Seamless steel tube for nuclear power and preparation method for seamless steel tube

A technology of seamless steel pipe and nuclear power, applied in the field of thick-walled seamless steel pipe for nuclear power and its preparation, to achieve the effects of reducing composition segregation, reducing band structure, and improving band structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a seamless steel pipe for nuclear power of the present invention comprises the following steps:

[0048] a. Smelting and casting: using scrap steel and sponge iron as raw materials, smelting, tapping, and continuous casting to obtain continuous casting slabs;

[0049] The invention adopts high-quality scrap steel and sponge iron as raw materials, can be smelted in an ultra-high-power electric arc furnace, and steel is tapped from the eccentric bottom of the furnace to ensure that the steel and slag are retained, and the steel is tapped without slag;

[0050] b. Hot-rolled tube: heat the continuous casting slab obtained in step a to 1260-1280°C and keep it warm for 6-7 hours; out of the furnace, when the temperature drops to 1210-1230°C, perforate the tube blank; roll the tube after perforation , the final rolling temperature is 860~900℃;

[0051] According to the specifications of the finished steel pipe, the tube blank of the corresponding speci...

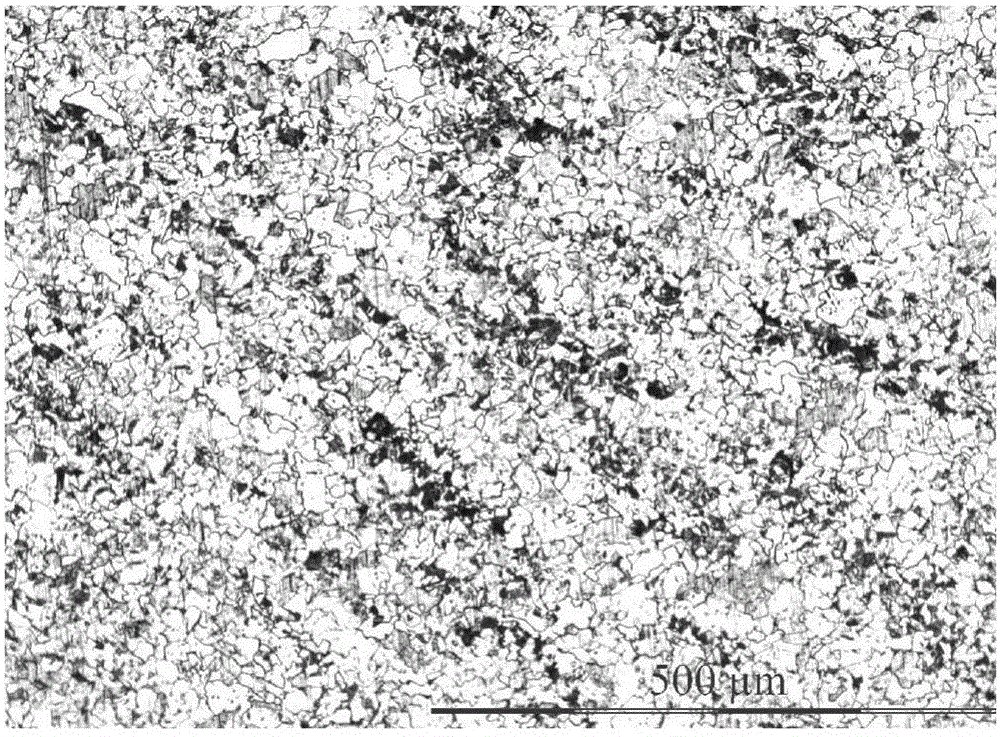

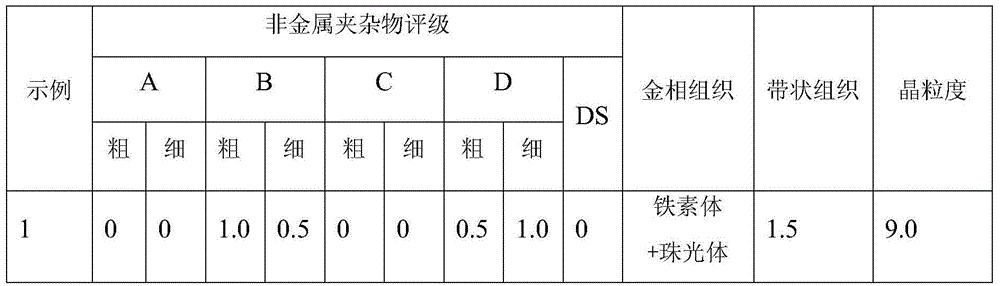

Embodiment 1

[0070] Production of Ф168.3×22 P280GH steel pipe

[0072] Using high-quality steel scrap + sponge iron as raw materials, using ultra-high-power electric arc furnace for melting, and tapping from the eccentric furnace bottom to ensure that the steel and slag are retained, and the steel is tapped without slag;

