Non-quenched and tempered steel for crankshaft, crankshaft forging and its preparation process

A technology of non-quenched and tempered steel and preparation process, which is applied in the field of crankshaft forgings and its preparation process, and non-quenched and tempered steel for crankshafts. It can solve the problems of high cost, complicated production process, and increased alloy elements, and achieve qualified hardenability, The effect of increased elongation and enhanced tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] The composition of non-quenched and tempered steel for crankshaft is shown in Table 1,

[0077] The composition of the non-quenched and tempered steel used in table 1 crankshaft (weight / %)

[0078]

[0079] The preparation process parameters of non-quenched and tempered steel for crankshaft are shown in Table 2,

[0080] Table 2 The preparation process parameters of non-quenched and tempered steel for crankshaft

[0081]

[0082]

[0083] The non-quenched and tempered steel for crankshafts was prepared using the preparation process parameters provided in Example 1-Example 5 and Comparative Example 1-Comparative Example 8. Use the obtained crankshaft to carry out the preparation of crankshaft forging with non-quenched and tempered steel, the preparation process parameters of crankshaft forging are as table 3,

[0084] Table 3 Preparation Process Parameters of Crankshaft Forgings

[0085] Crankshaft heating temperature / °C Crankshaft heating time / ...

experiment example 1

[0087] Detect performance, organization of the non-quenched and tempered steel for crankshaft that embodiment 1-embodiment 7 and comparative example 1-comparative example 6 provide, as table 4,

[0088] Among them, the detection method of the mechanical properties is: heating the samples according to the temperature of 1150-1250° C., then cooling in air, and testing the mechanical properties (strength, elongation and Brinell hardness) of the heat-treated samples. The detection method of hardenability is: take samples according to the normalizing temperature of 860±5°C, and then detect the hardenability value of the round steel after the end quenching treatment. The detection method of the band structure is: take the rolled round steel and detect the band structure at the 1 / 2 radius position of the round steel according to the national standard.

[0089] Table 4 Properties and structures of non-quenched and tempered steels for crankshafts

[0090]

[0091]

[0092] Detec...

experiment example 2

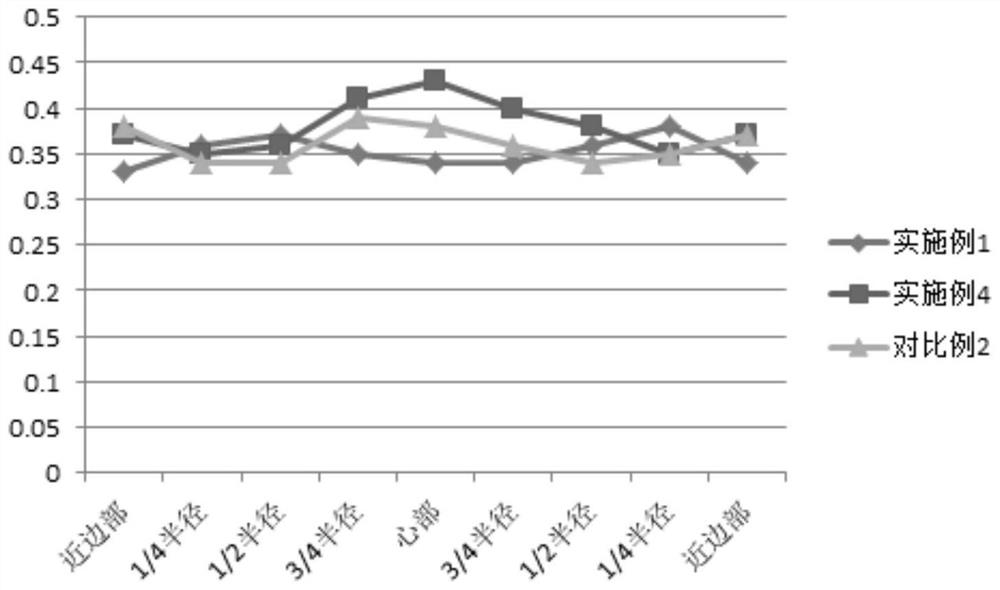

[0107] The crankshaft that embodiment 1, embodiment 4 and comparative example 2 provide is carried out the detection of segregation control situation with non-quenched and tempered steel as figure 1 . From figure 1 It can be seen that the segregation control of the non-quenched and tempered steel for crankshaft provided by Example 1 is better than that of the non-quenched and tempered steel for crankshaft provided by Comparative Example 2. The segregation control of the non-quenched and tempered steel for the crankshaft provided by Example 1 is better than the segregation control of the non-quenched and tempered steel for the crankshaft provided by Example 4. It shows that the value of Mn is too large, or the value of Mn is too small, will affect the segregation control of non-quenched and tempered steel for crankshaft.

