Titanium alloy ingot and preparation method thereof

A technology of titanium alloy and ingot casting, which is applied in the field of titanium alloy ingot casting and its preparation, to achieve the effect of reducing the depth of shrinkage cavity, reducing the depth of molten pool and improving the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] An embodiment of the present invention provides a method for preparing a titanium alloy ingot, comprising the following steps:

[0030] The non-finished titanium alloy ingots containing easily segregated elements are used as consumable electrodes, and vacuum consumable arc smelting is used to smelt the finished product. The finished smelting includes a stable smelting stage and a feeding stage in sequence; the smelting current in the feeding stage is step-by-step and the decreasing rate of smelting current at all levels is (0.02~0.5)KA / min→(0.02~0.2)KA / min→(0.2~2)KA / min→(0.02~0.2)KA / min.

[0031] Among them, the unit KA / min is kiloampere per minute, which refers to the value of current reduction per minute.

[0032] Among them, the segregation-prone elements include at least one of Cu, Fe, Cr, Mo, and Nb.

[0033] The technical personnel of the present invention have found through a lot of research that the rapid current drop in the early stage of the feeding stage is ...

Embodiment 1

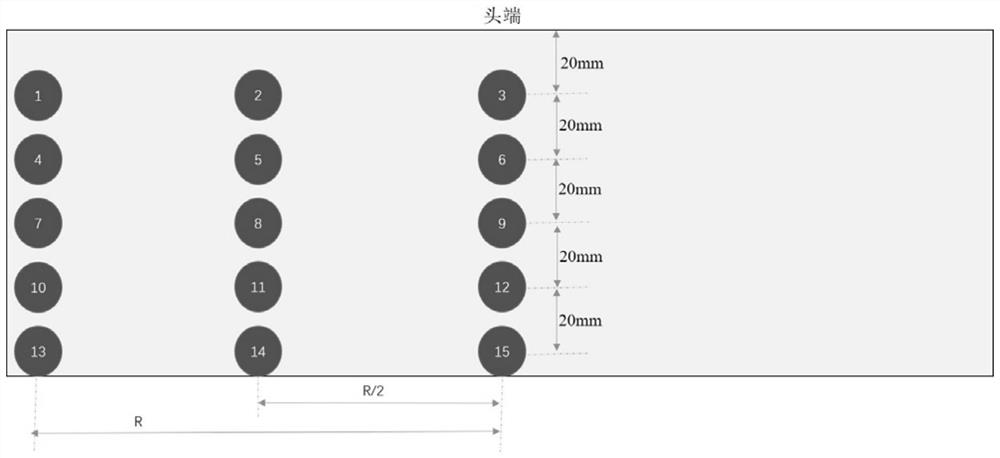

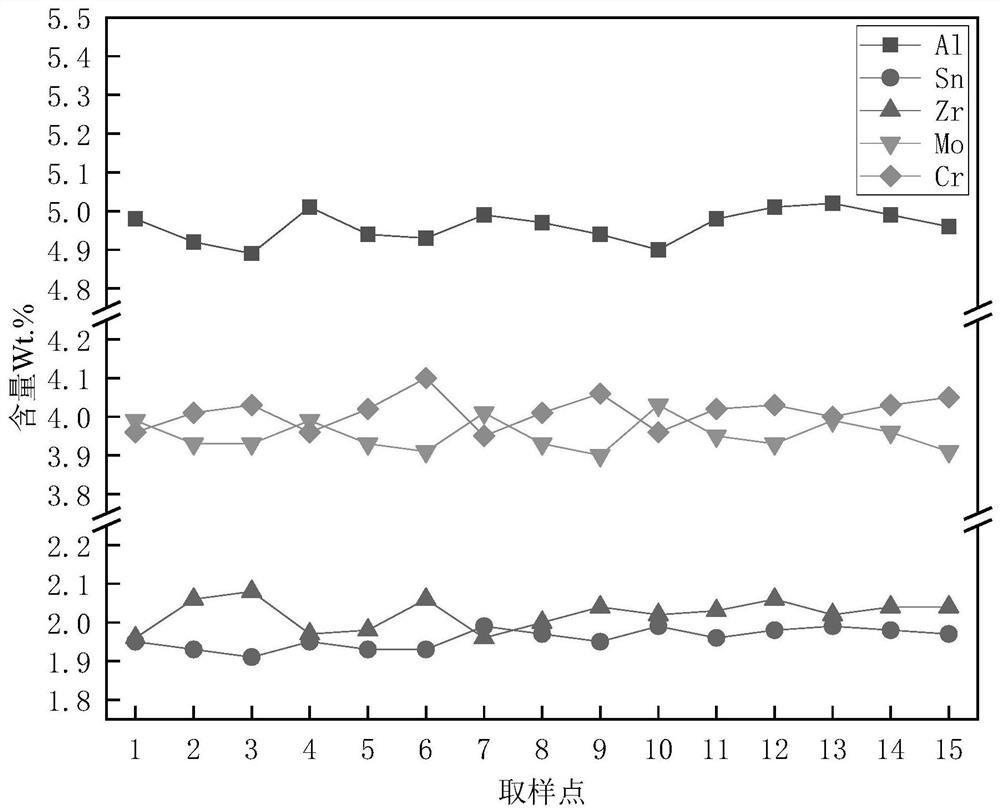

[0059] 1) A preparation process of a Φ680mm specification TC17 (nominal composition Ti-5Al-2Sn-2Zr-4Mo-4Cr) titanium alloy ingot:

[0060] According to the required elements and proportions of TC17 alloy, the selected raw materials are mixed evenly, and then pressed into a TC17 electrode block with a size of Φ420×200mm on a hydraulic press. The pressed electrode block is combined into an electrode with a size of Φ420×4800mm, and then protected by argon gas. It is welded into a consumable electrode for smelting in the plasma welding box. The welding electrode is smelted twice by vacuum consumable arc, the vacuum degree is controlled below 10.0Pa in the first and second vacuum consumable arc smelting, the stable smelting current of the first smelting is 13KA, and the smelting voltage is 32V , the stable arc current is 10A; the second smelting stable smelting current is 21KA, the smelting voltage is 35V, the arc stabilizing current is 12A, the cooling time after smelting is not l...

Embodiment 2

[0070] 1) A preparation process of a Φ680mm specification TB6 (nominal composition Ti-10V-2Fe-3Al) titanium alloy ingot:

[0071] According to the required elements and proportions of the TB6 alloy, the selected raw materials are mixed uniformly and then pressed on a hydraulic press to form TB6 electrode blocks with a size of Φ420×200mm, and the pressed electrode blocks are combined into electrodes with a size of Φ420×4800mm. It is welded into a consumable electrode for smelting in the plasma welding box. The welding electrode is smelted twice by vacuum consumable arc, the vacuum degree is controlled below 10.0Pa in the first and second vacuum consumable arc smelting, the stable smelting current of the first smelting is 13KA, and the smelting voltage is 32V , the stable arc current is 10A; the second smelting stable smelting current is 19KA, the smelting voltage is 34V, the arc stabilizing current is 12A, and the cooling time after smelting is not less than 4 hours to obtain Φ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com