Method for improving banded structure of 42CrMoA crankshaft

A banded structure and crankshaft technology, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as unqualified banded structures, and achieve the effect of reducing the level of banded structures and reducing banded structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A method for improving the belt-like structure of a 42CrMoA crankshaft, the specification of the crankshaft is φ290mm×5025mm, and the chemical composition mass percentages of the steel for the crankshaft are: C: 0.42%, Si: 0.25%, Mn: 0.75%, Ni : 0.33%, Cr: 1.13%, Mo: 0.22%, V: 0.08%, the balance is Fe and other inevitable impurities, and the ingot is cast in a vacuum refining mold.

[0018] The specific steps of this method are as follows:

[0019] Step 1), the hot ingot is opened and forged into an intermediate billet through a hydraulic press, and then the intermediate billet is returned to the furnace to heat 1250±10°C and kept for 15h. Drop to 950±10℃, return to the furnace for 2 hours, leave the furnace and let the material cool to 750-800℃, and send it to the precision forging machine for forging;

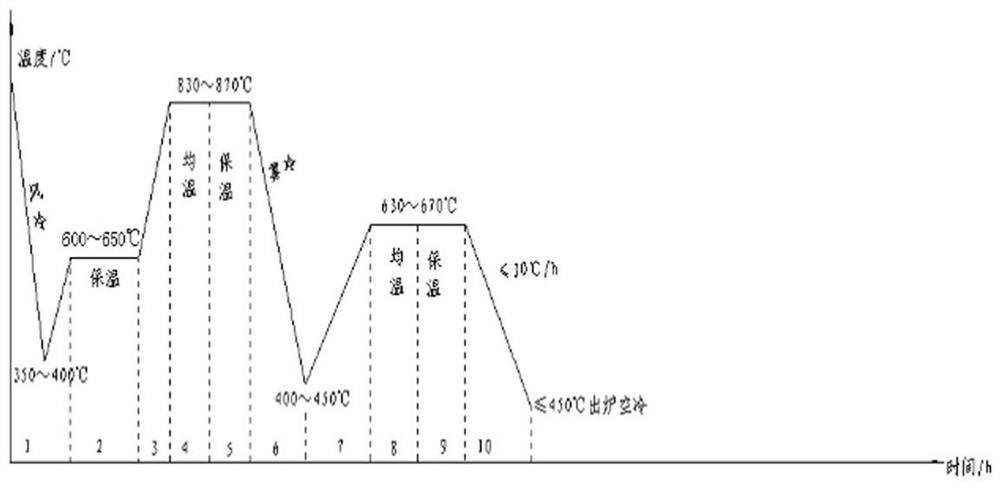

[0020] Step 2) After forging, air-cool the forgings to 350-400°C, heat up to 600-650°C with full power, keep for 3 hours, heat up to 860±10°C with full ...

Embodiment 2

[0023] Embodiment 2: A method for improving the banded structure of a 42CrMoA crankshaft, the specification of the crankshaft is φ345mm×5495mm, and the chemical composition mass percentages of the steel for the crankshaft are: C: 0.40%, Si: 0.26%, Mn: 0.71%, Ni : 0.35%, Cr: 1.13%, Mo: 0.22%, V: 0.09%, the balance is Fe and other inevitable impurities, and the ingot is cast in a vacuum refining mold.

[0024] The specific steps of this method are as follows:

[0025] Step 1), the hot ingot is opened and forged into an intermediate billet by a hydraulic press, and then the intermediate billet is returned to the furnace and heated at 1250±10°C for 15 hours. To 950±10℃, return to the furnace for 2 hours, leave the furnace and let the material cool to 750-800℃, and send it to the precision forging machine for forging;

[0026] Step 2) After forging, air-cool the forgings to 350-400°C, heat up to 600-650°C with full power, keep for 3.5h, heat up to 860±10°C with full power, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com