Cooling method of heavy and medium plate controlled rolling intermediate blank

A cooling method and controlled cooling technology, applied in the field of steel rolling production cooling, can solve the problems of large overall investment, complex equipment, high requirements on gas path cleanliness and pressure control range, etc., to reduce investment, simple equipment, and enhance cooling uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

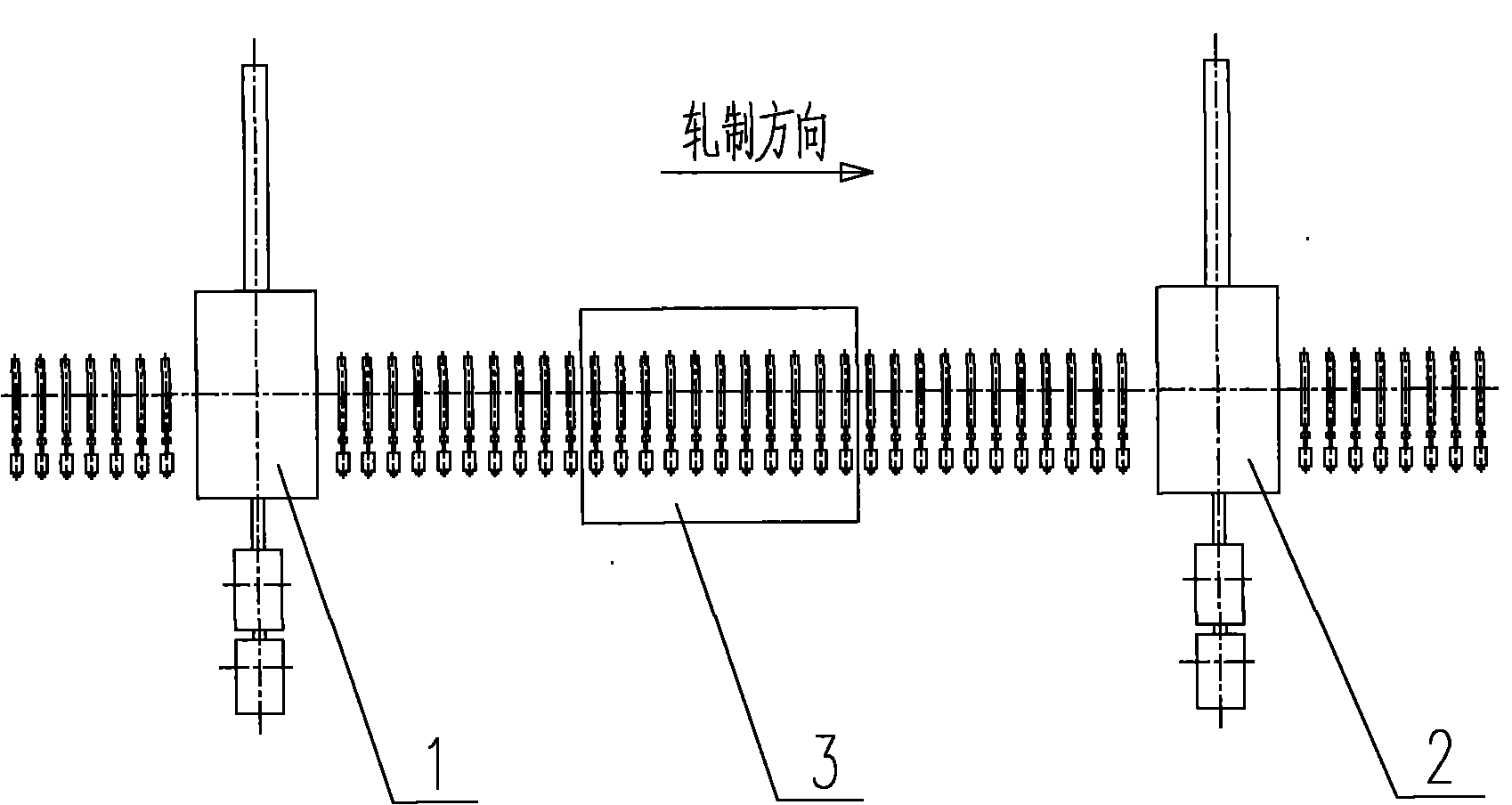

[0035] Embodiment one: to produce the container steel plate of 12mm thickness, adopt the attached figure 2 The intermediate billet controlled cooling technology arranged as an example to further describe its process method. The steel billet is heated to 1200°C, and the billet is sent to the rough rolling mill (1) by the conveying roller table for recrystallization rolling. The reduction is >50%. After the intermediate billet leaves the roughing mill, it enters the intermediate billet controlled cooling area (3) by the transfer roller table, and is rapidly cooled to the non-recrystallized area. The speed is controlled at 1°C / s and cooled to 800°C. The specific process parameters are all precisely controlled by the computer. The intermediate cooling water adopts the rolling mill cooling water in the public water circulation system of the workshop, and the water supply pressure is 0.4MPa. The intermediate slab after controlled cooling is directly entered into the finish rolli...

