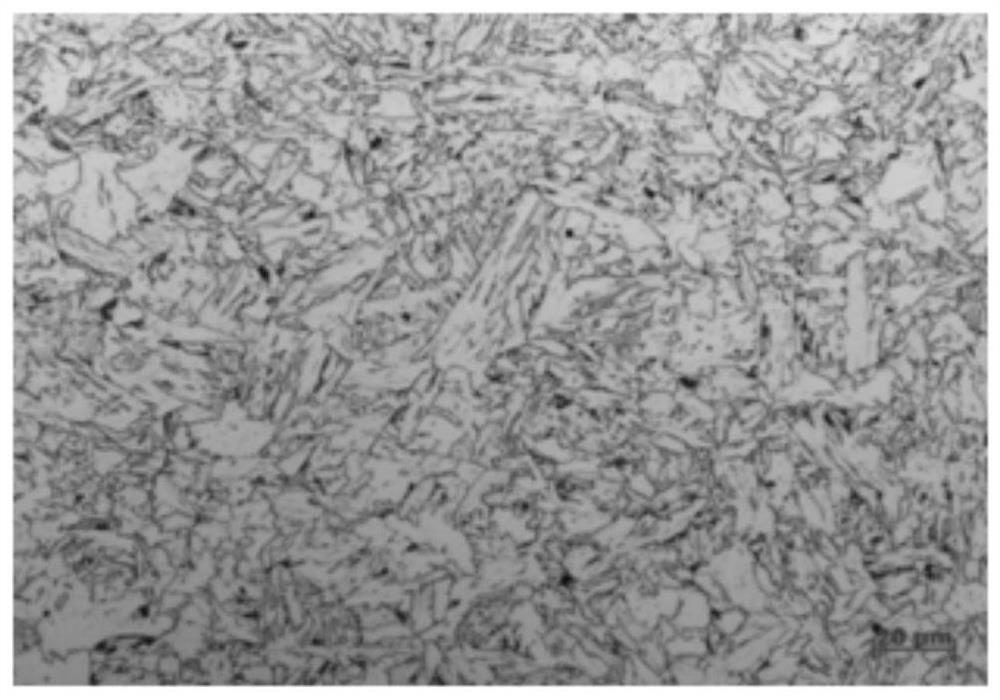

Control method for preventing machining cracking of 20Ni2MoA gear steel

The invention discloses a control method for preventing machining cracking of 20Ni2MoA gear steel. The 20Ni2MoA gear steel is prepared from 0.18%-0.21% of C, 0.20%-0.30% of Si, 0.70%-0.80% of Mn, smaller than 0.018% of P, smaller than 0.005% of S, 1.65%-1.75% of Ni, 0.20%-0.26% of Mo, smaller than or equal to 0.15% of Cr, smaller than or equal to 0.15% of Cu and the balance of iron and inevitable impurities. Electric furnace smelting and refining furnace smelting are adopted, wherein the superheat degree of a continuous casting furnace is controlled within 30 DEG C; deoxidation, desulfurization control and calcium treatment are performed; during continuous casting, low-superheat-degree constant-pulling-speed casting is adopted, the superheat degree of a tundish is controlled to be 10-25 DEG C, center segregation of a casting blank is controlled, and casting blank rolling is conducted, specifically, the heating rate of a cold-state 20Ni2MoA gear steel casting blank in the steel rolling procedure is controlled to be 3-5 DEG C / min; the preheating temperature is not higher than 840 DEG C, the soaking temperature is 1160-1200 DEG C, the finish rolling temperature is set to be 880 DEG C, the cooling rate is 8-10 DEG C / s, and the steel structure is granular bainite and a small amount of ferrite.

Owner:XINJIANG BAYI IRON & STEEL

Preparation of normalizing weldable fine grain steel plate with a yield strength of 420MPa

ActiveCN101413049BReduce intensityWarranty Strength RequirementsTemperature control deviceMetal rolling arrangementsMechanical propertyCooling temperature

The invention provides a method for preparing normalized weldable fine-grain steel plates with the yield strength of 420 MPa, which belongs to the technical field of manufacturing medium thick steel plates. A production process comprises the following steps: a continuous casting billet is heated to be between 1,200 and 1,250 DEG C, and the heat is preserved for 4 to 5 hours; hot rolling is performed after heat preservation; rolling is divided into two stages, namely recrystallization zone rolling and non-recrystallization zone rolling; intermediate temperature waiting thickness is controlled to be between 2.5 and 4.0 times the thickness of a finished product; the initial rolling temperature of a non-recrystallization zone is controlled between 850 and 880 DEG C; the final rolling temperature is controlled between 810 and 830 DEG C; water cooling is performed after hot rolling; the final cooling temperature is controlled between 650 and 740 DEG C, and cooling rate is controlled between5 and 8 DEG C per second; and the steel plates are normalized at a temperature between 880 and 910 DEG C and then are thermally insulated for 5 to 20 minutes. The method has the advantages that the steel plates are excellent in mechanical properties; the mechanical property of the steel plate can stably reach over 420 MPa; the tensile strength of the steel plates can stably reach over 550 MPa; and the V-type notched impact energy of the steel plates at 50 DEG C below zero can stably reach over 140 J.

Owner:SHOUGANG CORPORATION

Water quenching lining plate and preparation method and application thereof

ActiveCN113564452AImprove wear resistanceHigh strengthCoke quenchingEnergy inputWear resistanceToughness

The invention relates to the technical field of quenching lining plates, in particular to a water quenching lining plate and a preparation method and application thereof. The water quenching lining plate provided by the invention is prepared from the following chemical components in percentages by mass: 2.7-3.1% of C, 2.2-3.4% of Cr, 0.6-0.9% of Ni, 1.7-3.0% of Si, 0.6-1.7% of Mn, 0.3-0.6% of Mo, 0.1-0.15% of Re, 0.05-0.08% of Sb, smaller than or equal to 0.02% of P, smaller than or equal to 0.02% of S and the balance of Fe and other inevitable impurities. According to the water quenching lining plate provided by the invention, the low-Cr and low-C design thought is adopted, meanwhile, a specific amount of Re and Sb are added into the alloy material, the Re and Sb are matched with each other for grain refining and precipitation strengthening, so that the hardness, toughness, high-temperature wear resistance and other performance of the lining plate can be improved through the synergistic effect of the Re and Sb and other alloy components, and the production cost can be greatly reduced.

