Non-copper and nickel acid resistant pipeline steel X52MS and production method of hot-rolled plate coil thereof

A hot-rolled coil and manufacturing method technology, applied in the field of hot-rolled steel, can solve the problems of high production cost, poor product market competitiveness, and high price of pipeline steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A copper-nickel-free acid-resistant pipeline steel X52MS, comprising the following components in weight percent, C: 0.02-0.06wt%, Si: 0.05-0.35wt%, Mn: 1.0-1.4wt%, P≤0.018wt%, S≤ 0.003wt%, Cr: 0.10~0.50wt%, Ti: 0.005~0.10wt%, Nb: 0.005~0.10wt%, V: 0~0.05wt%, others are Fe and unavoidable trace impurities, the actual smelting time is 6 The percentage by weight of the experimental steel composition used in each numbering is as shown in Table 1:

[0027] Table 1 (unit wt%)

[0028] Numbering

C

Si

mn

P

S

Cr

Alt

V

Nb

Ti

Ceq

Pcm

1

0.0335

0.185

1.07

0.0093

0.001

0.167

0.0329

0.0038

0.0305

0.0135

0.23

0.10

2

0.0321

0.189

1.09

0.0087

0.001

0.157

0.0386

0.0036

0.0296

0.0167

0.23

0.10

3

0.033

0.191

1.1

0.0085

0.0009

0.155

0.0414

0.0033

0.0303

0.0151

0.23

0.10

...

Embodiment 2

[0039] A method for manufacturing copper-free and nickel-free acid-resistant pipeline steel X52MS hot-rolled coils, comprising the steps of:

[0040] (1) molten iron pretreatment, ensure that the content of S is less than wt0.004% in the pretreatment process;

[0041] (2) Converter steelmaking, control the content of S at the end of converter smelting to be less than wt0.006%;

[0042] (3) LF furnace refining, the content of S entering the station is less than wt0.0040%;

[0043] (4) RH furnace refining, the mass fraction of S in the RH furnace is controlled to be 8-12ppm, and the Ca / S ratio is greater than 2.0;

[0044] (5) The slab pouring adopts the full-protection pouring technology, adopts the dynamic soft reduction technology at the end of the solidification of the slab, controls the degree of superheat to 10-30°C, and the casting speed to 0.8-1.6m / min;

[0045] (6) Steel slab finishing, using dynamic light pressing at the end of slab solidification, stable superheat, ...

Embodiment 3

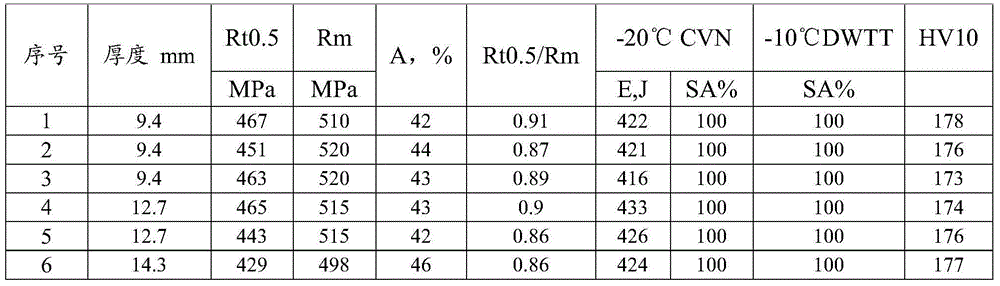

[0056] Carry out the following performance tests on 6 numbered experimental steels:

[0057] Tensile performance test: Rt0.5: 360~530MPa, Rm: ≥ 460MPa, A% ≥ 22;

[0058] Charpy V-notch impact performance test: The test temperature is -20°C, the size of the test steel is 10×10×55mm, the average impact energy of the V-notch sample is ≥300J, and the shear area is 100%.

[0059] DWTT performance test: test temperature -15°C, experimental steel shear area SA≥85%.

[0060] Hardness test: HV10≤240.

