High-toughness normalizing steel plate with 460MPa yield strength and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of medium-thick steel plate manufacturing, can solve the problems of long process flow, performance fluctuation, high production cost, etc., and achieve the goals of reducing segregation band and band structure, high weldability and eliminating internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

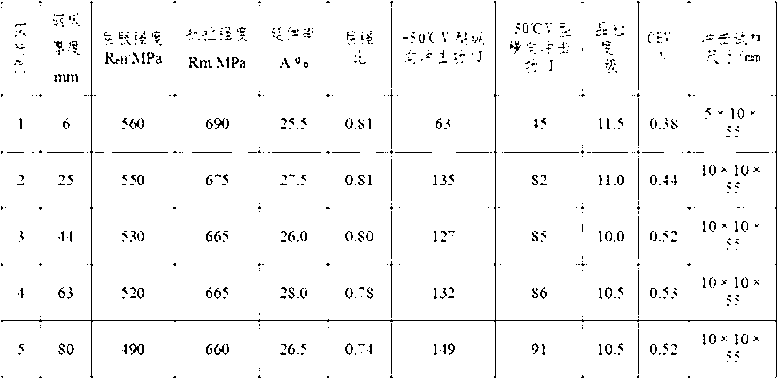

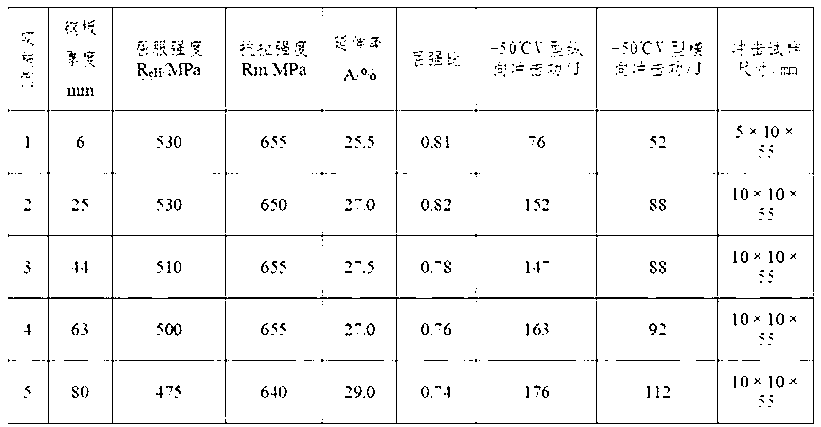

Embodiment 1

[0023] The normalized weldable fine-grained high-strength and tough steel plate with a yield strength of 460 MPa in this example is composed of the following components by weight percentage: C: 0.14%, Si: 0.60%, Mn: 1.20%, V: 0.12%, Ni : 0.15%, N: 0.005%, Alt: 0.015%, P: 0.010%, S: 0.005%, the rest is iron Fe and unavoidable impurities, and the grain size is 11.5. The thickness of the steel plate is 6mm;

[0024] The controlled rolling and normalizing process of the present embodiment are as follows:

[0025] (1) Heating system: heat the billet to 1240°C, and the total heating time is controlled at 1.2 minutes / mm;

[0026] (2) Rolling process: Two-stage rolling is adopted, that is, rolling in the recrystallization zone and rolling in the non-recrystallization zone. The thickness of the intermediate billet to be warmed is 12 times the thickness of the finished product, and the rolling start temperature in the non-recrystallization zone is 920°C. The final rolling temperature ...

Embodiment 2

[0030] The normalized weldable fine-grained high-strength and tough steel plate with a yield strength of 460 MPa in this embodiment is composed of the following components by weight percentage: C: 0.15%, Si: 0.50%, Mn: 1.40%, V: 0.16%, Ni : 0.25%, N: 0.020%, Alt: 0.040%, P: 0.015%, S: 0.004%, the rest is iron Fe and unavoidable impurities, and the grain size is 11.0. The thickness of the steel plate is 25mm;

[0031] The controlled rolling and normalizing process of the present embodiment are as follows:

[0032] (1) Heating system: heat the billet to 1240°C, and the total heating time is controlled at 1.0 min / mm;

[0033] (2) Rolling process: Two-stage rolling is adopted, that is, rolling in the recrystallization zone and rolling in the non-recrystallization zone. The rolling temperature is 840°C;

[0034] (3) Cooling process after rolling: air cooling after rolling;

[0035] (4) Normalizing process: the rolled steel plate is subjected to normalizing treatment, the normal...

Embodiment 3

[0037] The normalized weldable fine-grained high-strength and tough steel plate with a yield strength of 460 MPa in this embodiment is composed of the following components by weight percentage: C: 0.17%, Si: 0.35%, Mn: 1.67%, V: 0.17%, Ni : 0.30%, N: 0.015%, Alt: 0.020%, P: 0.007%, S: 0.004%, the rest is iron Fe and unavoidable impurities, and the grain size is 10 grades. The thickness of the steel plate is 44mm;

[0038] The controlled rolling and normalizing process of the present embodiment are as follows:

[0039](1) Heating system: heat the billet to 1230°C, and the total heating time is controlled at 1.1 minutes / mm;

[0040] (2) Rolling process: Two-stage rolling is adopted, that is, rolling in the recrystallization zone and rolling in the non-recrystallization zone. The rolling temperature is 815°C;

[0041] (3) Cooling process after rolling: air cooling is adopted after rolling;

[0042] (4) Normalizing process: the rolled steel plate is subjected to normalizing tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com