7050 alloy ingot casting material and preparation method thereof

An alloy ingot and alloy material technology, which is applied in the field of 7050 alloy material and ingot preparation, can solve the problems of low production efficiency, difficult casting of 7050, and high casting cost of large-size slabs, so as to reduce costs and reduce defective rates. , cooling effect uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

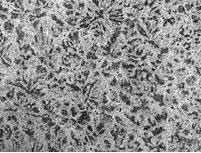

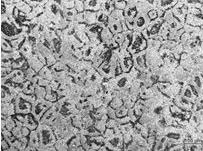

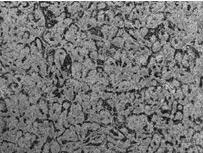

Image

Examples

Embodiment 1

[0051] A low-cost large-scale 7050 alloy material, its chemical elements and their mass percentages are as follows:

[0052] Si ≤ 0.12wt%, Fe ≤ 0.15wt%, Cu 2.0wt% ~ 2.6wt%, Mn ≤ 0.10wt%, Mg 1.9wt% ~ 2.6wt%, Cr ≤ 0.04wt%, Zn 5.7wt% ~ 6.7 wt%, Ti≤0.06wt%, Zr0.09wt%~0.14wt%, Be 0.0005~0.02%, the balance is aluminum and unavoidable impurities.

[0053] Concrete material preparation method comprises the following steps:

[0054] Step 1, batching; use 99.7% and 99.85% aluminum ingots, zinc ingots, metal magnesium ingots, aluminum-zirconium alloys, and titanium agents, and determine the above-mentioned feeding amount according to the internal control chemical composition and the specifications and quantities of the ingots, at 0.25kg / ton Aluminum is added to aluminum beryllium alloy.

[0055] Step 2, smelting: After completing the above calculation steps, add aluminum ingots and titanium agents to the smelting furnace, wait until the metal is completely melted, and when the metal te...

Embodiment 2

[0067] A low-cost large-scale 7050 alloy material, its chemical elements and their mass percentages are as follows:

[0068] Si ≤ 0.12wt%, Fe ≤ 0.15wt%, Cu 2.0wt% ~ 2.6wt%, Mn ≤ 0.10wt%, Mg 1.9wt% ~ 2.6wt%, Cr ≤ 0.04wt%, Zn 5.7wt% ~ 6.7 wt%, Ti≤0.06wt%, Zr0.09wt%~0.14wt%, Be 0.0005~0.02%, the balance is aluminum and unavoidable impurities.

[0069] Ingredients: use 99.7% and 99.85% aluminum ingots, zinc ingots, metal magnesium ingots, aluminum-zirconium alloys, and titanium agents. The above-mentioned feeding amount is determined according to the internal control chemical composition and the specifications and quantities of ingots. Add aluminum at 0.25kg / ton Aluminum beryllium alloy.

[0070] Melting: After completing the above calculation steps, add aluminum ingots and titanium agents to the melting furnace, and start slag removal when the metal is completely melted and the metal temperature reaches 740-760°C, then add zinc ingots, metal magnesium ingots, and aluminum-zircon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com