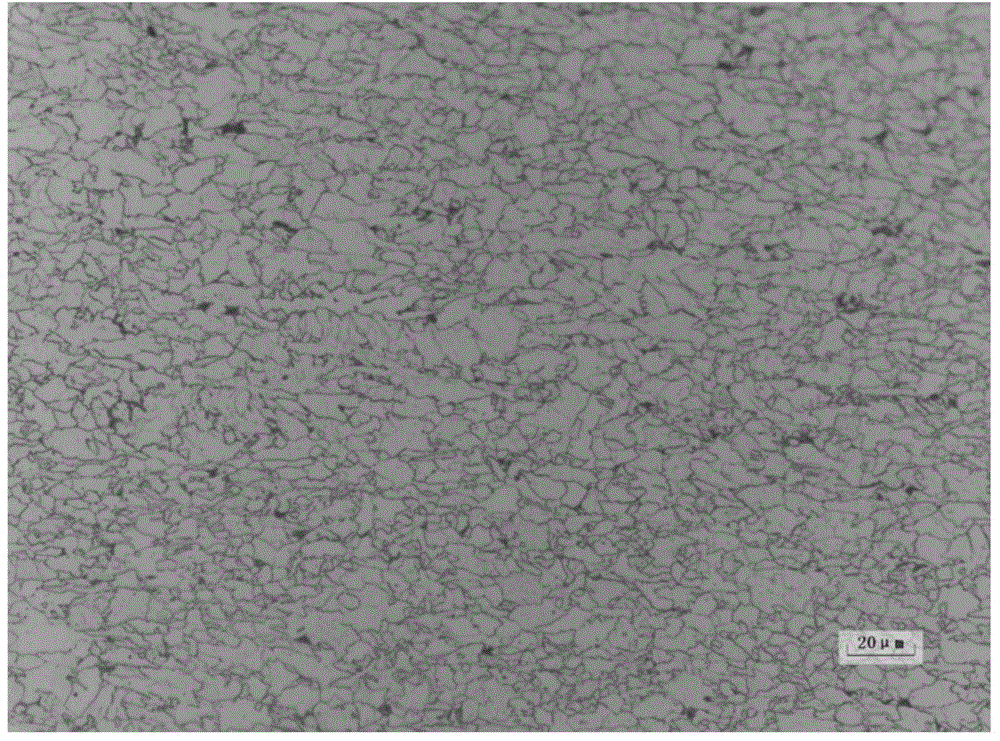

[0061] Metallographic structure: the grain size is 10 or finer.

[0062] The specific test results are shown in Table 3.

[0063] table 3

[0064]

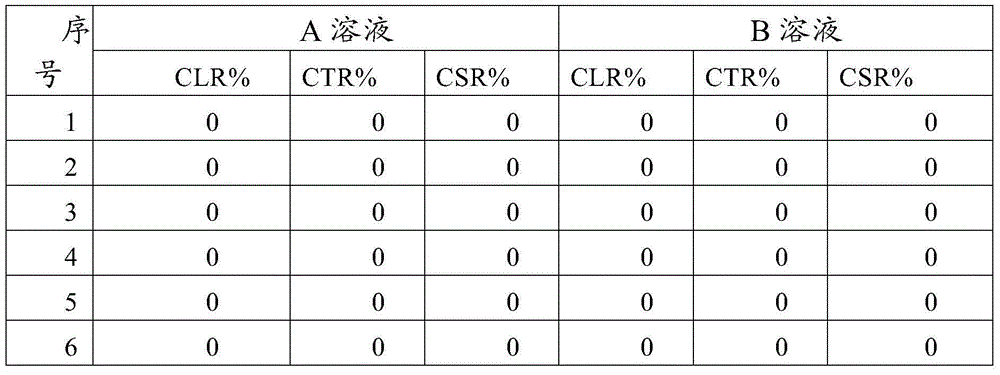

[0065] Anti-HIC performance test: at the 1 / 4, 1 / 2 position and plate edge of the steel plate width of the present invention, get a longitudinal sample respectively, test according to NACE TM0284-96 standard, provide A solution (containing saturated H 2 5% NaCl + 0.5% CH in S 3 COOH solution, PH=3) and B solution (containing saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com