A low yield ratio anti-sulfide stress corrosion 345mpa low temperature pressure vessel steel plate and its preparation method

A technology of anti-sulfide and stress corrosion, which is applied in the field of pressure vessel steel manufacturing, can solve the problems of unsuitable use environment, poor impact toughness, poor elongation, etc., and achieve easy control of process parameters, low low temperature toughness, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

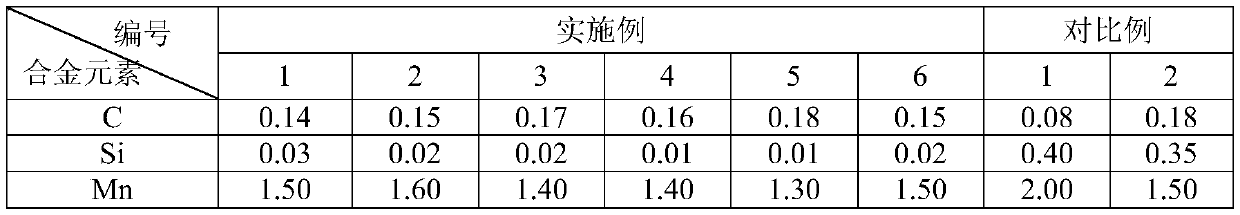

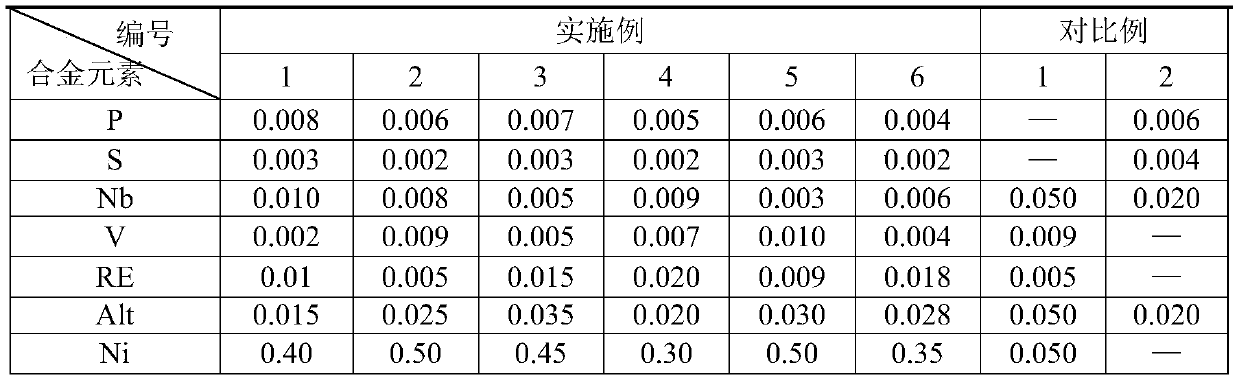

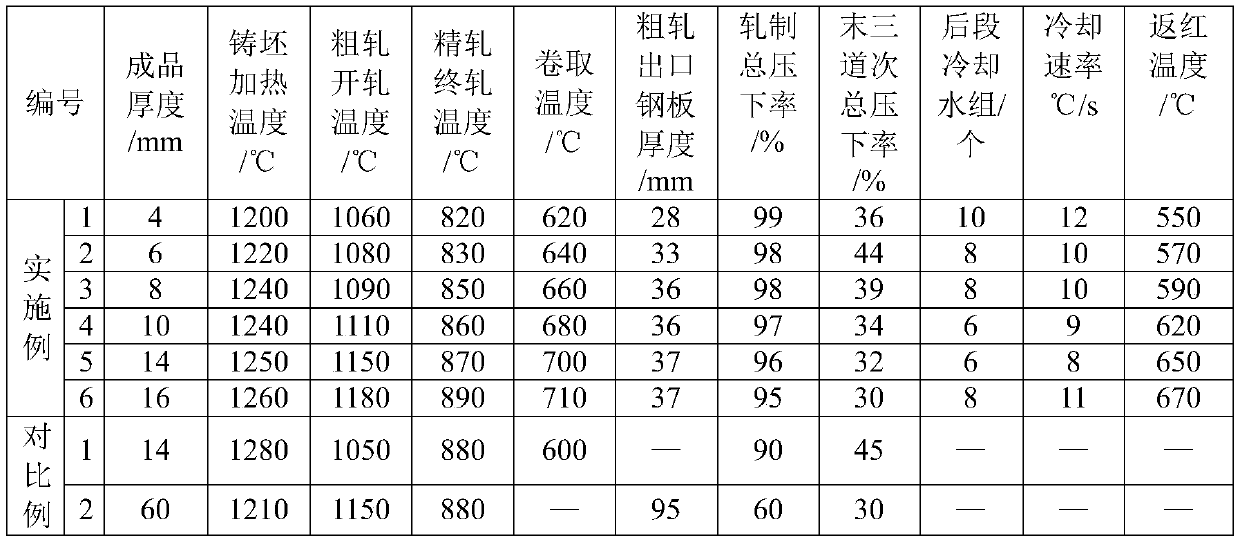

[0031] The chemical compositions of steel plates for low-temperature pressure vessels described in Examples 1 to 6 are shown in Table 1, and the process parameters are shown in Tables 2 and 3 respectively; the specific preparation method includes the following steps:

[0032] 1) Smelting; the temperature of the incoming molten iron is >1250°C, and the molten iron is pretreated, and the target value of the sulfur mass fraction in the molten iron is set not to exceed 0.005%; small-grain lime and high-quality fluorite are added in the process of converter tapping for pre-refining of tapping , followed by a one-time large amount of aluminum pre-deoxidation; the molten steel enters the LF furnace and stirs with argon gas at the bottom, and maintains a reducing atmosphere in the furnace; ferromanganese and ferrosilicon are deoxidized and alloyed, and need to be tapped at 1 Start adding at / 3, and finish adding before tapping 2 / 3; the tapping temperature is not lower than 1680°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com