Method for reducing center segregation of small high-carbon steel billet

A billet and high-carbon steel technology, which is applied in the field of reducing central segregation of high-carbon steel billet, can solve the problems of weakening the electromagnetic stirring at the end to eliminate segregation, limited improvement of central segregation, and unstable position of solidification end, etc., to achieve Avoid the secondary melting of equiaxed grains, enhance the effect, and reduce the effect of element segregation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

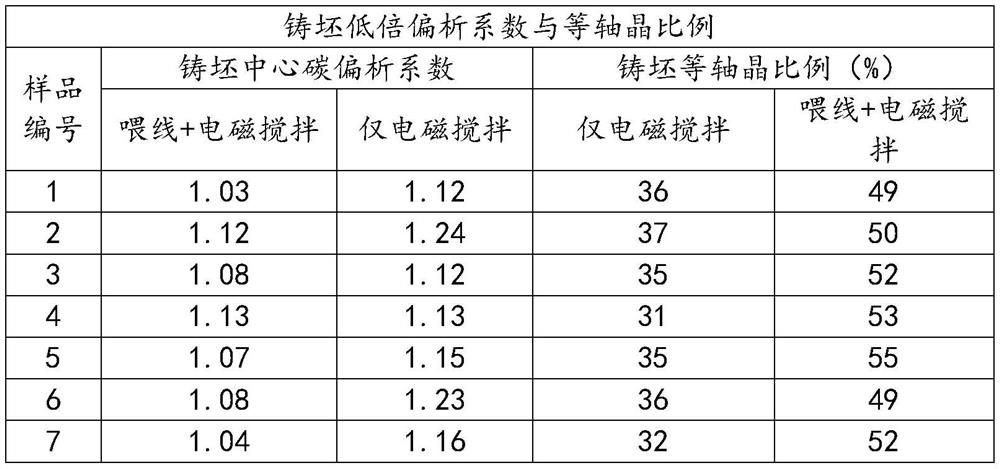

[0031] A method for alleviating central segregation of a high-carbon steel billet, in which the degree of central segregation of a high-carbon billet is reduced by simultaneously adopting electromagnetic stirring and crystallizer wire feeding technology in the continuous casting process, comprising the following steps:

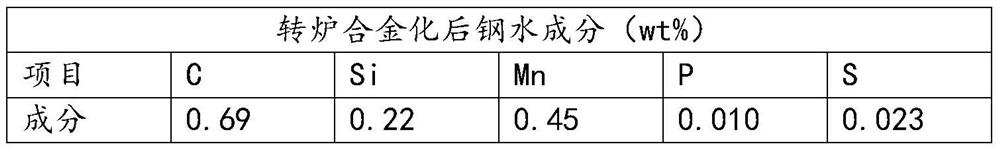

[0032] 1) After the converter smelting is completed, most of the alloys are added into the ladle along with the steel flow during the tapping process to complete the preliminary deoxidation alloying, and the composition after the converter alloying is shown in Table 1.

[0033]

[0034] Table 1

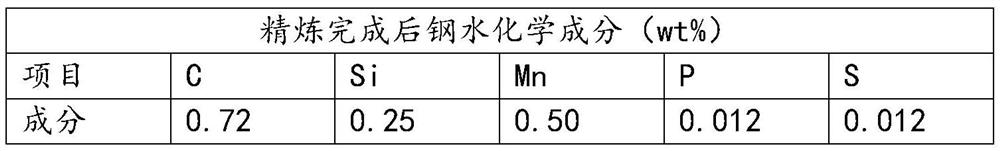

[0035] 2) Converter alloyed molten steel is transported to LF refining treatment at one point. During LF refining treatment, rapid slagging and further deoxidation and alloying are carried out. The exit temperature is 1580°C, and the composition of molten steel after refining is shown in Table 2.

[0036]

[0037] Table 2

[0038] 3) After refining, the molten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com