Owner:山西滨腾机械有限公司 +1

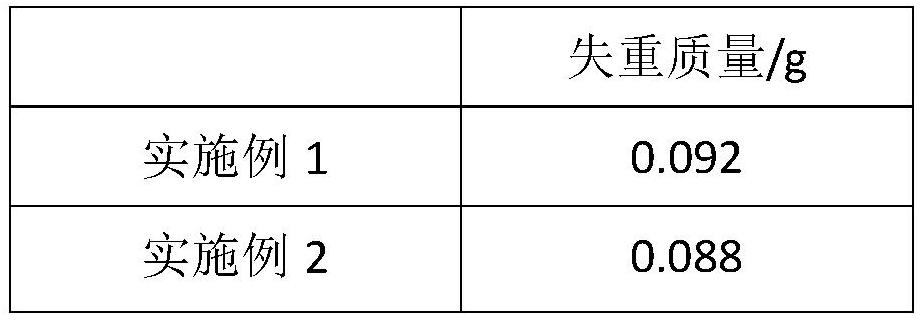

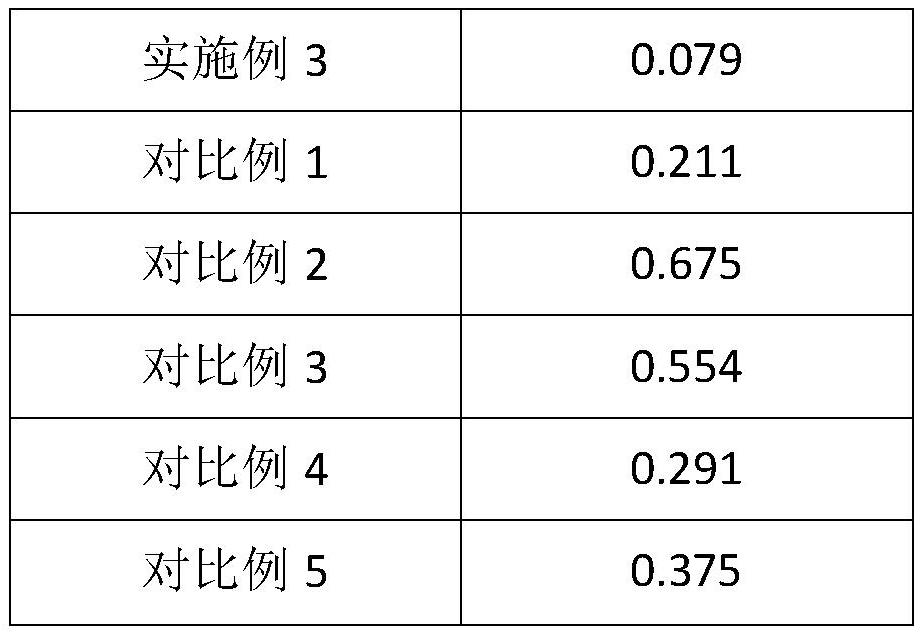

Copper-nickel-free acid-resistant pipeline steel x52ms and its hot-rolled coil manufacturing method

The invention relates to non-copper and nickel acid resistant pipeline steel X52MS. The non-copper and nickel acid resistant pipeline steel X52MS comprises the following components in percentage by weight: 0.02-0.06 wt% of C, 0.05-0.35 wt% of Si, 1.0-1.4 wt% of Mn, P not greater than 0.018 wt%, S not greater than 0.003 wt%, 0.10-0.50 wt% of Cr, 0.05-0.10 wt% of Ti, 0.005-0.10 wt% of Nb, 0-0.05 wt% of V, and the balance of Fe and inevitable trace impurities. The invention further provides a preparation method of a hot-rolled plate coil of the non-copper and nickel acid resistant pipeline steel X52MS. Part of all Cr is used for replacing original Ni / Cu elements, so that the material cost is largely reduced under the precondition of guaranteeing the material HIC resistance.

Owner:SHOUGANG CORPORATION

Non-quenched and tempered steel for crankshaft, crankshaft forging and its preparation process

ActiveCN110578096BIncreased ferrite contentAvoid Centrifugal Balance BurdenCrankshaftsRotary machine partsBrinellingCrankshaft

The application provides a non-quenched and tempered steel for a crankshaft, a crankshaft forging and a preparation process thereof, which belong to the technical field of non-quenched and tempered steel. Non-quenched and tempered steel by weight percentage: C 0.36‑0.39%, Si 0.50‑0.65%, Mn 1.35‑1.50%, P 0‑0.030%, S 0.040‑0.055%, Cr 0‑0.25%, Mo 0‑0.20 %, Al 0‑0.03%, N 0.010‑0.020%, carbon equivalent Ceq=0.75‑0.81%. The hardenability of non-quenched and tempered steel is: J5mm 47‑52HRC, J9mm 35‑42HRC, J13mm 30‑36HRC; tensile strength ≥ 760MPa; elongation A ≥ 14%; band structure ≤ 2.0; Brinell hardness is 220‑250HBW, suitable for making crankshaft forgings.

