Multipoint filling method of mine goaf full tailings

A goaf and full tailings technology, which is applied in the direction of filling materials, separation methods, chemical instruments and methods, etc., can solve the problem of inability to accurately know the internal structure of the goaf, the impact of the goaf on the filling effect, and poor filling and cementation quality and other problems, to achieve the effect of improving the dehydration effect, improving the filling effect, and reducing the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

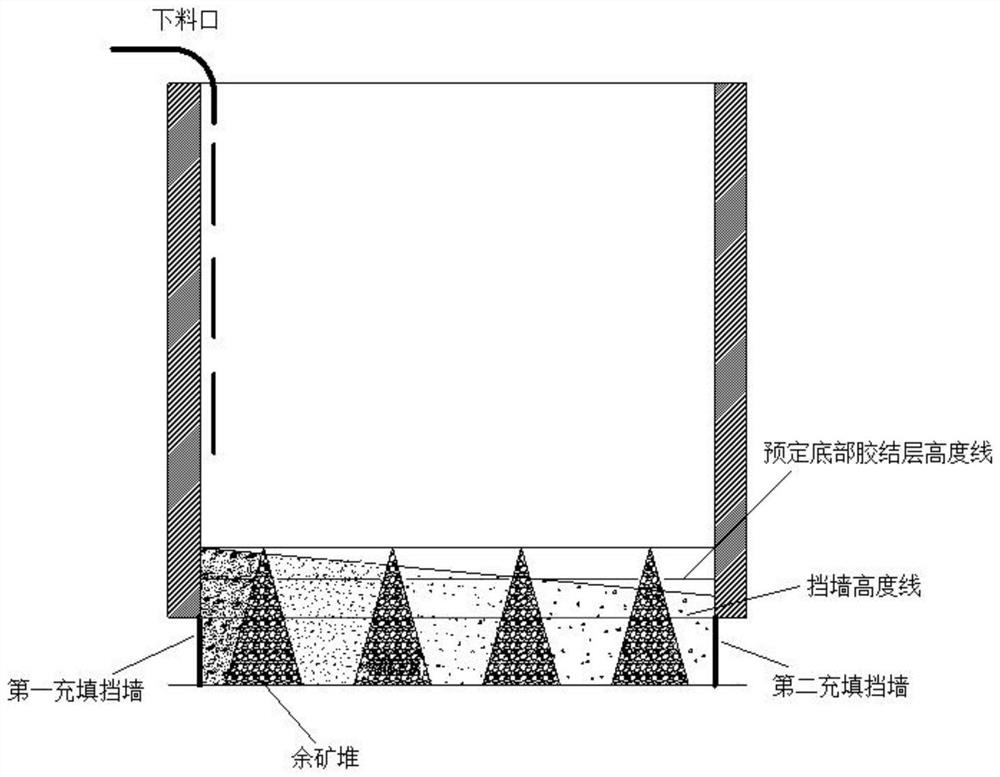

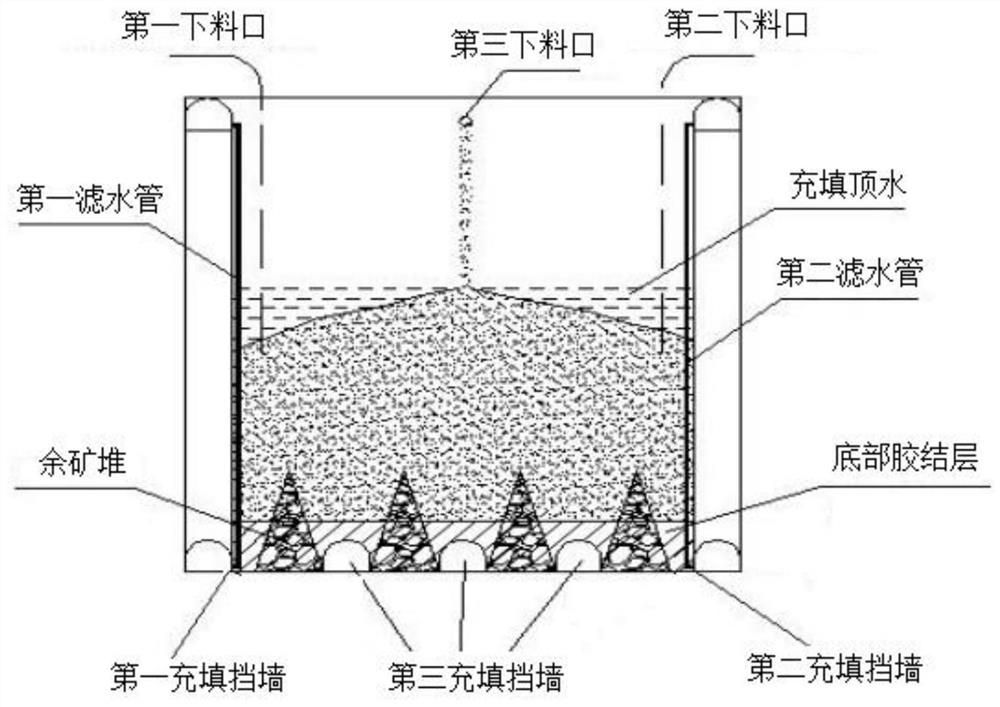

[0045] This embodiment specifically carries out the filling experiment in Huibaoling Iron Mine, wherein the height of the mine room is 70m, the length of the mine room is 60m, and the width of the mine room is the thickness of the ore body (5-30m); Multiple remaining ore heaps (10-20m in height) are formed in the goaf.

[0046] The method for filling the above-mentioned mined-out area includes the following steps:

[0047] Use a 3D laser scanner to scan the goaf (such as image 3 shown), to obtain the goaf volume and the scanning model of the internal structure of the goaf (such as Figure 4 shown);

[0048] Based on the length direction of the mine house, a first filling retaining wall and a second filling retaining wall are respectively set at both ends of the bottom of the mine house, and a third filling retaining wall is set at each outlet of the mine house to close the goaf area, wherein the first filling retaining wall, the second filling retaining wall and the third ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com