A smelting method for obtaining qualified mechanical properties at low temperature without nickel

A technology with mechanical properties and low temperature, applied in the field of smelting, it can solve the problems such as the lack of stable production of -40 ℃ castings, and achieve the effect of benefiting magnesium absorption and stable spheroidization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

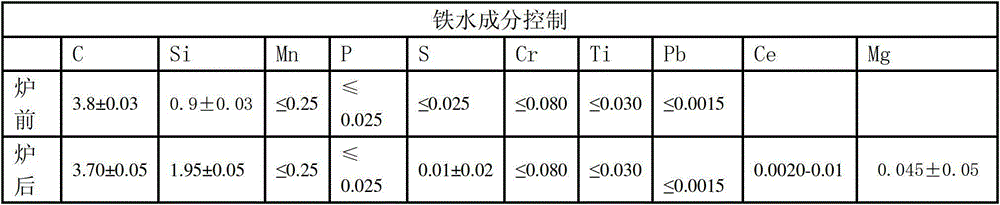

[0017] A smelting method for obtaining qualified mechanical properties at a low temperature without nickel, characterized in that the method includes the following steps:

[0018] a. Melting: The charge is accurately weighed, and added in the order of scrap steel, returned iron, and pig iron. During the melting process, the charge is compacted at any time. After the cold charge is melted, the temperature is quickly raised to a sampling temperature of 1420°C to 1440°C, and the spectral sample is taken for inspection. Continue to raise the temperature to around 1440-1460°C to stop the furnace, leave the molten iron for slag removal, and adjust the composition of the molten iron to the target value according to the test results of the spectral sample;

[0019] b. Embedding of nodulizers and inoculants: rush into the spheroidization process, clean up the ladle first, and then bury the nodulizers with fast detonation in the nodulization reaction chamber, and put the nodulizers with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com