Owner:SGIS SONGSHAN CO LTD

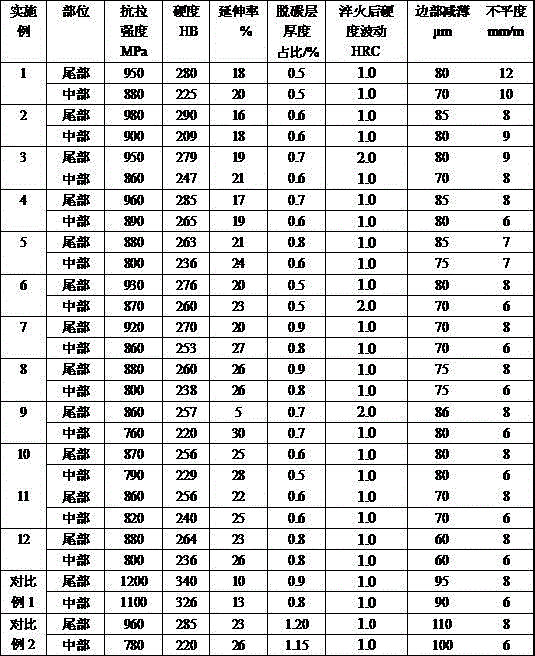

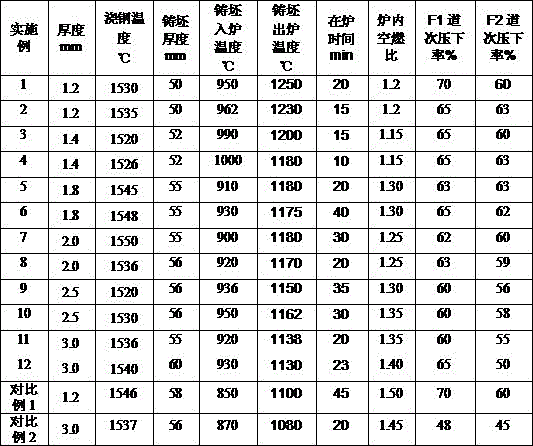

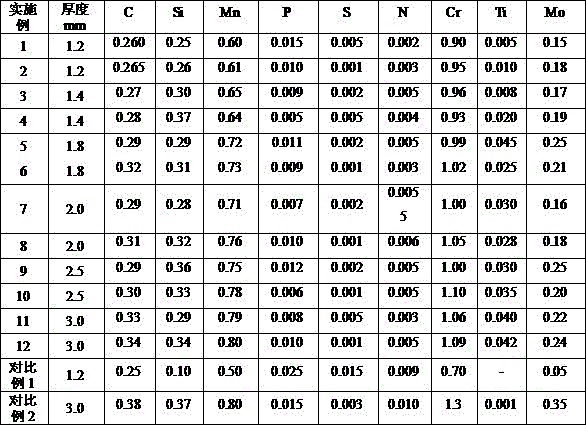

Steel for hot-rolled ultra-thin laser welding saw blade substrate and production method

The invention discloses steel for hot-rolling an ultra-thin laser welding saw blade base. The steel comprises the following components in percentage by weight: 0.26-0.34% of C, 0.25-0.37% of Si, 0.40-0.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, less than or equal to 0.006% of N, 0.80-1.10% of Cr, 0.15-0.25% of Mo and 0.005-0.045% of Ti. Production comprises the following steps: smelting and continuously casting to prepare a blank, heating a cast blank, rolling, performing laminar cooling, coiling, slowly cooling a steel roll in a warehouse or insulating hood to be the room temperature, and finely settling. The tension strength of a steel plate is 600-900MPa, the ductility A is 15-28%, the hardness is 160-260HB, the tensile strength fluctuation between the head part and the middle part of the steel roll is smaller than 150MPa, the thickness of a single side decarburized layer is less than or equal to 1.1% of the thickness of the steel plate, the hardness fluctuation after quenching is less than 2HRC, the thickness reduction of an edge part is less than or equal to 100mu m, the unflatness is less than or equal to 12mm / m, the thickness of a product is 1.0-3.0mm, the effect of replacing cold rolling by hot rolling can be partially achieved, and the cost is lowered.

Owner:武汉钢铁有限公司

Non-oriented silicon steel and method for producing non-oriented silicon steel by thin slab continuous casting and rolling process

ActiveCN108374130BHigh magnetic inductionReduce iron lossMetal rolling arrangementsThin slabContinuous rolling

The invention discloses a non-oriented silicon steel and a thin slab continuous casting and rolling process to produce the non-oriented silicon steel, and relates to the non-oriented silicon steel and a production method thereof. The invention comprises the following steps: step A: smelting; step B: continuous casting; step C: heating; step D: hot continuous rolling; step E: pickling; step F: cold rolling; and step G: recrystallization annealing. The invention utilizes the thin slab continuous casting and rolling process to produce qualified high-grade non-oriented silicon steel.

Owner:INNER MONGOLIA UNIV OF TECH

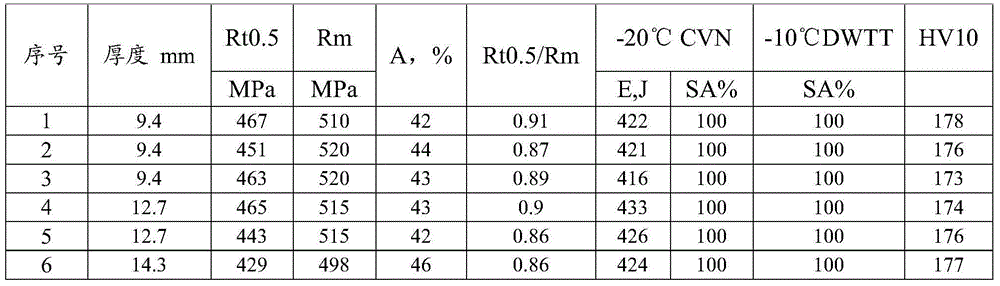

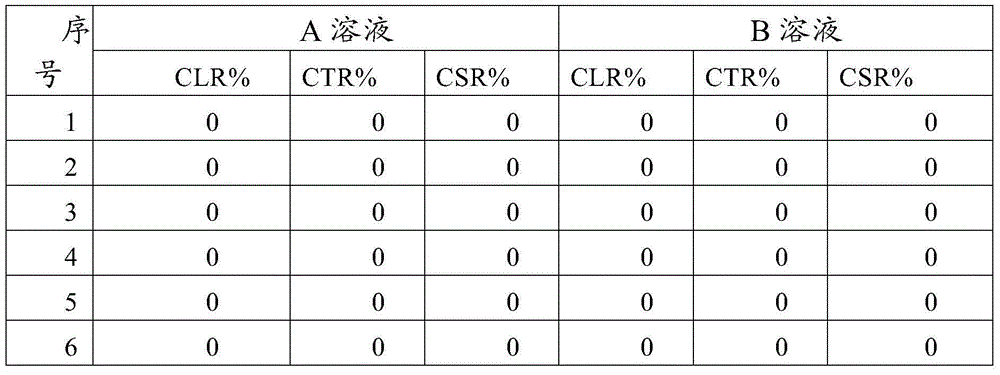

Method for producing X70 pipeline steel plate with ultrathin specification of 3-8mm and used under ultralow temperature condition by curling furnace

