A 200mm thick hydrogen-induced cracking resistant pressure vessel steel plate and its manufacturing method

A technology for anti-hydrogen cracking and pressure vessels, which is applied in the field of steel plate manufacturing, can solve problems such as not being able to meet the needs of large-scale, and achieve the effects of reducing banded structures, refining grains, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

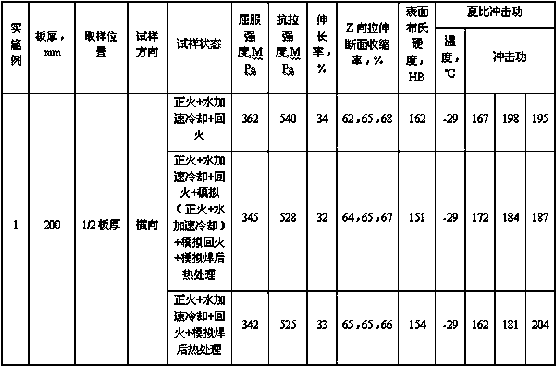

Embodiment 1

[0029]The thickness of the hydrogen-induced cracking-resistant pressure vessel steel plate in this embodiment is 200mm, and its chemical composition is calculated by weight percentage: C: 0.18%, Si: 0.30%, Mn: 1.17%, P: 0.003%, S: 0.0005%, H: 0.00006%, O: 0.0012%, N: 0.0040%, Cr: 0.20%, Ni: 0.25%, Nb: 0.005%, V: 0.003%, Ti: ≤0.002%, B: ≤0.0001%, and the balance is Fe and inevitable impurity elements.

[0030] The manufacturing process of the steel plate is as follows:

[0031] 1) Smelting process

[0032] The smelting raw materials are self-produced scrap steel and high-quality pig iron, and slag removal treatment is carried out after electric furnace smelting and LF smelting. Strictly control S≤0.001%, P≤0.006%, A, B, C, D and Ds non-metallic inclusions The individual items of the species are ≤ grade 1.0, and the sum of them is ≤ grade 3.5; low superheated argon gas protection is used for pouring, and the superheated degree of molten steel is 32°C during pouring. After the...

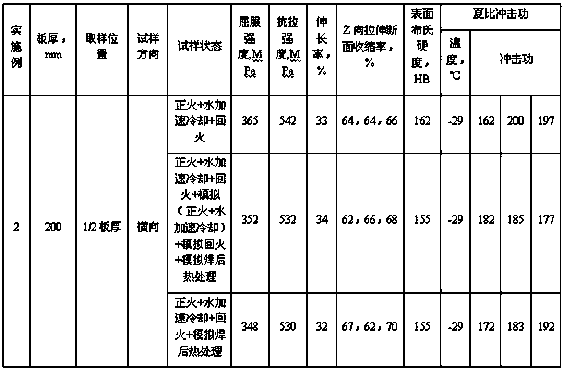

Embodiment 2

[0040] The thickness of the hydrogen-induced cracking-resistant pressure vessel steel plate in this embodiment is 200mm, and its chemical composition is calculated by weight percentage: C: 0.18%, Si: 0.28%, Mn: 1.18%, P: 0.004%, S: 0.0006%, H: 0.00006%, O: 0.0013%, N: 0.0042%, Cr: 0.21%, Ni: 0.28%, Nb: ≤0.006%, V: ≤0.004%, Ti: ≤0.003%, B: ≤0.0001%, remainder The amount is Fe and unavoidable impurity elements.

[0041] The manufacturing process of the steel plate is:

[0042] 1) Smelting process

[0043] The smelting raw materials are self-produced scrap steel and high-quality pig iron, and slag removal treatment is carried out after electric furnace smelting and LF smelting. Strictly control S≤0.001%, P≤0.006%, A, B, C, D and Ds non-metallic inclusions The individual items of the species are ≤ grade 1.0, and the sum of them is ≤ grade 3.5; low superheated argon gas protection is used for pouring, and the superheated degree of molten steel is 30°C during pouring. After the s...

Embodiment 3

[0051] The thickness of the hydrogen-induced cracking-resistant pressure vessel steel plate in this embodiment is 200mm, and its chemical composition is calculated by weight percentage: C: 0.18%, Si: 0.26%, Mn: 1.16%, P: 0.005%, S: 0.0007%, H: 0.00005%, O: 0.0010%, N: 0.0038%, Cr: 0.22%, Ni: 30%, Nb: ≤0.006%, V: ≤0.004%, Ti: ≤0.002%, B: ≤0.0003%, remainder The amount is Fe and unavoidable impurity elements.

[0052] The manufacturing process of the steel plate is as follows:

[0053] 1) Smelting process

[0054] The smelting raw materials are self-produced scrap steel and high-quality pig iron, and slag removal treatment is carried out after electric furnace smelting and LF smelting. Strictly control S≤0.001%, P≤0.006%, A, B, C, D and Ds non-metallic inclusions The individual items of the species are ≤ grade 1.0, and the sum of them is ≤ grade 3.5; low superheated argon gas protection is used for pouring, and the superheated degree of molten steel is 30°C during pouring. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com