Non-oriented silicon steel and method for producing non-oriented silicon steel by thin slab continuous casting and rolling process

A thin slab continuous casting, oriented silicon steel technology, applied in metal rolling and other directions, can solve the problems of affecting the magnetic properties and surface quality of finished products, prone to corrugated defects, and less continuous casting billets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

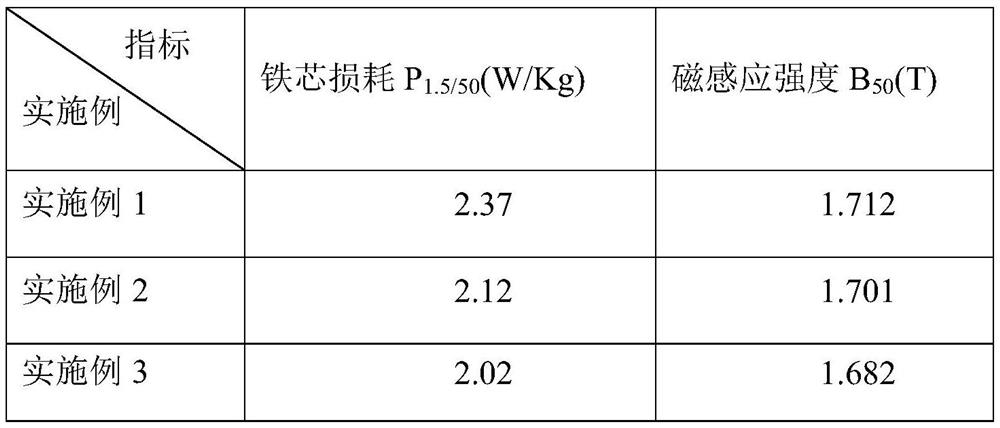

Embodiment 1

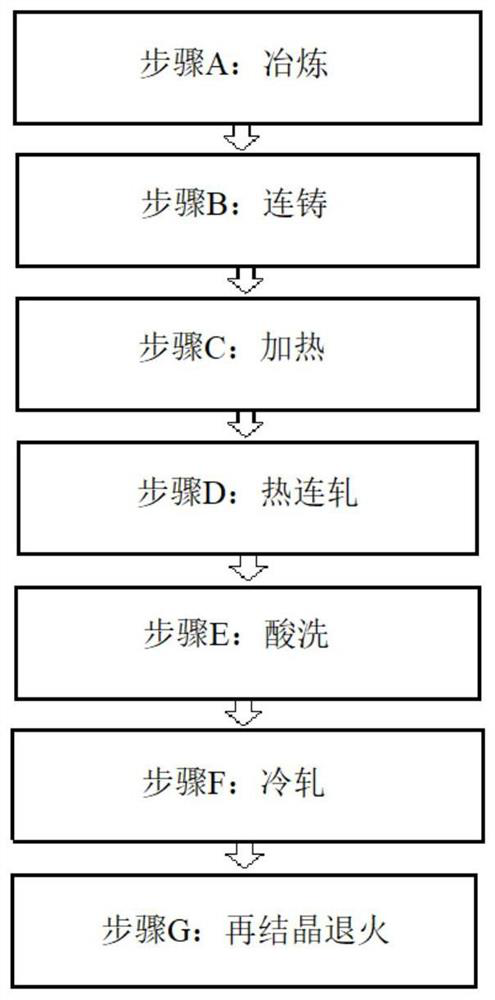

[0056] The thin slab continuous casting and rolling process of the present embodiment produces the method for non-oriented silicon steel, comprising the following steps:

[0057] Step A: smelting;

[0058] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0059] Si: 2.5%, Al: 1.5%, Mn: 1.5%, [S+O+C+N+Ti]: 76ppm, La: 0.005%, the balance is Fe and other impurity elements;

[0060] Add the rare earth element 1 minute after the RH refining and alloying, and stir after adding the rare earth element for 3 minutes;

[0061] Step B: continuous casting;

[0062] In step B, during the continuous casting process, the casting speed is controlled to be 4.6 m / min, and a slab with a thickness of 70 mm is obtained through continuous casting; wherein, the superheat degree of the tundish is controlled to -5°C, a...

Embodiment 2

[0073] The thin slab continuous casting and rolling process of the present embodiment produces the method for non-oriented silicon steel, comprising the following steps:

[0074] Step A: smelting;

[0075] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0076] Si: 3.0%, Al: 1.0%, Mn: 1.0%, [S+O+C+N+Ti]: 70ppm, (La+Ce): 0.008%, the balance is Fe and other impurity elements;

[0077] Add the rare earth element 2 minutes after the end of RH refining and alloying, and stir after adding the rare earth element, and the stirring time is 4 minutes;

[0078] Step B: continuous casting;

[0079] In the continuous casting process of step B, the casting speed is controlled to be 3.5 m / min, and a slab with a thickness of 50 mm is obtained through continuous casting; wherein, the superheating degree of the...

Embodiment 3

[0090] The thin slab continuous casting and rolling process of the present embodiment produces the method for non-oriented silicon steel, comprising the following steps:

[0091] Step A: smelting;

[0092] In the smelting process of step A, converter smelting is carried out first, and then RH refining treatment is carried out, and the mass percentage of the chemical composition of the end point of the molten steel after treatment is:

[0093] Si: 3.5%, Al: 0.10%, Mn: 0.10%, [S+O+C+N+Ti]: 67ppm, rare earth element (La+Ce+Nd): 0.01%, the balance is Fe and other impurity elements ;

[0094] Add the rare earth element 2 minutes after the end of RH refining and alloying, and stir after adding the rare earth element, and the stirring time is 4 minutes;

[0095] Step B: continuous casting;

[0096] In the continuous casting process of step B, the casting speed is controlled to be 2.8 m / min, and a slab with a thickness of 30 mm is obtained through continuous casting; wherein, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com