The invention relates to a method for producing an X70 pipeline steel plate with the ultrathin specification of 3-8 mm and used under the ultralow temperature condition by a curling furnace. The method comprises the steps of KR molten iron pretreatment, BOF smelting, LF refining, RH vacuum degassing, 150 mm-thick continuous casting billet continuous casting, continuous casting billet covering andslow cooling, continuous casting billet inspection and cleaning, casting billet heating, high-pressure water descaling, rolling, ACC cooling, straightening, steel plate shearing, inspection and warehousing, and the X70M pipeline steel plate with the ultrathin specification of 3-8 mm and used under the ultra-low temperature condition is manufactured. The yield strength of the steel plate is 500-630MPa, the tensile strength is 580-750 MPa, the elongation is larger than or equal to 30%, the yield ratio Rt0.5 / Rm is smaller than or equal to 0.90, and the product can meet the use requirements of X70M-grade pipeline steel under the ultralow temperature conditions that the Charpy impact energy at -80 DEG C is larger than or equal to 100 J and the drop-weight shearing area at -50 DEG C is larger than or equal to 95%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

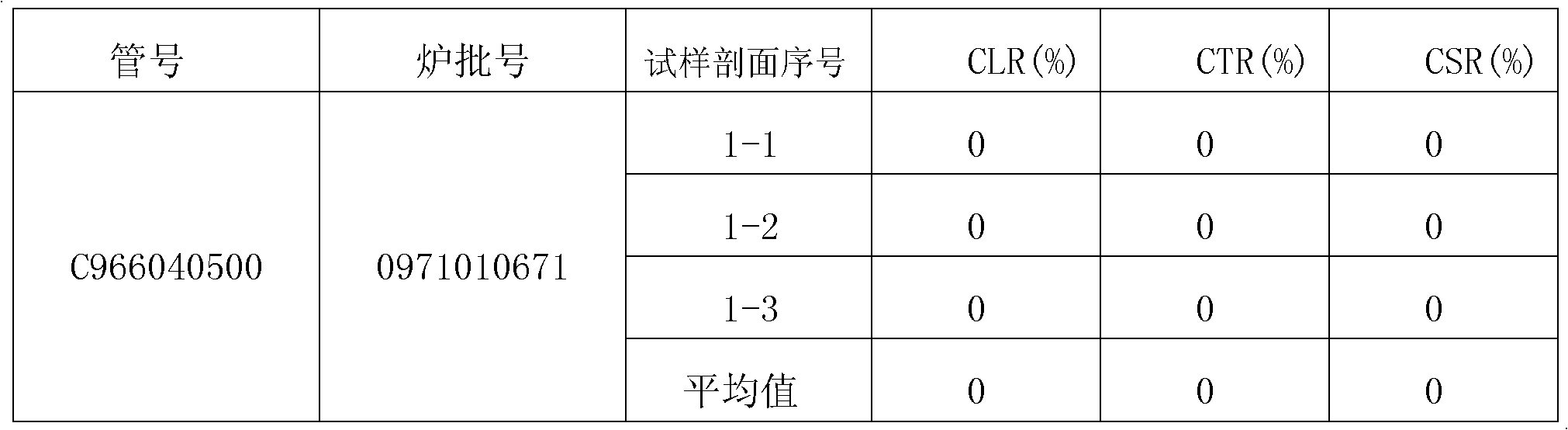

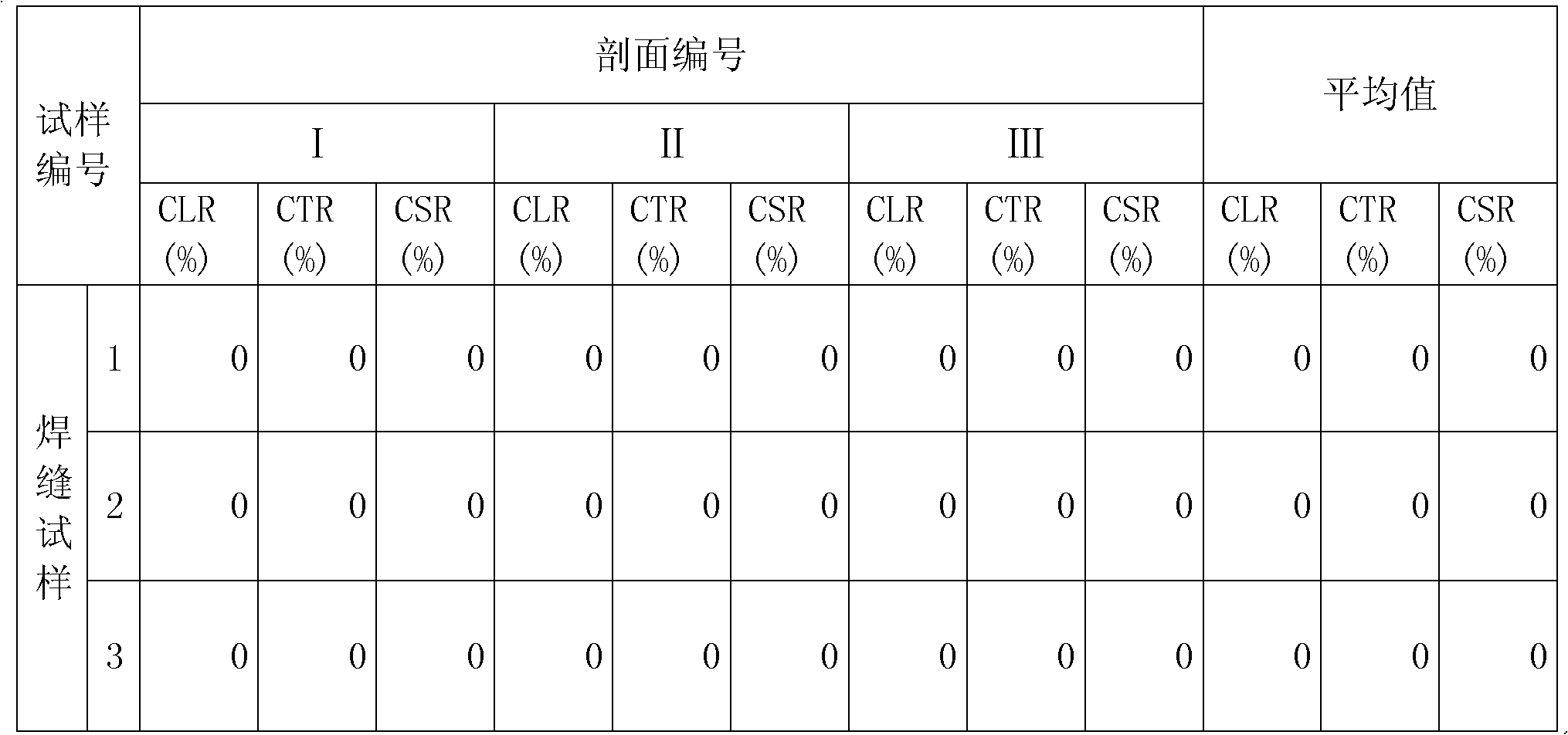

Method for manufacturing delivery steel pipe serving acid environment

InactiveCN102121081BGuaranteed corrosion resistanceFulfil requirementsHigh frequency current welding apparatusWelding/soldering/cutting articlesCrack resistanceIntermediate frequency

The invention discloses a method for manufacturing a delivery steel pipe serving an acid environment. The steel pipe comprises the following chemical components of raw materials in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 1.6 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.002 percent of S, less than or equal to 0.15 percent of Nb, V and Ti, less than or equal to 0.22 percent of Pcm, more than or equal to 1.5 percent of Ca / S and the balance of Fe. High frequency induction welding is adopted in welding of the steel pipe; the welding quality is improved in the welding process by increasing the welding extrusion quantity, controlling the open angle of seams and increasing welding protective gas; and on-line quenching and on-line tempering are performed in heat treatment of the seams by adopting six intermediate frequency heat treatment machines. By selection of raw material components and metallographic structures, completeness of a welding mechanism and improvement of the heat treatment process, the steel pipe has hydrogen induced cracking resistance and sulfide stress corrosion resistance and has high strength and high pressure resistance, the cost can be reduced, and the use of the steel pipe under the acid serving condition can be met.