[0073] When refining, the ladle furnace is used to blow argon and stir throughout the process, and the molten steel is treated with vacuum degassing and silicon-aluminum wire feeding to ensure the stability and purity of the molten steel composition;

[0074] Electromagnetic stirring and soft reduction measures are adopted during continuous casting to control the pouring of molten steel at low superheat to reduce the component segregation of the tube billet;

[0075] Through smelting and continuous casting, a continuous casting slab of Ф280 was obtained. The chemical composition of the slab is shown in Table 1.

[0076] Table 1 Chemical c...

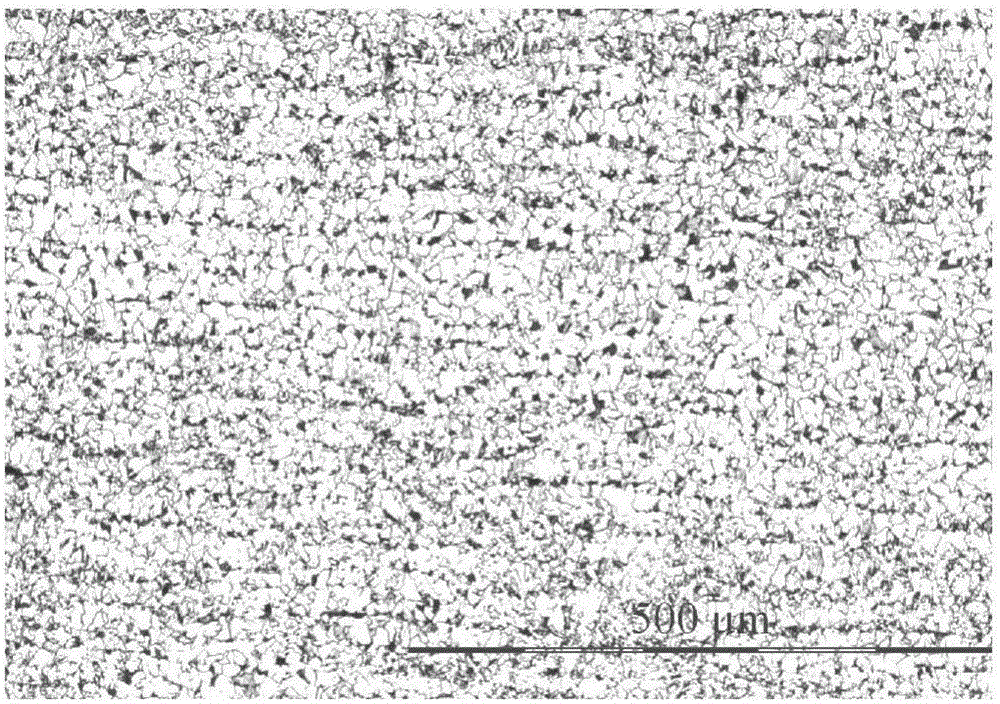

Embodiment 2

[0102] Production of Ф457×37 P280GH steel pipe

[0103] Smelting and casting:

[0104] Using high-quality steel scrap + sponge iron as raw materials, using ultra-high-power electric arc furnace for melting, and tapping from the eccentric furnace bottom to ensure that the steel and slag are retained, and the steel is tapped without slag;

[0105] When refining, the ladle furnace is used to blow argon and stir throughout the process, and the molten steel is treated with vacuum degassing and silicon-aluminum wire feeding to ensure the stability and purity of the molten steel composition;

[0106] Electromagnetic stirring and soft reduction measures are adopted during continuous casting to control the pouring of molten steel at low superheat to reduce the component segregation of the tube billet;

[0107] Through smelting and continuous casting, a continuous casting slab of Ф620 was obtained. The chemical composition of the slab is shown in Table 4.

[0108] Table 4 Chemical com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com