Embodiment 2

[0036] Embodiment two: to produce the X80 pipeline steel of 14.7mm thickness, adopt the attached figure 2 The intermediate billet controlled cooling technology arranged as an example to further describe its process method. The steel billet is heated to 1200°C, and the billet is sent to the rough rolling mill (1) by the transfer roller table for high-temperature recrystallization rolling. The termination temperature of the high-temperature recrystallization rolling is controlled at 1100°C, and rolled into an intermediate billet with a thickness of 50mm. The cumulative reduction in the recrystallization zone is >50%. After the intermediate billet exits the rough rolling mill, it enters the intermediate billet controlled cooling area (3) by the transfer roller table, and is rapidly cooled to the non-recrystallization temperature area. Water cooling, the cooling speed is controlled at 5°C / s, and the temperature is cooled to 900°C. The specific process parameters are all precisel...

Embodiment 3

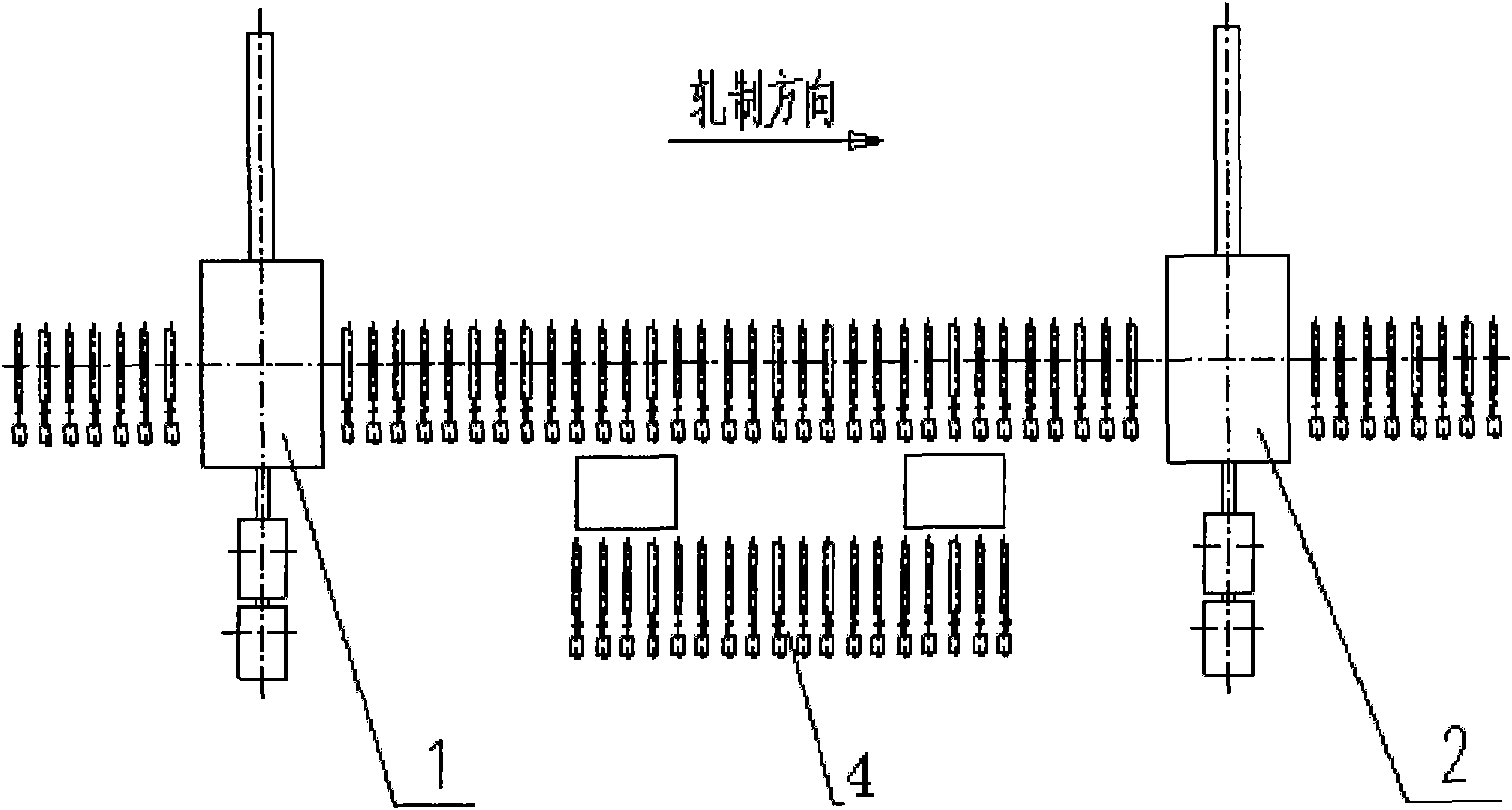

[0037] Embodiment three: take the DH36 ship plate steel of producing 50mm thickness as example, adopt the attached Figure 5Arranged intermediate billets control cooling technology. Send the heated billet into the rolling mill (1) for rolling in the recrystallization zone of the rough rolling stage. The termination temperature of the rough rolling stage is 1180° C., and the steel billet is rolled into an intermediate billet with a thickness of 110 mm in the rough rolling stage. The intermediate billet then enters the rolling mill from the transfer roller table (1) to the intermediate billet controlled cooling area in front of the mill (2) After the rapid cooling rate is controlled at 10°C / s, it is rapidly cooled to 950°C, and the intermediate cooling process adopts a pressure of 0.4-1.0MPa The cooling water of the rolling mill, as well as the impact jet water cooling method of the upper and lower headers with high-density and super-density nozzles, and the process parameters a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com