Owner:CHINA NAT OFFSHORE OIL CORP +2

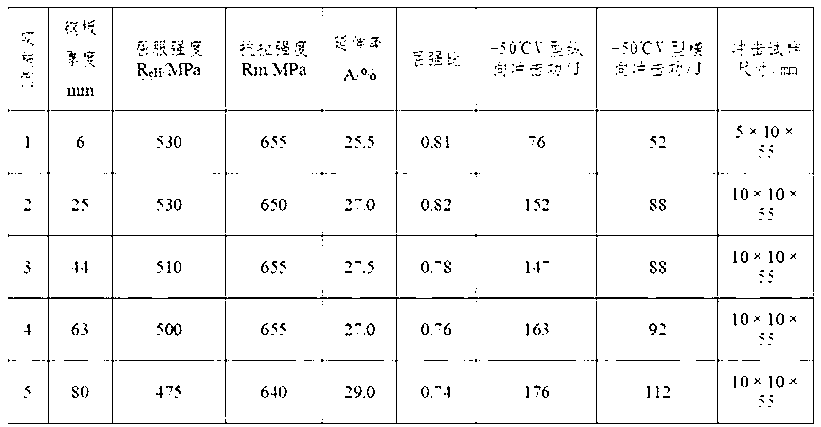

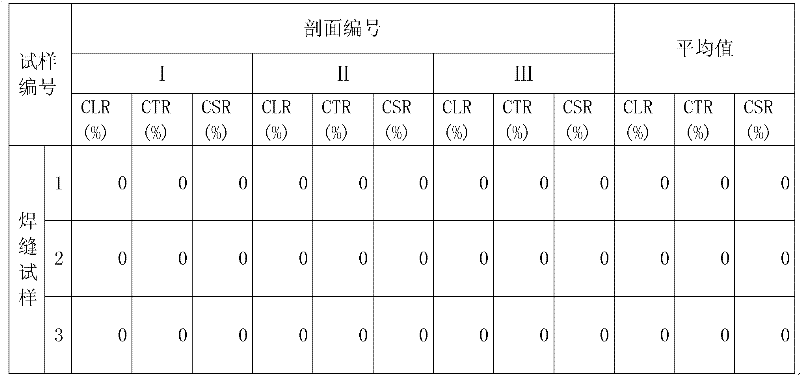

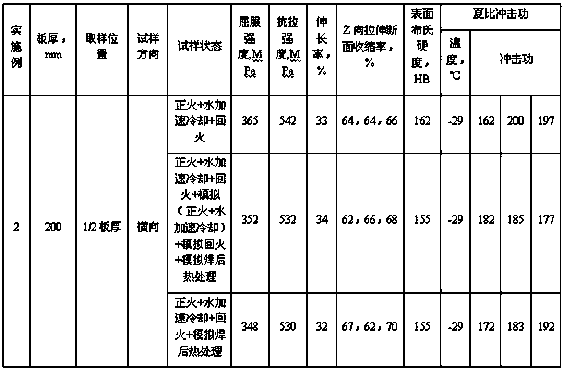

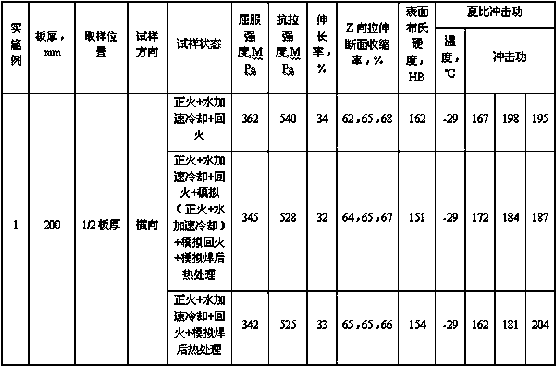

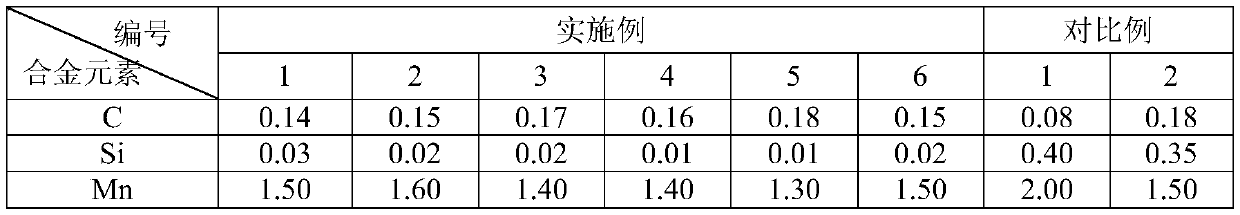

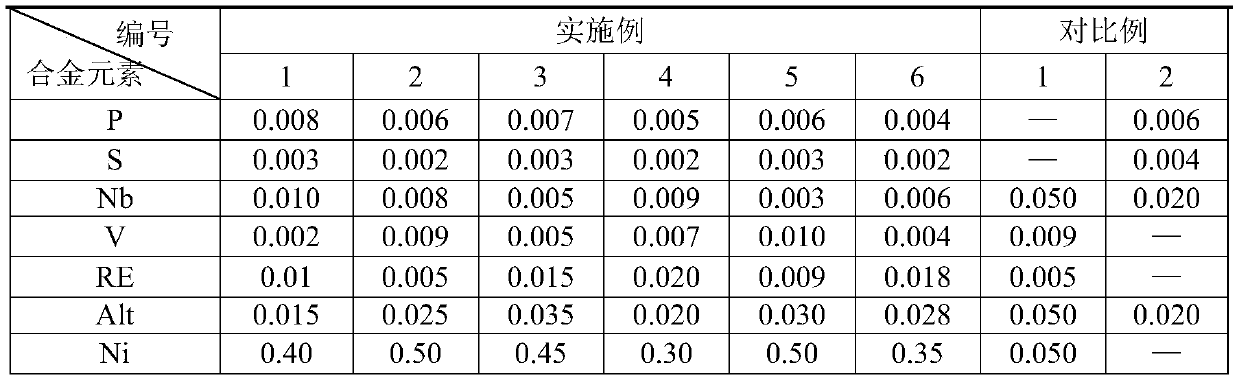

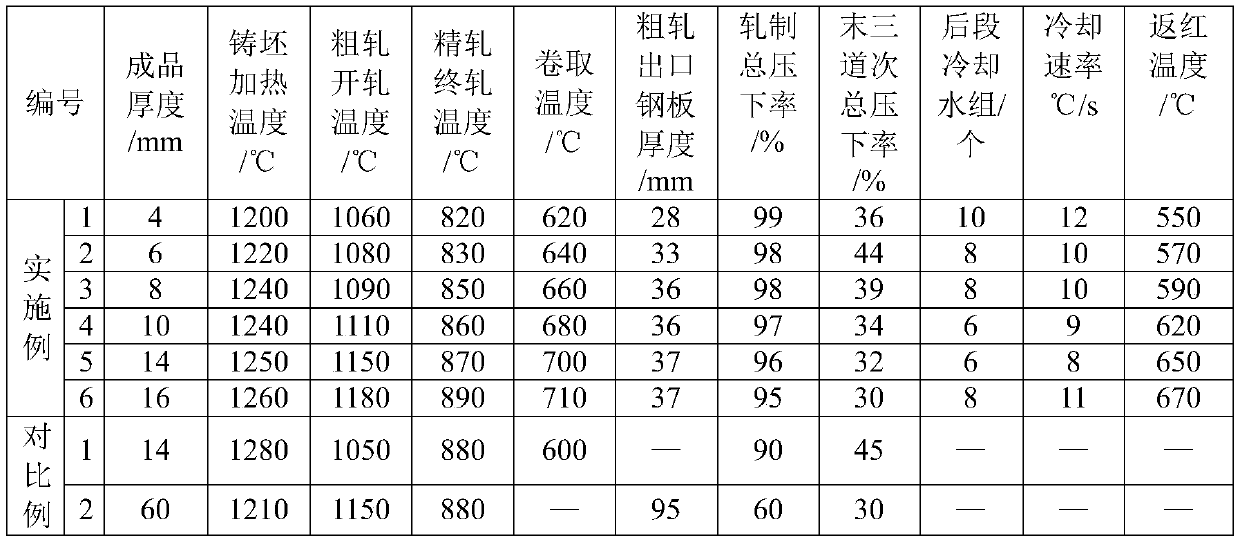

A 200mm thick hydrogen-induced cracking resistant pressure vessel steel plate and its manufacturing method

ActiveCN106086642BImprove mechanical propertiesExcellent resistance to hydrogen-induced crackingChemical compositionHydrogen

A 200 mm-thick pressure vessel steel plate resistant against hydrogen-induced cracking and manufacturing method thereof. The following lists the weight percentage of the chemical composition of the steel plate:0.15-0.20% of C, 0.20-0.40% of Si, 1.05-1.20% of Mn, ≤ 0.006% of P, ≤ 0.001% of S, 0.15-0.25% of Cr, 0.15-0.35% of Ni, ≤ 0.01% of Nb, ≤ 0.01% of V, ≤ 0.01% of Ti, ≤ 0.0005% of B, and a remainder of Fe and unavoidable impurities. An ingot mold casting process is used. The process comprises the steps: electric furnace → LF refining → VD refining → mold casting → steel ingot annealing → steel ingot heating → steel ingot rolling → steel plate annealing → defect detection → normalizing + water accelerated cooling → tempering → finishing → inspection → warehousing. The steel plate is provided with excellent mechanical performance and resistance against hydrogen-induced cracking. The strength and low temperature impact toughness of the steel plate are not significant reduced after a high temperature simulated post-weld heat treatment.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

A low yield ratio anti-sulfide stress corrosion 345mpa low temperature pressure vessel steel plate and its preparation method

