Production method of low-cost Q345q series bridge steel plate

A production method and low-cost technology, which can be used in the improvement of process efficiency, furnaces, heat treatment equipment, etc., and can solve the problems of complex process and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The raw molten iron was subjected to deep desulfurization of molten iron, top-bottom blowing in converter, argon blowing in ladle, LF refining, RH vacuum treatment and continuous casting process to obtain the chemical composition in Table 1. The slab thickness was 250mm, and the slab soaking section temperature was 1222°C. The heating time is 252min, the soaking time is 49min, the first stage rolling temperature is 1090℃, the second stage rolling temperature is 930℃, the thickness of the intermediate billet is 50mm, the thickness of the rolled piece is 10mm, the final rolling temperature is 785℃, and the air cooling method is adopted after rolling. After cooling, the test results of the mechanical properties of the steel plates are obtained in Table 2.

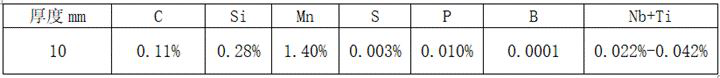

[0025] Table 1 Chemical composition of 10mm Q345qE steel plate

[0026]

[0027] Table 2 Mechanical properties of 10mm Q345qE steel plate

[0028]

Embodiment 2

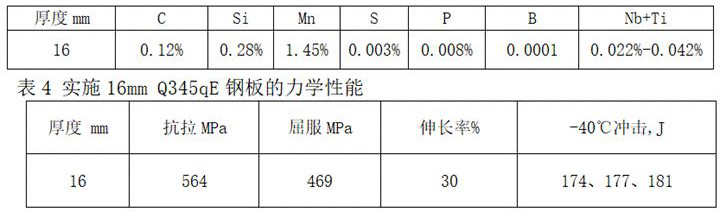

[0030]The implementation is the same as Example 1, the slab thickness is 250mm, the mass percentage of the slab chemical composition is shown in Table 3, the slab soaking section temperature is 1215°C, the heating time is 255min, the soaking time is 48min, the first stage rolling temperature is 1070°C, and the first stage rolling temperature is 1070°C. The starting rolling temperature of the second stage is 880℃, the thickness of the intermediate billet is 67mm, the thickness of the rolled piece is 16mm, and the final rolling temperature is 777℃. The temperature is 622°C. The test results of the mechanical properties of the obtained steel plates are shown in Table 3. The test results of the mechanical properties of the obtained steel plates are shown in Table 4.

[0031] Table 3 The chemical composition of the 16mm Q345qE steel plate

[0032]

Embodiment 3

[0034] The implementation is the same as Example 1, the slab thickness is 250mm, the mass percentage of the slab chemical composition is shown in Table 5, the slab soaking section temperature is 1235 ° C, the heating time is 257 min, the soaking time is 49 min, the first stage rolling temperature is 1095 ° C, and the first stage rolling temperature is 1095 ° C. The starting rolling temperature of the second stage is 880°C, the thickness of the intermediate billet is 91mm, the thickness of the rolled piece is 30mm, and the final rolling temperature is 786°C. After the rolling is completed, it is rapidly cooled by the ACC laminar cooling equipment. The temperature is 624°C. The test results of the mechanical properties of the obtained steel plates are shown in Table 6.

[0035] Table 5 The chemical composition of the 30mm Q345qE steel plate

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com