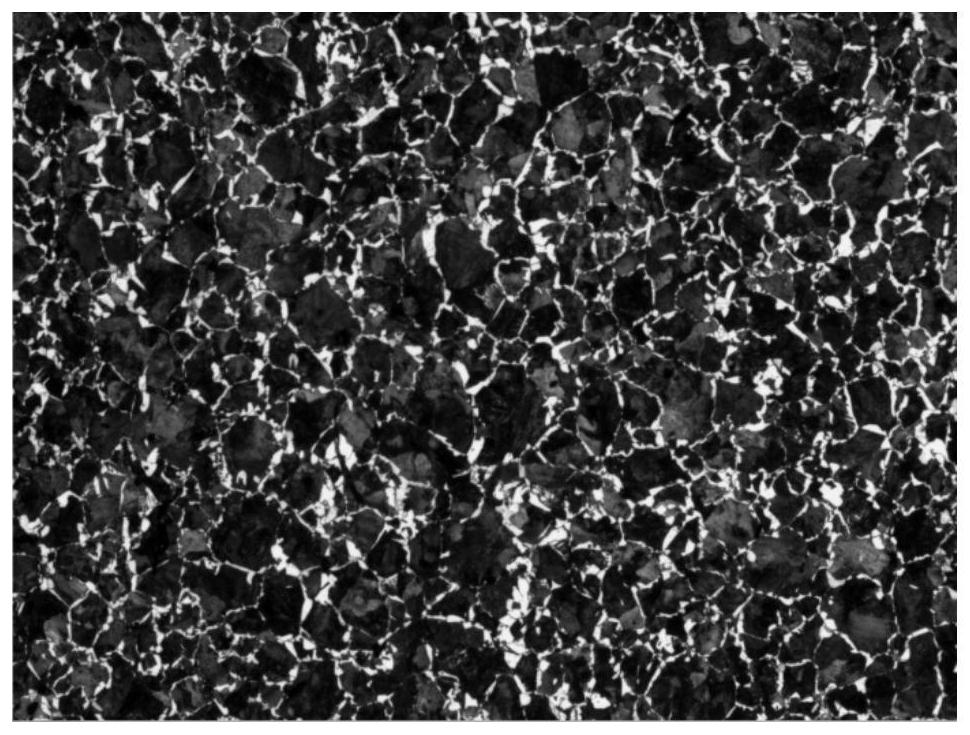

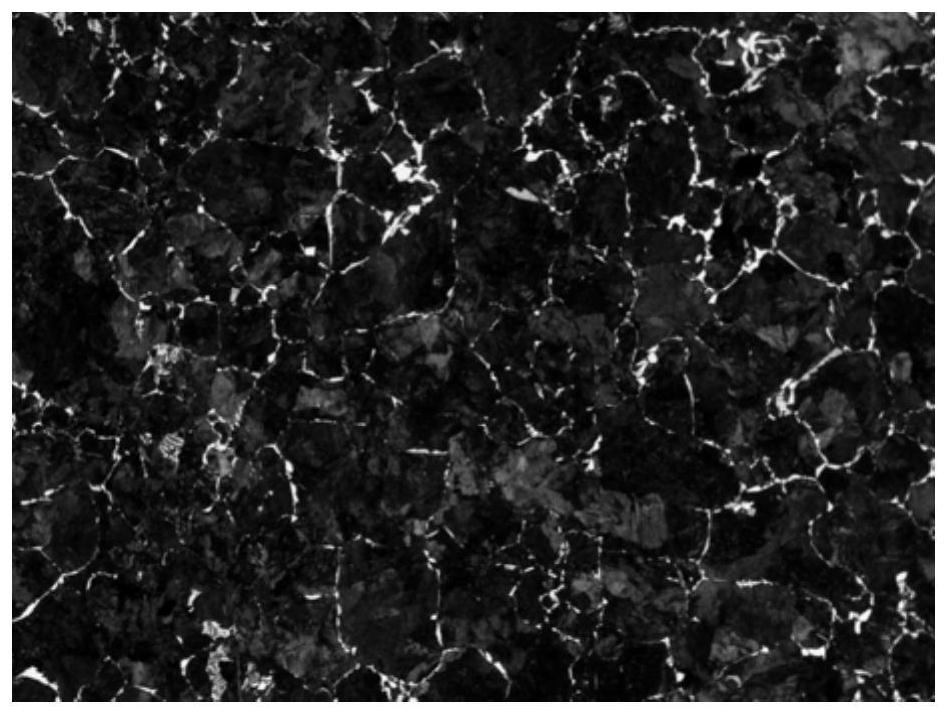

[0108] Detect the metallographic pictures of the crankshaft forgings obtained in Example 1 and Comparative Example 1. in, Figure 2A The metallographic i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com