The invention discloses a low-yield-ratio sulfide-stress-corrosion-resistant 345-MPa-grade steel plate for a low-temperature pressure vessel. The steel plate comprises the following chemical components in percentage by mass: no more than 0.20% of C, 0.01-0.10% of Si, 1.00-2.00% of Mn, no more than 0.008% of P, no more than 0.003% of S, no more than 0.01% of Nb, no more than 0.035% of Alt, no morethan 0.01% of V, no more than 0.02% of RE, 0.10-0.50% of Ni, and the balance Fe and inevitable impurities. The steel plate disclosed by the invention has the beneficial effects that by adoption of thecomposition design of low carbon, low silicon and micro-alloying elements as well as through a combination with the TMCP rolling process, the yield ratio of the steel plate is lower than or equal to0.65, the elongation reaches 35% or above, and the low-temperature impact toughness at negative 40 DEG C reaches 150 J; furthermore, the sulfide stress corrosion resistance, the weldability and the low welding crack sensitivity are higher; and the involved preparation process is simple, no heat treatment process is needed, and the steel plate is suitable for popularization and application.

Owner:武汉钢铁有限公司

Production process of small low-alloy Q355B angle steel

ActiveCN113930658AGood welding performanceLighten bandsMetal rolling arrangementsPearliteAlloy element

The invention discloses a production process of small-sized low-alloy Q355B angle steel. The chemical components of the Q355B angle steel are different from those of the high Mn design of traditional low-alloy Q355B angle steel. A single Ti microalloy element is added in the production process, the precipitation strengthening effect of Ti is utilized, the solution strengthening of Mn of the traditional Q355B angle steel is partially replaced, and the toughness is ensured in cooperation with a rolling process of low-temperature finish rolling. According to the low-alloy Q355B angle steel produced through the method, the thickness ranges from 6 mm to 10 mm, the yield strength ranges from 350 MPa to 460 MPa, the tensile strength ranges from 500 MPa to 600 MPa, the elongation ranges from 25% to 35%, and the impact energy at the temperature of 20 DEG C is larger than 50 J; and the metallographic structure of the steel is a polygonal ferrite and blocky pearlite structure, and the pearlite is uniformly distributed in a free state.

Owner:ANYANG IRON & STEEL

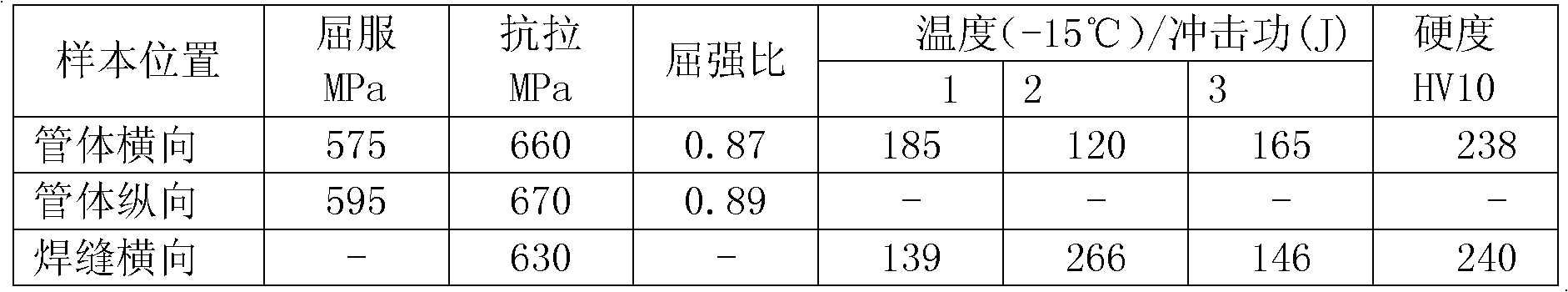

High-performance seamless pipeline tube and preparation method thereof

The invention discloses a high-performance seamless pipeline tube and a preparation method thereof. The pipeline tube comprises the following components in percentage by weight: larger than or equal to 0.13% and smaller than or equal to 0.16% of C, larger than or equal to 0.15% and smaller than or equal to 0.35% of Si, larger than or equal to 1.25% and smaller than or equal to 1.40% of Mn, smallerthan or equal to 0.005% of S, smaller than or equal to 0.01% of P, larger than or equal to 0.01% and smaller than or equal to 0.03% of Ti, larger than or equal to 0.02% and smaller than or equal to 0.04% of Nb, smaller than or equal to 0.08% of V, larger than or equal to 0.02% and smaller than or equal to 0.04% of Al, smaller than or equal to 0.006% of N, smaller than or equal to 0.1% of Cr, smaller than or equal to 0.08% of Ni, smaller than or equal to 0.08% of Cu, smaller than or equal to 0.01% of Mo, larger than or equal to 0.03% and smaller than or equal to 0.05% of Nb+V / 2, smaller than or equal to 0.01% of As+Sn, and the balance of Fe and inevitable impurities, wherein the carbon equivalent is smaller than or equal to 0.41%. Ti and Nb are added, V is selectively added for alloying, and the pipeline tube which is high in comprehensive performance and low in cost is successfully prepared.

