Preparation of normalizing weldable fine grain steel plate with a yield strength of 420MPa

A yield strength and fine-grain technology, which is applied in the field of preparation of normalized weldable fine-grain steel plates with a yield strength of 420MPa, can solve the problems of high production costs, increased production unit economic costs, difficulty in smelting and microstructure control, etc. problems, to avoid sharp drop, eliminate internal stress and bainite structure, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

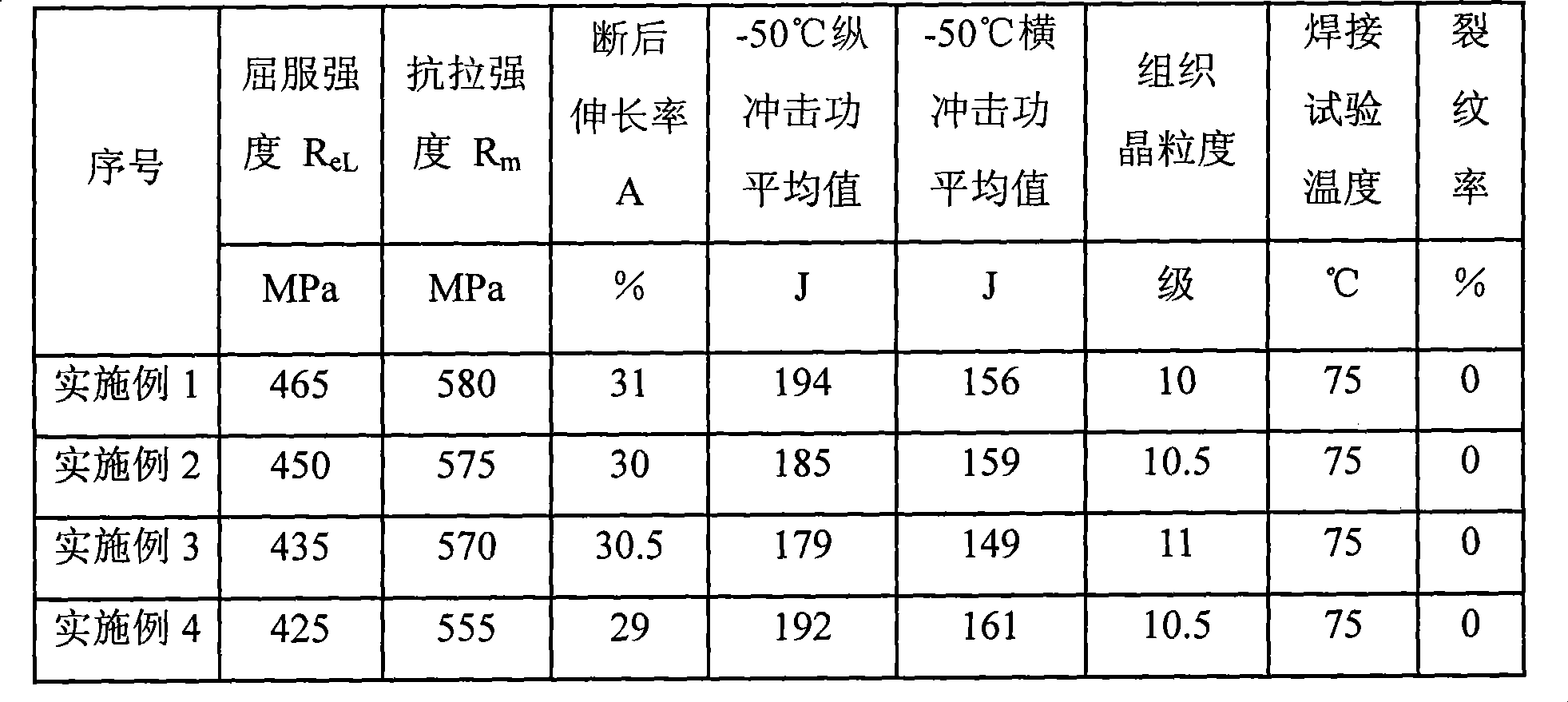

[0019] The normalizing temperature of the controlled-rolled steel plate is 880°C, and the temperature is kept for 20 minutes. The comprehensive mechanical properties of the steel plate are shown in Table 1.

Embodiment 2

[0021] The normalizing temperature of the controlled-rolled steel plate is 880°C, and the temperature is kept for 15 minutes. The comprehensive mechanical properties of the steel plate are shown in Table 1.

Embodiment 3

[0023] The normalizing temperature of the controlled-rolled steel plate is 900°C, and the temperature is kept for 10 minutes. The comprehensive mechanical properties of the steel plate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com