Cold-rolled steel sheet with tensile strength larger than 900 MPa and manufacturing method thereof

A technology of tensile strength and cold-rolled steel plate, applied in the direction of temperature control, etc., can solve the problems of uniformity of performance and unfavorable cold bending performance, unsatisfactory performance of delayed cracking resistance, unsatisfactory longitudinal bending performance, etc., to avoid hydrogen Gathering at the tip of micro-cracks, improving adverse effects, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with embodiments.

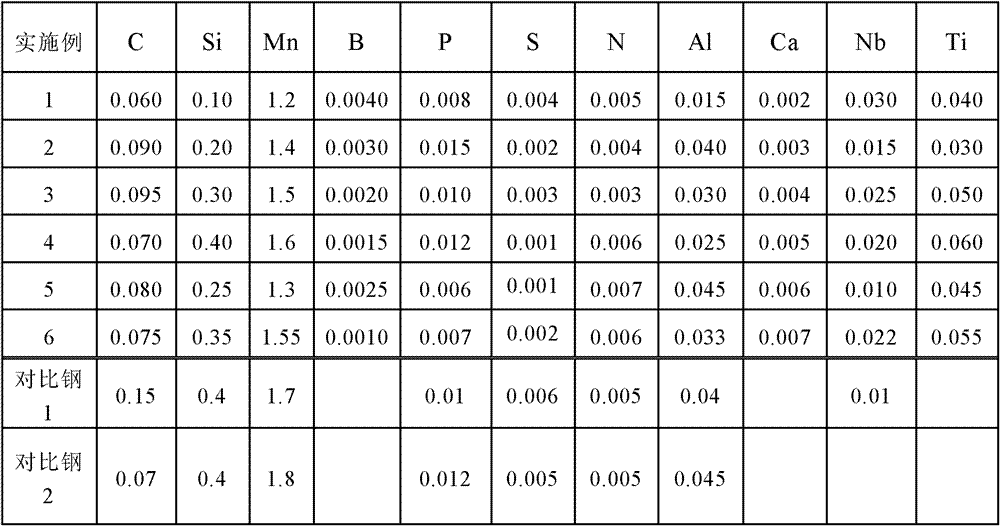

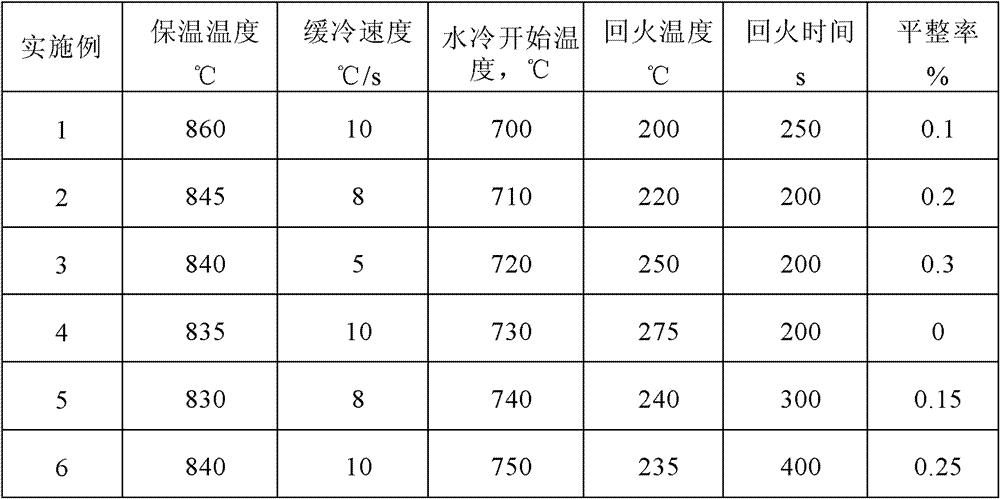

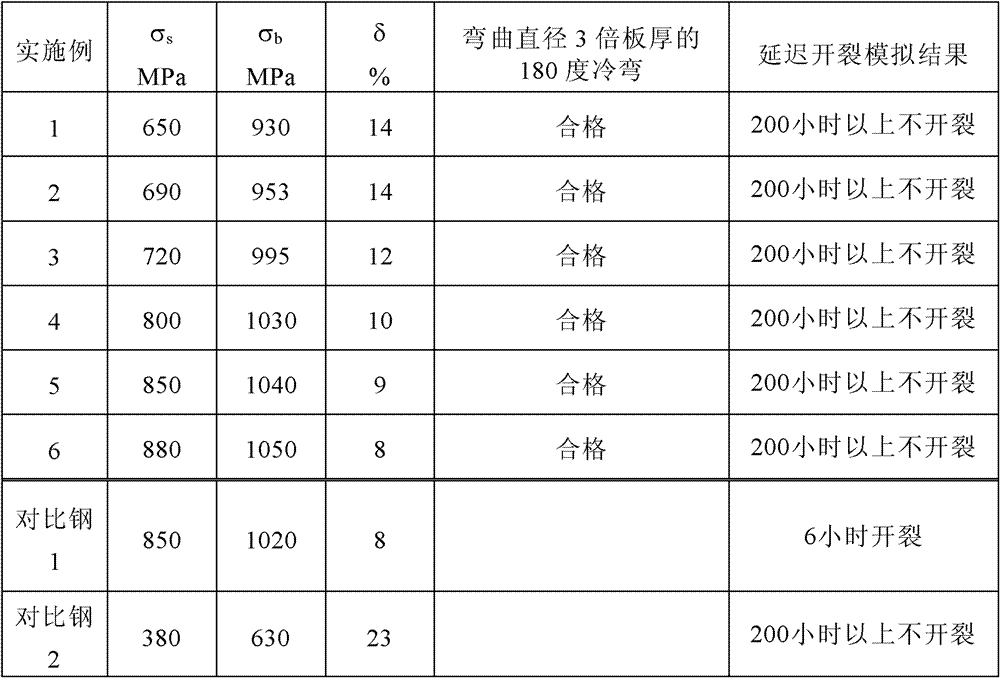

[0052] Table 1 shows the chemical composition of the steel examples of the present invention. Table 2 shows the technology of the steel of the invention. Table 3 shows the performance strength obtained after smelting, hot rolling, cold rolling, annealing and flattening of the steel of the present invention. It can be seen from Table 3 that according to the present invention, high-strength dual-phase steel with a strength of 900 MPa or more can be manufactured, and its cold bending performance is good. U bend is used to test its delayed cracking characteristics. A rectangular specimen with a sample size of 150mm×20mm has a U-bend diameter of 80mm. The specimen is bent into a U shape and fixed with bolts. Prepare a 5% HCl solution, immerse the sample in the solution at room temperature, and record the crack initiation time and breaking time of the sample.

[0053] Comparative steel 1 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com