Owner:DALIPAL PIPE

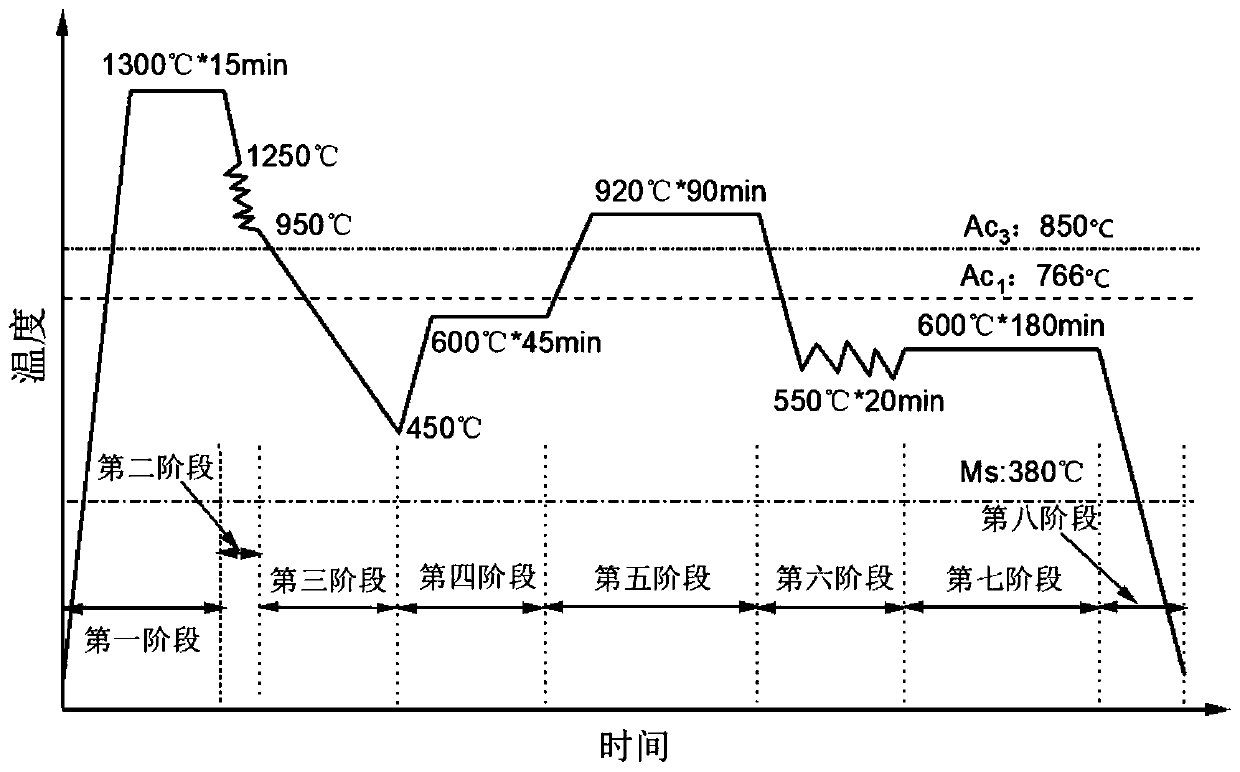

Isothermal normalizing heat treatment process

ActiveCN110343823ALighten bandsEasy to processFurnace typesHeat treatment furnacesAusteniteMechanical property

The invention discloses an isothermal normalizing heat treatment process. Through re-generating of austenite, the workpiece banded structure is reduced, the generated structure is more uniform, the machining property of the workpiece is improved, the workpiece mechanical property is improved, meanwhile, waste heat after rolling is used, electric energy is saved, and production cost is reduced.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH

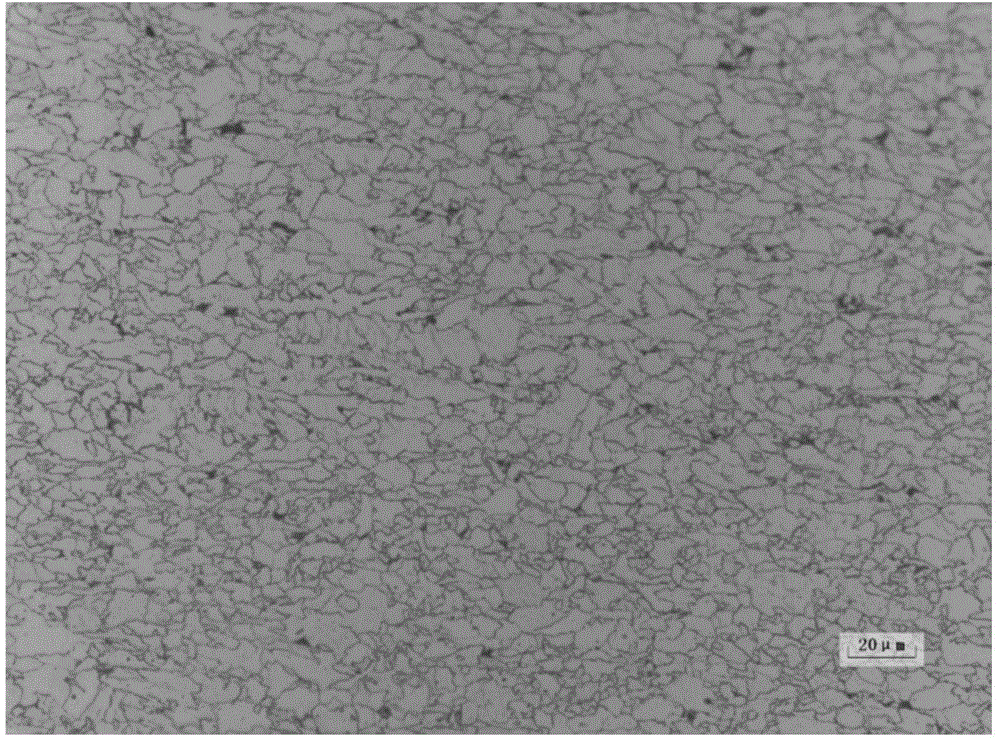

A method for producing 3-8mm ultra-thin specifications and x70 pipeline steel plates used under ultra-low temperature conditions by a coiling furnace

ActiveCN112322875BUniform internal organizationEasy to organizeHigh pressure waterUltimate tensile strength

The invention relates to a method for producing 3-8mm ultra-thin X70 pipeline steel plates used under ultra-low temperature conditions by a coiling furnace. The process flow: KR molten iron pretreatment—BOF smelting—LF refining—RH vacuum degassing—150mm thickness continuous casting slab continuous casting— Slow cooling of continuous casting slab with cover - continuous casting slab inspection and cleaning - casting slab heating - high pressure water descaling - rolling - ACC cooling - straightening - steel plate shearing - inspection and storage process steps, manufacturing 3‑8mm ultra-thin specifications and X70M pipeline steel plate used under ultra-low temperature conditions. The yield strength of the steel plate is 500-630MPa, the tensile strength is 580-750MPa, the elongation is ≥30%, and the yield ratio Rt 0.5 / Rm≤0.90, the product can meet the use requirements of X70M grade pipeline steel under the ultra-low temperature condition of -80°C Charpy impact energy ≥100J and -50°C drop hammer shear area ≥95%.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com