Round steel with low magnetic mark rate, crankshaft forging and manufacturing method thereof

A manufacturing method and technology of round steel, applied in the direction of crankshaft, etc., can solve the problems such as difficult control of non-quenched and tempered crankshaft magnetic marks, scrapped crankshaft, and reduced fatigue life of crankshaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0069] The composition of round steel with low magnetic trace rate is shown in Table 1.

[0070] The composition (weight / %) of the round steel of table 1 low magnetic trace rate

[0071] C Si mn P S Mo V Cr Al N Ceq Example 1 0.46 0.26 1.08 0.015 0.004 0.01 0.07 0.18 0.011 0.0124 0.87 Example 2 0.49 0.25 1.14 0.012 0.005 0.01 0.08 0.17 0.009 0.0118 0.92 Example 3 0.48 0.29 1.07 0.010 0.003 0.01 0.08 0.17 0.010 0.0133 0.90 Comparative example 1 0.51 0.26 1.18 0.016 0.003 0.01 0.07 0.18 0.012 0.0136 0.94 Comparative example 2 0.47 0.23 1.11 0.013 0.004 0.01 0.09 0.19 0.009 0.0127 0.91 Comparative example 3 0.46 0.28 1.09 0.009 0.002 0.01 0.08 0.20 0.013 0.0115 0.89

[0072]The main production process parameters of low magnetic trace rate round steel and crankshaft forgings are shown in Table 2,

[0073] Table 2 The main production process parameters of rou...

Embodiment 1

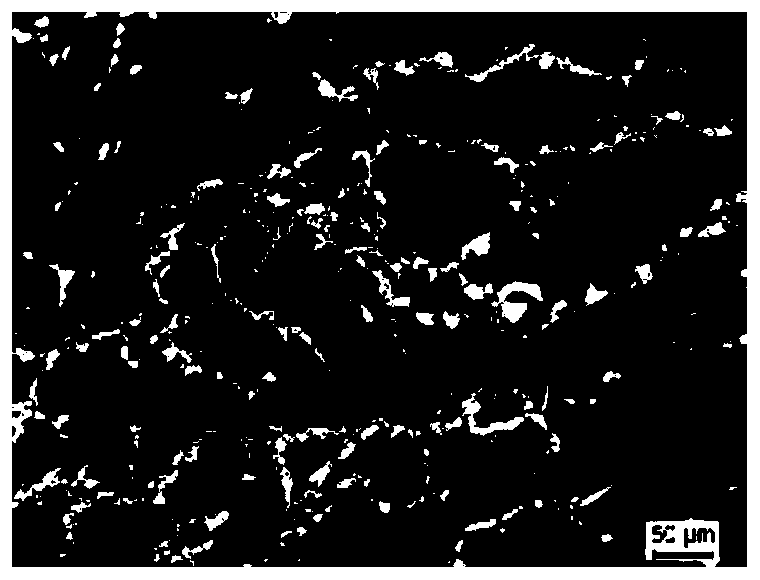

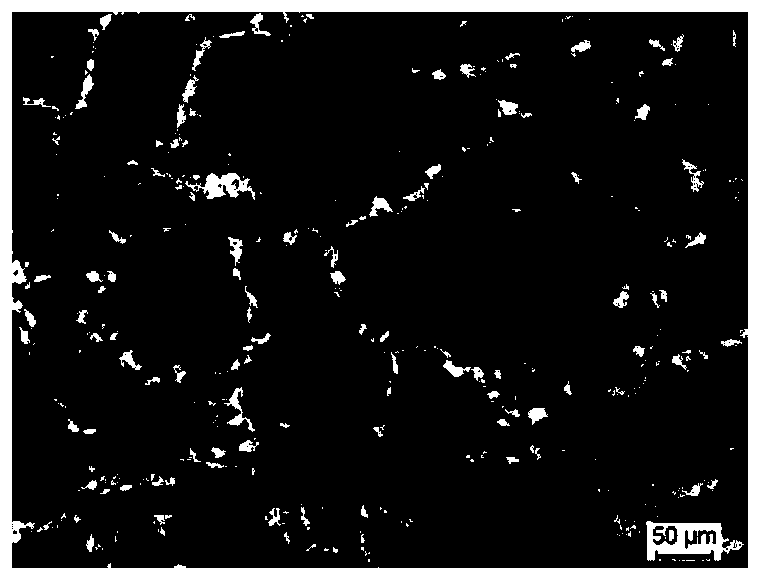

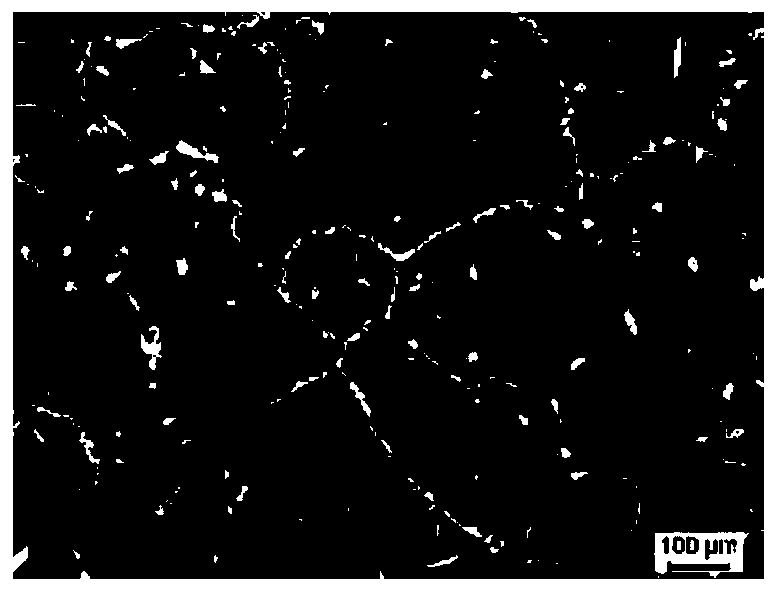

[0083] It can be seen from Example 1 that the composition of round steel satisfies C: 0.46-0.50%, Si: 0.20-0.30%, Mn: 1.05-1.15%, P≤0.020%, S≤0.035%, Cr≤0.25%, Mo≤ 0.05%, Al≤0.030%, V: 0.06-0.10%, N: 0.010-0.018%, Ceq: 0.87-0.92%; and the manufacturing method of the round steel satisfies the above conditions. The properties of the obtained round steel meet: tensile strength ≥ 850MPa, elongation A ≥ 17%, band structure ≤ 1.5, C segregation at the center of 4%, C segregation at the cross-section R / 2 of the round steel The value is 4.8%. Using it to prepare crankshaft forgings, the performance of the obtained crankshaft forgings meets: tensile strength ≥ 870MPa, elongation after forging ≥ 11%, metallographic structure includes ferrite and pearlite, does not contain bainite, and Brinell hardness is 240 -260HBW, magnetic trace rate is 1.1%.

[0084] As can be seen from Comparative Example 1, if the C content in the round steel is greater than 0.50%, the Mn content is greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com